.

12.06.2016

SLS Booster 'Chills Out' Ahead of Super-Hot Ground Test

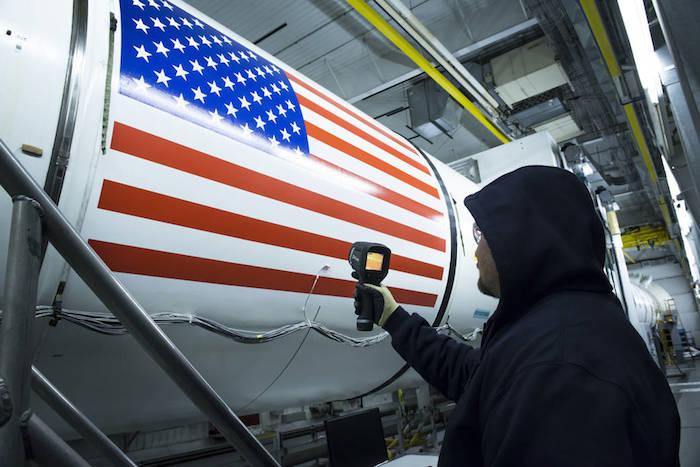

An Orbital ATK technician inspects hardware and instrumentation on a full-scale, test version booster for NASA's new rocket, the Space Launch System. The booster is being cooled to approximately 40 degrees Fahrenheit ahead of its second qualification ground test June 28 at Orbital ATK's test facilities in Promontory, Utah. Testing at the thermal extremes experienced by the booster on the launch pad is important to understanding the effects of temperature on the performance of how the propellant burns.

.

The Old Farmer's Almanac is predicting a hotter-than-normal summer for Utah, but at Orbital ATK's test facility in Promontory, crews are bundling up to chill down the booster for the world's most powerful rocket, NASA's Space Launch System.

The booster is being cooled to approximately 40 degrees Fahrenheit ahead of its second qualification ground test June 28. Testing at the thermal extremes experienced by the booster on the launch pad is important to understanding the effects of temperature on the performance of how the propellant burns. Data and analysis from past human-rated space programs have set the temperature limits for boosters between 40 and 90 degrees Fahrenheit. The booster was heated to 90 degrees Fahrenheit for the first successful booster qualification test in March 2015.

"In the winter or summer, you expect your car to start – regardless of what the temperature is outside," said Mat Bevill, deputy chief engineer in the SLS Boosters Office at NASA's Marshall Space Flight Center in Huntsville, Alabama, where the SLS program is managed for the agency. "That car had to be tested to ensure it performed as it was designed to do, even in wide temperature ranges. That's pretty much what we're doing -- except with a huge rocket booster."

The massive size of the booster means it will take more than a month to reach the cold temperature target for the booster inside the test stand. Three large air-conditioning units – similar to those used for outdoor ice skating rinks – have been placed around the test facility, and are continually pumping air at 25 degrees Fahrenheit into the test stand house surrounding the booster. Sensors inside and outside the booster measure the propellant temperature, and analytical models predict the time it takes for the booster to be conditioned to 40 degrees.

"Propellant temperature shouldn't be mistaken for the temperature of the booster when it's fired," Bevill added. "It may be conditioned to 40 degrees Fahrenheit, but once it fires, it is extremely hot – about 6,000 degrees Fahrenheit. That's hot enough to boil steel."

The day of the static fire, the test stand house will be rolled out of the way. "Cold conditioning in the summer isn't exactly optimal, but that's just one of the challenges with staying on schedule. We have to keep marching forward to be ready for flight," Bevill said. "But just like it takes a long time to cool the booster, it also takes a long time for it to warm back up. Testing early in the morning before it gets too hot helps, and we chill to a few degrees cooler than the target of 40 degrees to account for the summer heat on test day."

The two-minute, full-duration firing of the 177-foot booster will be the last full-scale test to support qualification of the hardware for the first two flights of SLS. Some 82 design objectives will be measured through more than 530 instrumentation channels on the booster. Along with measuring the ballistic performance at the lower end of the booster’s accepted propellant temperature range, the test also integrates SLS flight-like command and control for motor ignition and nozzle steering.

After this test, the next time a SLS booster will be fired up will be on the launch pad at NASA’s Kennedy Space Center in Florida. Two five-segment solid rocket boosters, along with four RS-25 engines, will propel SLS with the Orion spacecraft on its first mission in 2018.

"We’re working with Orbital ATK as they get ready to fire this booster in June," said Bruce Tiller, deputy manager of the SLS Boosters Office at Marshall. "In conjunction with testing, booster flight hardware is currently in production. NASA is preparing for the first flight of SLS, and each of these programmatic milestones provide crucial data to enable human missions to deep-space destinations, including Mars."

