9.02.2019

NASA’s Webb Is Sound After Completing Critical Milestones

NASA's James Webb Space Telescope has successfully passed another series of critical testing milestones on its march to the launch pad.

In recent acoustic and sine vibration tests, technicians and engineers exposed Webb’s spacecraft element to brutal dynamic mechanical environmental conditions to ensure it will endure the rigors of a rocket launch to space.

During liftoff, rockets generate extremely powerful vibrations and energetic sound waves that bounce off the ground and nearby buildings and impact the rocket as it makes its way skyward. Technicians and engineers aim to protect Webb from these intense sound waves and vibrations.

To simulate these conditions, flight components are intentionally punished with a long litany of tests throughout different facilities to identify potential issues on the ground. Webb was bombarded by powerful sound waves from massive speakers and then placed on an electrodynamic vibration table and strongly but precisely shaken. Together, these tests mimic the range of extreme shaking that spacecraft experience while riding a rocket to space.

“Webb’s launch vibration environment is similar to a pretty bumpy commercial airplane flight during turbulence,” said Paul Geithner, deputy project manager – technical, James Webb Space Telescope at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. “And, its launch acoustic environment is about 10 times more sound pressure, 100 times more intense and four times louder than a rock concert.”

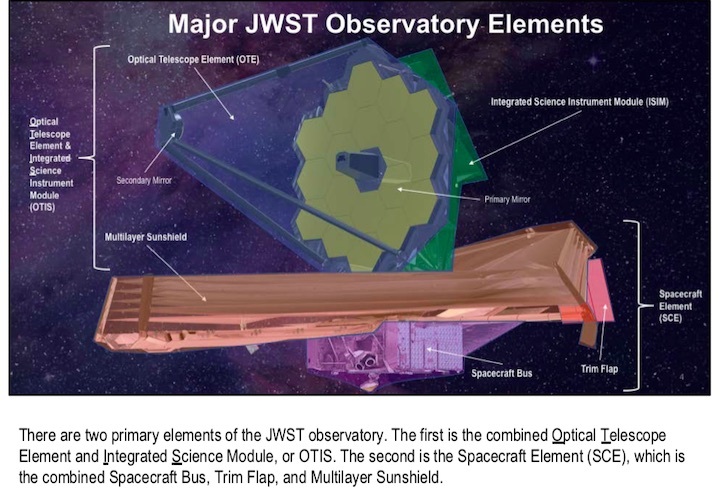

One half of the Webb observatory, known as the “spacecraft element,” was the subject of this latest testing. The spacecraft element consists of the “bus,” which is the equipment that actually flies the observatory in space, plus the tennis-court-size sunshield that will keep Webb’s sensitive optics and instruments at their required super-cold operating temperature. Northrop Grumman in Redondo Beach, California, NASA’s lead industrial teammate on Webb, designed and built the spacecraft element, and conducted the testing in their facilities with NASA support and guidance. Northrop Grumman and NASA engineers and technicians worked tirelessly together as a team over the last few months to complete these complex dynamic mechanical environmental tests.

The initial attempt at acoustic testing last spring uncovered a problem with a specific portion of sunshield hardware, which required some modifications taking several months. Subsequently, the acoustic test was redone, and this time everything went successfully. With acoustic testing complete, the spacecraft element was transported in a mobile clean room to a separate vibration facility, where its spacecraft hardware was exposed to the bumps and shakes that occur when riding a rocket soaring through the atmosphere at high Mach speeds. Northrop Grumman, NASA and its partner, ESA (European Space Agency), are familiar with the flight profile and performance of the Ariane 5 rocket that will carry Webb into space in early 2021, so technicians tuned the tests to mimic the conditions it’s expected to face during launch.

With the successful completion of its mechanical environmental testing, the spacecraft element is being prepared for thermal vacuum testing. This other major environmental test will ensure it functions electrically in the harsh temperatures and vacuum of space. The other half of Webb, which consists of the telescope and science instruments, had completed its own vibration and acoustic testing at Goddard and cryogenic-temperature thermal vacuum testing at NASA’s Johnson Space Center in Houston prior to delivery at Northrop Grumman last year. Once finished with thermal vacuum testing, the spacecraft element will return to the giant clean room where it was assembled, to be deployed from its folded-up launch configuration and into its operational configuration, which will be the final proof that it has passed all of its environmental tests. Then, the two halves of Webb — the spacecraft and the telescope elements — will be integrated into one complete observatory for a final round of testing and evaluation prior to launch.

