3.07.2018

NASA’s newest experimental aircraft, designed with quiet supersonic technology and intended to help open a new era in faster-than-sound air travel over land, will forever be known in the history books as the X-59 QueSST.

The U.S. Air Force, which is the government entity responsible for assigning X-number designations and the popular name associated with the aircraft, officially informed NASA of their decision on June 26.

“For everyone working on this important project, this is great news and we’re thrilled with the designation,” said Jaiwon Shin, NASA’s associate administrator for aeronautics.

“I’m confident that the contributions the X-59 QueSST will make to our nation and the world will ensure its place among the greatest NASA X-planes ever flown,” Shin said.

The X-plane number designation continues a tradition of naming important experimental aircraft and rockets that dates back to 1947 and the X-1, the rocket-powered airplane that Chuck Yeager flew to become the first human to fly faster than the speed of sound.

And while that famous X-1 was nicknamed the Glamourous Glennis, for Yeager’s wife, today’s X-59 takes its QueSST nickname from the quiet supersonic technology the aircraft will be equipped with.

Now under construction by Lockheed Martin Aeronautics Company at its famed Skunk Works plant in Palmdale, Calif., the X-59 QueSST is designed so that when flying supersonic, people on the ground will hear nothing more than a sonic thump – if anything at all.

Once fully tested and pronounced safe to fly within the National Airspace, the X-59 in late 2022 will begin making supersonic flights over select communities to measure residents’ reactions to any noise they might hear.

The scientifically valid data gathered from these community overflights will be presented to U.S. and international regulators, who will use the information to help them come up with rules based on noise levels that enable new commercial markets for supersonic flight over land.

Quelle: NASA

----

Update: 11.10.2019

.

NASA’s Supersonic X-59 QueSST Coming Together at Famed Factory

In the high desert of California, where some of the most important aircraft in aviation history have been built and flown, the next airplane destined to take its place among those aeronautical icons continues to take shape on a legendary factory floor.

That airplane is NASA’s X-59 QueSST (short for Quiet SuperSonic Technology), an experimental piloted aircraft designed to fly faster than sound without producing the annoying – if not sometimes alarming – sonic booms of previous supersonic aircraft.

That factory is better known as the Skunk Works, a renowned Lockheed Martin division that for the past 76 years has used an out-of-the-box approach to design and manufacturing that has produced the nation’s most advanced airplanes.

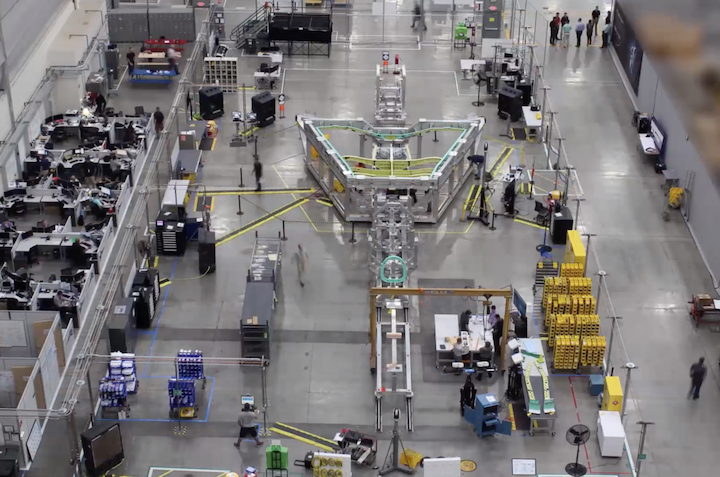

Now that legacy continues as the company assembles the X-59 for NASA in Palmdale, California, where, for the first time since the initial machined parts were delivered in November 2018, workers can see the familiar outline of an airplane forming.

“It’s pretty obvious when you look at it on the production floor. You can see there’s an aircraft starting to get built,” said Craig Nickol, NASA’s project manager for the X-59, which also is known as the Low Boom Flight Demonstrator.

And with the recent completion in September of a major project milestone – known as the Critical Design Review, or CDR – the X-59 will rapidly accelerate its evolution from an airplane on paper toward an airplane ready to roll out of the factory and take flight.

