SpaceX launched astronauts for the first time barely a week ago but CEO Elon Musk does not want the company resting on its laurels.

Instead, Musk urged SpaceX employees to accelerate progress on its next-generation Starship rocket “dramatically and immediately,” writing Saturday in a company-wide email seen by CNBC.

“Please consider the top SpaceX priority (apart from anything that could reduce Dragon return risk) to be Starship,” Musk wrote in the email.

SpaceX did not immediately respond to CNBC’s request for comment on Musk’s email.

His space company launched a pair of NASA astronauts on May 30, marking a historic first for SpaceX and a crucial step forward for the U.S. space program. A SpaceX Falcon 9 rocket and Crew Dragon capsule carried the astronauts to orbit and on to the International Space Station. That mission is ongoing, as Musk noted, with the spacecraft set to return the astronauts to Earth in the next couple months.

The Falcon 9 rocket that launched the astronauts is the mainstay of SpaceX’s business, with 85 missions over the past decade. But Starship represents the company’s aim to make obsolete even the cost-saving advances of its Falcon 9 fleet. Its Falcon 9 rockets are partially reusable, as the company often lands the large “booster” stage of the rocket and recovers the rocket’s nosecone. But Musk’s goal is to make Starship fully reusable — envisioning a rocket that is more akin to a commercial airplane, with short turnaround times between flights.

Musk last year unveiled the Starship prototype, built of stainless steel and dwarfing the company’s existing spacecraft. SpaceX is developing Starship with the goal of launching as many as 100 people at a time on missions to the moon and Mars.

So far, the company’s Starship development program in Boca Chica, Texas has suffered four dramatic setbacks. While SpaceX has made progress on each iteration, the most recent prototype exploded shortly after an engine test on May 29.

“We need to accelerate Starship progress,” Musk said in Saturday’s email.

Musk’s emphasis on Starship comes nine months after a controversial comment by NASA Administrator Jim Bridenstine, just before SpaceX unveiled the latest prototype. The NASA chief declared his agency wanted “to see the same level of enthusiasm” for SpaceX launching NASA astronauts as there was for the Starship program, saying it was “time to deliver.”

At the time, Musk said that SpaceX “resources are overwhelmingly” focused on finishing development of the Crew Dragon spacecraft. Now, with SpaceX having delivered on the first part of its commitment to fly NASA astronauts, Musk is turning the company’s attention to Starship.

SpaceX has raised nearly $1.7 billion since the beginning of 2019, with its valuation rising to around $36 billion according to CNBC sources. The company has steadily raised funding as its developed three ambitious programs: the Crew Dragon spacecraft, its Starlink internet satellites and the massive Starship rocket.

The Starship program has seen prototypes pass several critical milestones but SpaceX has yet to begin flight testing its most recent design. A previous iteration, known as Starhopper, completed a short launch and landing flight test in August.

Airlift to Texas

SpaceX continues to build up its facility in Boca Chica, an area along the Gulf of Mexico at the most southern part of the U.S. and Mexico border in Texas. Musk noted that he’s often been on site at Boca Chica recently and continues to do so. On Saturday he tweeted an aerial view of the complex, showing its growing array of production tents and rocket manufacturing bays.

In his email, Musk asked SpaceX employees to “consider spending significant time” in Boca Chica to help further accelerate Starship development. SpaceX has about 8,000 employees, most of whom are at the company’s Los Angeles area headquarters or its facilities at Cape Canaveral, Florida or near Austin, Texas. Although SpaceX has some land under lease in the Port of Los Angeles for Starship development, Musk’s email implied that the company is seeking to incentivize employees to move to Texas from California and Florida.

“For those considering moving, we will always offer a dedicated SpaceX aircraft to shuttle people,” Musk wrote.