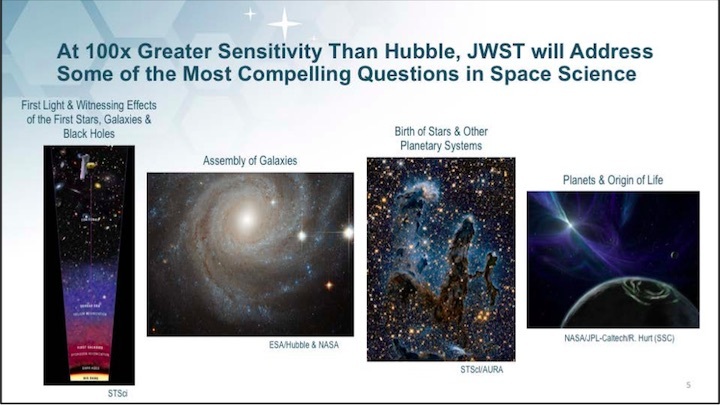

Webb will be the world's premier space science observatory. It will solve mysteries of our solar system, look beyond to distant worlds around other stars, and probe the mysterious structures and origins of our universe and our place in it. Webb is an international project led by NASA with its partners, ESA and the Canadian Space Agency.

Quelle: NASA

+++

Northrop Grumman Completes Next Critical Launch Milestones of NASA’s James Webb Space Telescope Spacecraft

REDONDO BEACH, Calif. – Feb. 8, 2019 – NASA’s James Webb Space Telescope Spacecraft Element (SCE) successfully completed acoustic and sine vibration testing at Northrop Grumman Corporation (NYSE: NOC) in Redondo Beach.

Both halves of NASA’s James Webb Space Telescope are housed in Northrop Grumman’s cleanroom as they undergo ongoing testing and integration efforts.

Acoustic and sine vibration testing validates the structural design and verifies the mechanical workmanship and integrity of the actual flight SCE by subjecting it to simulated rigors of the launch environment.

“Mission success remains our focus for Webb, a first of its kind space telescope,” said Scott Willoughby, vice president and program manager, James Webb Space Telescope, Northrop Grumman. “Successful environmental testing of the SCE builds further confidence in its structural design integrity, built to withstand the stresses of launch.”

The SCE was subjected to acoustic noise levels of 140.7 decibels (damage to hearing starts at 85dB while speakers at a concert can be as loud as 120dB or more), which simulated the high noise levels generated from rocket engines and turbulent air flow at high Mach speeds during launch. Vibration testing simulates the vibration and shaking Webb will experience during launch. During testing, the SCE was attached to a large electrodynamic shaker, vibrating it along three orthogonal axes. This back-and-forth or “sinusoidal” vibration was applied by starting at a low, subsonic frequency of 5 hertz (cycles per second) and “sweeping” up to a medium frequency of 100 hertz in the course of just over one minute. Ultimately, the SCE was subjected to protoflight vibration levels required to simulate a rocket launch experience. Testing on the ground assures that Webb can successfully withstand the rigors of its journey to space.

The completion of acoustic and sine vibration testing advances Webb’s SCE to its final environmental test, thermal vacuum testing. Post thermal vacuum testing, Webb will return to Northrop’s clean room for full deployment and integration of the Optical Telescope Element/Integrated Science Instrument Module later this year.

NASA’s James Webb Space Telescope Spacecraft Element during vibration testing at Northrop’s facility, in Redondo Beach, California.

The James Webb Space Telescope will be the world’s premier space science observatory of the next decade. Webb will solve mysteries of our solar system, look to distant worlds around other stars, and probe the mysterious structures and the origins of our universe. Webb is an international program led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Northrop Grumman is a leading global security company providing innovative systems, products and solutions in autonomous systems, cyber, C4ISR, space, strike, and logistics and modernization to customers worldwide. Please visit news.northropgrumman.com and follow us on Twitter, @NGCNews, for more information.

NASA’s James Webb Space Telescope on its way to acoustics testing at Northrop’s large acoustic test facility in Redondo Beach, California.

Team members from NASA and Northrop Grumman observing NASA’s James Webb Space Telescope Spacecraft Element being placed at Northrop’s large acoustic test facility, in Redondo Beach, California, in preparation for acoustics testing.

Quelle: Northrop Grumman

----

Update: 31.05.2019

.

Spacecraft element successfully endures extreme temperatures in thermal vacuum

REDONDO BEACH, Calif. – May 30, 2019 – NASA’s James Webb Space Telescope Spacecraft Element (SCE) successfully completed its last environmental test, thermal vacuum testing, at Northrop Grumman Corporation (NYSE: NOC) in Redondo Beach.

Thermal vacuum testing exposes Webb’s SCE to the extreme hot and cold temperatures it will experience in space. To test these extreme temperature ranges, the chamber uses liquid nitrogen shrouds and heater panels to expose the SCE to cold temperatures as low as -300 degrees Fahrenheit and hot temperatures as high as 220 degrees Fahrenheit. Real-time data collection via flight sensors on the SCE allow engineers to monitor Webb’s electrical/unit functionality and ensures the structure will withstand the rigors of its cold journey to and operation at the second Lagrange point.

“The world’s largest space telescope has to perform in extreme temperatures,” said Scott Willoughby, vice president and program manager, James Webb Space Telescope, Northrop Grumman. “Successful completion of thermal vacuum testing ensures the SCE can endure the volatile conditions it will face and further validates Webb’s readiness for launch.”

