.

16.10.2015

NASA's Webb "Pathfinder Telescope" Successfully Completes First Super-Cold Optical Test

Testing is crucial part of NASA's success on Earth and in space. So, as the actual flight components of NASA's James Webb Space Telescope come together, engineers are testing the non-flight equipment to ensure that tests on the real Webb telescope later goes safely and according to plan. Recently, the "pathfinder telescope," or just “Pathfinder,” completed its first super-cold optical test that resulted in many first-of-a-kind demonstrations.

.

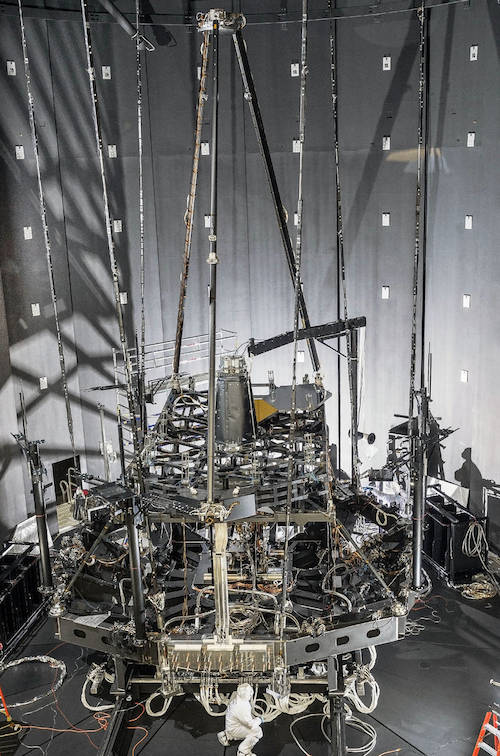

The Pathfinder was pushed into the Chamber for OGSE2.

Credits: NASA/Chris Gunn

-

"This test is the first dry-run of the equipment and procedures we will use to conduct an end-to-end optical test of the flight telescope and instruments," said Mark Clampin, Webb telescope Observatory Project Scientist at NASA's Goddard Space Flight Center in Greenbelt, Maryland. "It provides confidence that once the flight telescope is ready, we are fully prepared for a successful test of the flight hardware."

The Pathfinder is a non-flight replica of the Webb telescope’s center section backplane, or “backbone,” that includes mirrors.

The flight backplane comes in three segments, a center section and two wing-like parts, all of which will support large hexagonal mirrors on the Webb telescope. The pathfinder only consists of the center part of the backplane. However, during the test, it held two full size spare primary mirror segments and a full size spare secondary mirror to demonstrate the ability to optically test and align the telescope at the planned operating temperatures of -400 degrees Fahrenheit (-240 Celsius).

The first cryogenic optical testing of the Pathfinder was successfully completed in Chamber A at NASA's Johnson Space Center in Houston, Texas. Chamber A was originally used to test the Apollo capsule. This test demonstrated new helium and nitrogen cooling systems installed for the Webb telescope testing which allowed the Pathfinder to achieve those frigid temperature that will simulate operating temperatures we will have at the L2 Lagrange point. The cooling system is installed in the chamber. There is a vacuum chamber with a nitrogen shroud inside of it and then a helium shroud inside of the helium shroud. The Pathfinder is then inside the Helium shroud.

"The most significant breakthrough was the first-ever cryogenic optical alignment and testing of multiple primary mirror segments in a process known as 'phasing,'" said Lee Feinberg, Webb telescope Optical Telescope Element Manager at NASA Goddard.

"During the demonstration, mirrors that were initially misaligned by millimeters were aligned to each other using actuators operating at -400F to better than one-one-thousandth diameter of a human hair (or a fraction of a wavelength of light) such that the two primary mirror segments were optically equivalent to a single monolithic mirror," Feinberg said.

The second "first" involved the vertical orientation of the testing of the mirrors. It marked the first time a lightweight cryogenic mirror of this type had been tested in a second gravity orientation. "To understand a second gravity orientation, think of a cup," Feinberg said. "When the cup is face up so you can pour water in it, it is vertical to gravity. Now put the cup on its side and it is horizontal to gravity. Mirrors are like cups in this explanation." That allowed for successful cross-checking of the predicted zero-gravity performance of the mirrors.

