On Saturday 15 May, the Chinese state news agency Xinhua reported that the country had landed a robotic spacecraft on Mars. This is an important moment and it could be a taste of things to come.

Until China’s Zhurong rover touched down in the Utopia Planitia region of the Mars, only the US had succeeded in operating on the planet’s surface. Next year, however, a joint mission by the European Space Agency and Russia will attempt to replicate the success.

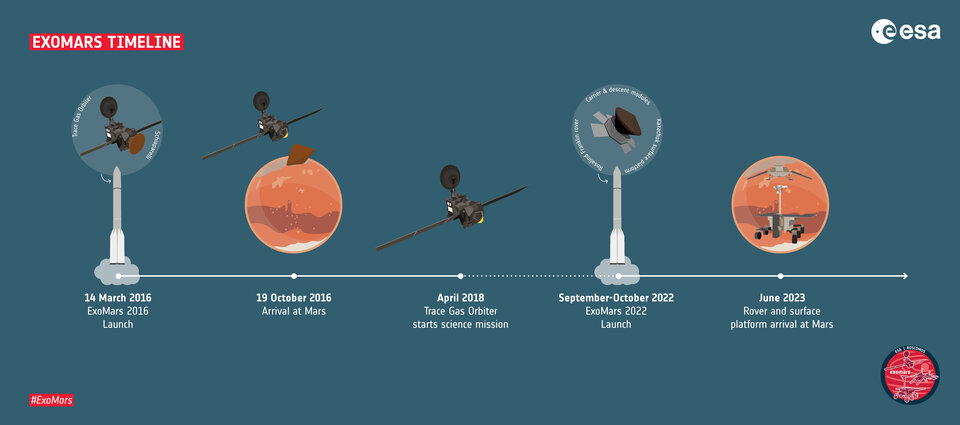

Launching in September 2022, and touching down in June 2023, ExoMars consists of a rover and a surface science platform. The rover is called Rosalind Franklin and has been built by Airbus Defence and Space in Stevenage, Hertfordshire. The platform is called Kazachok and has been built by Lavochkin in Khimki, Russia. Both contain instruments designed to answer whether life has ever existed on Mars. A drill on the rover will penetrate up to 2 metres below the surface, the first time such depths have been explored. Originally planned to launch last year, setbacks with the parachutes and the onset of the pandemic forced a postponement. If successful, it will double the number of space agencies now operating on the surface of Mars.

Quelle: The Guardian

----

Update: 23.05.2021

.

New ExoMars parachute ready for high altitude drop

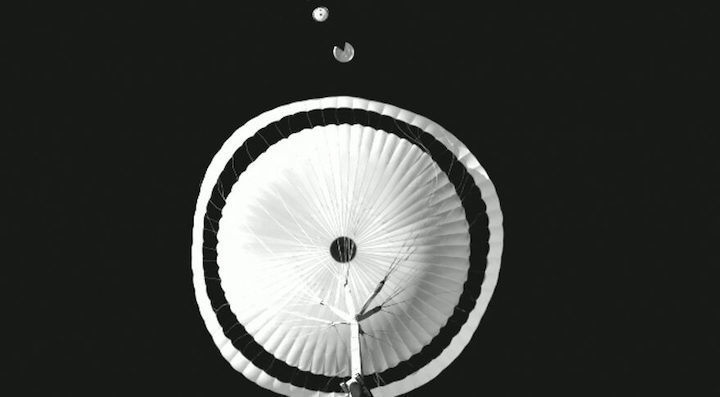

A series of ground-based high-speed extraction tests confirm the readiness of a new and upgraded parachute and bag system for a high-altitude drop test in early June, part of critical preparations to keep the ExoMars 2022 mission on track for its next launch window.

The tests, conducted with NASA/JPL’s dynamic extraction test rig in California, USA, focused on demonstrating the readiness of new equipment developed by Airborne Systems, as well as verifying changes to the parachute and bag provided by Arescosmo.