SpaceX owns and operates at least one private jet, as the company has charged Tesla for use of the aircraft as recently as the first quarter of 2020. But the extraordinary relocation offer underlines how crucial Musk sees the Starship project. The company’s Boca Chica team is already working nearly around the clock but Musk wants more, urging SpaceX employees to help Starship development progress even more quickly.

Quelle: CNBC

----

Update: 18.06.2020

.

SpaceX’s Starship program returns to its roots with a new rocket ‘test tank’

SpaceX’s Starship rocket development program has returned to its early-2020 roots as teams work to assemble the first new ‘test tank’ built in South Texas in more than three months.

Just like its three predecessors, the newest test tank’s purpose is relatively simple: demonstrate – at full scale – the efficacy of SpaceX’s current manufacturing processes. Back when SpaceX built and tested the first two tank prototypes in January 2020, the company was in the midst of making big changes throughout its coastal Boca Chica, Texas Starship factory – a major leap forward compared to the methods used to build Starship Mk1. While the first tank made it to 7.1 bar (~103 psi) before failing, a second tank survived all the way up to 8.5 bar (~125 psi), as did a third separate test tank built about a month later. According to CEO Elon Musk, 8.5 bar is more than satisfactory for Starship pressure vessels to safely launch humans into orbit, offering a safety margin of more than 40%.

Most recently, Starship SN4 became the first full-scale prototype to replicate the results SpaceX achieved with its shorter test tanks, effortlessly reaching 7.5 bar (~110 psi) during a cryogenic pressure test completed just last month. Despite those myriad successes, however, SpaceX rarely stops moving forward and Musk has already hinted at improvements the company may be hoping to prove out with a fourth Starship test tank.

The most obvious reason to build a new test tank after the success of full-scale Starship prototype SN4 is a substantial change in the steel alloy SpaceX is building rockets out of in South Texas. CEO Elon Musk has teased such a shift for almost a full year and it appears to have happened right on time – if not ahead of schedule. SpaceX currently uses 301 stainless steel for Starship production, while the new material – discussed earlier by Musk and confirmed by inscriptions on the exterior of what would later become the fourth test tank – is a slightly different 304 steel “with higher ductility” (malleability).

It’s unclear if this is the custom-built “30X” alloy SpaceX was planning on creating, given that “304L” steel is an already-available commodity material that is slightly more durable and corrosion-resistant but less ductile and ~10% more expensive than 301. Regardless, changing to a new alloy would almost certainly benefit from real-world testing to confirm that behaves in the ways SpaceX expects it to, while also verifying that existing fabrication methods (particularly welding) still suffice.

SpaceX’s Starship rocket development program has returned to its early-2020 roots as teams work to assemble the first new ‘test tank’ built in South Texas in more than three months.

Just like its three predecessors, the newest test tank’s purpose is relatively simple: demonstrate – at full scale – the efficacy of SpaceX’s current manufacturing processes. Back when SpaceX built and tested the first two tank prototypes in January 2020, the company was in the midst of making big changes throughout its coastal Boca Chica, Texas Starship factory – a major leap forward compared to the methods used to build Starship Mk1. While the first tank made it to 7.1 bar (~103 psi) before failing, a second tank survived all the way up to 8.5 bar (~125 psi), as did a third separate test tank built about a month later. According to CEO Elon Musk, 8.5 bar is more than satisfactory for Starship pressure vessels to safely launch humans into orbit, offering a safety margin of more than 40%.

Most recently, Starship SN4 became the first full-scale prototype to replicate the results SpaceX achieved with its shorter test tanks, effortlessly reaching 7.5 bar (~110 psi) during a cryogenic pressure test completed just last month. Despite those myriad successes, however, SpaceX rarely stops moving forward and Musk has already hinted at improvements the company may be hoping to prove out with a fourth Starship test tank.

