15.12.2017

NASA Conducts Final RS-25 Rocket Engine Test of 2017

NASA engineers capped a year of Space Launch System testing with a final RS-25 rocket engine hot fire on Dec. 13 at Stennis Space Center near Bay St. Louis, Miss. The 400-second test on the A-1 Test Stand was a “green run” test of an RS-25 flight controller. It marked the eighth RS-25 test of the year and the sixth flight controller to be tested for use on NASA’s new Space Launch System (SLS) vehicle. The engine tested also included a large 3D-printed part scheduled for use on future RS-25 flight engines. The part, a beach ball-sized pogo accumulator assembly, is a complex piece of hardware that acts as a shock absorber to dampen vibrations, or oscillations, caused by propellants as they flow between the vehicle and the engine. Initial reports show the 3D-printed hardware performed as expected, opening the door for more components scheduled for future tests. The test was part of the SLS Program's RS-25 affordability initiative – a collaborative effort between NASA and industry partner Aerojet Rocketdyne to reduce the engine's overall production costs by using new advanced manufacturing techniques while maintaining reliability and safety. Engineers were able to make the pogo accumulator with fewer welds using additive manufacturing, reducing the cost and time needed to make it. NASA is testing the RS-25 engines and controllers to help power the SLS rocket designed and send astronauts to deep-space destinations. The RS-25 engines for the initial SLS flights are leftover space shuttle main engines, modified to supply the added power needed for the larger, heavier SLS rocket. A major part of that modification is the new engine controller that serves as the “brain” of the engine, communicating with SLS flight computers to ensure engines are performing at needed levels. NASA tested the first SLS flight controller unit in March. The agency then launched a series of summer flight controller tests before testing an actual RS-25 flight engine in October. During tests, the controllers are installed on a developmental RS-25 engine, which is then fired in the same manner and for the same amount of time that will be needed during an SLS launch. Once tested and certified, the new flight controllers are installed on RS-25 engines designated for use on SLS missions. Four RS-25 engines will help power the SLS at launch, providing a combined 2 million pounds of thrust and firing in conjunction with a pair of solid rocket boosters. With the boosters, total thrust at liftoff will exceed 8 million pounds. The SLS Exploration Mission-1 (EM-1) will serve as the first flight for the new rocket and will carry an uncrewed Orion spacecraft. The EM-2 flight will transport a crew of astronauts aboard Orion. In addition to testing RS-25 engines for those flights at Stennis, NASA is preparing the B-2 Test Stand at the center to test the actual SLS core stage for EM-1. That testing will involve installing the actual flight core stage on the B-2 stand and firing all four RS-25 engines simultaneously, just as during an actual launch.

Quelle: NASA

---

Update: 18.12.2017

.

Orion Parachute Tests Prove Out Complex System for Human Deep Space Missions

When NASA’s Orion spacecraft hurtles toward Earth’s surface during its return from deep-space missions, the capsule’s system of 11 parachutes will assemble itself in the air and slow the spacecraft from 300 mph to a relatively gentle 20 mph for splashdown in the Pacific Ocean in the span of about 10 minutes. As the astronauts inside descend toward the water on future missions, their lives will be hanging by a series of threads that have been thoroughly ruggedized, tested and validated to ensure the parachute-assisted end of Orion missions are a success.

Through a series of tests in the Arizona desert, the engineers refining Orion’s parachutes have made the road to certifying them for flights with astronauts look easy, including a successful qualification test Dec. 13 that evaluated a failure case in which only two of the systems three orange and white main parachutes deploy after several other parachutes in the system used to slow and stabilize Orion endure high aerodynamic stresses. But behind the scenes, engineers are working hard to understand and perfect the system that must be able to work across a broad range of potential environmental conditions and bring the crew home.

While Orion’s parachutes may look similar to those used during the Apollo-era to the untrained eye, engineers can’t simply take that parachute system and scale it up to accommodate Orion’s much larger size. Through testing and analysis, technicians have developed Orion’s parachutes to be lighter, better understood and more capable than Apollo’s. NASA has also been able to adjust the system as elements of the spacecraft, such as attachment points, have matured.