Access the video

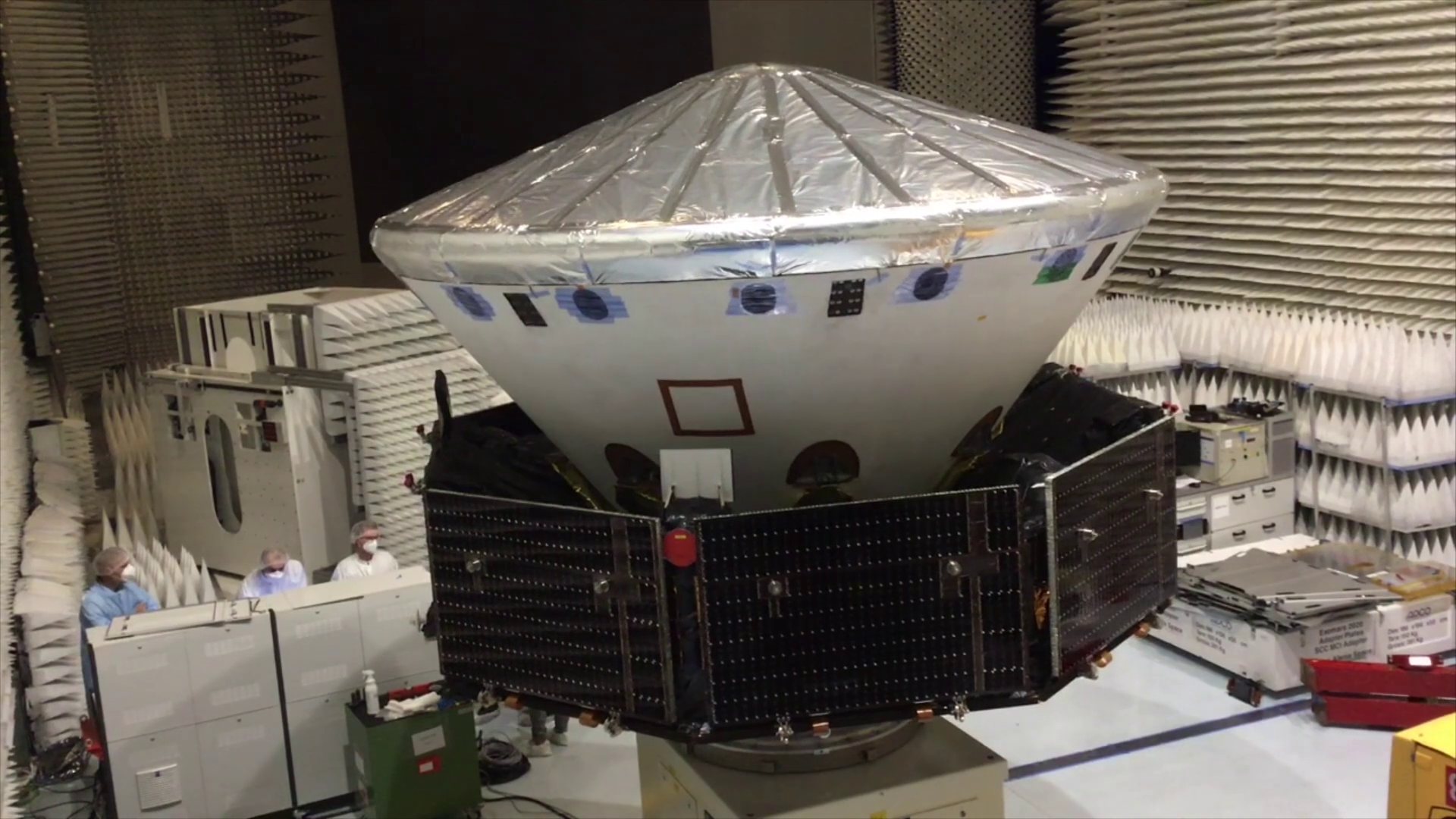

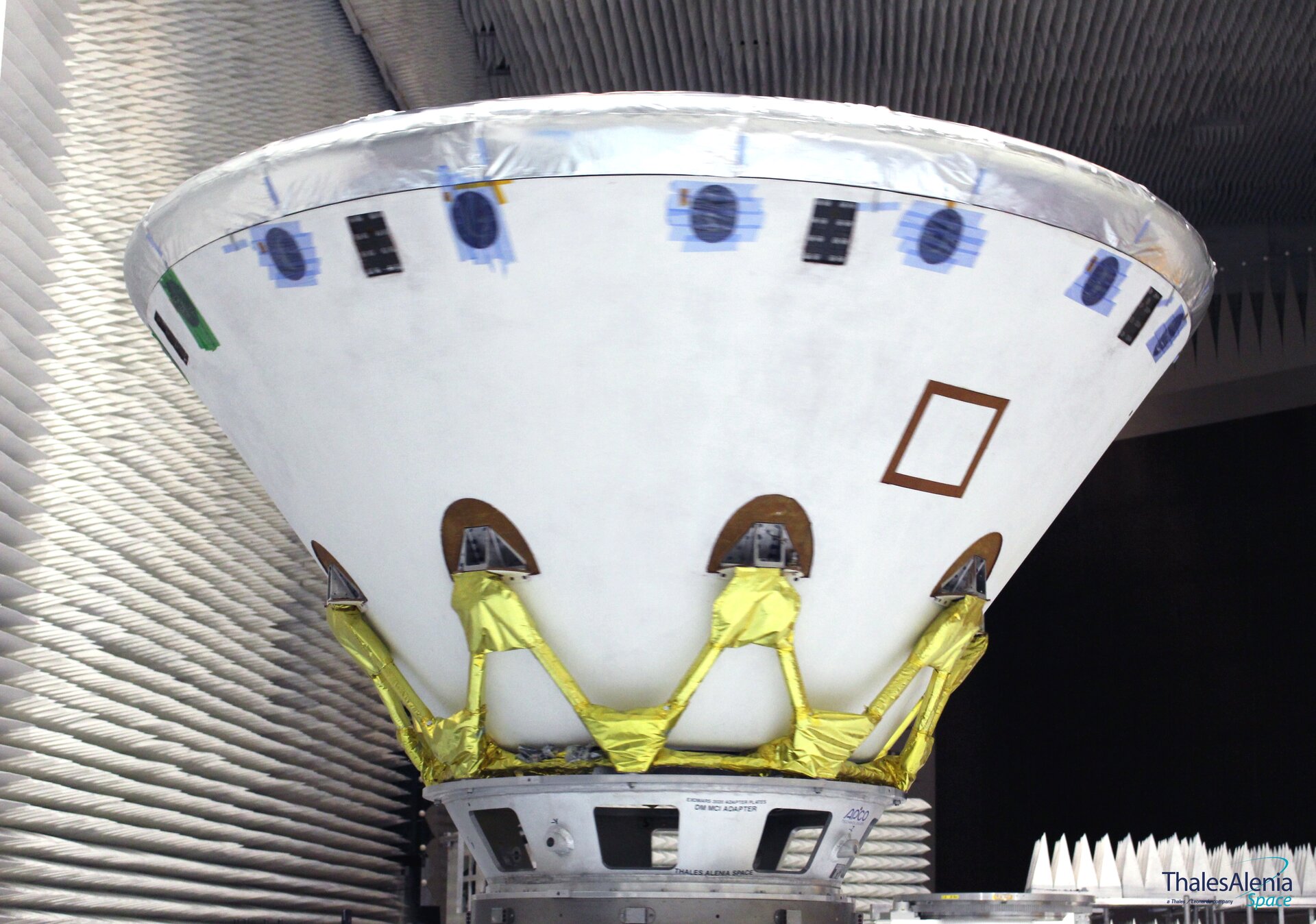

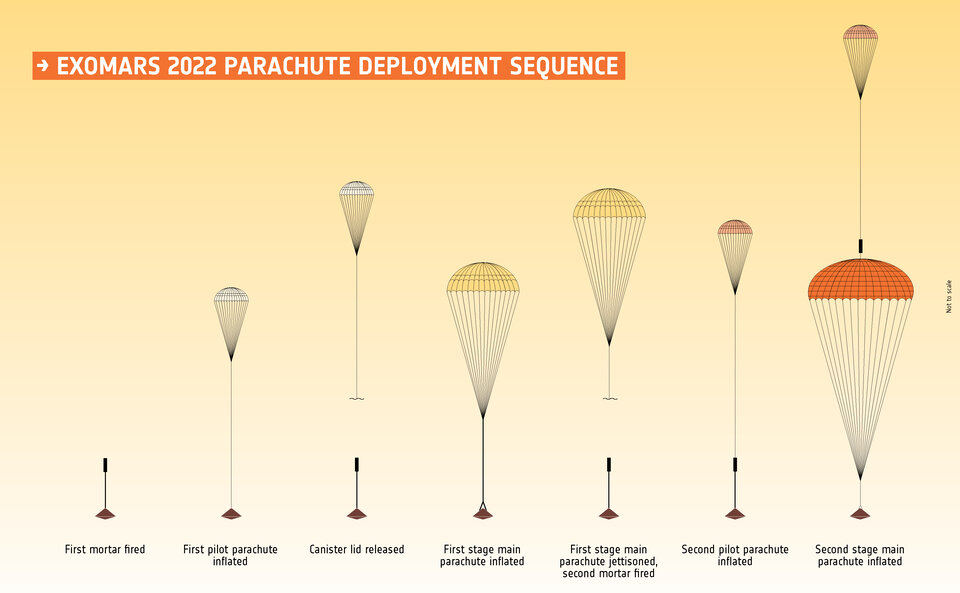

The ESA-Roscosmos ExoMars mission, with the Rosalind Franklin rover and Kazachok surface platform contained in a descent module, requires two main parachutes – each with its own pilot chute for extraction – to help slow it down as it plunges through the martian atmosphere. The 15 m-wide first stage main parachute will open while the descent module is still travelling at supersonic speeds, and the 35 m-wide second stage main parachute is deployed once at subsonic speeds.

The latest round of extraction tests focused on the first main parachute provided by both companies. Arescosmo addressed open issues from previous unsuccessful tests: a new bag design and a revised approach to folding to avoid line-twisting upon extraction. The Airborne Systems parachute and bag also completed several rounds of development tests to validate the extraction process.

Access the video

“Both performed very well in the tests,” says Thierry Blancquaert, ESA ExoMars programme team leader. “Close inspection showed that a few small areas in the parachute canopy had been subject to friction during the bag extraction process, reducing the strength of the fabric in these few places. Cross-examination with the video footage allowed the Airborne Systems team to pinpoint the moment the damage occurred and make modifications to the bag and packing of the parachute. This could be done with a remarkably quick turnaround of just a couple of days, to arrive at a successful result.”

The parachute had originally been packed inside the bag around the central mortar that contains the pilot chute, such that upon extraction it unwrapped in a 360º fashion. Folding the band of the parachute in two layers, so that it first unfolds in one direction and then 180º in the other direction, proved to reduce the tendency of the canopy to experience friction incurred by wrapping around the mortar.

The Airborne Systems first main parachute will now move forward for testing in its first high-altitude drop test scheduled at the start of June from Kiruna, Sweden.Two high-altitude balloons and dummy descent modules are available in the June window, which will see the descent vehicle dropped under the parachute from a stratospheric balloon at an altitude of about 29 km.

For Arescosmos, the first main parachute will act as a back-up, and instead the focus for them will turn to the second main parachute. Upgrades made to this parachute and bag were already implemented and tested in dynamic extraction tests in December 2020, which included using stronger parachute lines and reinforced material around the parachute apex. For the upcoming high-altitude test, a slightly smaller sized pilot chute (3.7 m compared with 4.5 m previously) will also be implemented, aimed at reducing the energy – and therefore the friction – generated upon extraction of the second main parachute from its bag. This cannot be tested on the ground-based rig in advance, which is only focused on the main parachute extraction from its bag.