While the boosters for the space shuttle had four booster segments, the SLS boosters will have five segments. The added booster segment for SLS contains more solid propellant that allows SLS to lift more weight and reach a higher altitude before the boosters separate from the core stage within the first two minutes of flight. The core stage, towering more than 200 feet tall with a diameter of 27.6 feet, will store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines.

The initial SLS configuration will have a minimum 70-metric-ton (77-ton) lift capability. The next planned upgrade of SLS will use a powerful exploration upper stage for more ambitious missions with a 105-metric-ton (115-ton) lift capacity. A later configuration will replace the five-segment solid rocket boosters with a pair of advanced solid or liquid propellant boosters to provide a 130-metric-ton (143-ton) lift capacity. In each configuration, SLS will continue to use the same core stage and four RS-25 engines.

.

An Orbital ATK technician checks the temperature of a full-scale, test version booster for NASA's new rocket, the Space Launch System. It will take more than a month to reach the booster's cold temperature target of 40 degrees Fahrenheit inside the test facility. Sensors inside and outside the booster measure the propellant temperature, and analytical models also predict the time it takes for the booster to be conditioned to 40 degrees.

Quelle: NASA

-

Update: 13.06.2016

.

NASA Completes Test Version of SLS Launch Vehicle Stage Adapter

A crane lifts the structural test article of the launch vehicle stage adapter (LVSA) after final manufacturing on a 30-foot welding tool at NASA’s Marshall Space Flight Center in Huntsville, Alabama. The LVSA will connect two major sections of the upper part of NASA's Space Launch System -- the core stage and the interim cryogenic propulsion stage (ICPS) -- for the first flight of the rocket and the Orion spacecraft. SLS will be the world's most powerful rocket and carry astronauts in NASA's Orion spacecraft on deep-space missions, including the journey to Mars.

Later this year at Marshall, the test version of the LVSA will be stacked with other structural test articles of the upper part of SLS. Engineers will examine test data and compare it to computer models to verify the integrity of the hardware and ensure it can withstand the forces it will experience during flight. The hardware's cone shape is due to the ICPS having a smaller diameter than the rocket's core stage. Teledyne Brown Engineering of Huntsville is the prime contractor for the LVSA.

Quelle: NASA

.

Update: 15.06.2016

.

Orion test capsule gets another splash-test at NASA Langley

A test version of the Orion spacecraft designed to carry astronauts to Mars and other deep-space missions underwent another splash-test at NASA Langley Research Center.

According to NASA, the test at the Hydro Impact Basin in Hampton last Tuesday was intended to better understand how an ocean landing after a mission could affect crew members and equipment.

Two crash-test dummies simulating male and female astronauts were packed with sensors, dressed in modified escape suits and strapped inside the capsule.

The craft is undergoing a series of nine water-impact tests this year. The first was conducted in April. Last week's test was the fifth, and the first swing-drop; the others were vertical drops.

Each test is intended to mimic a different scenario and variety of conditions, including parachute-assisted landings, wind, velocity and wave height, NASA said.

The Orion and the SLS heavy-lift rocket — the most powerful booster in the world — are being developed to carry astronauts farther than they've ever gone before.

The spacecraft completed its first unmanned test flight aboard a Delta IV heavy-lift rocket to Earth's orbit in December 2014.

Another unmanned flight is scheduled for 2018, when Orion will launch aboard an SLS for the first time, travel more than 40,000 miles to lap around the moon and return at speeds of up to 25,000 mph.

Lockheed Martin is NASA's prime contractor for building the Orion.

-

Quelle: Daily Press, NASA-Video-Frams

-

Update: 16.06.2016

.

'Spot Orion' Photos Take Off as Spacecraft Barrels Down Texas Interstate

Orion's on the move (but not through space).

-

Nasa’s Orion spacecraft is having a big week. On Tuesday, NASA took its flagship space module for a swim, and today, Twitter is buzzing with news of an all-American road trip.

Fans of humankind’s best chance at a manned mission to Mars flocked to the #SpotOrion hashtag on Twitter early Wednesday morning, following the capsule’s trip from its base at Johnson Space Center in Clear Lake, Texas to the George R. Brown Convention Center in downtown Houston. Parked happily on the back of a big rig truck, Orion chugged about 25 miles north on Interstate 45, puzzling commuters, while a NASA follow vehicle documented the whole thing on social media. Sure, we didn’t get any pure moments of childlike glee like the extremely southern narrator watching SpaceX’s Falcon 9 rocket pass by near the Kennedy Space Center back in April, but the Orion caravan got some people pretty excited all the same. Turns out even in Houston a 30-foot wide spacecraft on a semi truck isn’t an everyday occurrence.

