29.08.2017

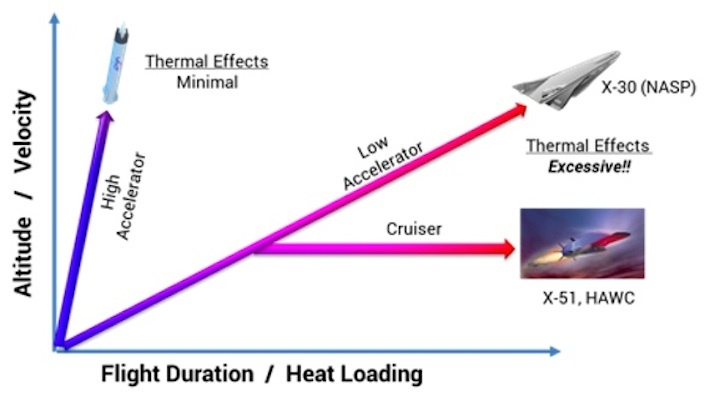

The idea of hypersonic, air-breathing launch systems brings to mind fast efforts like the X-30 National Aero-Space Plane (above), but such technology could be effective on a smaller scale for nanosatellite launch vehicles.

-

Fueled by nearly 20 years of consistent investment into both component- and system-level innovations, nanosatellites are revolutionizing the way satellite missions are being executed: faster and more affordably than ever. Significant strides in capability, combined with vastly lower manufacturing costs compared to traditional satellites, have made the deployment of nanosatellite constellations in low Earth orbit (LEO) for communications, imaging, and Earth observation missions achievable. Unfortunately for the nanosatellite industry, fully realizing their commercial and government market-based potential has been limited by a lack of access to appropriate, affordable launch opportunities. To establish and maintain a nanosatellite constellation cost-effectively, ideally, customers would be able to determine when and where each asset will go into LEO. However, this would require the nanosatellite customer to pay the majority, if not all, of the launch costs. With the cheapest launch vehicle costing around $30 million, this is far too expensive for nanosatellite customers. Even the smallest conventional rocket would still be a very large and costly vehicle to launch comparatively inexpensive nanosatellite-sized payloads to LEO.

| Solving the problems that all rocket-propelled launch vehicles impose on the nanosatellite community will require a paradigm shift in traditional launch vehicle design and reducing the lowest-cost single launch vehicle by at least an order of magnitude. |

Launch has always been the major bottleneck for traditional satellites, but its impact on the nanosatellite market sector is even more of a problem. As with all satellites, nanosatellites need to be placed in a specific orbit to maximize their utility. Getting to a specific orbit in a timely fashion is proving to be the real barrier to generating near-term revenue for the nanosatellite industry. Achieving a desired orbit is highly dependent on timing, the laws of physics, and geographical location, all of which have their challenges with the current launch options.

Today, the only option for nanosatellites to access space is to rideshare as secondary payload to a larger primary payload customer. Relegated to secondary status, nanosatellite customers are subject to the costly downside of being tied to the oft-unreliable schedules and suboptimal orbital destinations of primary payload customers. These launch barriers not only make establishing and replenishing nanosatellite constellations in LEO extremely difficult, they result in lead times that extend two to three years or more.

Arguably, one of the most detrimental side effects of this reality are the time-to-revenue models that many NewSpace startups are forced to contend with, as this not only curtails profitability, but confines nanosatellite companies to limited pool of investors who are willing, patient, and bold enough to place longer-term bets on “if-then” chances of a return on their investment. Ultimately, should these restrictive launch barriers persist, the overall growth of the nanosatellite market will unquestionably be constrained. Solving the problems that all rocket-propelled launch vehicles impose on the nanosatellite community will require a paradigm shift in traditional launch vehicle design and reducing the lowest-cost single launch vehicle by at least an order of magnitude.

Rockets alone aren’t the right-sized launch solution for nanosatellites…

Traditional launch vehicles utilize rockets for propulsion, and require approximately 90 percent propellant by weight to attain the change in velocity, delta-V, and altitude needed to place a payload in orbit. Rocket propellant includes both fuel and oxidizer, where the oxidizer represents two to eight times the weight of the fuel. These requirements dictate the minimum size that rocket-propelled launch vehicles must be to successfully orbit a payload. The smallest ground launched system to ever orbit a payload was the Japanese Lambda 4S, which was a four-stage vehicle with a gross lift-off weight (GLOW) of 9,391 kilograms, which placed approximately 22.6 kilograms into LEO. At 16.5 meters tall, this launch vehicle was a very large and heavy system for such a small payload. The US Vanguard rocket was a close comparison, being a three-stage vehicle with a GLOW of 10,050 kilograms, which successfully orbited a 23.6-kilogram payload in LEO. Similarly, this launch vehicle was a very large system for such a small payload. The challenge of substantially reducing the size and cost of vehicles demands that we move beyond using rocket propulsion as a sole means of accessing space.