Open Image

Further ground-based dynamic extraction test slots are anticipated during August to prepare for another pair of high-altitude drop tests foreseen for October/November this year, from Oregon, USA. Further high-altitude test opportunities are also considered during the first half of 2022. Subsequent test configurations will largely depend on the outcome of the upcoming tests in Kiruna, although it is expected to repeat successful tests at least once more.

High-altitude drop tests require complex logistics and strict weather conditions, making them difficult to schedule, while the ground tests can be repeated on a quick turnaround, buying significantly more time in the test campaign and reducing risk by allowing more tests to be conducted on a short time frame.

“Our strategy of having two highly qualified teams working on the parachutes, together with the availability of the ground-test rig, is already paying off and we are ready and looking forward to the next high-altitude drop tests,” says Thierry. “Landing safely on Mars is a notoriously difficult task. Investing our efforts in this test strategy is an essential part of ensuring a successful mission when we arrive at Mars in 2023.”

All parachute system qualification activities are managed and conducted by a joint team involving the ESA project (supported by Directorate of Technology, Engineering and Quality expertise), Thales Alenia Space Italy (prime contractor, in Turin), Thales Alenia Space France (PAS lead, in Cannes), Vorticity (parachute design and test analysis, in Oxford) and Arescosmo (parachute and bags manufacturing, in Aprilia). NASA/JPL-Caltech has provided engineering consultancy, access to the dynamic extraction test facility, and on-site support. The extraction tests are supported through an engineering support contract with Airborne Systems, who also provided NASA’s Mars 2020 parachutes, and by Free Flight Enterprises for the provision of parachute folding and packing facilities. Airborne Systems is also providing parachute design and manufacturing services since 2021.

Near Space Corporation provide the balloon launch services in Oregon. The Swedish Space Corporation Esrange facility provides the balloon launch services in Kiruna.

The ExoMars mission will launch on a Proton-M rocket with a Breeze-M upper stage from Baikonur, Kazakhstan, in the 20 September – 1 October 2022 launch window. Once landed safely in the Oxia Planum region of Mars on 10 June 2023, the rover will drive off the surface platform, seeking out geologically interesting sites to drill below the surface, to determine if life ever existed on our neighbour planet. The ExoMars programme, a joint endeavour between ESA and Roscosmos, also includes the Trace Gas Orbiter, which has been orbiting Mars since 2016. As well as its own science mission, Trace Gas Orbiter will provide essential data relay services for the surface mission; it is already providing data relay support for NASA’s surface missions, including the arrival of the Mars 2020 Perseverance rover in February 2021.

Quelle: ESA

----

Update: 5.06.2021

.

ExoMars rover twin begins Earth-based mission in ‘Mars Terrain Simulator'