The best angles were reserved for insiders, though — the craft’s own Twitter account snapped the most epic shot on the hashtag, featuring the capsule straddling several lanes with downtown Houston’s skyline in the background.

.

For a sense of scale, here’s Orion in the middle of a normal SUV and a sedan. According to Google Maps, the whole trip is supposed to take about 35 minutes, but we’re willing to bet a 22,000-pound spacecraft wasn’t exactly speeding (on land at least).

.

The craft easily cleared bridges, but on camera it looks like it was a close call.

.

NASA wants to show off what they’ve been doing to further interplanetary travel, and on the heels of releasing three awesome new high-res Mission to Mars posters, they’re displaying the capsule mockup at this weekend’s Comicpalooza in Houston.

.

Orion’s now parked inside the convention center, where fans will have an opportunity to see the craft up close and take pictures (when it’s not on the back of a moving truck).It’s worth noting that this isn’t the final Orion capsule, but the PORT Mockup used by NASA as a training tool to prepare astronauts on methods for quickly exiting the vehicle after a water landing. Still, it looks cool all the same — here’s NASA astronaut Mike Fincke narrating a water landing training exercise.

Quelle: INVERSE

-

Update: 19.06.2016

.

Europe’s Orion service module shipment to U.S. delayed by three months

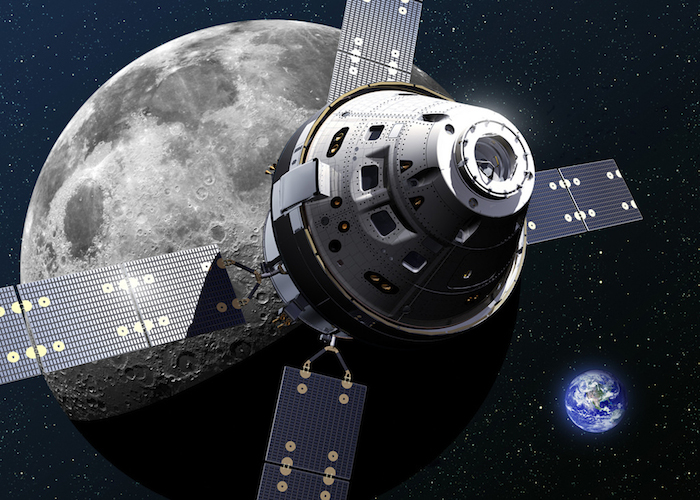

The European-built service module for NASA's Orion crew-transport vehicle will be three months late in shipping to the United States for test and integration by Orion prime contractor Lockheed Martin following a June 16 critical design review. Shipment has been rescheduled for April. Credit: Airbus

PARIS—The European-built service module for NASA’s Orion crew-transport vehicle will be three months late in being shipped to the United States following modifications to the design recommended by a June 16 program review, a senior European Space Agency official said June 17.

The new shipment date has been tentatively set for late April, rather than late January. ESA, NASA and the two main industrial teams – Airbus Defence and Space for the service module and Lockheed Martin Space Systems, which is prime contractor for Orion — met June 16 at ESA’s Estec facility in Noordwijk, Netherlands, to conclude a service module critical design review.

Nico Dettman, head of ESA’s space transportation department, said the delay is partly a result of the fact that several components could not yet be assessed in the full critical design review and need more time to be integrated into the design.

Dettman said another issue forcing the delay resulted from a reassessment by NASA of the stresses the service module needs to be capable of handling in orbit. These “in-orbit load” specifications have recently been tightened. But any design modifications will not affect the service module’s core structure, he said.

“If it has an impact, it will be limited to the solar array wings, not the structure – nothing where flight hardware has been manufactured that we will have to touch,” Dettman said. “It’s a late modification, but not too late.”

“They are not nice, but it is quite normal and they happen all the time,” Dettman said of the fresh set of requirements, often referred to as customer change notices. “I am quite sure there will be some changes after the EM-1 flight. We obviously would prefer that there be a stable configuration but because of the complexity, the configuration changes to improve quality and reliability of the system.”

The Orion capsule and service module are scheduled to make their flrst flight, an unmanned mission called EM-1, on NASA’s new Space Launch System heavy-lift rocket, with a launch window of between September and November 2018.

ESA, NASA and Lockheed Martin officials had said in a May 19 briefing on the start of service module assembly that the program was so pressed for time that integration would begin even before the critical design review, on the assumption that no major issues would be found that would force a redesign.

Dettman said the early assessment is that a final “close-out” design review now set for late October to address the latest issues would allow for an April shipment to Lockheed Martin and would not, in and of itself, delay the EM-1 schedule.

