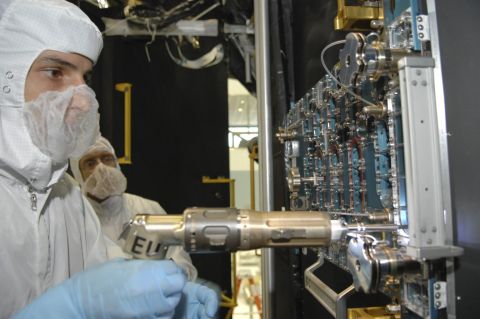

The pistol-grip tool slung on an astronaut's spacesuit as he works on the Hubble Space Telescope.

NASA

.

NASA conducted a spacewalk today to replace the International Space Station's batteries. Twelve aging nickel-hydrogen batteries will be replaced with six new lithium-ion batteries, a mission that will take two spacewalks. In today's, astronauts Shane Kimbrough and Peggy Whitson will be at work for six and a half hours.

If you watched the spacewalk, then you saw the astronauts using NASA's "pistol-grip tool," a cordless power drill designed for use in space. Built by Swales Aerospace Inc., it is the staple of NASA's space tool arsenal. The pistol-grip tool helped build the International Space Station as well as the Hubble Space Telescope, and it's been at all the repairs along the way. Needless to say, NASA's cordless power drill needs to do a few things that the one in your garage can't.

For one thing, it has to withstand quick fluctuations in temperature by hundreds of degrees. The ISS orbits the Earth every 90 minutes, 16 times per day, passing in and out of the sunlight each time it does. In such an environment, liquid lubricants would cause a power tool to seize, so the pistol-grip tool uses dry film lubricants that evaporate at room temperature. And it's incredibly light. The pistol-grip tool is made of Lexan, a glass-infused plastic, and wrapped in aluminum tape.

"The astronauts have limited mobility in their space suits, so one of the things they have to cope with is hand fatigue due to constantly fighting against the pressure of the suit," said Jill McGuire, tools manager for the HST Program in a NASA article about tool design. "Therefore, we need to build larger tools that have specially designed handles and triggers that make it easier for them to work in their suits."

The pistol-grip tool functions much in the same way a regular power drill does, with a battery that slots into the handle, only it has a large information screen where astronauts can change the speed and torque (between less than 1 and 38 foot-pounds, and between 5 and 60 rpm). The drill is designed to turn slowly—no need to rush things in space—but still produce enough torque to undo bolts and fasteners.

For one of the most famous spacewalks, the mission to replace the HST's power supply after a critical failure, NASA engineers needed to design a new drill. The components that needed to be replaced, similar to a computer board, were behind a panel that was not designed to be taken off by spacewalking astronauts.

They needed something that could turn faster than the pistol-grip tool so the 111 fasteners could be taken off quickly enough to remove the panel, and they needed something small enough to work with in a confined space. The result was a mini power drill that took five years to design. It could spin at 210 rpm and had an attached "capture plate" to collect all the fasteners without letting them float into space.

Most of the other tools NASA uses are specifically designed for one task, but the pistol-grip tool remains the primary tool used by spacewalkers in the 21st century. Perhaps in the future, robots will perform these tasks with tools affixed to their arms, but for now, the best solution for a broken space station is an astronaut and his trusty space drill.

Quelle: PM