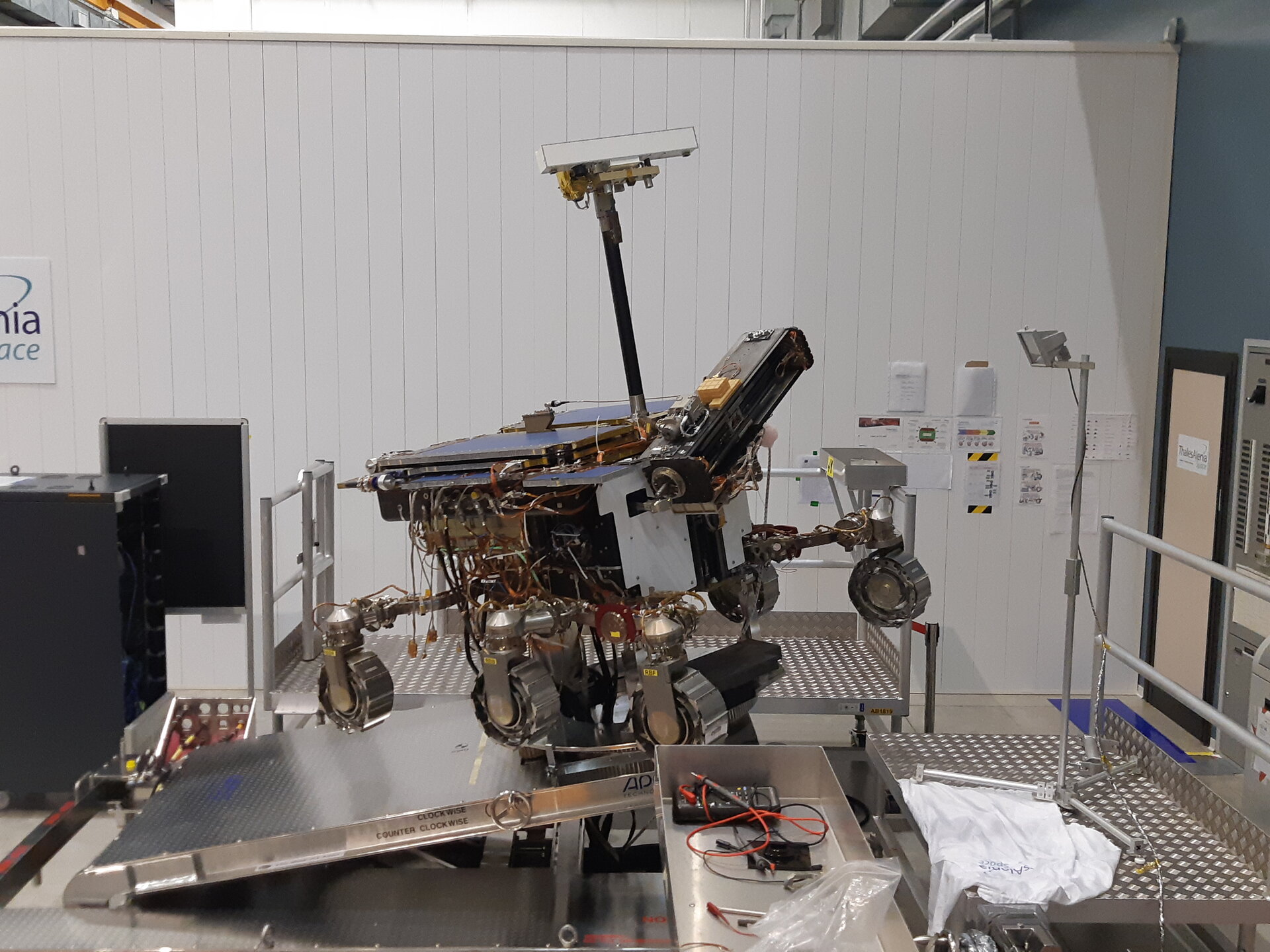

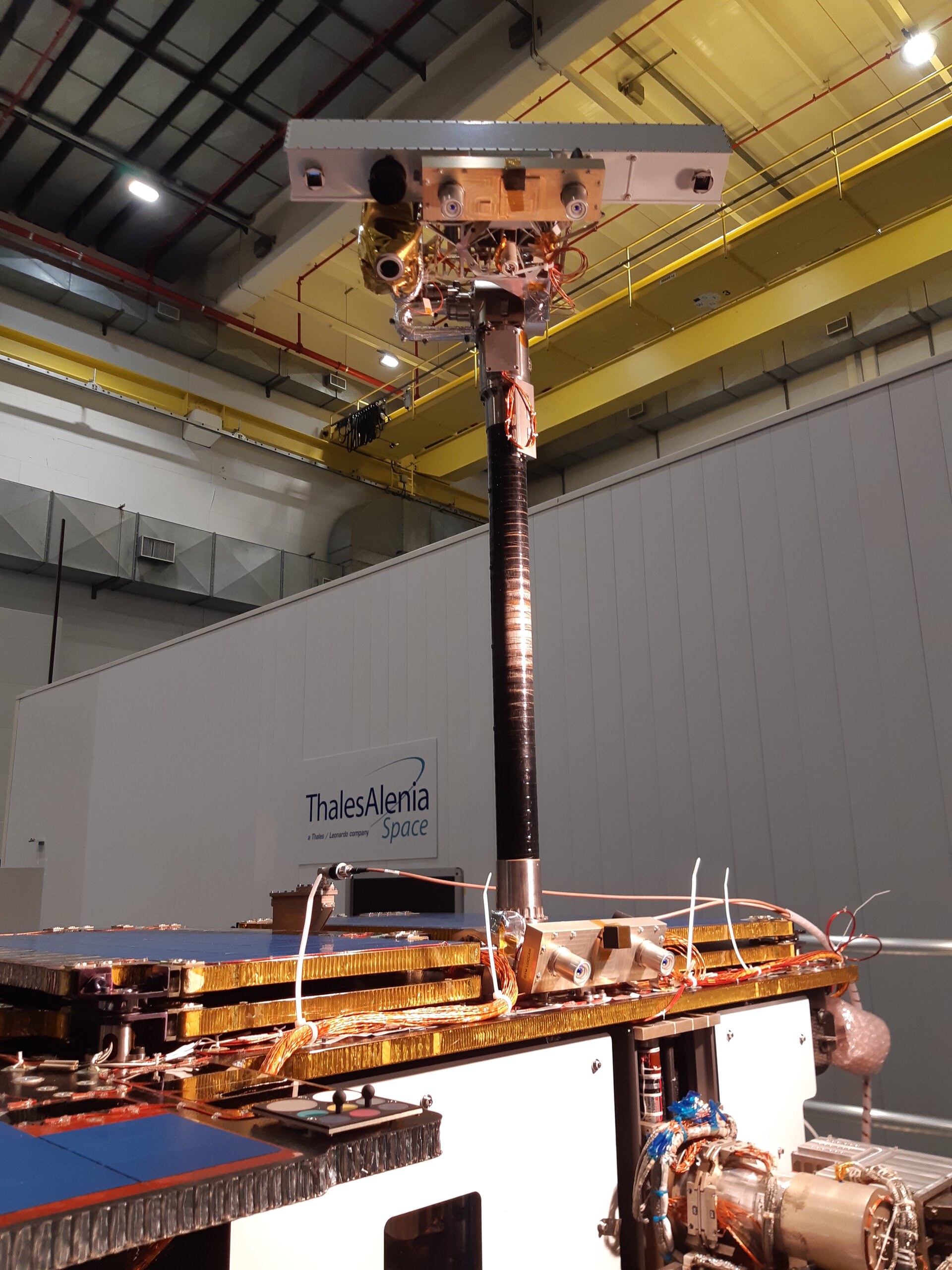

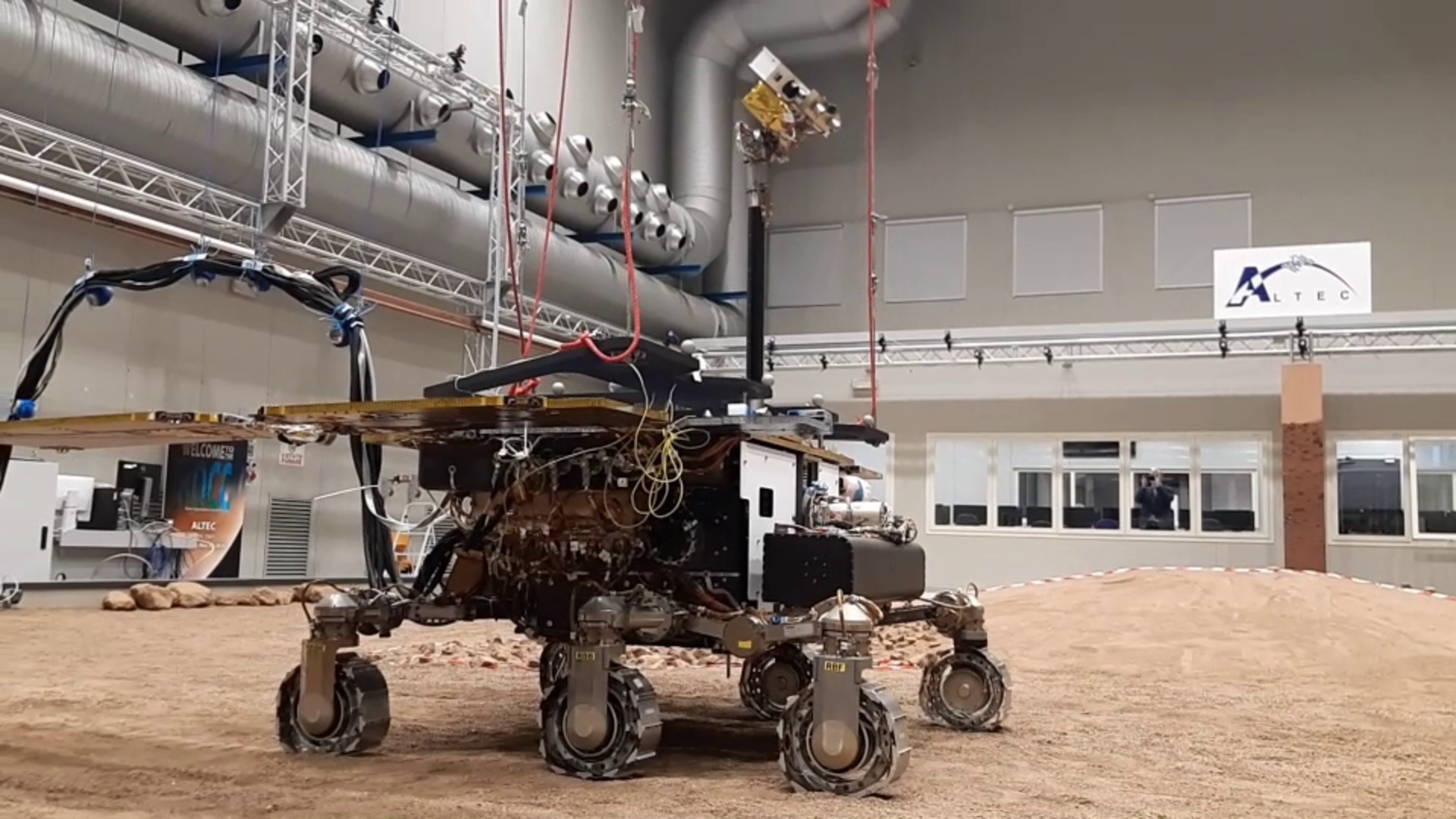

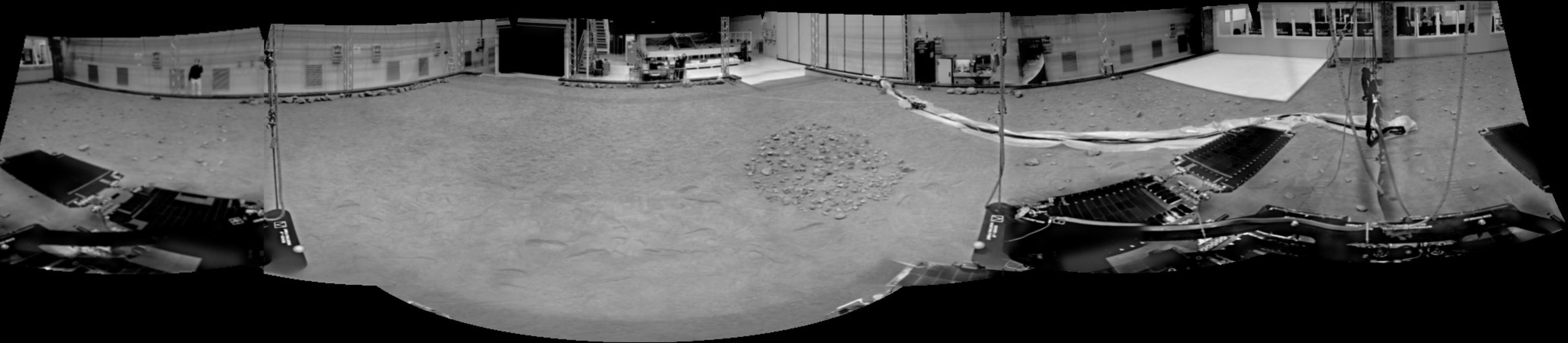

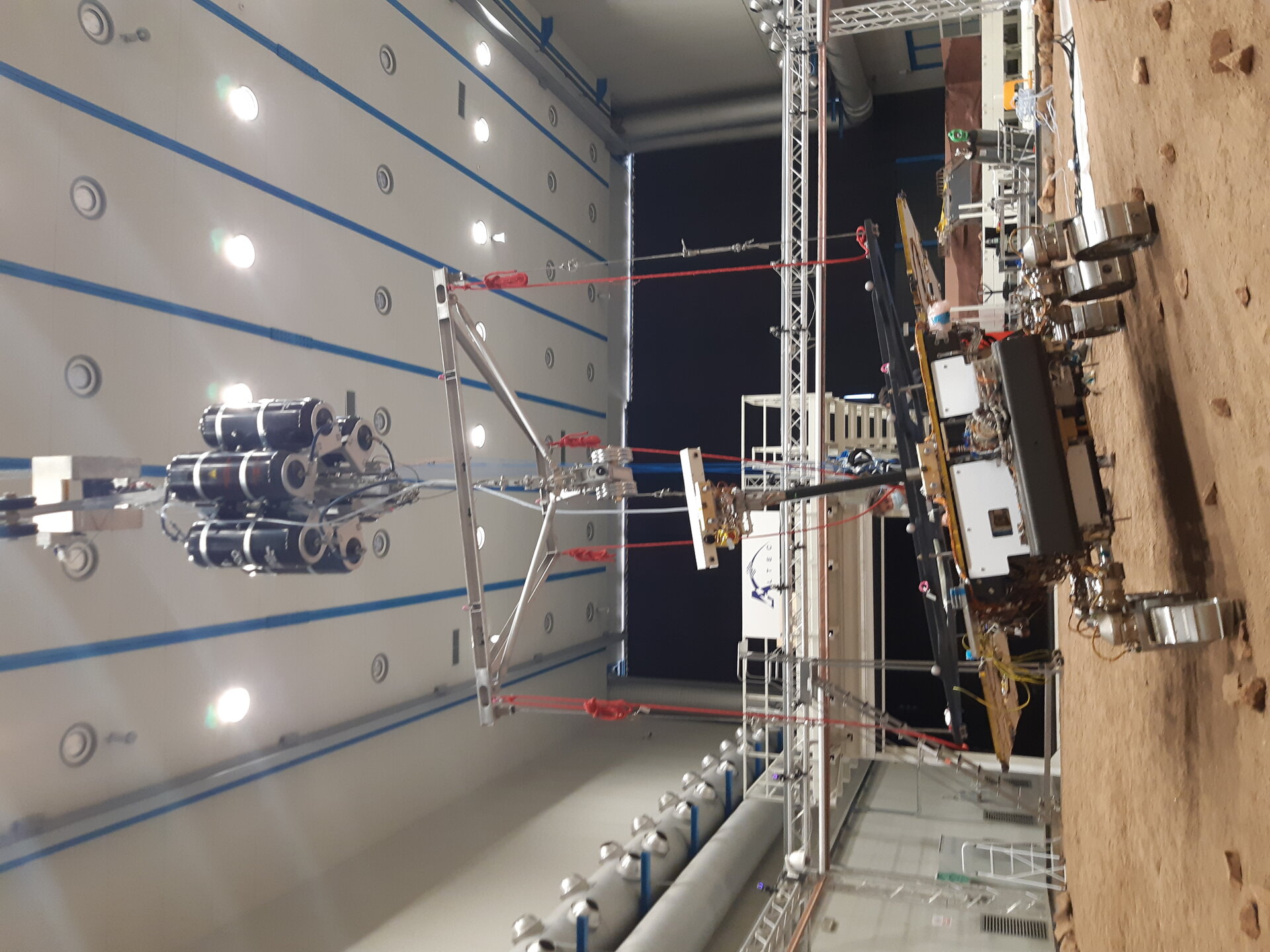

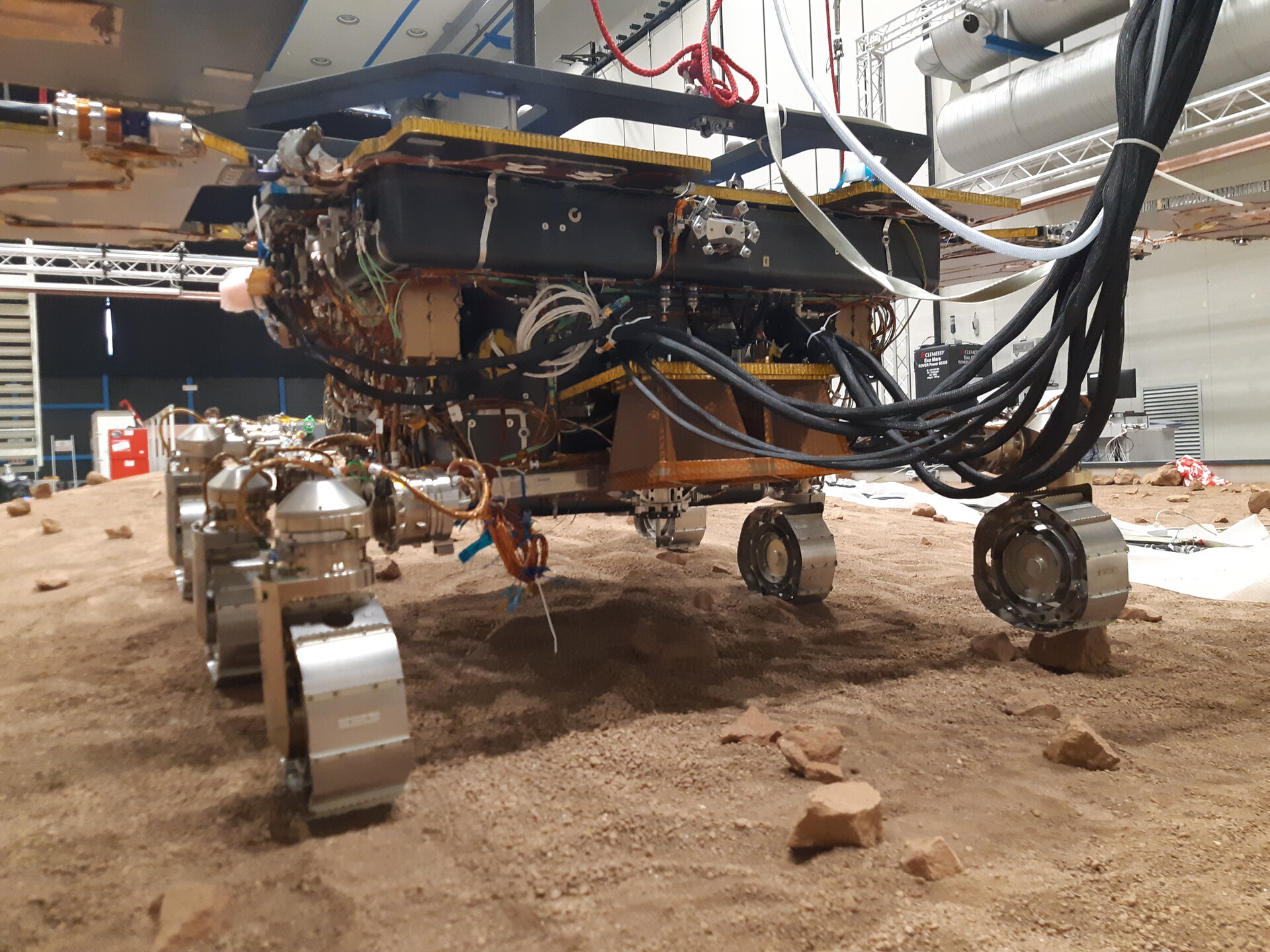