“Through our testing, we’ve addressed some known failures that can happen in complex parachute systems to make the system more reliable,” said Koki Machin, chief engineer for the system. “We built upon the strong foundation laid by Apollo engineers and figured out how to manage the stresses on the system during deployment more efficiently, decrease the mass of the parachutes by using high tech fabric materials rather than metal cables for the risers that attach the parachute to the spacecraft, and improve how we pack the parachute into Orion so they deploy more reliably.”

Orion’s parachute system is also incredibly complex. About 10 miles of Kevlar lines attach the spacecraft to the outer rim of nearly 12,000 square feet of parachute canopy material – over four times the average square footage of a house – and must not get tangled during deployment. In addition to the fabric parachutes themselves, there are cannon-like mortars that fire to release different parachutes. Embedded in several parachutes are fuses set to burn at specific times that ignite charges to push blades through bullet proof materials at precise moments, slowly unfurling the parachutes to continue the sequential phases of the deployment sequence. All of these elements must be developed to be reliable for the various angles, wind conditions and speeds in which Orion could land.

With the analysis capabilities that exist today and the historical data available, engineers have determined that approximately 20-25 tests, rather than the more than 100 performed during the Apollo era, will give them enough opportunities to find areas of weakness in Orion’s parachute system and fix them. After the three remaining final tests next year, the system will be qualified for missions with astronauts.

“There are things we can model with computers and those we can’t. We have to verify the latter through repeated system tests by dropping a test article out of a military aircraft from miles in altitude and pushing the parachutes to their various limits,” said CJ Johnson, project manager for the parachute system. “Lots of subtle changes can affect parachute performance and the testing we do helps us account for the broad range of possible environments the parachutes will have to operate in.”

Orion parachute engineers have also provided data and insight from the tests to NASA’s Commercial Crew Program partners. NASA has matured computer modeling of how the system works in various scenarios and helped partner companies understand certain elements of parachute systems, such as seams and joints, for example. In some cases, NASA’s work has provided enough information for the partners to reduce the need for some developmental parachute tests.

“Orion’s parachute system is an extremely lightweight, delicate collection of pieces that absolutely must act together simultaneously or it will fail,” said Machin. “It alone, among all the equipment on the crew module, must assemble itself in mid-air at a variety of possible velocities and orientations.”

Parachute testing is just one part of the vast expanse of work being performed across the country that enable humans to venture farther into space than ever before.

Two pilot parachutes pull out two main parachutes of the Orion spacecraft during a test Dec. 15, 2017.

NASA is testing Orion’s parachutes to qualify the system for missions with astronauts.

Quelle: NASA

---

Update: 21.12.2017

.

418th FLTS supports NASA in Orion spacecraft parachute test

A mockup of an Orion spacecraft is released from a C-17 Globemaster III Dec. 13 over the Yuma Proving Ground in Arizona. Airmen and testers from the 418th Flight Test Squadron joined Army, NASA and contractor personnel to participate in the test of the Orion’s parachute landing system. (U.S. Air Force photo by Christopher A. Okula)

Airmen and testers from the 418th Flight Test Squadron, Army and NASA personnel, prepare a mockup of a NASA Orion spacecraft aboard a C-17 Globemaster on loan from Joint Base Lewis-McChord, Washington, Dec. 13. The spacecraft was airdropped over the Yuma Proving Ground in Arizona as part of a test of the craft’s parachute landing system. NASA is continuing contingency tests of the Capsule Parachute Assembly System, or CPAS. (U.S. Air Force photo by Christopher A. Okula)

-

EDWARDS AIR FORCE BASE, Calif. --

Airmen and testers from the 418th Flight Test Squadron joined Army, NASA and contractor personnel to participate in an airdrop of a mockup of the Orion spacecraft. The capsule was airdropped from a C-17 Globemaster on loan from Joint Base Lewis-McChord, Washington, over the Yuma Proving Ground in Arizona. NASA is continuing contingency tests of the Capsule Parachute Assembly System, or CPAS.

According to the space agency, NASA’s Orion spacecraft is built to take humans farther than they’ve ever gone before. The craft will serve as an exploration vehicle that carries a crew to space and sustain them during their space travel. The spacecraft is designed to re-enter the Earth’s atmosphere safely and land by using a system of 11 parachutes.