SPONSORED CONTENT

The most obvious reason to build a new test tank after the success of full-scale Starship prototype SN4 is a substantial change in the steel alloy SpaceX is building rockets out of in South Texas. CEO Elon Musk has teased such a shift for almost a full year and it appears to have happened right on time – if not ahead of schedule. SpaceX currently uses 301 stainless steel for Starship production, while the new material – discussed earlier by Musk and confirmed by inscriptions on the exterior of what would later become the fourth test tank – is a slightly different 304 steel “with higher ductility” (malleability).

It’s unclear if this is the custom-built “30X” alloy SpaceX was planning on creating, given that “304L” steel is an already-available commodity material that is slightly more durable and corrosion-resistant but less ductile and ~10% more expensive than 301. Regardless, changing to a new alloy would almost certainly benefit from real-world testing to confirm that behaves in the ways SpaceX expects it to, while also verifying that existing fabrication methods (particularly welding) still suffice.

The only other notable visual differences between Starship Test Tank #4 and its predecessors are small changes in welding. On the new tank’s dome and ring, SpaceX has removed wavy strips of metal known as a weld doublers, used to strengthen vertical welds on all previous ships and test tanks. While only realizing miniscule weight savings, the change is a visual confirmation that SpaceX is growing more confident in its weld quality, perhaps also signifying the introduction of a new kind of welding.

Last but not least, the circumferential weld joining Test Tank #4’s dome and ring (a dark horizontal line) appears to be centered on the ring, whereas the domes of previous ships and tanks have typically been attached to the upper or lower 20-30% of their respective rings. The purpose of this change is unknown.

Regardless, Test Tank #4 is currently in the midst of an hours-long cryogenic proof test and appears to be almost fully loaded with several hundred tons of liquid nitrogen. Check out the frosty tank live at the link below as we wait to see if the Starship hardware survives.

Quelle: TESLARATI

----

Update: 19.06.2020

.

SpaceX set to finish three Starship prototypes in the same month

SpaceX appears to be on track to complete its third Starship prototype in a month just days after the company finished testing a new steel tank and at the same time as it prepares to roll another full-scale ship to the launch pad.

Postponed by several weeks after the (fleeting) success of the Starship serial number 4 (SN4) prototype, violently destroyed by a minor testing mishap on May 29th, SpaceX’s fifth full-scale Starship tank section (SN5) could roll to an adjacent testing facility at any point in the next few days. In fact, SN4’s successor has likely been ready to begin tank proof and static fire testing for several weeks since it was stacked to its full height on May 12th. SN4 rolled to the launch pad on April 23rd and remained SpaceX’s top Starship priority until its demise more than a month later.