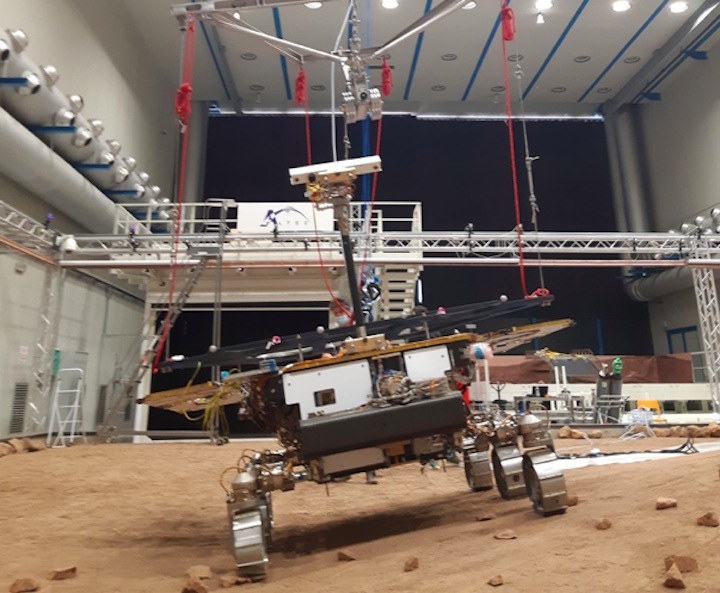

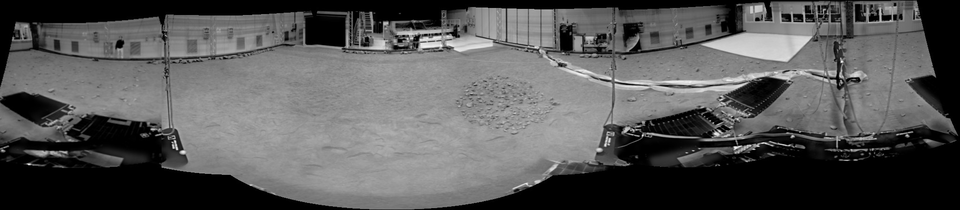

The replica ExoMars rover that will be used in the Rover Operations Control Centre to support mission training and operations is fully assembled and has completed its first drive around the Mars Terrain Simulator at ALTEC, in Turin, Italy.

The rover ‘Ground Test Model’ (GTM) will play a critical role in the coming months as rover operators prepare for Rosalind Franklin’s arrival in Oxia Planum on Mars in June 2023.