The Orion capsule was airdropped Dec. 13 with the planned failure of some of the chutes to test aerodynamic stresses on the remaining Orion parachutes.

Aircrew members assigned to the 418th Flight Test Squadron included Lt. Col. Zachary Schaffer, Maj. Daniel Edelstein, Capt. Eric Michael, Senior Master Sgt. Michael Gordon, Staff Sgt. Kermit Maronge, Staff Sgt. Leah Starkes, Staff Sgt. Vanessa Jordan, Jacob St. Germain, Dean Van Oosterhout, Christian Turner and Christopher Okula.

The Orion spacecraft Capsule Parachute Assembly System team pose for a photo before the mockup spacecraft is loaded onto a C-17 Globemaster III, Dec. 11, in Yuma, Arizona. (U.S. Air Force photo by Christopher A. Okula)

Quelle: USAF

---

Update: 26.12.2017

.

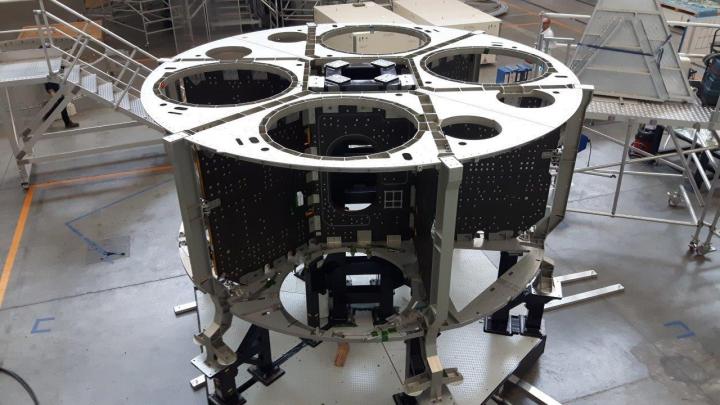

ORION EUROPEAN SERVICE MODULE-2 STRUCTURE COMPLETE

Wrapping up our blog entries on the frame of the second European Service module for Orion, these pictures show the completed internal structure for Flight Model-2. It will support up to four astronauts and send them further than any human being has ever been from Earth in a few years.

The pictures show the two circular tank bulkheads in place, bolted to the vertical panels. The top ring will attach to the Crew Module Adapter that connects the Orion capsule to the service module.

The pictures were taken at the Thales Alenia Space facility in Turin, Italy, in November 2017.

This structure can be seen as the chassis of the Orion spacecraft, providing structural rigidity while absorbing vibrations and energy from launch.

The holes are to save weight and accommodate future payloads. It will also hold all the other elements together such as the spacecraft’s thrusters, water tanks, fuel tanks, gas tanks, electronics and wires.

The top bulkhead is thicker as it handles more loads. Orion’s storage tanks are supported from the top bulkhead which distributes the forces from 9 tonnes of propellant between the European Service Module structure and NASA structures such as the Crew Module Adapter and the launcher fairing, while the lower platform “only” provides support to prevent the tanks from swinging.

Quelle: ESA

+++

WORKING ON THE WATER TANK

Credits: NASA–Radislav Sinyak

In a series of blog posts based on images taken at Thales Alenia Space building facility in Turin, Italy, we will now have a look at the water tanks in Orion’s second European Service Module – the one that will provide power and life-support to up to four astronauts.

The tank in this picture is made of titanium and around 50 cm in diameter and 90 cm long. It holds 70 l of drinking water for the astronauts that will fly through space inside Orion. This water tank is one of four that each European Service Module for Orion holds, bringing the total potable water to 280 l for each mission.

Credits: NASA–Radislav Sinyak

The shiny alloy exterior hides the technical machinery inside. A metallic bellow made of stainless steel pushes the water down as needed to pump the water and expel it from the tank down pipes to the crew module for the astronauts.

Much of the service module is based on technology used in ESA’s Automated Transfer Vehicle (ATV) that flew to the International Space Station. ATV used Teflon bladders inside metal tanks to store its water cargo, but ATV was a much larger spacecraft and transported more, so for Orion’s service module ESA chose a metal bellow system.

Pumping without gravity

Without gravity, an open bottle of water will not empty when turned upside down. Instead, the water needs to be squeezed out like toothpaste from a tube on earth. Spacecraft use rigid water tanks and use (plastic) bladders or (metallic) bellows inside that fill with gas as needed to expel the water.