"In another major achievement, four large super cold windmills carrying steerable cameras were able to measure the alignment of all of the mirrors and structure to better than one-tenth of a millimeter using a process called photogrammetry," Feinberg said. Photogrammetry is a technique that takes images from multiple to simulate operating temperatures orientations, combines those images, and then using triangulation algorithms to determine distances between objects in those scenes.

The phasing demonstration used a new metrology device developed for NASA to test segmented telescopes by 4D Technologies Corporation called a multi-wavelength interferometer and used a reflective null lens designed and built by Harris Corporation.

After this test completed, the flight Aft Optics System, which includes the Tertiary Mirror and Fine Steering Mirror, was installed on the Pathfinder to prepare for a second test. The full Pathfinder was then outfitted with special fiber-fed infrared optical sources that simulate star images. Those star images, or infrared sources, along with a specially instrumented infrared detector will be used during the second test to perform end-to-end testing of the full Pathfinder telescope system and ensure they function as simulated stars.

After that second test is complete late in 2015, all optical test systems will have been checked out.

A third and final precursor test called “Thermal Pathfinder” will follow in 2016 that will fully test all the test equipment needed to simulate the temperature environment of space. Once this is complete, all test equipment and procedures needed to test the actual full flight telescope and the Integrated Science Instrument Module or ISIM assembled as a unit in early 2017 will be checked-out and ready.

Orbital ATK fabricated the composite structure of the pathfinder backplane. The pathfinder (minus the mirrors) was tested at Northrop Grumman in Redondo Beach, California

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Quelle: NASA

-

Update: 5.11.2015

.

NASA's James Webb Space Telescope Science Instruments Begin Final Super Cold Test at Goddard

An engineering team lifted and lowered the heart of NASA's James Webb Space Telescope into the giant thermal vacuum chamber at NASA's Goddard Space Flight Center in Greenbelt, Maryland. This move marks the start of the third and final cryogenic test at Goddard to prepare the Integrated Science Instrument Module (ISIM), or the “heart” of the telescope, for space.

The James Webb Space Telescope team lifts the Integrated Science Instrument Module (ISIM) structure by crane as it leaves the Goddard clean room for the thermal vacuum chamber.

Credits: NASA/Chris Gunn

-

This super cold test is vitally important for this large space telescope. Unlike a telescope you'd use in your backyard, scientists rely on remotely controlled mirrors and complex science measuring tools (instruments) to take in light from the distant universe. To do this, they must be rigorously tested on the ground to ensure they will work in space.

Webb telescope's images will reveal the first galaxies forming approximately 13.5 billion years ago. The telescope will also see through interstellar dust clouds to capture stars and planets forming in our own galaxy. At the telescope's final destination in space, one million miles away from Earth, it will operate at incredibly cold temperatures of -387 degrees Fahrenheit, or 40 degrees Kelvin. This is 260 degrees Fahrenheit colder than any place on the Earth’s surface has ever been.

.

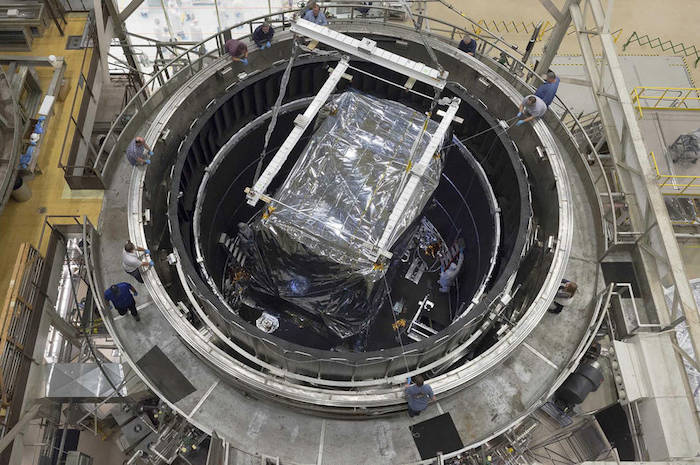

This rare overhead view of the thermal vacuum chamber at NASA's Goddard Space Flight Center in Greenbelt, Maryland shows engineers readying the Integrate Science Instrument Module (ISIM) that was just lowered into the chamber for its final cryogenic test at Goddard.