“The CDR showed us the design was mature enough to continue into the next phase and essentially finish the assembly,” Nickol said, noting the next milestone will come in December when an independent review board will present their findings from the CDR – a gathering known as a Key Decision Point.

“They’ll go through their review of the CDR, present any findings or issues that need to be addressed and then will make a recommendation if we should proceed with the project,” Nickol said.

Based on the results from the CDR, no show-stopping issues were identified and the pace of assembly work on the X-59 is already ramping up.

“I think now the rubber is really hitting the road as we have dozens of parts coming in each week that we’ve completed the design engineering on and will be ready for installation,” said Mike Buonanno, a Lockheed Martin aerospace engineer who is the company’s vehicle lead for the X-59.

“We’re on track to meet all the key performance requirements of the airplane, including those driven by its shape, which is so essential to the mission of the X-59,” Buonanno said.

The Shape of the Mission

The X-59’s mission is to gather data that has the potential to aid in the opening of a new era of commercial supersonic air travel over land.

Here’s the deal:

During the 1960’s, as both the United States and Europe were developing a civilian supersonic transport – the SST and Concorde, respectively – the general public made it known they did not want to endure the constant annoyance of sonic booms from airplanes flying over their work and homes.

So, in 1973, after several years of research and due process, the Federal Aviation Administration (FAA) banned aircraft from flying over land faster than Mach 1 – the speed of sound, which can vary based on temperature and atmospheric conditions. That would prevent the loud sonic booms.

Although the SST program was cancelled in 1971, the Concorde went on to fly for British Airways and Air France from 1976 to 2003, its supersonic cruising near the United States limited to only over the Atlantic Ocean.

Still, the demand for commercial supersonic air travel continued, which prompted this question: What if you could fly a supersonic airplane that didn’t produce loud sonic booms? What if, for those on the ground below, those sonic booms were quiet enough not to be an annoyance, or perhaps not heard at all?

That’s what the X-59 is going to help find out.

Based on decades of research into supersonic flight that included work in wind tunnels, testing concepts on aircraft in flight, and using powerful supercomputers to run simulations, NASA’s aeronautical innovators think they’ve come up with a solution.

By carefully designing the aircraft’s shape and overall configuration, engineers have found a way to manipulate the shockwaves coming off an airplane flying supersonic so they don’t produce sonic booms as intense as those the public is wary of.

It will be the X-59’s job to validate those theories, and once that’s done the airplane will go on the road, so to speak, and be flown over several U.S. communities (yet to be selected) so residents below can provide reactions to what they might or might not hear.

That data will then be passed on to the FAA and international regulators who, it is hoped, will use that information to help rewrite the rules so that supersonic flight over land is regulated based on noise levels and not the arbitrary speed of Mach 1.

When that happens, a major hurdle will be cleared for the nation’s aviation community to move forward in establishing a new market for commercial supersonic flight over land, where people and packages can get to their destinations in half the time.

Skunk Works' Rules

Perhaps it’s only fitting the future of commercial supersonic aviation in the form of the X-59 is being built by the company responsible for the fastest airplane in history – the SR-71 Blackbird – using innovative production processes that go back 76 years.

“The purpose of us building the X-59 at the Skunk Works isn’t really for us to pioneer new manufacturing technologies. It’s to use what we know works well to get the airplane built and flying for our customer,” Buonanno said.

That’s not to say the company isn’t using the most modern technology available in delivering their aircraft. It is.

But what makes the Skunk Works unique in its approach to manufacturing is embodied in 14 rules originated by aviation legend Kelly Johnson, who led the Lockheed team in World War II that designed and built the nation’s first jet fighter – the XP-80 – in only 143 days.

Those rules call for small teams, simple approaches, close communication, streamlined paths of authority, and a healthy dose of common sense all summarized by the words quick, quiet, and quality.

Today that manufacturing heritage is guiding Lockheed Martin as it builds the one-of-a-kind X-59.

“We still hold true to those rules that Kelly Johnson came up with 76 years ago, especially of having engineers on the floor ready to respond to issues, with the key goals of keeping drills drilling and wrenches turning on a regular basis,” said Tom Alexander, Lockheed Martin’s special projects operations manager.

