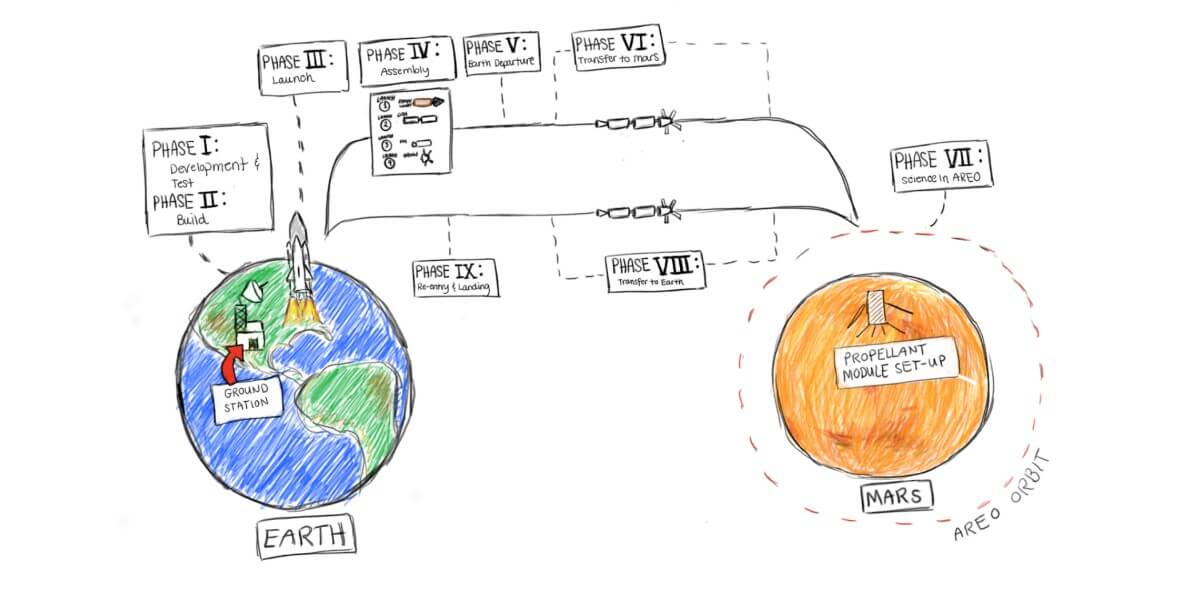

ASTE 421 STUDENTS DREW UP A 9 STEP OUTLINE OF THE RUBEUS MISSION. COURTESY OF LISA HILL

Looking To New Avenues

Humankind has been reaching for the stars ever since Yuri Gagarin became the first person in history to reach outer space on April 12, 1961. There have been a lot of other “firsts” in the 50 years of human spaceflight. But the golden ticket of missions in our current era, the one that organizations like NASA, SpaceX, and Novawurks are all aiming for, is the grand manned-mission to Mars. The Internet and news media are replete with theories on how to do it, down to ship models and plans drawn up by engineers and science fanatics alike.

For the Spring 2017 semester, astronautical engineering seniors got a chance to plan their own Mars mission in the capstone design course – ASTE 421: Space Mission Design.

Taught jointly by Professor David Barnhart and Dr. Lisa Hill, a systems engineer at Space Systems Integration, the course challenged students to design a transportation ship to go to and return from Mars, facilitate research, figure out how to sustain life for a multi-year mission, and lay the foundation for further interplanetary exploration.

The ten seniors and one junior who made up the class were given charge of their own “department” within the mission. Each department dealt with a critical piece of the trip, such as designing and analyzing the ship’s parts, the assembly, fueling, food and hygiene facilities, orbital projections of the departure and return trips, construction of a Mars science lander, risk control and more.

Upon project completion, the team was reviewed by a panel of space industry professionals, including engineers and analysts from SpaceX, NASA JPL, Boeing and Novawurks.

“I like what you think about,” Hill told her students. “Sometimes I don’t even think of the things you think of because you’re unconstrained.” She was referring to the unconventional, creative whims of inexperience and the hefty pressure of a short, five-month period to come up with a mission that was not only coherent but also comprehensive.