Webb’s SCE completed its two prior environmental tests (acoustic and sine vibration). After thermal vacuum testing, the SCE will return to Northrop Grumman’s clean room to begin post-environmental testing, including deployments. Later this year, the Webb telescope will become a fully integrated observatory for the first time through integration of the SCE to the Optical Telescope Element/Integrated Science Instrument Module.

The James Webb Space Telescope will be the world’s premier space science observatory of the next decade. Webb will solve mysteries in our solar system, look to distant worlds around other stars, and probe the mysterious structures and the origins of our universe. Webb is an international program led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Northrop Grumman is a leading global security company providing innovative systems, products and solutions in autonomous systems, cyber, C4ISR, space, strike, and logistics and modernization to customers worldwide. Please visit news.northropgrumman.com and follow us on Twitter, @NGCNews, for more information.

NASA’s James Webb Space Telescope Spacecraft Element is so large, Northrop Grumman engineers and technicians had to utilize a hydraulic elevator platform to bottom load the SCE into the thermal vacuum chamber at Northrop Grumman’s test facility in Redondo Beach, Calif.

Quelle: Northrop Grumman

----

Update: 24.07.2019

.

NASA's Webb Telescope Shines with American Ingenuity

To send humans to the Moon 50 years ago, an entire nation rose to the challenge. Surmounting countless hurdles, inventing new technologies while staring into the face of the unknown, NASA successfully pioneered multiple lunar landings. NASA demonstrated to the world the importance of partnerships and what a unified country can achieve.

Similarly, the task of building the world's most complex and powerful space telescope, NASA's James Webb Space Telescope has required steadfast contribution from across the United States. In total, 29 states throughout the U.S. have lent a hand manufacturing, assembling, and testing Webb components. After launch, Webb's science and data will reach a global audience.

Webb's 18 innovative lightweight beryllium mirrors had to make 14 stops at 11 different places across 8 states (visiting some states more than once) around the U.S. to complete their manufacturing.

Their journey began in beryllium mines in Utah, and then moved across the country for processing and polishing. Explore an interactive map showing the journey of the mirrors. After the spacecraft is fully assembled in California, the telescope will journey to French Guiana for lift-off, and the beginning of their final journey to space

Much like the Apollo program, NASA's Webb telescope is an exemplar of ingenuity. In order to step foot on the Moon, technology that had never been seen before was conceived and developed into existence.

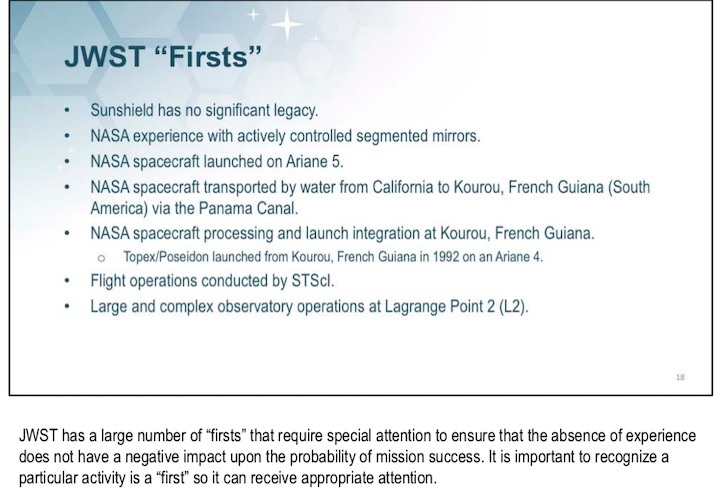

To observe periods of cosmic history beyond the reaches of even the Hubble Space Telescope, the Webb team needed to invent multiple brand new technologies and testing methods to verify them for flight and service on orbit a million miles away.

"When we first thought of Webb, it wasn't technically feasible. We had to succeed at inventing some things before we could build it-not unlike the Apollo Program in this regard," said Paul Geithner, Deputy Project Manager - Technical at NASA's Goddard Space Flight Center in Greenbelt, Maryland.

Some of Webb's hardware has even seen thermal vacuum testing inside the very same historic 'Chamber A' at NASA's Johnson Space Center in Houston that was used to validate Apollo spacecraft components for their historic missions.

Named in honor of James E. Webb, who led NASA's Apollo program, the Webb telescope represents revolutionary science that not only changes what we know, but also how we think about the night sky and our place in the cosmos.

Webb will be the world's premier space science observatory. It will solve mysteries in our solar system, look beyond to distant worlds around other stars, and probe the mysterious structures and origins of our universe and our place in it. Webb is an international project led by NASA with its partners, (European Space Agency) and the Canadian Space Agency.

Echoes of NASA's Apollo program live on proudly today. With the new Artemis program, NASA has set its sights on creating a sustainable presence on the Moon, to serve as a waypoint for the ultimate goal of launching humans to Mars.

Quelle: SD

----

Update: 29.08.2019

.