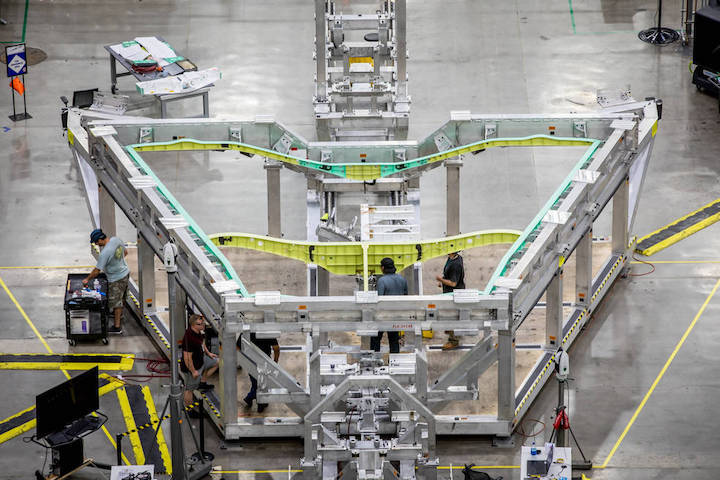

The X-59 assembly work taking place on the Lockheed Martin production floor is concentrated within three major sections of tooling.

The forward jig is home to the X-59’s fuselage, the center section to the airplane’s single-piece wing, and the rear jig is set up for the fabrication of the airplane’s tail holding the vertical fin and the horizontal stabilizer – a section also known as the empennage.

Most of the activity right now is focused on the fuselage and wing jigs, but the empennage section (which also includes the airplane’s single jet engine) will receive more attention starting in November, all of which keeps things right on schedule going into 2020.

“By about a year from now they should have most of this aircraft assembled and the subassemblies mated together. And a little over a year from now this aircraft should be ready to go into major testing,” Nickol said.

Initial flight tests to ensure the vehicle is operating well in 2021 will be followed by a series of supersonic flights to validate if it is producing quieter sonic booms as expected. After that, the X-59 will begin its community overflights to gather public response data, with the plan to present that information to the FAA and others in 2023.

“Sometimes building an airplane is a little tough but having that exciting end goal really helps keep the team energized,” Buonanno said.

X-59 Assembly Update Outtake

Aviation trivia buffs take note: the answer is C612.

After years of working on a preliminary design and then months of fine-tuning the many engineering drawings and resulting configurations for an airplane like this, that’s the number for the final version of the X-59.

“The exterior lines of the airplane, what we call the outer mold line, are now frozen. This is the way the X-59 will look, although we might have to make some very minor changes, such as where we put antennas,” Nickol said.

That external look also includes a red, white, and blue paint scheme designed to accentuate the supersonic jet’s unique, sonic-boom-quieting shape. While that won’t change, some of the logos and related markings will be updated when Lockheed Martin officially turns over ownership of the airplane to NASA.

Internally, meanwhile, the story is the same. The design is set, although small adjustments may be needed based on experience gained during the ongoing manufacturing, assembly, and integration process.

“We don’t expect to have any further configuration level updates, meaning there won’t be a C613,” Nickol said

Quelle: NASA

----

Update: 13.03.2020

.

X-59 QueSST More than the Sum of Its Parts

A time-lapse video shows recent progress in assembling NASA’s X-59 Quiet SuperSonic Technology aircraft at the Lockheed Martin Skunk Works® factory in Palmdale, California.

A time-honored tradition employed by the aerospace community for decades is continuing with the assembly of NASA’s X-59 Quiet SuperSonic Technology aircraft at the Lockheed Martin Skunk Works® factory in California.

Perfectly acceptable components from other aircraft – some major, some minor – are finding new life as parts installed on the X-59, an experimental airplane whose mission is to help open a new era of commercial supersonic air travel over land.

Landing gear from an Air Force F-16 fighter, a cockpit canopy from a NASA T-38 trainer, a propulsion system part from a U-2 spy plane and a control stick from an F-117 stealth fighter are among the repurposed parts to be used on NASA’s newest airplane.

It’s all about saving time and money.

“The X-59 is designed so that, as it flies faster than sound, any sonic booms that reach the ground are so quiet they can barely be heard – if at all. That’s what’s new here,” said Craig Nickol, NASA’s X-59 project manager.