These were the project design requirements the ASTE 421 team had to live up to:

The space mission would have to sustain human life for the duration of the trip, conduct research on topics such as human endurance to deep space radiation and anti-gravity, and install foundational technologies required to sustain life on Mars. The rest she left to their imaginations.

“The mission requirements became useful when we had to figure out where to start in mission planning.” said Roberto Lopez, a senior astronautical engineering student.

“The bookkeeping and infrastructure for a group project of this scale is crucial,” Allie Gheris, another teammate, observed.

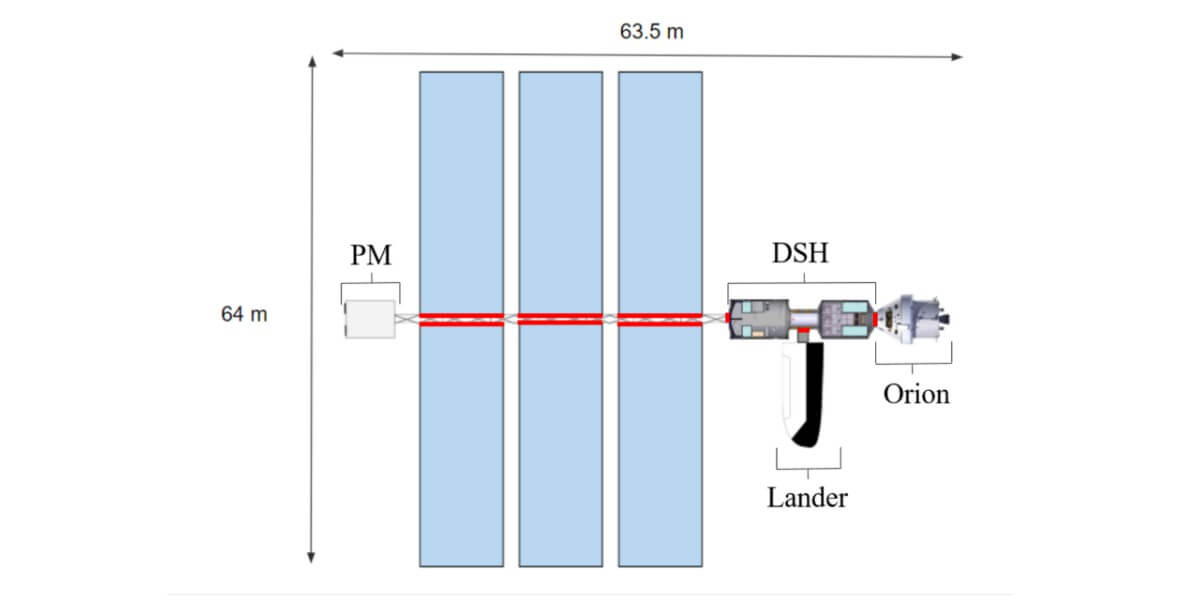

THE GROUP DESIGNED THE RUBEUS SHIP TO BE SOLAR-POWERED, COUPLED WITH A DSH, ATTACHED LANDER, AND ORION AT ITS HEAD. COURTESY OF LISA HILL

Project RUBEUS

What these students came up with was a practical design of a Mars ship named RUBEUS, fully equipped with astronaut quarters, research facilities, and a lander packed with machines to permanently install on the Martian surface. Solar-powered electric propulsion would send the crew to and from the Red Planet.