Many elements of the SLS rocket are now undergoing testing of their own and there remain risks to the schedule from the launcher side as well as the Orion system.

In response to SpaceNews inquiries, service module prime contractor Airbus on June 17 said it would withhold comment on the new schedule until ESA’s Program Board for Human Spaceflight and Robotic Exploration meets to review the critical design review findings and issue a final report and recommendation.

ESA officials have said they structured the Airbus service module contract in such a way as to include margins for delays. Dettman said that because of the contract’s terms, the three-months shipment delay will have no impact on ESA’s service module program cost.

Quelle: SN

-

Update: 26.06.2016

.

A test version of the booster for NASA's new rocket, the Space Launch System, will fire up for the second of two qualification ground tests at 10:05 a.m. EDT (8:05 a.m. MDT) Tuesday, June 28 at prime contractor Orbital ATK's test facility in Promontory, Utah. NASA Television will air live coverage of the booster test June 28 beginning at 9:30 a.m.

The test will provide NASA with critical data to support booster qualification for flight. When completed, two five-segment boosters and four RS-25 main engines will power the world's most powerful rocket, with the Orion spacecraft atop, to achieve human exploration to deep-space destinations, including our journey to Mars.

Image Credit: Orbital ATK

--

NASA to Discuss, Broadcast Booster Test for Space Launch System Rocket

The booster for the world's most powerful rocket, NASA's Space Launch System (SLS), which will power the agency’s astronauts on the journey to Mars, will fire up for a major ground test at 10:05 a.m. EDT (8:05 a.m. MDT) Tuesday, June 28, at Orbital ATK Propulsion Systems’ test facilities in Promontory, Utah.

This is the last time the booster will be fired in a test environment before the first test flight of SLS with NASA's Orion spacecraft, known as Exploration Mission-1 (EM-1), in late 2018.

NASA Television will air a NASA Social event that provides the latest updates and background on SLS and Exploration Mission-1 at 3:30 p.m. Monday, June 27, and will air live coverage of the booster test June 28 beginning at 9:30 a.m.

Following the test, NASA will hold a media teleconference at 11 a.m. to discuss initial assessment of the booster firing. The teleconference participants will be:

Bill Gerstenmaier, associate administrator for Human Exploration and Operations at NASA Headquarters in Washington

Charlie Precourt, vice president and general manager of Orbital ATK's Propulsion Systems Division in Promontory, Utah

Alex Priskos, manager of the NASA SLS Boosters Office at Marshall Space Flight Center in Huntsville, Alabama

To participate in the media teleconference, reporters must contact NASA public affairs officer Cheryl Warner at 202-358-1100, or cheryl.m.warner@nasa.gov and provide their media affiliation no later than 2 p.m. June 27.

This is the second two-minute, full-duration qualification ground test for the booster. It will provide NASA with critical data to support booster qualification for flight and test the motor at the colder end of its accepted propellant temperature range -- a targeted 40 degrees Fahrenheit.

The first, full-scale booster qualification test was successfully completed in March 2015 and demonstrated acceptable performance of the booster design at 90 degrees Fahrenheit -- the highest end of the booster’s accepted propellant temperature range. Testing at the thermal extremes experienced by the booster on the launch pad is important to understanding the effects of temperature on the ballistic performance of the propellant.

Quelle: NASA

-

Update: 27.06.2016

.

Orion’s Service Module Completes Critical Design Review

A test version of the Orion service module as been undergoing acoustic and vibration testing at NASA Glenn’s Plum Brook Station in Sandusky, Ohio.

-

NASA and ESA (European Space Agency) conducted a critical design review (CDR) culminating in a final review board June 16 for Orion’s European-built service module. The service module is an essential part of the spacecraft that will power, propel, and cool Orion in deep space as well as provide air and water for crew members. The CDR rounds out the latest in a series of reviews for the three human exploration systems development programs that will enable the journey to Mars.

During the review process, technical experts examined the module designs and numerous items were processed and closed out, giving engineers confidence the module design is mature enough to continue with fabrication, assembly, integration and testing.

The recently completed review focused on the overall service module design while discussing differences between Orion’s first deep space mission atop the Space Launch System (SLS) rocket and the mission to follow that will carry crew. No new major issues were identified during the review, and the teams worked together to develop a plan for work going forward in areas such as power, solar array management and propellant usage.

“The teams at NASA and ESA worked together successfully over the past few weeks to bring design decisions and required products to the CDR board,” said William Gerstenmaier, associate administrator for NASA’s Human Exploration and Operations Mission Directorate. “International collaboration is an important part of the effort NASA is leading to pioneer deep space.”