“So, while we’re pushing technology in terms of the X-59’s overall shape and configuration, at the same time we can take advantage of using reliable systems from aircraft we know or have experience with and install those,” Nickol said.

The alternative – designing those same types of parts from scratch – would come with a big downside. Additional years and millions of dollars – no one is sure exactly how much – would be needed to build, test and certify these components and systems as being safe for flight.

And while integrating the repurposed parts so they all safely work together is still a challenging task, going that route is definitely appreciated by the Lockheed Martin team who was responsible for the original design of the X-59 and then earned the $247.5 million contract to build the airplane.

“Development of those systems would be complex and potentially add risk to the program. With the availability of these components we didn’t need to take on that risk to be successful with the X-59,” said Peter Iosifidis, Lockheed Martin’s X-59 program manager.

Another factor in favor of using existing components from other aircraft is the fact the X-59 is a one-of-a-kind-airplane. Only one will be built. There are no plans to build and operate a fleet of airplanes like the X-59.

“That’s not our job at NASA and that’s not the purpose of this research aircraft. As a result, it’s much more efficient to leverage existing components because we’re not going into a large production run,” Nickol said.

It’s Nice to Share

This practice of building a new experimental aircraft like the X-59 with parts large and small from other vehicles is not new, either for aeronautics research or for space exploration.

“Sharing components between airplanes for research programs like this is a pretty common practice used for many years,” said Brian Griffin, the deputy operations lead for the X-59 project at NASA’s Armstrong Flight Research Center in California.

Two examples:

The Shaped Sonic Boom Demonstration aircraft that flew in 2003 and 2004 – a direct precursor project to the X-59 – relied on a used Northrop F-5E fighter jet. Its body shape was modified in a manner that successfully proved supersonic shockwaves could in turn be shaped in way to lessen the loudness of a sonic boom.

Two X-29 aircraft, with their unique forward-swept wings, flew 242 times between 1984 and 1991. They tested new fly-by-wire technologies and the use of composite materials in the construction of the wings. The aircraft design included use of the forward fuselage and nose landing gear of an F-5A, and the main landing gear of an F-16.

On the space side of NASA, sharing of components is just as commonplace.

For example, a helium pressure regulator from a retired space shuttle orbiter was installed and used as part of the descent stage for the Curiosity rover that landed on Mars in 2012.

The Magellan radar mapping probe to Venus, launched aboard the space shuttle Atlantis in 1989, was made from spare parts leftover from the Voyager program to the outer planets, the Galileo program to Jupiter, the Ulysses program to study the sun and the Mariner 9 program to Mars.

And to save money and time, NASA even used a leftover hatch from the Gemini program as an airlock door on the Skylab space station that was visited by three crews flying an Apollo spacecraft in 1973 and 1974.

X-59 Shopping Spree

So, where does one go to find used landing gear from an F-16, a throttle assembly or air turbine starter from an F/A-18, or any of potentially dozens of system components from other aircraft that might still be useful?

A good start is “The Boneyard” at Davis-Monthan Air Force Base at Tucson, Arizona.

Situated in the desert at the edge of the city, the base is host to the 309th Aerospace Maintenance and Regeneration Group (AMARG) and home to more than 4,400 aircraft – either retired or in storage – from the Air Force, Navy, Marines, Army, and Coast Guard.

With little rain, low humidity and a hard-packed soil to park on, airplanes there can sit outdoors for years and experience little deterioration. Those aircraft that are wrapped in a covering or otherwise especially prepared for long-term storage can be brought back into service with less effort than building a new airplane.

It’s the perfect place to get a good deal on a used aircraft part.

But if the vision of some NASA engineers walking around, kicking tires and peeking under the hood looking for a decent-looking part they can grab is flashing through your mind, you have the wrong picture of how it really works.

“No, we didn’t go there and have that used car lot type of approach where we got to pick and choose whatever we wanted,” Griffin said.

Instead, most of the searching was done by Air Force officials looking through aircraft databases for parts that met NASA’s specifications. Once the Air Force made a selection, it was up to Griffin and his team to go to Tucson and ensure everything looked in order.

“Once the paperwork was done, we worked with the people at AMARG to prepare and ship the hardware to us at Armstrong,” Griffin said.