Credits: NASA–Radislav Sinyak

How does it work on Orion? Imagine an aluminium air duct that expands like an accordion. At launch the bellows are compressed and nitrogen gas is pumped during the mission to expand the bellow and push water out of the tank.

The stainless steel is manufactured to a thickness of just 0.15 mm and keeping the metal supple without breaking is just one of the many technical challenges on this spacecraft – and a first use of metallic bellows in spacecraft for Europe.

+++

ACOUSTIC TESTING

A video on acoustic testing of the European Service Module Structural Test Article at Lockheed Martin’s acoustic lab.

Quelle: ESA

---

Update: 27.12.2017

.

NASA's Space Launch System rocket gets maiden mission patch

December 26, 2017

— The maiden launch of NASA's new heavy-lift rocket now has its own mission patch.

The space agency recently finalized the insignia representing Exploration Mission-

"EM-1 lays the foundation for the first crewed flight of SLS and Orion, as well as a regular cadence of missions thereafter near the moon and beyond," stated NASA in a November release.

The new EM-1 patch features the launch of the SLS at the center of its triangular design. The rocket is depicted lifting off from Complex 39B at NASA's Kennedy Space Center in Florida. The major SLS components are shown in simplified form, including the orange insulation-covered core, two side-mounted five-segment solid rocket boosters and the shuttle-legacy RS-25 engines at the base of the core.

The Orion spacecraft and its European-built service module are mounted on top of the booster. Atop the Orion is its launch abort system tower.

At the base of the patch, protruding from the launch plume, are the three spires of the pad's lightning protection system and the gantry tower that is part of the new SLS mobile launcher.

The scene is set against the backdrop of a nearly full moon. Red and blue vectors, jetting out beyond the border of the emblem, wrap around the white celestial body, symbolizing the EM-1 flight trajectory, while also infusing the colors of the U.S. flag to the insignia.

NASA is planning to use the EM-1 logo on lapel pins, embroidered patches, decals and apparel for its Orion and SLS team members. The design was first introduced in a memo to employees.

The EM-1 mission patch is the first insignia to represent the SLS, which has gone without a project or program logo. It is the third Orion flight emblem after designs for Pad Abort 1 (PA-1), a launch abort system test in May 2010, and Orion's first launch to space, Exploration Flight Test-1 (EFT-1), an Earth-orbit mission that flew on a United Launch Alliance Delta IV Heavy rocket in December 2014.

Orion also has a project logo, which was created for NASA by Michael Okuda, a graphic designer known for his work on the "Star Trek" TV series and movies.

In addition to EM-1, for which SLS and Orion hardware is now under construction and testing, NASA is also preparing to fly Ascent-Abort 2, an atmospheric flight to validate the abort system's ability to get a crew to safety if needed during a launch gone awry. Ascent-Abort 2 is targeted for April 2019.

NASA is targeting EM-1 for December 2019, though manufacturing and production concerns could delay the launch to June 2020 or later. Exploration Mission-2 (EM-

Quelle: CS

---

Update: 10.01.2018

.

NASA Invites Media to View Orion Test Capsule, Recovery Hardware

U.S. Navy divers and other personnel in a Zodiac boat secure a harness around a test version of the Orion crew module during Underway Recovery Test (URT) 5 in the Pacific Ocean off the coast of California. NASA and the U.S. Navy will conduct its sixth test Jan. 17-23 for recovery of the agency’s Orion spacecraft from the sea in preparation for its first uncrewed flight on the Space Launch System rocket.

Media are invited to see a test version of NASA’s Orion spacecraft and the hardware that will be used to recover the spacecraft upon its return from space, and talk with team members involved in the recovery operations at 9 a.m. PST Thursday, Jan. 25, at U.S. Naval Base San Diego.

In preparation for Exploration Mission-1, NASA and the U.S. Navy will conduct testing Jan. 17-23 for recovery of the agency’s Orion spacecraft from the sea following its first uncrewed flight on the Space Launch System rocket. This test is part of a series to demonstrate and evaluate the processes, procedures and hardware for recovery operations.