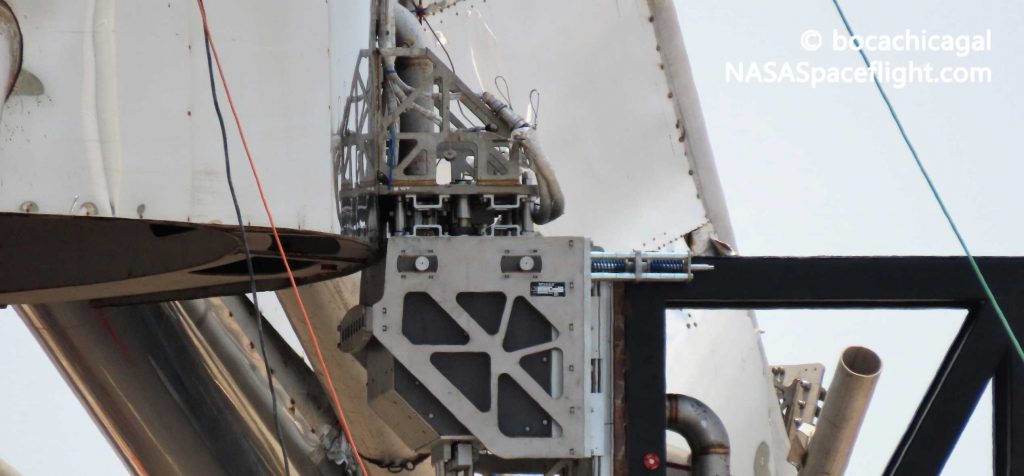

As it turns out, the explosion that destroyed the ship also launched a ~25 metric ton (~55,000 lb) counterweight installed a few days prior some 100m (300+ ft) into the air, where it proceeded to fall back to earth and obliterate the steel mount Starship SN4 sat on. The loss of that pad hardware necessitated its own several-week delay but SpaceX appears to be nearly done installing and outfitting replacements as of June 18th – an incredible turnaround given the scale and complexity of everything involved. Of course, the whole purpose of those rapid repairs is to get back to the business of testing Starships as quickly as possible.

SN5

Initially expected as early as 8am local on June 17th, Starship SN5’s trip to the launch pad has been a long time coming. Completed around May 20th after approximately a month of concerted effort, the ~30m (100 ft) tall tank departed SpaceX’s Vehicle Assembly Building (VAB) for the first on June 13th, although it was quickly moved back inside as technicians simultaneously worked to complete Starship SN6.

Previously scheduled to become the first Starship to reach its full height with the installation of a functional nosecone, SN5 will likely pick up where SN4 left off, instead. That process will effectively be no different, albeit sans nosecone, starting with ambient and cryogenic proof (pressure) tests and eventually moving to one or several static fires with either one or three Raptor engines. Testing the quick disconnect umbilical port that caused SN4’s demise will also likely be a priority. If all goes according to plan in that first week or two of tests, SpaceX may finally be ready to launch a full-scale Starship prototype for the first time, performing a 150m (~500 ft) hop test with SN5.

However, since CEO Elon Musk first discussed plans for an initial 150m hop test, SpaceX received a surprise suborbital launch license from the FAA, rather than the limited experimental permit most expected. That license effectively allows SpaceX to perform an unlimited number of Starship tests as long as the trajectory follows the administration’s strict safety guidelines and remains suborbital. Unless SpaceX’s ~150m target was based in some technical limitation, the sky is quite literally the limit for a more ambitious flight debut if the company believes Starship SN5 can handle it.

SN6

In the event that Starship SN5 follows its predecessor into a less early (but still early) grave, SpaceX thankfully won’t have to wait long at all to continue its hardware-rich test program. When Starship SN5 first departed the VAB on June 13th, it did so to give SpaceX room to finish Starship SN6, placing its aft engine section on a stand inside the building and stacking the upper two-thirds of the ship’s tank on top.

Several days to a week or more of internal and external work remain to fully mate the two Starship SN6 sections, but the vast majority of its assembly is now behind SpaceX. SpaceX continues to refine its methods with each successive prototype, gradually producing Starships that are getting closer and closer to the ideal finished product. There’s a chance that, unlike Starship SN4, SN5 can be modified with the installation of a nosecone and flaps to support more ambitious 2-20 km (~1.2-12 mi) flight tests if it makes it over the 150m hurdle unscathed but if not, SN6 could become the first Starship to have a nosecone installed.

SN7

Last but absolutely not least, SpaceX recently built a new Starship test tank for the first time since March. While stouter than an actual Starship-class methane or oxygen tank, this particular test tank is maybe only 25% shorter than the methane tanks installed on Starship prototypes. According to Musk and effectively confirmed by writing all over the prototype, this particular test tank – formerly Starship SN7 – was built to determine if a different kind of steel could be preferable for future ships.

Shortly after the June 15th test began to wind down, Musk announced that the new material (304L stainless steel) had performed quite well, reaching 7.6 bar (110 psi) before it sprung a leak. The fact alone that it sprung a leak instead of violently depressurizing is already a major sign that 304L is preferable to 301L, as it means that Starships built out of it could fail much more gracefully in the event of a leak instead of collapsing or violently exploding. A step further, SpaceX has already managed to repair the leak on SN7 and will likely test the tank again in the next few days.