Credits: NASA/Chris Gunn

-

To create temperatures that cold on Earth, the team uses the massive thermal vacuum chamber at Goddard called the Space Environment Simulator, or SES, that duplicates the vacuum and extreme temperatures of space. This 40-foot-tall, 27-foot-diameter cylindrical chamber eliminates almost all of the air with vacuum pumps and uses liquid nitrogen and even colder liquid helium to drop the temperature, thereby simulating the space environment.

"ISIM's final test is an exciting time for us," said Bill Ochs, Webb's Project Manager. "After this test ends, we will be able to start integrating ISIM with the rest of the telescope."

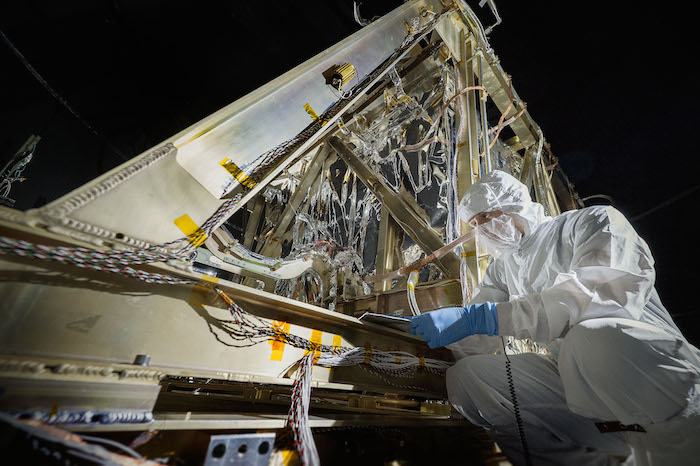

Navigating tight spaces inside the chamber while dressed in a white clean room suit to prevent contamination, Jack Marshall and other engineers readied ISIM for its super cold test.

"After we moved ISIM into the chamber, we close the lid. Then we pump air into the chamber, so we can continue to set up inside the chamber," said Marshall. "Once everything is set, we pump out the air inside the chamber to create a vacuum. We then use liquid nitrogen and liquid helium to cool surfaces on the chamber walls and test structure, simulating the temperatures the telescope will see in space."

The several-month-long test is used to ensure all of the science instruments are ready for flight.

"Everything went smoothly and as planned," Neil Becker, mechanical engineer. "We are at the beginning of the final cryogenic test, most of the mechanical work is done."

The ISIM completed a successful acoustic test and an electromagnetic interference test a couple of months ago. A team will monitor this new grueling test for months, around the clock, to see how the instruments handle the extreme temperatures.

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

---

At NASA's Goddard Space Flight Center, the Integrated Science Instrument Module (ISIM), or the "heart" of the James Webb Space Telescope, is undergoing a third and final round of cryogenic tests in Goddard's massive thermal vacuum chamber to prepare for the vacuum and extreme temperatures of space. In this Oct. 27, 2015 photograph, Contamination Control Engineer Alan Abeel conducts final inspections and places contamination foils before the start of the test.

This super cold test is vitally important for this large space telescope. Unlike a telescope you'd use in your backyard, scientists rely on remotely controlled mirrors and complex science measuring tools (instruments) to take in light from the distant universe. To do this, they must be rigorously tested on the ground to ensure they will work in space.

The Webb telescope's images will reveal the first galaxies forming approximately 13.5 billion years ago. The telescope will also see through interstellar dust clouds to capture stars and planets forming in our own galaxy. At the telescope's final destination in space, one million miles away from Earth, it will operate at incredibly cold temperatures of -387 degrees Fahrenheit, or 40 degrees Kelvin. This is 260 degrees Fahrenheit colder than any place on the Earth’s surface has ever been.

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Quelle: NASA

-

Update: 11.11.2015

.

