.

18.03.2016

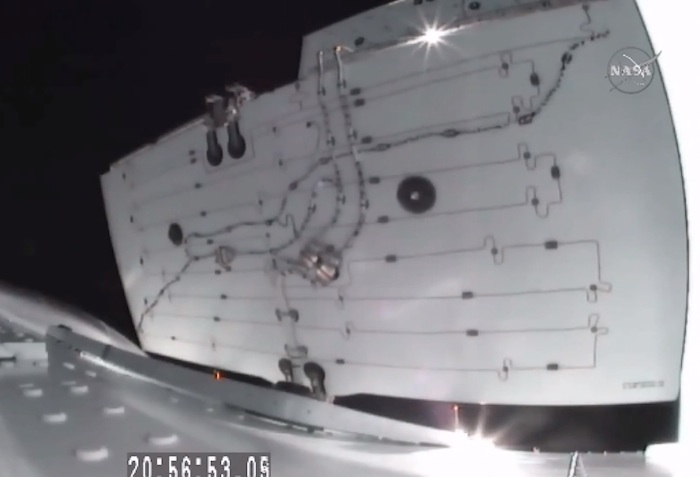

Expedition 39 crew members captured this image of the arrival, capture and berthing of the SpaceX Dragon cargo capsule at the International Space Station April 20, 2014.

Credits: NASA

-

Media accreditation now is open for the April launch of a cargo resupply service mission to the International Space Station. SpaceX’s Dragon cargo spacecraft is targeted for launch at 4:43 p.m. EDT Friday, April 8.

The Dragon capsule will launch on a Falcon 9 rocket from Space Launch Complex 40 at Cape Canaveral Air Force Station (CCAFS) in Florida, carrying science research, crew supplies and hardware to the orbiting laboratory in support of the Expedition 47 and 48 crews. The flight also includes the Bigelow Aerospace expandable habitat module that will be attached to the space station for testing. In its scheduled return to Earth in May, the Dragon capsule will bring back biological samples from astronauts, including those collected during NASA’s one-year mission. This launch is the eighth contracted mission by SpaceX under NASA’s Commercial Resupply Services contract.

Media prelaunch and launch activities will take place at CCAFS and at nearby NASA Kennedy Space Center. The deadline to apply for media access to Kennedy is 5 p.m., March 24 for non-citizens and 5 p.m. March 31 for U.S. citizens. The registration deadline for international media access to the Air Force station has passed for this event.

All media accreditation requests must be submitted online. International media are required to upload a scanned copy of their visa and passport or green card when submitting their online accreditation request.

Quelle: NASA

-

Update: 19.03.2016

.

INFLATABLE ADDITION TO THE SPACE STATION WILL LAUNCH IN APRIL

BIGELOW AEROSPACE IS SENDING UP AN EXPANSION PACK FOR THE ISS

BEAM Me Up

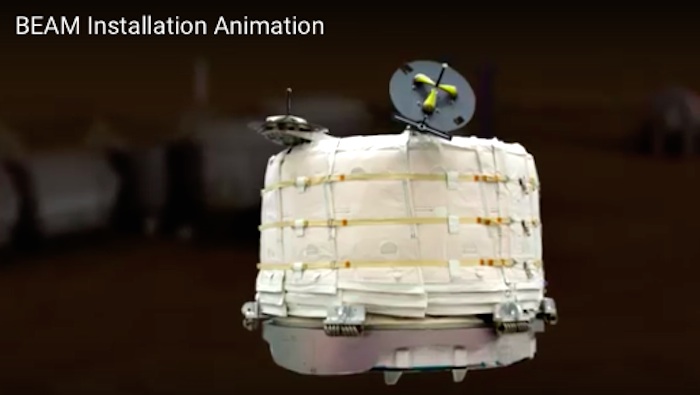

The Bigelow Expandable Activity Module (BEAM) is expected to arrive at the International Space Station in April.

The first astronauts on Mars probably won't live in a tin can like the International Space Station. Big, heavy structures are expensive to launch, and aren't great at protecting against the radiation they'd be pummeled with on Mars. Instead, the first Martians might live in something like a pop-up tent.

Bigelow Aerospace designs inflatable space habitats--lightweight modules that ride compacted in the trunk of a spacecraft, then expand to a much larger size in space. In a launch scheduled for April 8, the company is sending one of its modules up to the International Space Station for testing.