Media interested in attending must contact U.S. Naval Base San Diego Public Affairs at nbsd.pao@navy.mil or 619-556-7359 by Thursday, Jan. 18. All media must arrive no later than 8 a.m. at the naval base’s Pass and Decal building, located north of the intersection at 32nd Street and Harbor Drive.

Orion is America’s exploration spacecraft designed to carry astronauts to deep space destinations, including the Moon, Mars and beyond.

Quelle: NASA

---

Update: 17.01.2018

.

NASA Picks Up Where It Left Off In 2017, Tests RS-25 Flight Controller

NASA engineers picked up this year where they left off in 2017, conducting a certification test of another RS-25 engine flight controller on Jan. 16, 2018, on the A-1 Test Stand at Stennis Space Center near Bay St. Louis, Mississippi. The 365-second, full-duration test came a month after the space agency capped a year of RS-25 testing with a flight controller test in mid-December. A 3D printed part tested in December was tested again. This rocket engine component, a pogo accumulator assembly, is part of an ongoing series of tests with parts made using advanced manufacturing techniques that will make building future engines more affordable.

For this “green run” test, the flight controller was installed on RS-25 developmental engine E0528 and fired just as during an actual launch. Once certified, the flight controller will be removed and installed on a flight engine for use by NASA’s new deep-space rocket, the Space Launch System (SLS). NASA is building SLS as the most powerful rocket in the world, designed to carry humans on the Orion spacecraft and enable missions to the Moon and Mars.

Launch of the SLS rocket will be fueled by four RS-25 engines firing simultaneously to generate 2 million pounds of thrust and working in conjunction with a pair of solid rocket boosters to produce more than 8 million pounds of thrust.

RS-25 engines for the initial SLS flights are former space shuttle main engines, modified to provide the additional power needed by the larger SLS rocket. A key part of that modification is the new flight controller, which works as the RS-25 “brain,” helping the engine communicate with the SLS rocket and providing precision control of engine operation and internal health diagnostics. NASA is testing all RS-25 engines and flight controllers for SLS missions at Stennis.

The initial SLS Exploration Mission-1 (EM-1) will serve as the first test flight for the new rocket and will carry an uncrewed Orion spacecraft. All the engines for this flight have been tested at Stennis and are ready to be attached to the rocket’s core stage being built at NASA’s Michoud Assembly Center in New Orleans. Current engine tests are for controllers for Exploration Mission-2, the first flight that will transport astronauts aboard Orion.

In addition to testing the engines for those flights at Stennis, NASA is preparing the B-2 Test Stand at the center to test the entire SLS core stage with its four engines for EM-1. This “green run” testing will involve installing the flight core stage on the B-2 stand and firing all four RS-25 engines simultaneously, just as during an actual launch. RS-25 tests at Stennis are conducted by a team of NASA, Aerojet Rocketdyne and Syncom Space Services engineers and operators. Aerojet Rocketdyne is the RS-25 prime contractor. Syncom Space Services is the prime contractor for Stennis facilities and operations.

Quelle: NASA

---

Update: 20.01.2018

.

USS Anchorage Participates in NASA’s Orion Mission Test

The San Antonio-class amphibious transport dock ship USS Anchorage departs Naval Base San Diego to conduct an underway recovery test in conjunction with NASA off the Southern California coast, Jan. 17, 2018. The test is part of a government interagency effort to safely practice and evaluate recovery processes, procedures, hardware and personnel in an open ocean environment that will be used to recover the Orion spacecraft upon its return to Earth. Navy photo by Petty Officer 2nd Class Jesse Monford

-

The San Antonio-class amphibious transport dock ship USS Anchorage departed from Naval Base San Diego yesterday to conduct an underway recovery test in conjunction with NASA off the Southern California coast.

The test is part of a government interagency effort to safely practice and evaluate recovery processes, procedures, hardware and personnel in an open ocean environment that will be used to recover the Orion spacecraft upon its return to Earth.

This will mark the fourth time Anchorage will conduct an underwater recovery test mission with NASA. Throughout the program’s history, a variety of San Antonio-class ships have been involved in preparing NASA and the Navy, using a mock capsule designed to roughly the same size, shape, and center of gravity as NASA’s Orion crew module.