The review was conducted at ESA’s European Space Research and Technology Centre in Noordwijk, Netherlands with teams from NASA, ESA, Lockheed Martin and Airbus Defence & Space in Bremen, Germany. Lockheed Martin is NASA’s main contractor building Orion, and Airbus is ESA’s contractor for the service module.

“This was a tremendous effort on the part of the team from both sides of the Atlantic,” said James Free, deputy associate administrator for NASA’s Human Exploration and Operations Mission Directorate, who participated in much of the CDR. “Anytime you do something for the first time you can run into challenges, but we have been working side-by-side with ESA and Airbus to make Orion integration go as smoothly and efficiently as possible.”

The CDR identified April 2017 as the target for the service module delivery to Kennedy Space Center in Florida. Teams will begin integrating hardware into the rocket before the service module is delivered, and NASA plans to continue to optimize processing when it arrives at Kennedy. Initial results maintain EM-1 launch date no later than November 2018.

“There is some design maturation work that will occur while the module is being manufactured,” added Free. “We will also continue to evaluate updates to the shipping plans for the service module to prioritize work and refine schedules, and we will identify the best options to integrate our overall schedule.”

Results of the service module’s review will be briefed to senior NASA and ESA officials in the coming weeks.

This milestone is the latest in a series of accomplishments critical for the agency’s deep space missions. NASA’s SLS was its first human-rated rocket in almost 40 years to complete and clear a CDR, which wrapped in October 2015. The world’s only human-rated deep space vehicle, Orion, and the Ground Systems Development and Operations Program that will provide the facilities and ground support at Kennedy to prepare SLS and Orion for the journey to Mars, completed a joint CDR in March 2016.

Quelle: NASA

-

Update: 28.06.2016 / 13.55 MESZ

.

Watch a test of the world's largest solid rocket booster tomorrow on NASA TV

-

Tomorrow morning, NASA and Orbital ATK are test-firing the world's largest solid rocket booster in northern Utah.

It will be the second and final qualification test of the 54-meter, five-segment booster design that will be used on the Space Launch System, NASA's new heavy lift rocket scheduled to debut in late 2018. Four-segment versions of the booster were used to help power space shuttles into orbit for three decades.

The test will take place near Orbital ATK's Promontory, Utah facilities. The Planetary Society (me!) will be on hand to tour Orbital ATK's facilities, get an up-close look at the booster and watch the two-minute test burn from a viewing site about two kilometers away.

NASA TV

QM-2 booster test: Watch live

The test firing of Qualification Motor 2 (QM-2) is scheduled for Tuesday, June 28 at 8:05 a.m. local Utah time (10:05 a.m. EDT, 14:05 UTC). NASA TV coverage starts at 9:30 a.m.

.

Qualification Motor 2

NASA and Orbital ATK plan to test-fire the QM-2 solid rocket booster on Tuesday, June 28.

Qualification tests help certify that the Space Launch System's upgraded boosters are ready for flight. The rocket is laid on its side and held in place against a massive concrete block near the side of a sagebrush-dotted hillside. A movable, climate-controlled test stand housing covers the booster, and will be rolled away before ignition.

NASA says there are 82 design objectives for Tuesday's test, and more than 530 instrumentation channels will collect data. The booster's flight computer will also command the rear nozzle to swivel around during the burn, simulating the way the booster helps steer SLS during ascent.

A single SLS solid rocket booster burns through 6 tons of its solid-grain, polybutadiene acrylonitrile propellant—more commonly referred to as PBAN—every second. The booster's five propellant segments are doughnut-shaped and cast in different patterns that vary the amount of fuel burning at any given time. Since a solid rocket booster cannot throttle like a conventional liquid engine, changes in the burn rate serve as a throttle control mechanism.

The ignition sequence begins when a pyrotechnic device called an initiator starts a chain reaction down the center column of the booster, igniting the propellant. Once lit, a solid rocket booster burns until its fuel supply is depleted. Tuesday's test will last the same two-minute duration of a standard SLS flight.

.

Boosters 101

Cool booster, hot fire

Like the space shuttle, the Space Launch System must launch in a variety of weather conditions on the Florida coast. Based on lessons learned from the shuttle program, SLS boosters are rated to operate at internal temperatures between 40 and 90 degrees Fahrenheit.

Because it takes a long time for outdoor temperature changes to affect the propellant itself, that 40-to-90-degree spread doesn't necessarily match the allowable temperature range on launch day.

During qualification testing, engineers test-fire the booster at both ends of the temperature range. The lower the propellant temperature, the slower the burn rate.