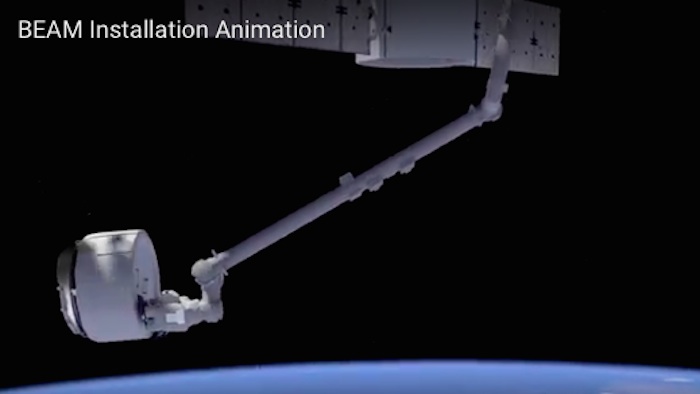

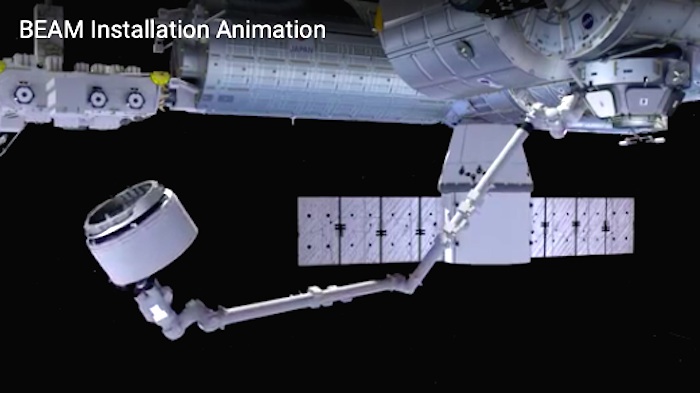

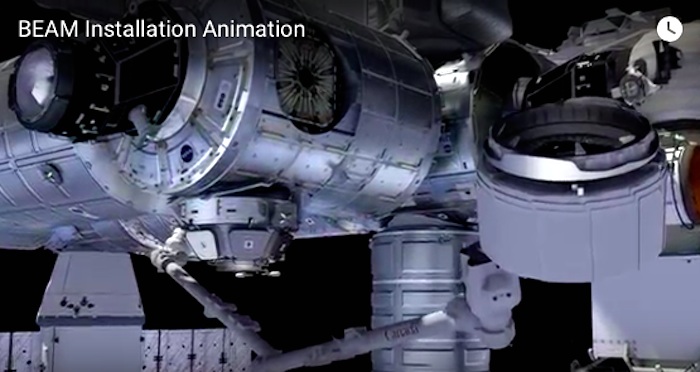

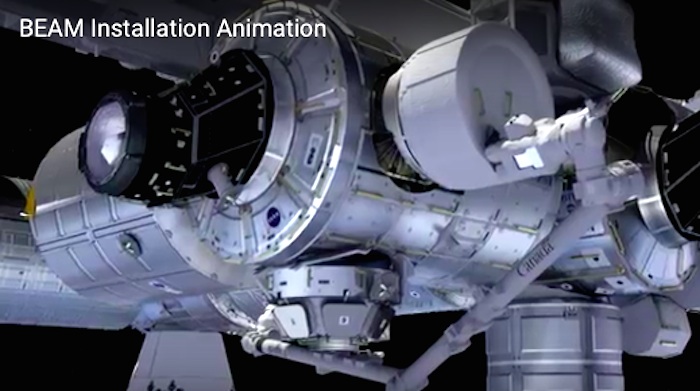

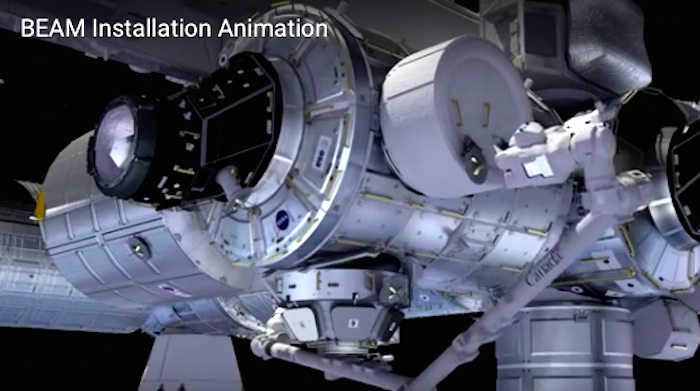

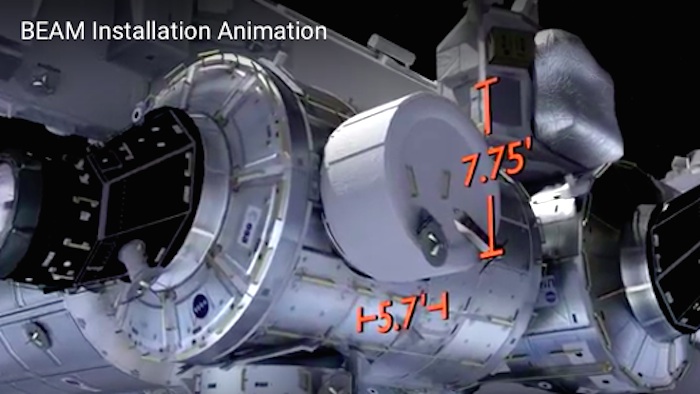

The module had previously been scheduled to launch in the fall of 2015, but after SpaceX suffered a rocket explosion in June, its missions to the ISS have been grounded.Next month, after SpaceX's Dragon capsule docks with the space station, one of the station's robotic arms will unload the Bigelow Expandable Activity Module, or BEAM, from the Dragon's trunk, and then install it to the station itself. Then the module will inflate to about 13 feet long and 10 and a half feet in diameter.