Lessons Learned

NASA and Navy teams have taken lessons learned from previous recovery tests to improve operations and ensure the ability to safely and successfully recover the Orion capsule when it returns to Earth following Exploration Mission 1, slated for December 2019.

The mission will be an unmanned flight conducted to pave the way for subsequent crewed missions and to enable future missions to the moon, Mars and beyond, officials said.

Anchorage’s specially trained bridge team will be on watch while the ship conducts operations. Small boats carrying Navy divers and NASA’s recovery team will maneuver alongside the mock module to rig tending lines, guiding the capsule to Anchorage as the ship safely operates on station.

Navy-NASA Partnership

Conducting both daytime and nighttime recovery operations, NASA crew members will work alongside the Navy to manage how the capsule is brought in, set down and safely stored. NASA plans to conduct three more underway recovery test missions before the launch of Exploration Mission 1.

Anchorage is homeported in San Diego and is part of Naval Surface Forces and U.S. 3rd Fleet.

U.S. 3rd Fleet leads naval forces in the Pacific and provides the realistic, relevant training necessary for an effective global Navy.

Quelle: U.S. Department of Defense

---

Update: 21.01.2018

.

Exploration Mission-1 Identifier

The Exploration Mission-1 artwork showcases the Space Launch System (SLS) rocket carrying the Orion spacecraft and lifting off from Launch Pad 39B at NASA’s Kennedy Space Center in Cape Canaveral, Florida. The triangular shape represents the three main programs that comprise NASA’s Deep Space Exploration Systems: Orion, SLS, and Exploration Ground Systems, and is a classic shape for NASA mission emblems dating back to the shuttle era.

Several elements within the design carry symbolic meaning for this historic flight. The silver highlight surrounding this patch gives nod to the silver Orion spacecraft, including the European service module that will be voyaging 40,000 miles past the Moon in deep space. The orange rocket and flames represent the firepower of SLS. The setting is historic Launch Pad 39B, represented by the three lightning towers. The red and blue mission trajectories encompassing the white full Moon proudly emphasizes the hard work, tradition, and dedication of this American led-mission while also embracing NASA’s international partnership with ESA (European Space Agency) as both agencies forge a new future in space.

The Exploration Mission-1 emblem was designed in collaboration by the creative team working for the Deep Space Exploration Systems programs, which includes Orion, SLS, and Exploration Ground Systems, located at NASA Headquarters in Washington, Glenn Research Center in Cleveland, Johnson Space Center in Houston, Marshall Space Flight Center in Huntsville, Alabama, and Kennedy. Because the maiden mission of SLS and Orion is uncrewed, the program teams had the rare opportunity to conceive the mission identifier. Exploration Mission-2, which will fly with crew, will have an insignia designed by NASA’s Astronaut Office with the help of the crew that will fly aboard the most capable deep space system to take flight.

Quelle: NASA

+++

Orion Spacecraft Recovery Rehearsal Underway

NASA’s new deep space exploration systems will send crew 40,000 miles beyond the Moon, and return them safely home. After traveling through space at 25,000 miles per hour, the Orion spacecraft will slow to 300 mph after it passes through the Earth’s atmosphere. The spacecraft then slows down to 20 mph before it safely splashes down in the Pacific Ocean.

When astronauts come back from deep space, they will need to be picked up as quickly as possible. That’s where Kennedy Space Center’s NASA Recovery Team comes in.

Under the auspices of Exploration Ground Systems, Melissa Jones, NASA’s recovery director, and her team will recover the Orion capsule and crew. NASA and the U.S. Navy are working together to ensure they are ready before the first uncrewed Orion mission aboard the agency’s new Space Launch System rocket, known as Exploration Mission-1.

This week, the integrated NASA and U.S. Navy team are aboard the USS Anchorage, testing out new ground support equipment and practicing their procedures.

After Orion completes its mission out past the Moon and heads to Earth, Jones will get the call Orion is coming home. Then, it is her job to get the joint NASA and U.S. Navy team to the capsule’s location quickly and bring it and the astronauts safely aboard the U.S. Navy recovery ship.

“We are testing all of our equipment in the actual environment we will be in when recovering Orion after Exploration Mission-1,” Jones said. “Everything we are doing today is ensuring a safe and swift recovery when the time comes for missions with crew.”

