.

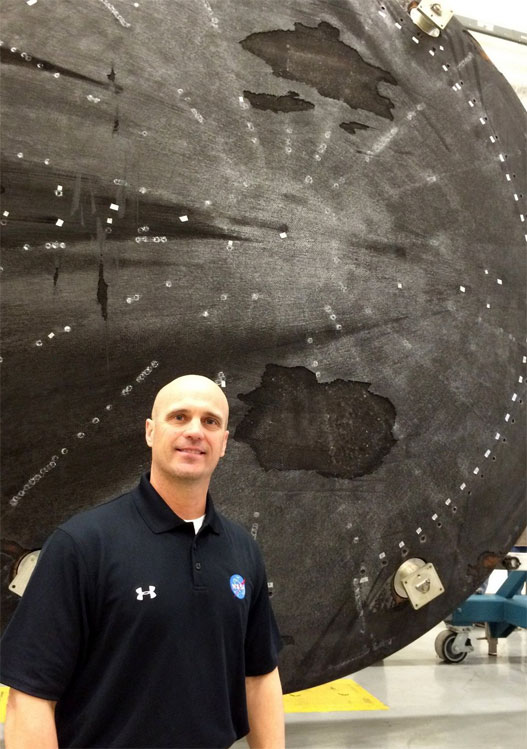

Larry Gagliano, Orion project manager at NASA's Marshall Space Flight Center, photographed in front of the spaceship's heat shield at Marshall on March 10, 2015.

.

A steady stream of young NASA employees came to a high-bay building at Huntsville's Marshall Space Flight Center Tuesday afternoon to a see a spaceship heat shield. Specifically, they came to see the shield that protected NASA's Orion spaceship from re-entry heat approaching 4,000 degrees Fahrenheit on its test flight Dec. 5, 2014.

Lots of things fly in space, and anything that comes back with important things inside needs a heat shield. But this shield is human-rated - capable of protecting the most valuable cargo NASA flies - and it flew 3,600 miles out. That's farther into space than any human-rated American space hardware since Apollo 40 years ago. And that's before many of the workers who came to see it Wednesday were born. That makes the shield two things for NASA: a valuable test object and evidence the space agency is building rockets for humans to fly again.

The shield is at Marshall for the next three months so technicians can grind it down to almost nothing on the center's massive and unique 7-axis milling machine. The shield's covering is made of a heat retardant substance called Avcoat that is similar to what NASA used for Apollo, minus the toxic materials like asbestos.

Before the big grind-down, technicians from Ames Research Center in Silicon Valley, Calif., will come to Marshall and carve blocks out for study and comparison to their models. After the shield is gone, the skeleton will go to Langley Research Center in Hampton, Va., for more tests.

.

The 7-axis milling machine NASA will use to grind off the Orion space capsule's heat shield at Marshall Space Flight Center in Huntsville, Ala.

.

A NASA worker in Huntsville looks at the Orion heat shield in Alabama for removal of its heat shield. An open-door opportunity to see the spaceflight hardware brought a steady stream March 10, 2015 to the building where the shield will be removed.

.

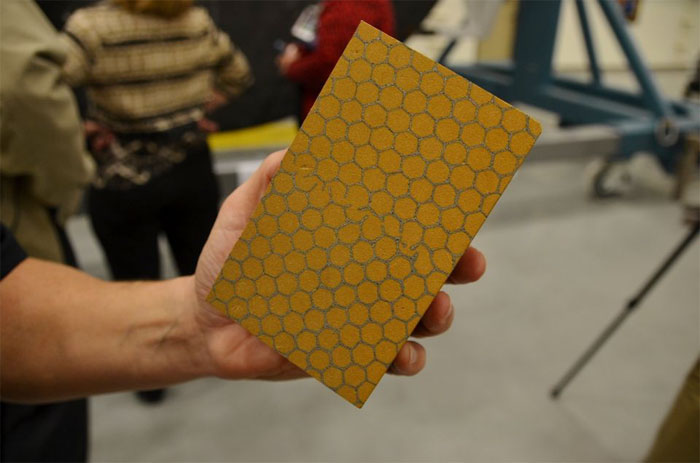

This is a block of the heat shield material called Avcoat. The Avcoat is hand-injected into each of the thousands of honeycomb chambers of the framing material and applied to the shield.

.

What a honeycomb heat shield looks like after passing through 3,000 degree Fahrenheit temperatures on re-entering the Earth's atmosphere.

.

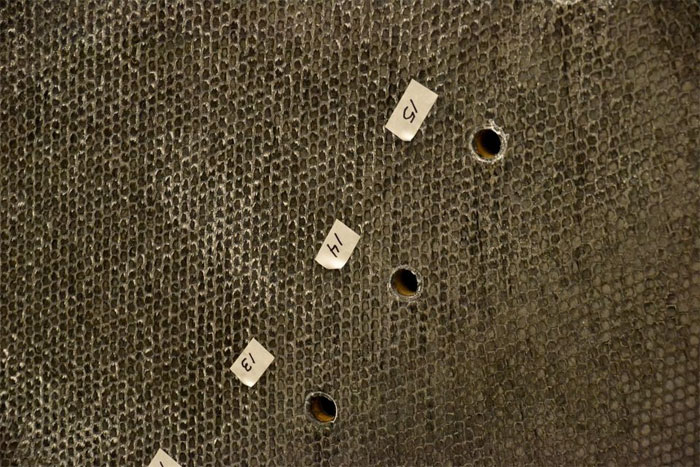

These holes in the heat shield were drilled to remove test instrumentation

.

This is a closeup of the bottom right side of the shield as Orion re-entered the atmosphere after its December test flight. The divots in the shield weren't caused by wear but by handling during recovery from the ocean.

.

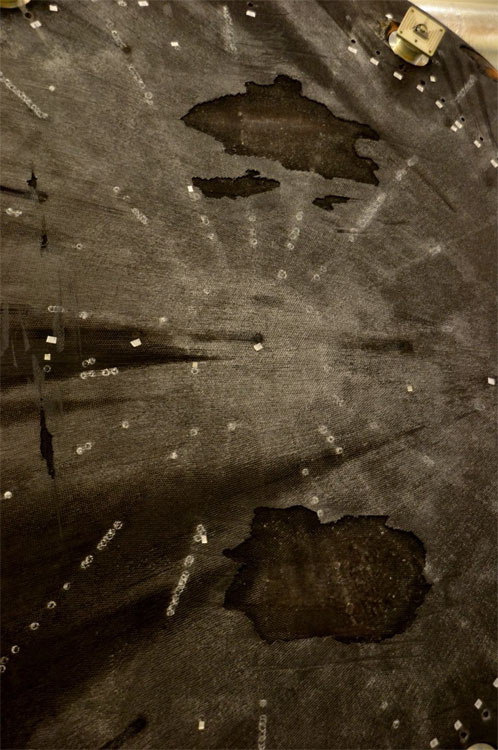

The heat shield was marked in different patterns by the heat of re-entry. NASA will study the angle, surface and other factors to determine precisely why.

.

The heat protectant burned away from Orion's shield differently in different locations but would have protected astronauts across the shield. Why the different burn levels in one question NASA will look at next.

.

A larger view of the shield tilted for observation before milling begins to remove the shield from the capsule's bottom

.

The underside of Orion's heat shield was a web of sensors and connecting wire to measure the effect of re-entry on the shield.

.

More divots taken out of Orion's heat shield by recovery operations.

.

More divots taken out of Orion's heat shield by recovery operations

.

More divots taken out of Orion's heat shield by recovery operations.

.

Quelle: AL

4415 Views