Meanwhile, Musk says that a second improved 304L test tank is already on its way, after which SpaceX will likely attempt to build and test the first fully-304L Starship prototype. Further down the line, SpaceX intends to develop its own custom steel alloy, optimized specifically for Starship’s needs. The first tests of that ’30X’ alloy could begin as early as August 2020 according to a February Musk tweet.

Quelle: TESLARATI

----

Update: 25.06.2020

.

Boom! SpaceX pops huge Starship SN7 test tank on purpose in pressure test

SpaceX pushed a massive tank for its latest Starship prototype beyond its limits Tuesday (June 23) in an intentionally explosive test in South Texas.

The Starship SN7 prototype tank ruptured during a pressure test at SpaceX's Boca Chica proving grounds, the second in just over a week for the spacecraft component. But where a June 15 test resulted in a leak, Tuesday's test was a bit more dramatic.

Video cameras from the South Padre Island tourism site Spadre.com and NASASpaceflight.com watched as SpaceX filled the tank with super-chilled liquid nitrogen to test its ability to hold super-cold propellant during an actual launch. The tank eventually reached its limit and burst, spewing out billowing white nitrogen clouds.

A close up from NASASpaceflight.com on Twitter , captured by Starship watcher Mary (also know as BocaChicaGal), shows the moment the tank ruptured. The tank pops and collapses, sinking into the nitrogen plumes.

SpaceX has been performing a series of tests at Boca Chica to refine its designs for the stainless steel Starship, which the company aims to use for eventual Mars flights and moon landings. Last month, NASA picked Starship as one of three commercial moon lander designs that could land the agency's Artemis astronauts to the moon.

Some of SpaceX's Starship tests have been successful, such as a series of ground-based rocket engine tests and the brief 2019 flight of an early Starship prototype called Starhopper. Others, not so much.

On May 29, SpaceX's SN4 Starship prototype exploded shortly after completing a test of its Raptor rocket engine .

SpaceX CEO Elon Musk has said the company will learn from each Starship test to improve future designs. Last week's test of the SN7 Starship tank, which leaked but did not explode, was a promising sign, Musk said on June 15. The company is shifting from 301 stainless steel to 304L, he has said.

"Tank didn't burst, but leaked at 7.6 bar. This is a good result & supports idea of 304L stainless [steel] being better than 301," Musk tweeted wrote on Twitter, adding that the tank would eventually be used in a destructive test. "We're developing our own alloy to take this even further. Leak before burst is highly desirable."

Quelle: SC

----

Update: 26.06.2020

.

SpaceX transports fifth Starship prototype to the launch pad

SpaceX has at long last transported its fifth full-scale Starship prototype to a nearby launch pad, kicking off a week of busy pre-test preparations while the sixth rocket is already nipping at its heels.

Starship SN5’s move to the pad ends the longest gap between full-scale prototype testing since Starship Mk1 was destroyed in November 2019, a partially-expected failure that began a more than three-month period of infrastructure upgrades. The first upgraded Starship (SN1) rolled to the pad on February 25th, followed by SN3 on March 29th and SN4 on April 23rd, indicative of a fairly consistent monthly cadence of Starship production (and destruction).

Almost exactly two months after its predecessor headed from the factory to SpaceX’s Boca Chica, Texas launch facilities, Starship SN5 has taken its place on a brand new launch mount. The cause of that month-long delay is fairly simple. When Starship SN4 exploded on May 29th, it damaged the existing launch mount and some additional ground support equipment (GSE), forcing SpaceX to scrap the destroyed mount and build a new one from scratch. In a matter of weeks, SpaceX’s crack team of pad engineers and technicians have done exactly that.