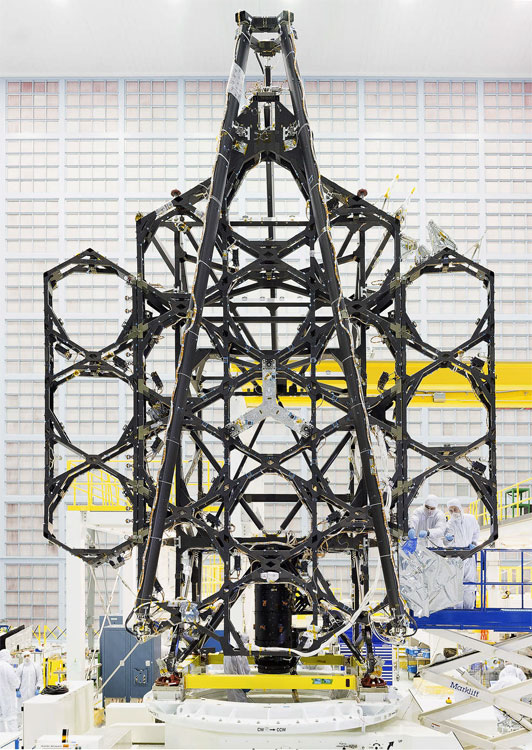

Looking up at the massive flight #JWST telescope structure inside the clean room at @NASAGoddard. What a view!

Quelle: NASA

-

Update: 16.11.2015

.

James Webb Space Telescope 'Wings' Successfully Deployed

Recently inside the clean room at NASA's Goddard Space Flight Center in Greenbelt, Maryland, engineers successfully completed two deployments for the James Webb Space Telescope's "wings" or side portions of the backplane structure that fold up. The wings and telescope structure are essential because they make up the telescope's carbon fiber framework which will hold all 18 of the telescope's mirrors and the tower for the primary mirror.

.

Engineers successfully completed two deployments for the James Webb Space Telescope's "wings" or side portions of the backplane structure that fold up.

Credits: NASA

-

"We deploy the wings one at a time. Each individual deployment can take up to 16 hours or more to complete," said Adam Carpenter, Mechanical Integration Engineer at Goddard, as he and other engineers prepared for the move. "It is a delicate operation requiring multiple groups to perform specific tasks."

Leading up to this test, engineers lined the telescope structure with cables. In space, these cables will enable the telescope to open up and will provide electrical signals to the active mirror segments. During the wing test, however, the engineers needed to make sure the cables did not block the deployment, and so the team arranged the cables carefully.

"The two wings of the telescope structure will eventually hold 6 of Webb's 18 primary mirror segment assemblies," said Carpenter said. "They are necessary so that the observatory can fold up in order to fit into the launch vehicle."

The James Webb Space telescope, once fully assembled, will be bigger than any rocket that can launch the telescope into space. So the engineering team designed the telescope to fold like origami to fit inside its Ariane 5 rocket. Once launched, Webb will be shipped out to its destination one million miles out in space.

Webb telescope's images will reveal the first galaxies forming approximately 13.5 billion years ago. The telescope will also see through interstellar dust clouds to capture stars and planets forming in our own galaxy. At the telescope's final destination in space, one million miles away from Earth, it will operate at incredibly cold temperatures of -387 degrees Fahrenheit, or 40 degrees Kelvin. This is 260 degrees Fahrenheit colder than any place on the Earth’s surface has ever been.

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Quelle: NASA

-

Update: 21.11.2015

.

Webb Telescope Mirror Mount on the Robotic Arm

A primary mirror segment (black hexagonal shape) from the James Webb Space Telescope was mounted on a grey/silver robotic arm at NASA Goddard Space Flight Center. The arm will install the mirror onto the Telescope Structure.

Quelle: NASA

-

Update

.

James Webb Team Ready to Install Telescope's 18 Gold-Coated Primary Mirror Segments