To place a satellite in orbit, a launch vehicle must accelerate the mass to approximately 28,000 kilometers per hour. This requires the vehicle’s propulsion system to provide the delta-V from its initial launch speed to orbital velocity, and absorbing losses in delta-V due to gravity and drag. The delta-V of a vehicle is essentially a function of two terms: specific impulse and propellant mass fraction. The specific impulse, defined as the thrust divided by the propellant mass flow rate, is the typical figure of merit used to quantify the performance of propulsion systems. This is where rocket motors suffer because, as previously mentioned, the propellant includes both fuel and oxidizer, where their specific impulse has reached a maximum of approximately 300-350 lbf./(lbm.-sec) with available propellants. This upper limit forces design engineers to focus their attention on raising the propellant mass fraction to maximize delta-V. Unfortunately, propellant mass fraction tends to decrease with smaller launch vehicle designs. Design approaches that employ fewer stages to minimize manufacturing cost encounter the negative impact of needing more propellant, and larger tanks, to push a heavier inert mass to orbital velocity.

To produce a launch system that is significantly smaller, low-mass, and more affordable than traditional launch vehicles, engineers must look to a higher specific impulse system. This is where hypersonic air-breathing propulsion (HAP), specifically ramjets and scramjets, can have a significant impact and bring about a paradigm shift in the nanosatellite market.

Hypersonics: The launch solution for nanosatellites

Unlike rocket propulsion, HAP utilizes the air in the atmosphere for the oxygen required for combustion, which eliminates the need to carry oxidizer onboard the launch vehicle. HAP specific impulse values can be more than ten times that of rocket propulsion. A combination of rocket and air-breathing propulsion can deliver a substantial reduction in launch vehicle size, weight, and cost, and offer nanosatellite customers the flexibility of choosing when and where they go into LEO. To capitalize on the benefits of HAP, the launch system must operate in air-breathing propulsion mode as an accelerator over a large part of the trajectory to orbit. Since the vehicle is heaviest at launch, most of fuel is expended early in flight, which is where ramjet propulsion can play a key role.

| Hypersonic air-breathing propulsion (HAP), specifically ramjets and scramjets, can have a significant impact and bring about a paradigm shift in the nanosatellite market. |

Ramjet technology reached maturity in the late 1950s in the US. Early ramjet development efforts, like the Navy’s Bumblebee program, which began in the 1940s, relied heavily on flight testing and, as a result, were very successful. This approach led to the rapid fielding of the Navy ramjet powered surface-to-air missile, the Talos, in 1958. The Air Force fielded the only other ramjet-powered system, the Bomarc, in 1959, which was developed to intercept aircraft carrying nuclear bombs, far from populated areas. During the 1950s, NACA’s F-29 program also employed a high-frequency flight-testing development approach. Ramjet flight demonstrations carried out under this program reached acceleration rates of near 9 g at steep flight path angles, and maximum speeds of Mach 3.5. Further work conducted under the Bumblebee program produced the Mach 4.0-capable Typhon missile, but the program was cancelled before fielding as guidance systems at the time were too slow for effective control of the vehicle.

The Air Force’s long-range, ramjet powered Advanced Strategic Air Launch Missile (ASALM), was designed to operate at flight speeds of Mach 4 and logged seven successful flight tests between 1979 and 1980. During the first flight test, the ASALM vehicle accelerated from about Mach 2.0 to over Mach 5.5 when an anomaly occurred involving the fuel system. The fuel anomaly resulted in a flight test demonstration that covered nearly the full operational speed range of a ramjet with a relatively heavy vehicle and a fixed inlet geometry. By today’s standards, the development time for these systems was extremely rapid, which was undoubtedly due to their frequent and extensive flight-testing.

To attain flight speed above about Mach 6 requires the standard subsonic combustion ramjet to switch to supersonic combustion ramjet, dubbed scramjet, which, theoretically, can extend flight speeds to Mach 20 or higher. A single engine could be used to operate in either ramjet or scramjet mode over the widest possible flight speed range, which would enable a significant reduction in the size, weight, complexity, and cost of the vehicle. This dual mode ramjet, as it is called, was demonstrated at Mach 5 and Mach 6 during ground testing of the NASA Hypersonic Research Engine (HRE) program in the late 1960s and early 1970s. Switching between ramjet and scramjet modes was easily accomplished by adjusting fuel scheduling within the combustor. Scramjet work by Antonio Ferri and General Applied Sciences Lab (GASL) added to this with their work on three-dimensional, thermal compression scramjet inlets that demonstrated wide flight speed ranges with a fixed geometry engine. These were all significant advances that led to more interest in aerospace plane concepts.

