12.04.2018

The red-hot debate over rocket fuel inside a bastion of solid fuel power.

Rocket science, it turns out, is no different than the rest of society. People have divided themselves up into two tribes.

When it comes to space launches, there are two basic options for rocket fuel: solid and liquid. Solid rocket fuel is just that: a thick mix of fuel and oxidizer that is poured into a rocket booster, cooked to a pencil-eraser consistency, and set on fire during launch. The energy is directed through a nozzle, generating enough thrust to get a rocket into the air. Nuclear weapons in silos and submarines use these.

Liquid rocket engines feature tanks of fuel inside the boosters, one for fuel and another for oxidizer. The two substances, chilled to super-low temperatures so they don’t convert to gas, are mixed inside the engine at the time of launch, ignited, and routed through a nozzle. The result is a tongue of hot exhaust and thrust. This is the system that powers SpaceX’s rockets.

Each fuel comes with pros and cons, and engineers can show you charts graphs of the various thrust profiles to illustrate each approach. But don’t let the seeming simplicity of the stats fool you: The schism between solid and liquid is a clash of two different visions that are fighting for the future of spaceflight.

Do Us a Solid

Promontory, Utah is where Orbital ATK manufactures solid rocket motors. This is the place that built several generations of nuclear missiles and Space Shuttle boosters, all using solid fuel. If there’s anywhere that could put up a defense for this technology, it’s here.

Solid rockets have some obvious virtues. They store well. In fact, they can sit for decades and still operate when needed, which is why solid is the rocket fuel of choice for nuclear deterrence. “For storability, it’s very hard to beat,” says Ben Case, an engineering manager for conceptual design and flight performance at Orbital ATK, who we met while visiting the plant at Promontory. “And we don’t come along with some of the toxicity issues that a liquid storable would have.”

No rocket discussion goes on for long without mentioning “specific impulse” or ISP. This measures the thrust generated by any given amount of fuel, and liquid engines have a higher specific impulse than solids, which explains a great deal of their attraction.

But Orbital ATK engineers are quick to focus on a different metric: ISPdensity. The solid propellant, infused with fuel and oxidizer, can whip up a lot of thrust, quickly. “Even though solids have lower ISP per pound, you can pack a lot of impulse into that volume because it’s so dense,” Case says.

Watching technicians make solid-fuel rocket motors shows reveals a complicated process. Inside the Utah facility, technicians lower a cast inside the rocket core and pour putty-like solid fuel around it. Then they bake the fuel. When the cast is removed, it leaves voids that direct the burn and thereby control thrust at various times of a flight. The areas between rocket segments also include structural barriers that serve as firebreaks, slowing the burn by channeling the flames into the center. “The shape of that interior propellant, that surface area, is directly proportional to the thrust at any given time,” says Case.

That’s the best defense solid rocket supporters can muster against the more precise control of a liquid engine. Liquid rocket engines far exceed the control of a solid. Liquid engines can throttle up or down as needed. These engines can even shut down, a useful safety feature. No so with solid rockets.

But once a solid rocket is made, it’s ready to fly. Solid rockets just sit there until the electric ignition is sparked. It could be months or years. The solid rocket motor doesn’t care much. Hence their use to power nuclear missiles, which need to launch at a moment’s notice. It’s also the choice for the Space Launch System, NASA’s giant heavy lift rocket Orbital ATK is working on.