Last year, in March 2015, NASA heated the booster to 90 degrees. For Tuesday's test, they're cooling it to 40 degrees. Right now, three giant air conditioning units—the same kind used to cool ice rinks—are keeping the booster's test stand housing temperature at a frigid 25 degrees. NASA says it took more than a month to get the booster down to 40 degrees, and tomororw, when the stand is rolled back from the booster, the propellant temperature will slowly begin to rise. That's why the test is scheduled for early morning—midday highs tomorrow may be close to 100 degrees.

Once the booster ignites, the propellant won't stay cold for long. Exhaust temperatures hit about 6,000 degrees. That's almost as hot as the top layer of the sun's photosphere (6,700 degrees), and easily hot enough to melt most metals. The booster's casing used to be lined with asbestos for heat protection; after the retirement of the shuttle, the insulation was re-engineered to be asbestos-free.

.

QM-1 fire and smoke (2015)

A Space Launch System solid rocket booster completes a test firing in Promontory, Utah on March 11, 2015.

We'll be posting pictures and videos from Promontory here at planetary.org, and you can also follow me on Twitter for more updates.

Want more booster backgrounders? You can read last year's articles on the QM-1 test. Here's a preview article featuring an interview with an SLS engineer (I hope to make it over to Promontory Point to see the real golden spike while I'm here), along with some pretty pictures by Bill Dunford.

Quelle: The Planetary Society

-

Update: 18.15 MESZ

-

NASA's Space Launch System Booster Passes Major Milestone on Journey to Mars

-

The second and final qualification motor (QM-2) test for the Space Launch System’s booster is seen, Tuesday, June 28, 2016, at Orbital ATK Propulsion System's (SLS) test facilities in Promontory, Utah. During the SLS flight the boosters will provide more than 75 percent of the thrust needed to escape the gravitational pull of the Earth, the first step on NASA’s Journey to Mars.

Credits: NASA/Bill Ingalls

-

A booster for the most powerful rocket in the world, NASA’s Space Launch System (SLS), successfully fired up Tuesday for its second qualification ground test at Orbital ATK's test facilities in Promontory, Utah. This was the last full-scale test for the booster before SLS’s first uncrewed test flight with NASA’s Orion spacecraft in late 2018, a key milestone on the agency’s Journey to Mars.

“This final qualification test of the booster system shows real progress in the development of the Space Launch System,” said William Gerstenmaier, associate administrator for the Human Exploration and Operations Mission Directorate at NASA Headquarters in Washington. “Seeing this test today, and experiencing the sound and feel of approximately 3.6 million pounds of thrust, helps us appreciate the progress we’re making to advance human exploration and open new frontiers for science and technology missions in deep space.”

The booster was tested at a cold motor conditioning target of 40 degrees Fahrenheit –the colder end of its accepted propellant temperature range. When ignited, temperatures inside the booster reached nearly 6,000 degrees. The two-minute, full-duration ground qualification test provided NASA with critical data on 82 qualification objectives that will support certification of the booster for flight. Engineers now will evaluate these data, captured by more than 530 instrumentation channels on the booster.

When completed, two five-segment boosters and four RS-25 main engines will power SLS on deep space missions. The solid rocket boosters, built by NASA contractor Orbital ATK, operate in parallel with SLS’s main engines for the first two minutes of flight. They will provide more than 75 percent of the thrust needed for the rocket and Orion spacecraft to escape Earth’s gravitational pull.

"Today's test is the pinnacle of years of hard work by the NASA team, Orbital ATK and commercial partners across the country," said John Honeycutt, SLS Program manager at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “SLS hardware is currently in production for every part of the rocket. NASA also is making progress every day on Orion and the ground systems to support a launch from Kennedy Space Center in Florida. We're on track to launch SLS on its first flight test with Orion and pave the way for a human presence in deep space."

The first full-scale booster qualification ground test was successfully completed in March 2015 and demonstrated acceptable performance of the booster design at 90 degrees Fahrenheit – the highest end of the booster’s accepted propellant temperature range. Testing at the thermal extremes experienced by the booster on the launch pad is important to understand the effect of temperature on how the propellant burns.

The initial SLS configuration will have a minimum 70-metric-ton (77-ton) lift capability. The next planned upgrade of SLS will use a powerful exploration upper stage for more ambitious missions, with a 105-metric-ton (115-ton) lift capacity. In each configuration, SLS will continue to use the same core stage and four RS-25 engines.

Quelle: NASA

-

Update: 11.07.2016

.