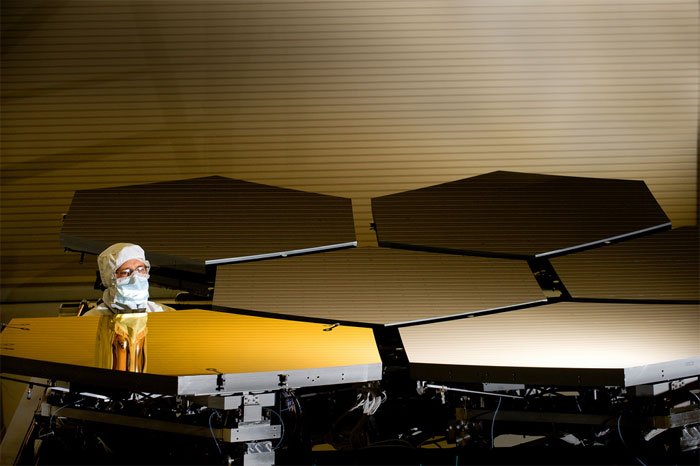

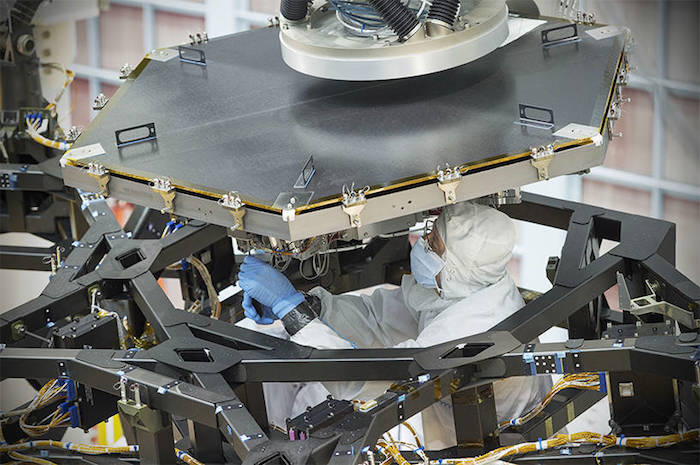

A robotic arm lifts and lowers a golden James Webb Space Telescope flight spare primary mirror segment onto a test piece of backplane at NASA’s Goddard Space Flight Center in Greenbelt, Md. In this image the JWST team practices the positioning that will be done on the actual telescope in the cleanroom. Dave Sime, an assembly crew chief, inspects the mirror placement from the underside of the backplane. Photo Credit: NASA/Chris Gunn

-

The James Webb Space Telescope (JWST), a NASA collaboration with the European Space Agency (ESA) and the Canadian Space Agency (CSA), continues to take shape in a 1.3 million-cubic-foot clean room as engineers at NASA’s Goddard Space Flight Center in Greenbelt, Md., continue putting together what is being billed as “Hubble’s successor” for a planned late 2018 launch.

The telescope is being primed to receive all 18 of its primary flight mirrors. In addition, the “wings” of the backplane structure, which will carry those mirrors, were deployed, while the mirrors themselves were measured with precision to ensure they will be a perfect fit. Concurrently, the Integrated Science Instrument Module (ISIM), characterized as the scientific “heart” of JWST, is undergoing its final “super cold” test inside a thermal vacuum chamber, simulating the harsh conditions it will encounter 1 million miles (1.5 million kilometers) from the ground.

Backplane Structure Being Readied For Mirror Segments

NASA announced on Wednesday, Nov. 18 that the JWST telescope structure was lifted into an optical stand, with the structure being readied to receive all 18 of the telescope’s hexagonal, gold-coated mirrors (the mirrors themselves are made of beryllium). Days earlier it was announced that the telescope’s two “wings,” the side portions of the backplane structure, were deployed twice with success.

“We deploy the wings one at a time. Each individual deployment can take up to 16 hours or more to complete,” said Adam Carpenter, Mechanical Integration Engineer at Goddard, as he and other engineers prepared for the move. “It is a delicate operation requiring multiple groups to perform specific tasks. The two wings of the telescope structure will eventually hold 6 of Webb’s 18 primary mirror segment assemblies.”

These wings will be folded inside the fairing of an Ariane 5 launch vehicle for its projected October 2018 launch from Europe’s Spaceport in Kourou, French Guiana; as the telescope cannot be serviced following its launch (unlike the Hubble Space Telescope or HST, which was serviced five times in low-Earth orbit by space shuttle crews between 1993 and 2009), these components’ successful deployment in space is vital to the mission’s success.

NASA also divulged that Goddard engineers were also recently performing “mirror metrology,” described as “ultra-high accuracy measurements,” to ensure the next-generation mirrors are a perfect fit in the telescope’s structure.

“The complexity of the mirror assemblies comes from the fact that they are designed to be very lightweight, work at cryogenic temperatures below -400F, survive launch vibration and forces, be align-able on-orbit via actuators, and then stay aligned for up to two weeks as though they are a single large mirror,” said Lee Feinberg, NASA Optical Telescope Element Manager for the James Webb Space Telescope at the Goddard Space Flight Center in Greenbelt, Md.