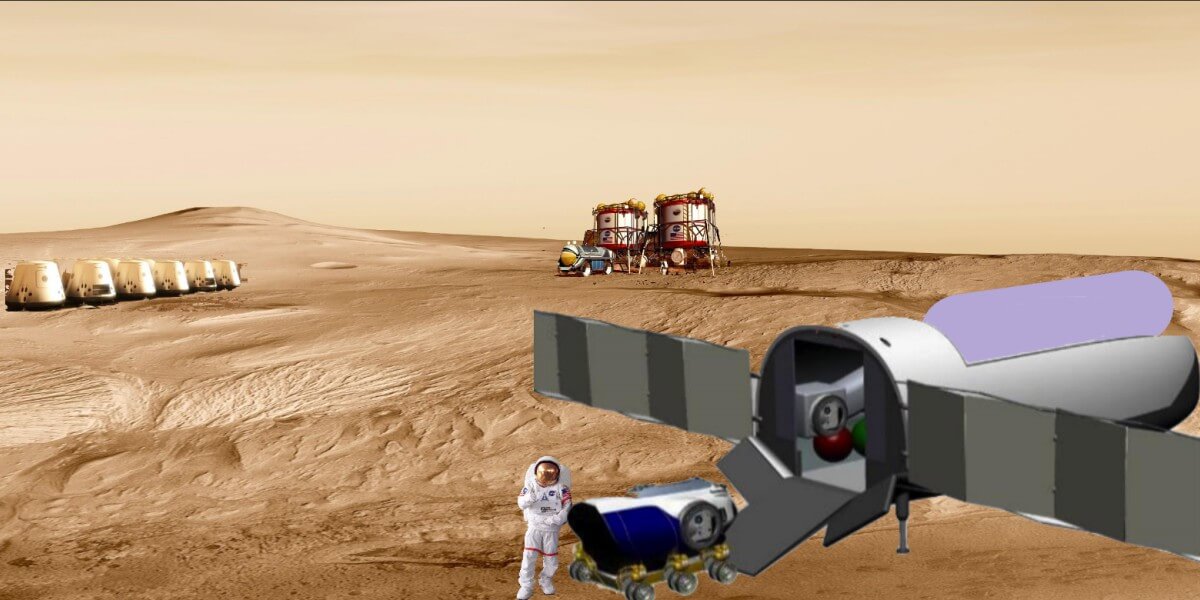

But this mission is no lunar landing. Mars’ terrain and atmosphere contains too many unknown factors to send astronauts down immediately. Instead of braving the grounds and sending the manned mission to the desert planet without extra resources, the team made “Project RUBEUS” a preparation.

The four astronauts would remain on the ship and enter Mars’ orbit, becoming the planet’s satellite. The ship would then deploy its lander and remotely control it’s descent.

However, landing on Mars is hard. Mars’ atmospheric pressure is less than 1 percent that of Earth, so engineers have to come up with a safe way to land spacecraft at a high velocity. The team designed a powered descent mechanism that would slow the lander down and ground on the widest surface to reduce impact and potential damage. In addition, this lander design serves as a risk reduction for future human colonization.

Once the dust clears, the lander would then open up to release drones and a rover for further exploration of the terrain as well as a few key machines.

One of these, a Regolith Advanced Surface Systems Operations Robot, or RASSOR rover, would drill into the ground and extract water from the icy dirt. Several other chemical manufacturing machines would separate oxygen, nitrogen and propellant and store them in polymer balloons for future astronauts to use after landing on the planet for the first time. This reduces the amount of cargo future missions require and ensures life support in an environment with limited resources.

Then, after the lander’s drop-off and set-up completes, the ship would have to remain in orbit for two more years before eventually slingshotting away from the planet for a return to earth. It would take an additional year of space travel before the crew would arrive home, the mission a success.

THE LANDER DEPOSITED BY THE RUBEUS SHIP WOULD FUNCTION AS A RESERVE BASE FOR FUTURE MISSIONS. COURTESY OF LISA HILL

The Industry Proposal

The team budgeted, broke down, and explained every detail of the long process. The project, proposed to take off in 2026, not only included the schematics of the ship but also the research process necessary to develop the technology before its maiden voyage. For example, solar power needs to be five percent more efficient by 2026 in order for the mission to be successful, so a part of the projected $8 billion budget would go towards solar panel enhancement.

Like in real life, it wasn’t an entirely seamless process. The students explained a few of the difficulties they encountered in working on such a large-scale project.

“You can’t really fix one system and have it be self-contained. You always need to consider other people’s work.” said Merritt Opdycke, a senior astronautical engineering student.

Despite their difficulties, the review panel was largely pleased with the presentation, which was reinforced by the group’s ability to consider and address weaknesses. The panel also offered industry advice, such as how the presentation would be received by professionals, what sort of communication processes would go into developing such a mission, and what factors needed to be considered first.

“It doesn’t matter who the people are, the process and struggle they go through is the same,” Hill said. “No magic technical solution exists.”

Barnhart and Hill hope to carry the momentum of the capstone class into the next semesters.

“This was an opportunity for students to know what aspect of the field they want to enter.” said Hill. “And a chance for me to see how well these large groups work together.”

Quelle: USC Viterbi School of Engineering