A Peek Inside SLS: Fuel Tank For World’s Largest Rocket Nears Completion

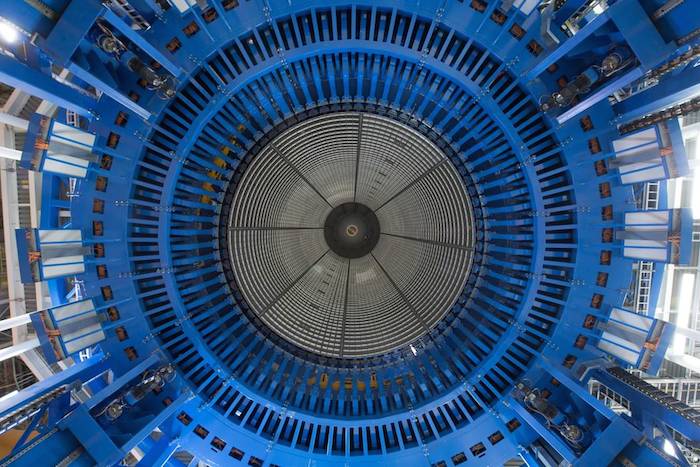

While this may look like a futuristic tunnel to another world, it is really looking up inside a nearly complete fuel tank for NASA’s powerful, new rocket—the Space Launch System—that will take humans to destinations never explored by people before. At over 300-feet tall and 5.75 million pounds at liftoff, SLS needs plenty of fuel to leave Earth. Once a final dome is added to the liquid hydrogen rocket fuel tank, shown here, it will come in at 27.5-feet in diameter and over 130-feet long, making it the largest major part of the SLS core stage. The core stage forms the rocket’s backbone and has five major parts, all of which are being manufactured at NASA’s Michoud Assembly Facility in New Orleans. Core stage tanks carry all the cryogenic liquid hydrogen and liquid oxygen combusted in four RS-25 engines to produce two million pounds of thrust. The tank holds 537,000 gallons of chilled liquid hydrogen that is completely combusted in the engines in the short 8.5 minutes it takes to send the SLS and Orion crew vehicle into orbit. The blue section, shown here, is part of the world’s largest robotic weld tool in the Vehicle Assembly Center at Michoud. Inside the tool, five barrels and one dome were welded to make the tank, shown here in silver; engineers will cap it with one more dome to complete tank welding. While the tank is smooth on the outside, the inside appears to have ridges because the cylindrical barrels that form the tank are manufactured with square patterns created by stiffening ribs machined into them to make the walls light but uniformly strong in every direction. When it is finished, a barge will carry this tank to NASA’s Marshall Space Flight Center in Huntsville, Alabama. While this qualification tank won’t actually fly, it will be tested at Marshall in a stand that simulates launch and ascent forces. Traveling to deep space requires a large vehicle that can carry huge payloads, and SLS will have the power and payload capacity needed to carry crew and cargo needed for exploration missions to deep space, including Mars. For the first flight of the SLS rocket, the Block I configuration can lift 70-metric-tons (77 tons). The next planned upgrade of SLS, known as Block 1B, will use a more powerful exploration upper stage for more ambitious missions with a 105-metric-ton (115-ton) lift capacity. For both configurations, SLS will use the same core stage and four RS-25 engines. The Boeing Co., headquartered in Chicago, is the prime contractor for the SLS core stage, including avionics, and Aerojet Rocketdyne of Sacramento, California, is the prime contractor for the RS-25 engines.

Quelle: NASA

-

Update: 21.07.2016

.

NASA to Begin Testing Next Generation of Spacecraft Heat Exchangers

NASA’s deep space Orion spacecraft requires tight control of thermal temperatures to protect crew and equipment.

Credits: Lockheed Martin

.

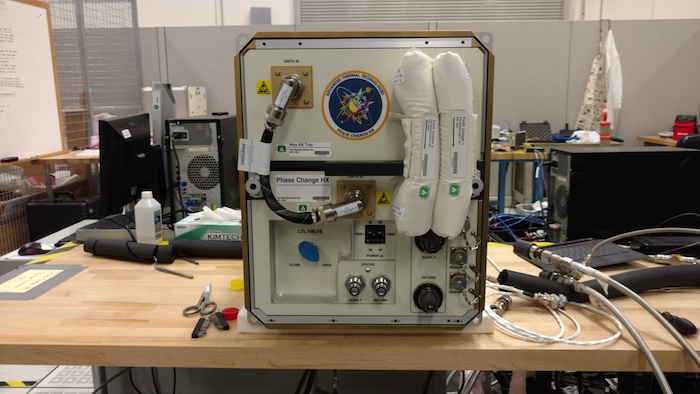

Phase Change Heat Exchanger Demonstration Facility for use on the International Space Station will test use of wax to control temperatures for possible use on the Orion spacecraft.

Credits: NASA/Rubik Sheth

.

Crew members aboard the International Space Station (ISS) are receiving a unique hardware delivery today that can help shape NASA’s human journey beyond Earth and into deep space.