Navy and NASA Complete Underway Recovery Test

SAN DIEGO–San Antonio-class amphibious transport dock USS Anchorage (LPD 23) successfully completed test recovery operations of NASA’s Orion test article, Jan. 23.

The Underway Recovery Test-6 (URT-6) is part of a U.S. government interagency effort to safely retrieve the Orion crew module, which is capable of carrying humans into deep space.

This marks the fourth completion of a URT aboard Anchorage. NASA engineers worked alongside Sailors from the Anchorage, the San Antonio-class amphibious transport dock USS New Orleans (LPD 18), Special Boat Team 12, and Navy divers from Explosive Ordinance Disposal Mobile Unit 3 to test recovery operations of the Orion test article. Tests were conducted in varying sea states, during the day and at night.

"Our crew has actually been training for several months closely with NASA on everything from planning conferences to onsite training to be ready for the mission,” said Capt. Dennis Jacko, Anchorage commanding officer. "I think the ship and the crew are doing a great job for a historic tasking we have added to a very busy schedule as we prepare for deployment. Everybody stepped up and provided the best support with our NASA partners for a very successful test."

With their main role of conducting amphibious operations, San Antonio-class ships have unique capabilities that make them an ideal partner to support NASA’s mission. One of the more important capabilities is the ship’s ability to recover the test capsule using the ship's well deck, which was designed to launch and recover amphibious craft. Anchorage also has the ability to carry and deploy multiple small boats to aid in the recovery process of the capsule and contains an advanced medical facility ideal for treating the returning astronauts.

URT-6 consisted of releasing the test capsule from the well deck, then carefully maneuvering the ship alongside the capsule at slow speed. Once the test article was far enough from the ship, the lines attaching the capsule to the ship were released. Then, divers attached a stabilization ring designed by NASA that would help in sustaining the astronauts in the capsule for up to three days. Divers then removed the collar, attached lines from the small boats to steady and guide the capsule toward Anchorage, where Rigid Hull Inflatable Boats (RHIB) would then assist in attaching lines from a NASA-designed winch which then hauled the capsule into the well deck.

The whole recovery is a high risk evolution, especially when the capsule is being towed closely behind the ship, but NASA took our inputs and modified the equipment for this URT mission," said Chief Petty Officer Beau Lontine, a Navy diver assigned to Explosive Ordnance Disposal Mobile Unit 3. "There are so many things that could go wrong if just one person isn't paying attention. We've conducted training with the hardware and rigging to allow for a safe recovery of the capsule. It might seem like a basic recovery, but it is far from a simple evolution."

The tests allowed NASA and the Navy to continue to demonstrate and evaluate the recovery processes, procedures, hardware and personnel in real, open-ocean environment before conducting actual recovery operations.

Also aboard Anchorage to observe the URT for the first time is NASA Astronaut Stephen Bowen, who is also a retired Navy captain.

“I’m very pleased with what I’ve seen so far,” said Bowen. “The reason you do this is to better understand. You realize you don’t have all the answers right now. There will be changes made; things are going to evolve, and they should get better over time.”

URTs have been conducted since 2014 and will continue to be until NASA engineers believe the recovery process is without error. The next URT, URT-7, is scheduled to be on the San Antonio-class amphibious transport dock USS Somerset (LPD 25) in October 2018 when NASA will conduct the validation and verification of the recovery hardware.

According to NASA's Recovery Director Melissa Jones, future tests will ensure NASA and the Navy arrive at a safe and more efficient way to recover the capsule for an early 2020’s mission involving a flying crew.

“Testing this week went very well,” said Jones. “We’ve actually shaved about 15 minutes off our timeline already with one run, which is important to us because when we recover crew, we have to get them out as quickly as possible.”

The Orion spacecraft is designed to meet the evolving needs of our nation's deep space exploration program for decades to come. It will serve as the exploration vehicle that will carry the crew to space, provide emergency abort capability, sustain the crew during the space travel and provide safe re-entry from deep space return velocities.

Anchorage is homeported in San Diego and is part of U.S. 3rd Fleet. Third Fleet leads naval forces in the Pacific and provides realistic, relevant training necessary for an effective global Navy.

Quelle: dvids