Putting Webb into position for its observations is one thing, but getting the giant segmented mirror to focus on galaxies millions, even billions, of light-years away is another challenge all together. In order to ensure Webb achieves a single perfect focus, engineers will use six tiny mechanical motors, or actuators, attached to the back of each mirror piece to capture the images they expect Webb to produce.

“Aligning the primary mirror segments as though they are a single large mirror means each mirror is aligned to 1/10,000th the thickness of a human hair,” says Feinberg. “What’s even more amazing is that the engineers and scientists working on the Webb telescope literally had to invent how to do this.”

.

The amazing mirrors that will fly aboard NASA’s James Webb Space Telescope will allow the James Webb Space Telescope to see farther away and further back in time to detect the light from the very first and most distant stars and galaxies. In this photo, an engineer’s crystal clear reflection is seen on the surface of one of the primary mirror segments. The image is so clear you can see an expression of concentration in the engineer’s face. Behind the engineer looking into the mirror’s surface, the top part of the canister that the mirror was shipped in hangs from four straps. Other engineers use flashlights to inspect the mirror segment.

Photo Credit and Caption: NASA/Chris Gunn

Another problem with “traditional” telescope mirrors is the fact that they are heavy. If Webb’s mirror was made same as the Hubble, then it simply could not be launched. To get around this, Northrop Grumman (the company that is leading the effort to build Webb) decided to make Webb’s mirrors from Beryllium, which is a very strong but light metal. In order for the telescope’s instruments to function properly, the observatory also needs to be kept very cold, -400 degrees Fahrenheit cold, and Beryllium holds its shape at those cryogenic temperatures and is a good conductor of electricity and heat.

Gold coats the finished mirrors and is used to improve the mirror’s reflection of infrared light.

As mentioned before, JWST cannot be serviced once in space; lessons learned from Hubble are still fresh. The real thing must function perfectly post-launch (especially at 1 million miles out from Earth, the second Lagrangian point, or L2). In addition, the telescope will be exposed to extreme conditions, which can stress any spacecraft. The side in shadow will face temperatures of -400 degrees Fahrenheit (-240 degrees Celsius). In stark contrast, the other side of the telescope must be shielded from the Sun’s light and heat by a tennis-court sized sunshield comprised of five layers.

The article stated: “The goal of the Pathfinder tests is to thoroughly check the replica mirror segments in the cryogenic conditions that the flight ones will operate under when the telescope is deployed following its arrival at the L2 Lagrange point. To that end, the JWST engineering teams have been in the process in recent years of revamping the famous cryo vacuum Chamber A at NASA’s Johnson Space Center in Houston, TX, which had previously been used for testing the Apollo spacecraft in the 1960s.” These tests will ensure that once the flight telescope is ready, it can be successfully tested, staying on target for a timely launch.

ISIM Enters Final Deep Freeze, Simulating Extreme Flight Conditions

While JWST’s optics continue to come together, in late October NASA announced that the telescope’s science instruments were entering their third and final cryogenic test inside Goddard’s Space Environment Simulator (SES), a giant thermal vacuum chamber. This test will again expose the ISIM to similar conditions it will encounter at L2, ensuring it will operate successfully during its mission.

Engineer Jack Marshall discussed the procedures taken during these “super cool” tests. “After we moved ISIM into the chamber, we close the lid. Then we pump air into the chamber, so we can continue to set up inside the chamber. Once everything is set, we pump out the air inside the chamber to create a vacuum. We then use liquid nitrogen and liquid helium to cool surfaces on the chamber walls and test structure, simulating the temperatures the telescope will see in space,” he related. This test will span several months, showing engineers how these components react to extreme cold and the vacuum of space; once successfully wrapped up, the ISIM can be integrated with the rest of the telescope.

According to NASA, the ISIM also recently underwent a successful acoustic test and an electromagnetic interference test.