The Phase Change Material Heat Exchanger (PCM HX) Demonstration Facility hitched a ride to the space station on SpaceX’s Dragon cargo craft, which launched July 18 on a Falcon 9 rocket from Cape Canaveral Air Force Station in Florida. Dragon arrived at station in the early hours of July 20, and crew will soon begin unloading the spacecraft of the nearly 5,000 pounds of science, research and hardware for the orbiting laboratory.

This hardware is one of NASA’s Game Changing Development program’s efforts that will advance space technologies and may lead to entirely new approaches for the agency’s future missions and solutions to significant national needs. Even more novel is that this high-tech gear is stuffed with wax that has a crayon-like texture.

Thermal challenge

The use of wax dates as far back as 221-206 B.C., but it may not come to mind as ideal for 21st century space travel, but that’s the case, explains Rubik Sheth, project manager and systems engineer in the Thermal Systems Branch at NASA’s Johnson Space Center in Houston.

One future destination for NASA’s Orion spacecraft is supporting a crew in cislunar space. “It gets really hot when the spacecraft is between the sun and the moon,” Sheth says, so sending humans to deep space around the moon is a thermal challenge. “We need these phase change material heat exchangers to absorb the excess waste energy that Orion will take in,” he explains.

Sheth notes that heat exchangers freeze or thaw a material to sustain critical temperatures inside a spacecraft, thus protecting crew members and equipment.

That material of choice to be showcased on the phase change material heat exchanger aboard the ISS is N-pentadecane. “It’s pretty much like crayon wax in its consistency and the way it feels,” Sheth says.

How it works

The phase changer material heat exchanger -- PCM HX for short -- stores energy by thawing a phase change material, in this case wax, using hot coolant. That energy is later rejected by the spacecraft’s radiator, then refreezes the wax and prepares it for the next spike of heat load. This new type of heat exchanger could help offset heat experienced by Orion and better regulate temperatures, says Sheth. “That’s why we’re flying it to the space station to see how it works in microgravity, and then take the next step in implementing the concept.” Wax and wane of idea Using wax in a PCM HX was tried out in trial and error fashion on NASA’s Skylab experimental space station that housed crews in 1973-1974. Similarly, wax was utilized earlier as a passive means of cooling instrumentation on lunar rovers used in the Apollo moon-landing project. However, results were inconsistent, Sheth points out.

“We took a total re-look,” Sheth says. Working with United Technologies Aerospace Systems of Windsor Locks, Connecticut, the wax-based PCM HX was built for flight demonstration. The test facility for ISS uses a thermal control system with built-in heaters and thermoelectric devices that aids in the freezing and thawing cycles of the PCM HX.

A removable kitchen drawer-like section of the PCM HX facility is loaded with about 10 pounds (4.5 kilograms) of wax. “The wax itself can hold 200 kilojoules of energy per kilogram. So for every kilogram of wax I can stuff 200 kilojoules of energy in there.” Sheth says.

That is the equivalent of about eight hours of energy to light a compact fluorescent light bulb.

A PCM HX using wax, as contrasted to using gallons and gallons of water, equates to a potential mass savings for Orion spacecraft builders.

Back on Earth

Aboard the ISS, the equipment can operate day and night. But it’s a power-hungry unit when working to lower temperatures down to between 10 and 30 degrees Celsius. That means having to share power with other station payloads; choreography is needed to distribute electricity between experiments.

“We want to run through December of this year,” Sheth says.

By year’s end, the wax is to be removed from the facility and then returned to Earth. The actual demonstration facility will remain onboard the ISS, ready for other experiments that require coolant temperatures below -10 degrees Celsius, Sheth points out.

Once back in NASA hands, the wax will be visually inspected for any deformities and then cut it in half. “We want to see how the wax maintained the internal geometry of the heat exchanger unit itself,” Sheth says. That appraisal could make a future wax-based PCM HX even more efficient.

Sheth says the goal is to give the Orion spacecraft team a report for Orion's Exploration Mission 2, or EM-2, subsystem critical design review process for the phase change material to be chosen for EM-2, slated to be the first crewed mission on NASA’s Space Launch System rocket.

The ISS PCM HX Demonstration Facility endeavor took some two years of time to develop.

“It has been rewarding in so many ways,” Sheth says. “From engineering the facility, getting it approved for the ISS, and sending the hardware up to station on Dragon, it is incredible what we have accomplished.”

.

Phase Change Heat Exchanger Demonstration Facility for use on the International Space Station will test use of wax to control temperatures for possible use on the Orion spacecraft.

Credits: NASA/Rubik Sheth

.

A removable kitchen drawer-like section of the Phase Change Heat Exchanger Demonstration Facility carries some 10-pounds (4.5 kilograms) of wax.

Credits: NASA/Rubik Sheth

Quelle: NASA

6115 Views