While, judging from several sets of canceled road closure days, the new mount wasn’t built quite as quickly as someone high up in SpaceX would have hoped, the speed of the recovery from SN4’s destructive demise is still extremely impressive. For full-scale operations, SpaceX needs a strong metal structure capable of providing a Starship prototype the propellant, power, and communications links it needs to perform tests, as well as standing up to the weight of a full-loaded Starship (>1000 metric tons) and preventing the rocket from flying away during static Raptor engine tests. Additionally, the launch mount will eventually need to survive the fury of one and even three Raptor engines once Starships graduated to flight testing.

As of June 3rd, the replacement launch mount was partially-completed steel skeleton.

Barely two weeks later, SpaceX had flipped that skeleton, installed it on the actual launch mount table, finished all structural work, installed a conical frame to enable hydraulic ram testing to simulate Raptor engine thrust, and outfitted the mount with a wide variety of complex plumbing, wiring, and fixtures. The current design is about as simple as it can get but is still relatively complicated, with a wide range of systems that must work perfectly together throughout an equally wide range of temperatures and other stressful conditions.

Starship SN5’s installation on that replacement mount serves as a final confirmation that the new structure is more or less complete. Now SpaceX will be faced with the different challenges of christening the new launch mount and ensuring that it’s functioning as planned at the same time as Starship SN5 is attempting to do the same thing. The company also appears to have taken the previous launch mount’s demise as an opportunity to implement some minor design changes, all of which will also need to be tested and verified.

Delays are quite likely but Starship SN5 is currently scheduled to kick off its first test campaign as early as June 29th. SpaceX will likely begin with an ambient pressure test to check for leaks, followed by a cryogenic proof test with liquid nitrogen to confirm that SN5 performs as expected while subjected to the ultra-cold temperatures its liquid methane and oxygen propellant will be kept at. SN5 would then move into wet dress rehearsals (WDR) with live propellant and one or several static fires with a single Raptor engine. Finally, if that complex series of tests goes a little bit better than it did with SN4, Starship SN5 will become the first full-scale prototype to attempt controlled flight, hopping to at least 150m (~500 ft).

Quelle: TESLARATI

----

Update: 30.06.2020

.

SpaceX Starship event expected this September, says Elon Musk

SpaceX CEO Elon Musk has implied that he will continue the tradition of annual Starship update events later this year, likely presenting on the progress the company has made over the last 12 months at its South Texas rocket factory.

Beginning in Guadalajara, Mexico at the September 2016 International Astronautical Congress (IAC), Musk has presented a detailed annual update on the status of SpaceX’s next-generation Starship launch vehicle in September or October for the last four years. Formerly known as the Interplanetary Transport System (ITS) and Big Falcon Rocket (BFR), Starship is effectively a continuation of the unprecedented progress SpaceX has made with Falcon 9 and Heavy reusability.

SpaceX has managed to reliably reuse Falcon boosters 5+ times and is on the way to replicating that with payload fairings, but Musk has concluded that the Falcon family – despite being some of the largest operational rockets in existence – is just too small to feasibly recover and reuse the orbital second stage. With Starship, SpaceX wants to take a slightly different approach.

A senior SpaceX engineer and executive believes that Starship’s first orbital launch could still happen by the end of 2020.(SpaceX)

While also a two-stage rocket, Starship will have a magnitude more thrust than Falcon 9 and twice the thrust of Saturn V, the largest liquid rocket ever successfully launched. More importantly, both Starship stages are designed to be easily and rapidly reusable, while also entirely getting rid of deployable payload fairings. In theory, once fully optimized, Starship and the Super Heavy booster should be capable of placing 150 metric tons (~330,000 lb) of payload into low Earth orbit (LEO) in a single launch.

Of course, that is going to be an immense challenge – arguably the single most ambitious project in the history of commercial spaceflight – and SpaceX has quite a ways to go before it can even come close. Aside from the huge publicity and excitement it generates, offering detailed explanations of how exactly SpaceX is progressing towards those goals and how Starship’s design is evolving is likely the primary reason Musk has chosen to continue doing annual presentations.