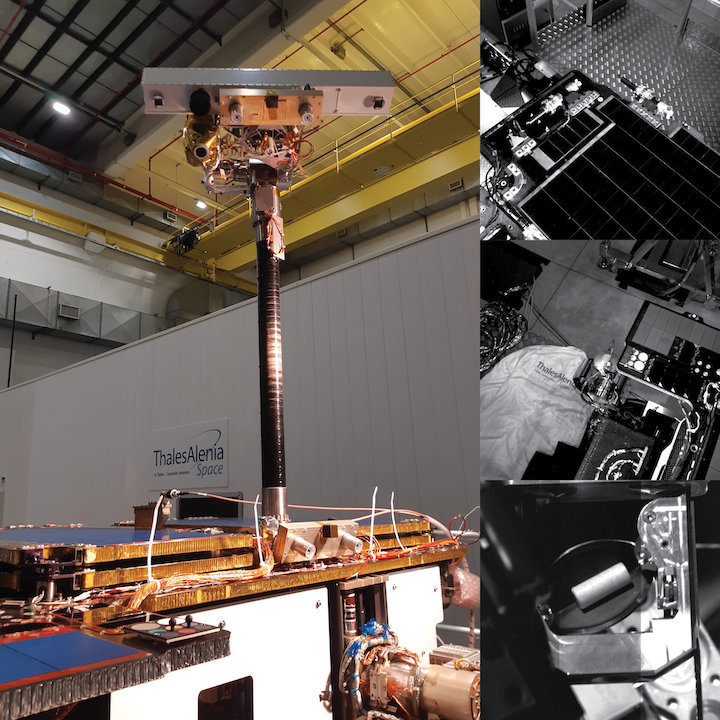

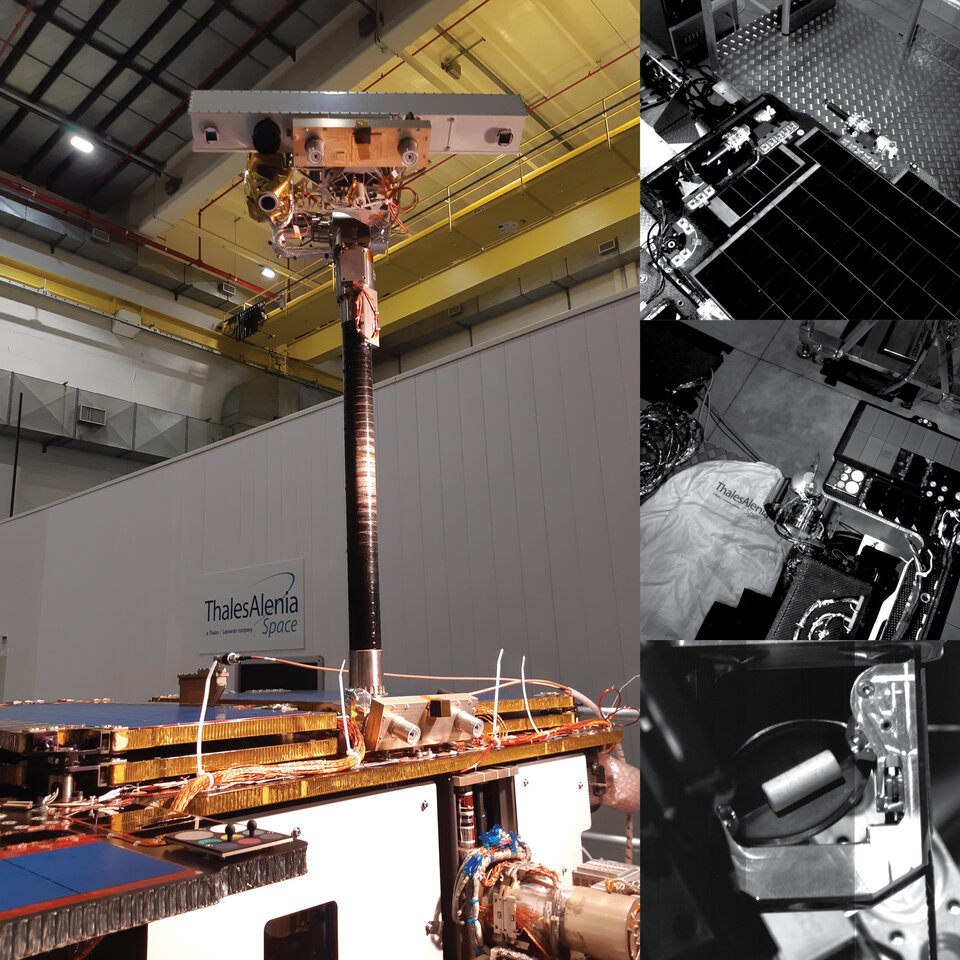

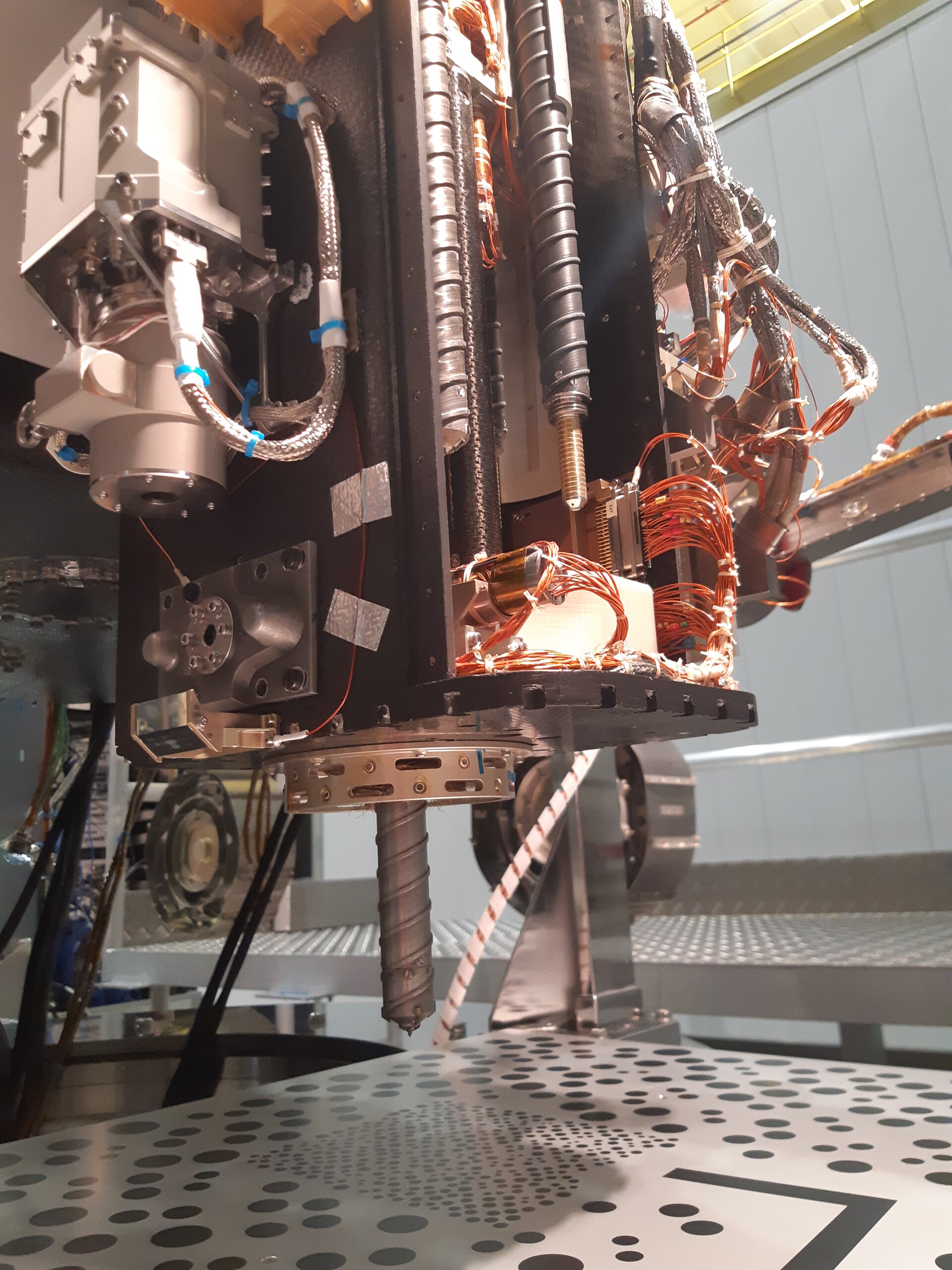

The GTM already completed important commanding tests while stationary in the Thales Alenia Space cleanroom, and now it has been fully assembled in the Mars Terrain Simulator.

To best represent what the real Rosalind Franklin rover will experience on Mars, the GTM is supported by a device to recreate the martian gravity level. Mars gravity is about one-third of Earth’s so two-thirds of the rover’s 290 kg total mass is absorbed by the ‘Rover Unloading Device’ attached to the GTM from the ceiling of the test area.