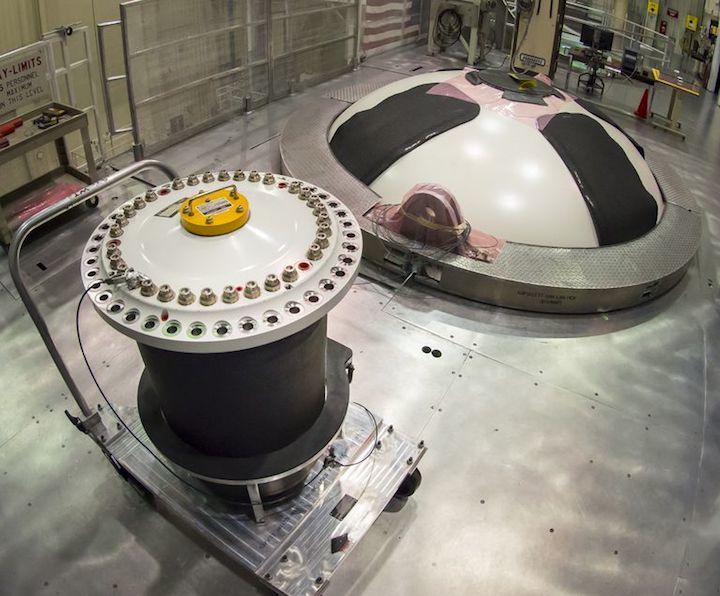

Final assembly.

-

While comparing the two fuels, it’s hard not to recall the explosion that SpaceX suffered on the launch pad, losing a payload in a fiery detonation while its tanks were being fueled. It’ a rare accident but a reminder that liquid fueled rockets have extra steps before launch that solids just don’t — and extra steps are invitations to mistakes.

Liquid Launches

Using liquid engines in the first and second rocket stages is the newer, sexier approach. This has some A-list supporters, especially billionaires behind the commercial space renaissance like SpaceX’s Elon Musk and Blue Origin’s Jeff Bezos. Their launch vehicles enjoy the extra thrust but also take advantage of liquid engines’ other attributes.

Liquid fuel engines operate without charring the entire lining of their fuel tanks, so the turnaround times between flights are much shorter. Just refill the tanks and it should be ready to fly again. And to be sure, the very engines can be tested to be sure they are performing as planned. That kind of testing is not available with a solid rocket.

Thus, rivalry between solid and liquid is another front in the wider war over reusability. Reusing rockets is all the rage. Blue Origin and SpaceX land their rocket stages in impressive displays of innovation while promising that reusability will lower the cost of getting to orbit and open up space to more people.

And the way some commercial space supporters talk about solid rocket motors places them in the ash heap of history. “To critics, the solid rocket motor — an elongated version of the boosters that fly on the space shuttles — is expensive, antiquated technology,” the NY Times noted eight years ago. That complaint still resonates. Lori Garver, a former NASA official and a primary force of the commercial space effort within the agency, just months ago called SLS “unnecessary and obsolete” after SpaceX’s Falcon Heavy launched for the first time.

But here’s the thing: Solid rocket boosters were reused all throughout the Shuttle era. Fished out of the Atlantic and sent back to Utah, the cores would be rebuilt after each flight. The entire process of manufacturing was repeated in the same factory, and only the outer steel case was reused. These very same steel parts flown during the shuttle era are being used on SLS, by the way. Is that a frugal no-brainer or a timid, job-generating throwback? You choose.

Refurbishing solid rocket motors takes lots of time between flights. But if you don’t want to make spaceflight as routine as airplane travel—as Elon Musk has said—then this pace is less of a problem.

Happy Together

Orbital ATK’s Case is an engineer at heart, not a partisan. He knows that liquid engines are critical for the final phase of a rocket’s flight, when it needs a heavy push to get the payload where it needs to go. In fact, Orbital ATK’s new Next Generation Launch rocket would use liquid upper stages, just like everyone else, to deliver Air Force satellites to orbit.

“You see advantages reflected in NGL, where we our lower stages are solid where that high thrust is very critical,” Case says “And we also have the liquids that give you the higher ISP and the start/stop capabilities.”

Orbital ATK ignition.

-

Yet this talk of happy coexistence belies a more existential debate over the future of spaceflight. How people feel about solid rocket motors is a good stand-in for how they feel about future launches. The market of the near term will have room for solid rocket motors and liquid engines. But what’s inside the rockets of the next generation, the ones that will take humans to Mars?

Quelle: PM