Starting in the 1960s, NASA and the Air Force set their sights on an aerospace plane as a reusable, single-stage to orbit launch system that could take off and land on a runway. The most notable program was a joint effort between NASA and DoD called the National Aero-Space Plane (NASP) program that started in 1986. The NASP program utilized a combination of ramjets and scramjets in a crewed, reusable, single-stage to orbit (SSTO) vehicle. To gain the benefit of not carrying oxidizer onboard, the NASP vehicle had to cover a large portion of the delta-V needed for orbital velocity, while taking a longer aircraft like trajectory. No prototype vehicle was ever flight tested during NASP, as designing for vehicle thermal loading at hypersonic speeds within the atmosphere for a long period of time proved to be a formidable challenge. With the absence of flight tests during the NASP program, hypersonic system development was reduced to ground testing and numerical analysis, both of which require correlation and/or verification with flight test data.

After the more than $2 billion NASP program was cancelled, NASA picked up the baton and started the X-43A program, otherwise known as the Hyper-X program, which successfully demonstrated scramjet operation in the atmosphere up to Mach 10. Unfortunately, cost and fiscal pressures led to NASA shutting down much of the hypersonic air-breathing propulsion work for space access.

More recent interest in hypersonic systems has largely been focused on the development of long-range weapons systems. In 2002, the Office of Naval Research (ONR) and DARPA initiated the HyFly program, which aimed to demonstrate a hypersonic missile able to cruise at speeds of up to Mach 6 and a range of 1,100 kilometers using liquid hydrocarbon fuel. Unfortunately, the HyFly program scheduled only three flight tests, all of which ended prematurely because of subsystem anomalies that precluded any operational performance of the propulsion system. The Air Force X-51 program employed a waverider vehicle design, using a scramjet flowpath that employed a rocket boost to approximately Mach 5 before starting the scramjet. Four flight tests were conducted, but only two flights successfully demonstrated scramjet operation. The X-51 was the first ramjet system with an actively fuel-cooled structure to address longer operation requirements. Hypersonic weapon applications eliminated the wide flight speed operation, but, like NASP, the flight test results of the X-51 reiterated the thermal loading challenge.

| Hypersonic air-breathing propulsion holds the key to optimizing the utility of nanosatellite technology, and unharnessing the growth of the emerging nanosatellite market. |

The problem of thermal management continues to plague hypersonic system development. The aerospace plane must content with both a wide speed range for HAP and vehicle thermal loading. The long-range weapons eliminate the wide speed range, but thermal management continues to plague progress. The problem of responsive space access for nanosatellites brings about the application for HAP that eliminates the thermal loading issue by reducing the length of time a system is required to operate within the atmosphere. With a lightweight payload, a launch system propelled by a combination of air breathing and rocket propulsion can achieve high acceleration rates and execute a steeper flight path angle to orbit, which makes access to space for nanosatellites the ideal near-term application for capitalizing on HAP benefits. The current problem that traditional launch vehicles impose on the fast-emerging nanosatellite industry presents the perfect opportunity to give HAP new life and purpose, while addressing the need for far greater resilience and security in space and facilitating the sustained growth of the NewSpace industry.

Conclusion

Hypersonic air-breathing propulsion holds the key to optimizing the utility of nanosatellite technology, and unharnessing the growth of the emerging nanosatellite market. Affordable and reliable nanosatellite launch can be realized in an orbital launch system that utilizes a combination of rocket and HAP (i.e. ramjet/scramjet). This unique launch system presents the most viable pathway to drastically reducing the cost of accessing space. By keeping payload capability low, the trajectory of this unique type of launch vehicle is similar to that of an all-rocket vehicle, and eliminates major thermal management issues that continue to plague hypersonic weapon systems programs. Altogether, this innovative launch vehicle will deliver a significant reduction in both time and cost of development, while providing critical flight-test data to quickly and successfully bridge the gap in the development of hypersonic system design tools. A revolutionary vehicle that combines both HAP and rockets is the only viable way to significantly reducing the cost of launch and offering nanosatellite customers the control of when and where they go into orbit instead of having to acquiesce to the schedules and geographic limitations of traditional launch providers.