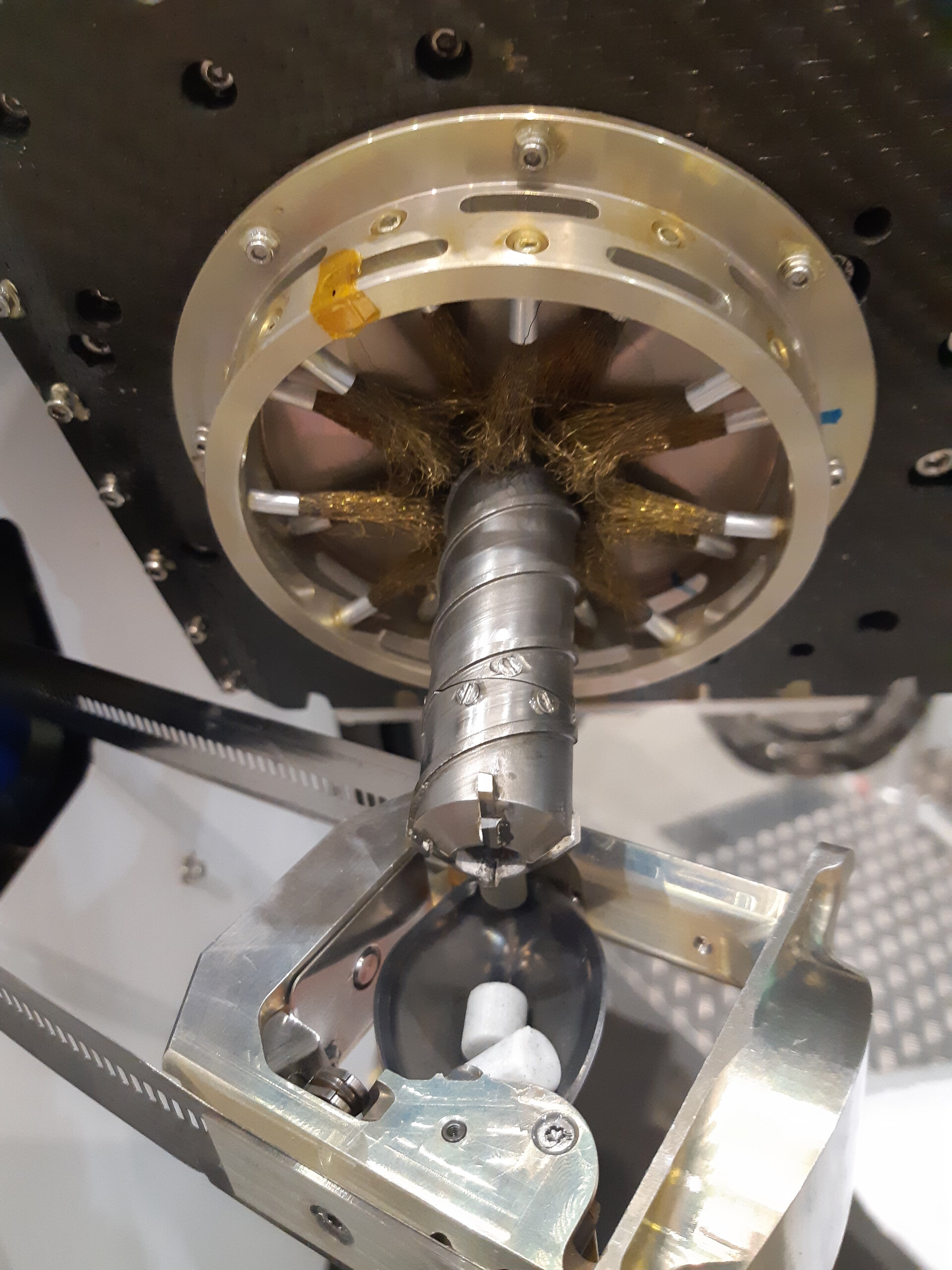

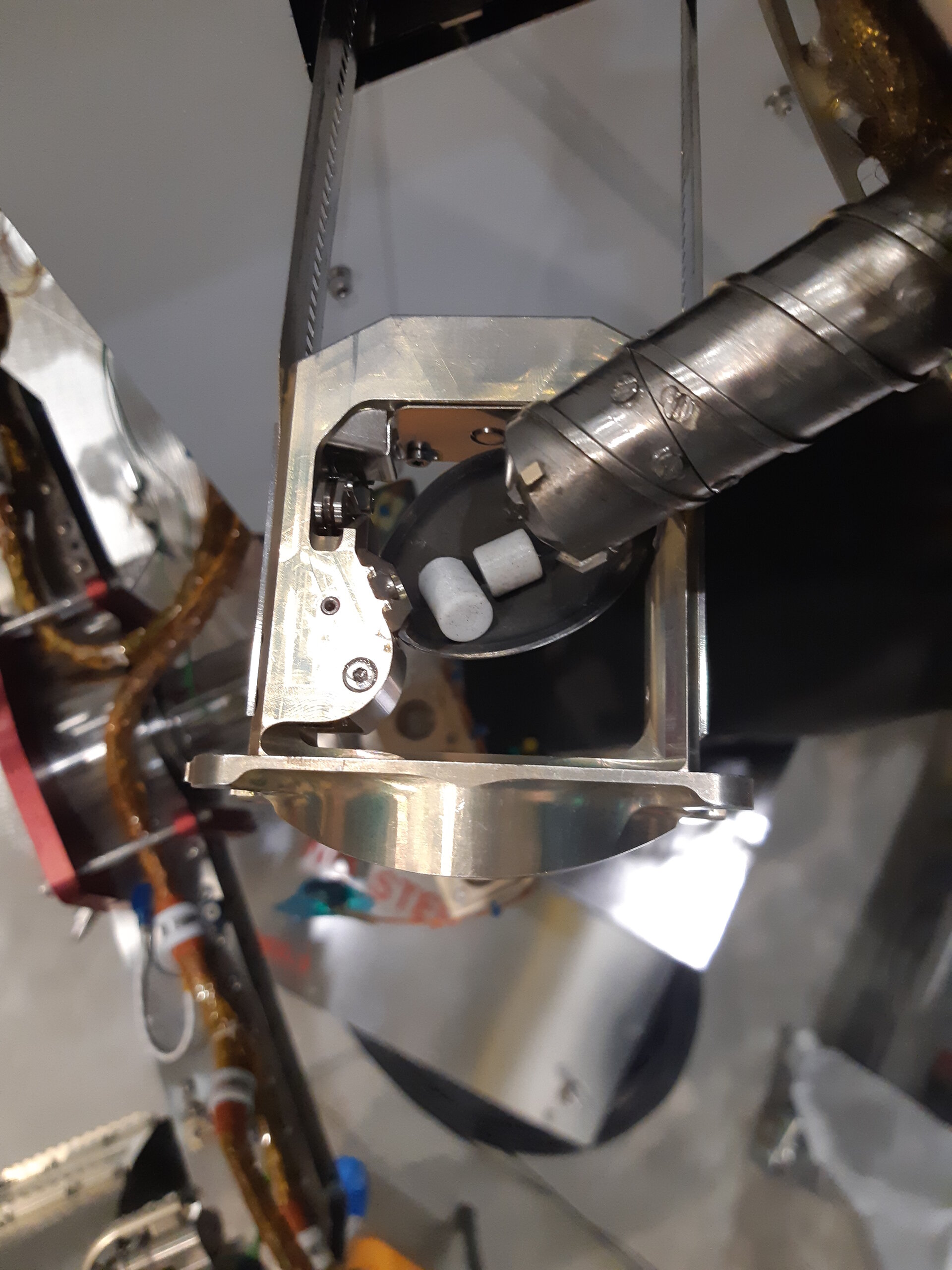

Rover operators will rehearse numerous activities with the replica rover, from moving across different terrain to deploying its science instruments.

The first tests were simple driving activities: moving over different surfaces, tackling a side slope, small hill, and boulder-strewn terrain. On top of the hill, the rover was also commanded to take a panoramic image sequence.

The test paves the way for more advanced activities in the coming months. For example, while the first driving test was executed by following direct drive commands, upcoming is a trajectory control test: that is, the rover will automatically correct deviations induced by the topography and roughness of the terrain to stay within 20 cm of the commanded path. Later, more advanced autonomous driving functions will be tested whereby the rover will use onboard computing capabilities to assess the safety of the terrain on its own.

The GTM will also be used in the coming weeks for drilling activities. The ExoMars rover is unique in Mars exploration in that it will be first to drill 2 m below the martian surface to retrieve samples for analysis in its sophisticated onboard laboratory. Underground samples are more likely to include biomarkers, since the tenuous martian atmosphere offers little protection from radiation and photochemistry at the surface. Understanding if life once existed on Mars is a key question in planetary science, and at the heart of the ExoMars programme.

The Rover Operations Control Centre (ROCC) is hosted by ALTEC in Turin, Italy.

Quelle: ESA

----

Update: 11.07.2021

.

ESA resumes ExoMars parachute tests

WASHINGTON — The European Space Agency has resumed tests of the parachutes for its ExoMars lander, a system whose problems contributed to a two-year delay in the mission’s launch.

ESA conducted two high-altitude drop tests using balloons flown from Kiruna, Sweden, in late June. Those tests were designed to see if the parachutes could be extracted from their containers and deployed in atmospheric conditions similar to those found on Mars.

ExoMars uses two main parachutes, each with a smaller “pilot” parachute used as part of the extraction process. One parachute, 15 meters in diameter, will be deployed while the ExoMars entry vehicle is traveling at supersonic speeds. Once the vehicle slows to subsonic speeds, it releases that parachute and deploys a 35-meter parachute.

One of the tests last month, of a 15-meter parachute made by Airborne Systems, a U.S. company that produced the parachute NASA’s Perseverance Mars rover, went as planned. “We’re very happy to report that the first main parachute performed perfectly: we have a supersonic parachute design that can fly to Mars,” Thierry Blancquaert, ExoMars program team leader, said in an ESA statement.

The second test involved a 35-meter parachute made by Italian company Arescosmo. In that test, the pilot parachute unexpectedly detached during deployment of the larger parachute, causing a tear. Blancquaert said that, despite the tear, the parachute still sufficiently decelerated a mockup of the decent module.

“We have to know why this problem with the drogue happened, but the main parachute decelerated as expected and did its job,” said David Parker, director of human and robotic exploration at ESA, in a July 6 interview. “But we don’t want that to happen again.”

In 2019, a similar series of drop tests revealed problems with the extraction system, tearing the parachutes. Those problems contributed to ESA’s decision in March 2020 to delay the launch of ExoMars, which had been scheduled for July of that year, to the next launch window in September 2022.

With assistance from NASA, ESA has been working to modify the extraction system, conducting ground tests at the Jet Propulsion Laboratory. Those earlier problems, involving friction between the parachute canopy and the bag that contained it, aren’t linked to the latest test anomaly and appear to be resolved, ESA noted in its statement.

Another change has been the addition of the Airborne Systems parachute as a backup to the original European-developed parachute. “That came out of the earlier problems. We thought we needed to put some risk mitigations in place and give ourselves some options,” Parker said.

Another round of parachute drop tests, two of each parachute, is scheduled for late this year in Oregon. A final series of parachute tests will take place next summer, around the time the spacecraft is headed to the Baikonur Cosmodrome for launch on a Proton rocket. “We have some opportunity for confidence tests very late before launch,” he said.

The other technical issue that delayed the ExoMars launch last year, beyond complications caused by the pandemic, involved Russian electronics in the descent module. Parker said those components are being rebuilt in Russia and will be shipped back to Europe for integrated system tests on both a testbed and then on the spacecraft itself.

Quelle: SN