*****

Three years prior to launch, buzz about JWST continues to grow. In an interview conducted for the 25th anniversary of HST in April, NASA astronaut James Newman discussed JWST: “…JWST is not a replacement, but a successor to HST, as it has its own distinct capabilities, seeing primarily in the infrared (IR). …Whenever we field a new sensor of any kind, and JWST certainly promises to have impressive sensing capabilities, we learn SO MUCH. There is no doubt in my mind that we will find tremendous surprises as well as expected results when we turn JWST on.”

When operational, JWST will be able to see the first galaxies forming approximately 13.5 billion years ago. NASA Goddard’s engineers and the telescope’s prime contractors at Northrop Grumman continue to ensure when October 2018 hits, JWST is ready to spread its wings and fly, bringing incredible images home.

.

Ball Aerospace optical technician Scott Murray inspects the first gold primary mirror segment, a critical element of NASA’s James Webb Space Telescope, prior to cryogenic testing in the X-ray & Cryogenic Facility at NASA’s Marshall Space Flight Center in Huntsville, Ala. Credit: NASA/MSFC/David Higginbotham

The robotic arm lifts and lowers a golden James Webb Space Telescope flight spare primary mirror segment onto a test piece of backplane at NASA’s Goddard Space Flight Center in Greenbelt, Md. While the team practices the positioning that will be done on the actual telescope in the cleanroom, Dave Sime, an assembly crew chief, inspects the mirror placement from the underside of the backplane. Image Credit: NASA/Chris Gunn

Quelle: AS

-

Update: 26.11.2015

.

NASA’s Webb Space Telescope Receives First Mirror Installation

An engineer at NASA's Goddard Space Flight Center worked to install the first flight mirror onto the telescope structure at NASA's Goddard Space Flight Center in Greenbelt, Maryland.

Credits: NASA/Chris Gunn

-

NASA has successfully installed the first of 18 flight mirrors onto the James Webb Space Telescope, beginning a critical piece of the observatory’s construction.

In the clean room at NASA’s Goddard Space Flight Center in Greenbelt, Maryland this week, the engineering team used a robot arm to lift and lower the hexagonal-shaped segment that measures just over 4.2 feet (1.3 meters) across and weighs approximately 88 pounds (40 kilograms). After being pieced together, the 18 primary mirror segments will work together as one large 21.3-foot (6.5-meter) mirror. The full installation is expected to be complete early next year.

.

nside a massive clean room at NASA's Goddard Space Flight Center in Greenbelt, Maryland the James Webb Space Telescope Team prepared for the first flight mirror's installation onto the telescope structure.

Credits: NASA/Chris Gunn

.

“The James Webb Space Telescope will be the premier astronomical observatory of the next decade,” said John Grunsfeld, astronaut and associate administrator of the Science Mission Directorate at NASA Headquarters in Washington. “This first-mirror installation milestone symbolizes all the new and specialized technology that was developed to enable the observatory to study the first stars and galaxies, examine the formation stellar systems and planetary formation, provide answers to the evolution of our own solar system, and make the next big steps in the search for life beyond Earth on exoplanets.”

Several innovative technologies have been developed for the Webb Telescope, which is targeted for launch in 2018, and is the successor to NASA's Hubble Space Telescope. Webb will study every phase in the history of our universe, including the cosmos’ first luminous glows, the formation of solar systems capable of supporting life on planets like Earth, and the evolution of our own solar system.

The 18 separate segments unfold and adjust to shape after launch. The mirrors are made of ultra-lightweight beryllium chosen for its thermal and mechanical properties at cryogenic temperatures. Each segment also has a thin gold coating chosen for its ability to reflect infrared light. The telescope’s biggest feature is a tennis court sized five-layer sunshield that attenuates heat from the sun more than a million times.

“After a tremendous amount of work by an incredibly dedicated team across the country, it is very exciting to start the primary mirror segment installation process" said Lee Feinberg, James Webb Space Telescope optical telescope element manager at Goddard. "This starts the final assembly phase of the telescope."

The mirrors must remain precisely aligned in space in order for Webb to successfully carry out science investigations. While operating at extraordinarily cold temperatures between minus 406 and minus 343 degrees Fahrenheit, the backplane must not move more than 38 nanometers, approximately one thousandth the diameter of a human hair.