Some of the parts were dismantled from their original aircraft and shipped in crates to California, while, in the case of the F-16 landing gear, the F-16 fuselages were shipped on a flatbed truck with the gear still installed.

A New Chapter in History

Even before the X-59 first takes flight in 2021 to write a new chapter in aviation history, many of the refurbished parts that will be used in its final assembly already have their own fascinating stories to tell about the airplanes they came from.

Based on aircraft serial numbers and publicly available information compiled by the not-for-profit F-16.net website, several interesting details about the two F-16C fighter jets that are supplying landing gear parts for the X-59 are known.

For example, one of the F-16C’s began military service in 1985 with the 363rd Tactical Fighter Wing at Shaw Air Force Base in South Carolina. It was retired from the Air Force as part of the 40th Flight Test Squadron at Eglin Air Force Base in Florida and moved to AMARG in 2015.

The other F-16C began its service in 1986 with the 86th Tactical Fighter Wing stationed in Ramstein, Germany. It ended its military career in 2014 with the 62nd Fight Squadron at Luke Air Force Base in Arizona and transferred to AMARG after cracks were found in the aircraft structure associated with the canopy – a problem that grounded dozens of F-16s at the time.

According to the F-16.net database of unit assignments and years served at each unit, neither F-16C aircraft flew any combat missions. Both were officially transferred from AMARG to NASA on June 9, 2017.

The heritage of the two NASA T-38’s is even more compelling.

These are the type of aircraft that, even today, NASA astronauts fly to remain proficient in high-performance aircraft – a necessary experience to prepare for spaceflight whether you’re a pilot or not – and to travel around the nation as needed.

During the Space Shuttle Program, they were most visible as the sleek aircraft with a crew of astronauts for that mission seen flying to the Kennedy Space Center in Florida at the beginning of each countdown.

With tail numbers of N912NA and N914NA, they were assigned to the Johnson Space Center in Houston. NASA 912 was retired and delivered to AMARG in 2011 following the final spacesShuttle mission earlier that year.

NASA 914 had a more dramatic conclusion to the first chapter in its history.

On February 24, 1987, astronaut Brewster Shaw – who at that time had already flown in space twice and would fly again in 1989 – was cruising to California in the T-38 with NASA research pilot Rob Rivers, who also was aboard and flying in the front seat.

As an investigation later determined, the jet was hit by lightning as the twin-engine airplane was over the Pacific Ocean, about 10 miles from their destination runway. Within moments the right engine was out and on fire, the left engine also was on fire but still working, and the cockpit was filling with smoke.

Shaw, who was more familiar with the area than Rivers, took control of the airplane and was able to get the two of them and the aircraft safely on the ground without having to eject and endanger anyone below.

In auto insurance terms the airplane was “totaled,” removed from service and put in storage. Three decades later parts of its cockpit and the other T-38 will find use again not only on the X-59 itself, but in a pair of ground-based simulators and an egress trainer.

NASA has selected Lockheed Martin Aeronautics Company of Palmdale, California, to provide support for the community overflight response phase of the agency’s Low-Boom Flight Demonstration (LBFD) mission, part of the Integrated Aviation Systems Program in the agency’s Aeronautics Research Mission Directorate. The contract is awarded through the agency’s Armstrong Flight Research Center in Edwards, California.

The indefinite-delivery/indefinite-quantity price contract has a total value of $40 million and a performance period that runs through Dec. 14, 2025.

The contract will provide extra structural components and subsystems for the X-59 aircraft as a risk-reduction strategy to minimize downtime for the airplane during high-tempo operations.

The X-59 is designed to fly at supersonic speeds without producing the loud sonic booms typically associated with such speeds, instead reducing them to quiet sonic thumps.

In 2024, NASA will fly the X-59 over select communities to measure public perception of the sound. The data from these tests will be given to U.S. and international regulators, potentially opening the future to commercial supersonic flight over land.

Quelle: NASA

----

Update: 23.03.2021

.

Cutting Edge Ground Recorders Selected to Measure Future X-59 Quiet Supersonic Flights

For the deserts of Southern California, the major milestones of aviation have long been marked by the unique sights, and sounds, of flight.

From the late Chuck Yeager’s breaking of the sound barrier in 1947, to the space shuttles’ approach and landing at NASA’s Armstrong Flight Research Center (then Dryden) in Edwards, and through today, one recognizable sound is the sonic boom – a loud, sometimes startling event that we hear on the ground when an aircraft overhead flies faster than the speed of sound, also called supersonic speed.

NASA, for decades, has led the effort to study sonic booms, the loudness of which are considered the key barrier to enabling a future for overland, commercial supersonic aircraft. That future will be closer to reality when the agency’s X-59 Quiet SuperSonic Technology (QueSST) airplane takes to those familiar skies in 2022, taking the first steps to demonstrating the ability to fly at supersonic speeds while reducing the sonic boom to a significantly quieter sonic thump.

While NASA will fly the X-59 over communities around the U.S. as early as 2024 to analyze the public’s perception and acceptability of quiet supersonic flight, the agency will first need to prove that the X-plane is as quiet as it’s designed to be.

To do this, NASA will measure the sound of the sonic thumps in the Mojave Desert using cutting edge technology – a brand new, state-of-the-art ground recording system for a brand new, state-of-the-art X-plane.

NASA has contracted Crystal Instruments of Santa Clara, California to deliver a high-fidelity sonic boom – and soon to be, a quiet sonic thump – recording system, capable of providing the data necessary for the agency to validate the acoustic signature of the X-59.

“This will be the first time that we have a single system across NASA to do this research, and it will incorporate a lot of newer technologies to allow us to get this done,” said Larry Cliatt, NASA’s tech lead for the acoustic validation phase of the NASA’s Low-Boom Flight Demonstration mission. “I consider it the next generation of sonic boom, and soon to be quieter sonic thump, recording systems.”

NASA will utilize the Crystal Instruments Ground Recording System, or CI-GRS for short, to gather time, waveform, and spectral data related to sonic booms and sonic thumps. The CI-GRS will also feature the ability for NASA to install custom software and algorithms to perform various specialized operations for real-time sonic thump analysis.

With this technology, NASA will have the ability to extract, review, and analyze specific data from a recording. For example, the CI-GRS will have the capability to accommodate software that can distinguish a low-amplitude sonic thump from the X-59 among other ambient sounds. That software will also be able to calculate a number of different types of acoustic metrics, including perceived sound level, which is the currently accepted measure for sonic boom loudness.

“What we are building is a data acquisition system that will use the latest advancements in technology, with cutting edge hardware and software capabilities, so that NASA can capture the high-quality sonic boom data they need,” said Darren Fraser, Crystal Instruments vice president of sales.

The first deliveries of the CI-GRS are expected to be deployed for initial field testing at NASA Armstrong, and later, some will deploy outside Edwards Air Force Base with units spread out as a 30-nautical-mile-long ground microphone array. This will be part of the next rounds of the Carpet Determination in Entirety Measurements flights, called CarpetDIEM for short.

These flights will simulate the acoustic validation phase for the X-59 by deploying an aircraft from NASA Armstrong, which will fly over the array at supersonic speeds, testing the units’ ability to record sonic boom data, before they capture the X-59’s quiet sonic thumps.

The lessons learned from the CarpetDIEM tests will facilitate any necessary updates and modifications for the final CI-GRS design, which will then be used in the same method for the X-59 with as many as 70 ground recording stations.

Another requirement NASA will need the CI-GRS to meet will be its ability to operate remotely. In previous, similar supersonic acoustic research efforts, NASA deployed sonic boom recorders in the field, and collected the sensors at the end of each test day. A 30-mile-long microphone array in the Mojave Desert, however, presents a logistical challenge.

“This ground recording system will be more robust and ruggedized when it comes to its operational use, and that’s what we anticipate, with the ability to deploy for several days at a time,” said Cliatt. “These will also incorporate two-way communications so that they can be deployed over a large area when the X-59 flies over communities starting in 2024, so the ultimate total of 175 of these can be controlled from a single remote host.”

The next CarpetDIEM flights are expected for late 2021.

“The CI-GRS is going to be a first of its kind, much like the X-59, and I think there will be a lot of firsts in a new age of potential commercial supersonic travel,” said Fraser. “We think this will set the stage for the future, and I think that’s what everybody wants to look toward.”

Quelle: NASA

----

Update: 20.07.2021

.

Quelle: NASA