"There have many significant achievements for Webb over the past year, but the installation of the first flight mirror is special," said Bill Ochs, James Webb Space Telescope project manager. "This installation not only represents another step towards the magnificent discoveries to come from Webb, but also the culmination of many years of effort by an outstanding dedicated team of engineers and scientists."

The mirrors were built by Ball Aerospace & Technologies Corp., Boulder, Colorado. Ball is the principal subcontractor to Northrop Grumman for the optical technology and lightweight mirror system. The installation of the mirrors onto the telescope structure is performed by Harris Corporation of Rochester, New York. Harris Corporation leads integration and testing for the telescope.

.

James Webb Space Telescope mirror

The James Webb Space Telescope team successfully installed the first flight mirror onto the telescope structure at NASA's Goddard Space Flight Center in Greenbelt, Maryland.

Credits: NASA/Chris Gunn

The James Webb Space Telescope is an international project led by NASA with its partners, ESA (European Space Agency) and the Canadian Space Agency. NASA works with the international science community to explore our solar system and beyond. We look to unravel mysteries that intrigue us all as we explore to answer big questions, like how did our solar system originate and change over time, and how did the universe begin and evolve, and what will be its destiny?

Quelle: NASA

.

Update: 30.11.2015

.

NASA's Webb "Pathfinder Telescope" Successfully Completes Second Super-Cold Optical Test

Recently, the James Webb Space Telescope's "pathfinder telescope," or “Pathfinder” completed its second super-cold optical test that resulted in the first checkout of specialized optical test equipment designed to illuminate the telescope’s optics through to the instrument focal planes, and the procedures used to operate this test equipment.

.

Engineers inspect the James Webb Space Telescope's "pathfinder telescope," after its second super-cold optical test in Chamber A at NASA's Johnson Space Center.

Credits: NASA/ Chris Gunn

-

While the actual flight elements of NASA's Webb telescope are assembled, engineers are testing the non-flight equipment installed in the test chamber to ensure that tests on the real Webb telescope later go safely and according to plan.

After the first Pathfinder test was completed in June 2015, the Aft Optics System or AOS, which includes the Tertiary Mirror and Fine Steering Mirror, was installed on the Pathfinder to prepare for a second test.

The Pathfinder is a non-flight replica of the Webb telescope’s center section backplane, or “backbone,” that includes flight spare mirrors. The full Pathfinder was then outfitted with special fiber-fed infrared optical sources that simulate star images. Those star images, or infrared sources, along with a specially instrumented infrared detector were used during the second test to perform end-to-end testing of the full Pathfinder telescope system. The AOS and the source system was built by Ball Aerospace and Technologies Corp's facilities in Boulder, Colorado.

“Practice makes perfect. Since we will be testing the world’s largest ever cryogenic telescope for the first time in the world’s largest cryogenic test chamber, we need to be experienced in using our test equipment so we can focus on the performance of the telescope,” said Mark Clampin, Webb telescope Observatory Project Scientist at NASA's Goddard Space Flight Center in Greenbelt, Maryland.

The flight backplane comes in three segments, a center section and two wing-like parts, all of which will support large hexagonal mirrors on the Webb telescope. The pathfinder only consists of the center part of the backplane. However, during the test, it held two full size spare primary mirror segments and a full size spare secondary mirror to demonstrate the ability to optically test and align the telescope at the planned operating temperatures of -400 degrees Fahrenheit (-240 Celsius). The test equipment used to test the telescope primary mirror and used to hold the entire pathfinder telescope were built by Harris Corporation of Rochester, New York.

The first and second cryogenic optical testing of the Pathfinder were conducted in Chamber A at NASA's Johnson Space Center in Houston, Texas, where the testing of the flight hardware will occur in 2017. The extremely cold conditions inside the chamber are created by running liquid nitrogen and extremely cold helium gas through plumbing criss-crossing the surface of two big metal shells or “shrouds” nested inside the chamber walls.

"Now that the second test is done, it means that all optical test systems have been checked out," said Lee Feinberg, Webb telescope Optical Telescope Element Manager at NASA Goddard.

A third and final precursor test called “Thermal Pathfinder” will follow in 2016 that will fully test all the test equipment needed to simulate the temperature environment of space. Once this is complete, all test equipment and procedures needed to test the actual full flight telescope in early 2017 will be checked-out and ready.

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Quelle: NASA

4968 Views