On the ISS, astronauts will monitor BEAM's pressure, temperature, and ability to deflect radiation and debris. The module will be closed off from the rest of the space station for most of the time, but occasionally astronauts will enter the BEAM to take measurements.

Bigelow has tested other small-scale versions in orbit, unmanned. Genesis I and II launched in 2006 and 2007, respectively, and are still helping the company assess the long-term safety of the design.

The BEAM module launching in April weighs 1,400 pounds. That may sound like a lot, but it beats the space station by a long shot. Whereas BEAM weighs an average of 5.46 pounds per cubic foot of space it provides, the ISS weighs 28.6 pounds per cubic foot.

.

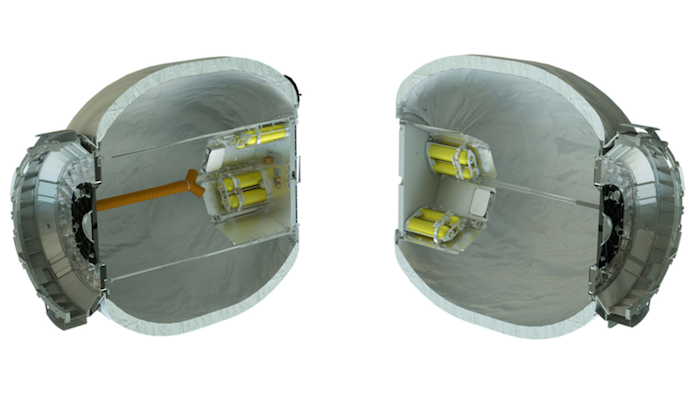

Inside the BEAM module

Bigelow's design stems from NASA's TransHab design, which stalled in the 1990s due to budget constraints. It uses a material called Vectran, which is said to be twice as strong as Kevlar. Because the material is flexible, the inflatable habitats are expected to be better than metal at protecting against radiation and micro-meteorite strikes. They'll absorb hits, rather than shattering on impact or scattering radiation like metal does.

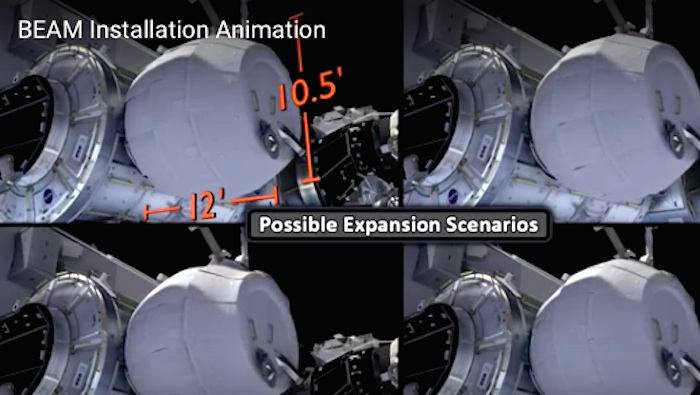

If the BEAM module performs well on the ISS, Bigelow hopes to launch a larger version within the next few years. Their pill-shaped BA-330 will be 45 feet long and 22 feet in diameter, and the modules can link together to form an even larger habitat.

The company envisions using the habitats to build private space stations and space hotels in orbit. And eventually, the inflatable domiciles could provide a home for astronauts colonizing the moon and Mars. BEAM us up, Bigelow!

Quelle: PS

-

Update: 20.03.2016

.

NASA is sending a 3D printer to space that you can use

NASA is preparing to send its first commercial manufacturing facility to the International Space Station (ISS). The 3D printing company Made in Space has partnered with NASA to send their Additive Manufacturing Facility (AMF) to the space station on a launch scheduled to take place next Tuesday.

.

Made in Space’s Additive Manufacturing Facility / Image courtesy of Made in Spac

.

Users on Earth can pay to use AMF, a 3D printer specially designed to operate in a microgravity environment, to print products on the space station. Once it arrives, Made in Space will be able to command AMF remotely from their headquarters in the NASA Ames Research Park.

Spencer Pitman, head of product strategy at Made in Space, told TechCrunch that the company has already secured 20 paying customers for AMF. Their customers include high schools that are hosting space-related design challenges, universities that will print medical research components, and companies that will print commercial parts for satellites and other spacecraft.

“We will even be printing a 3D printable exercise device for Autodesk and wrenches for Lowe’s,” Pitman said.

.

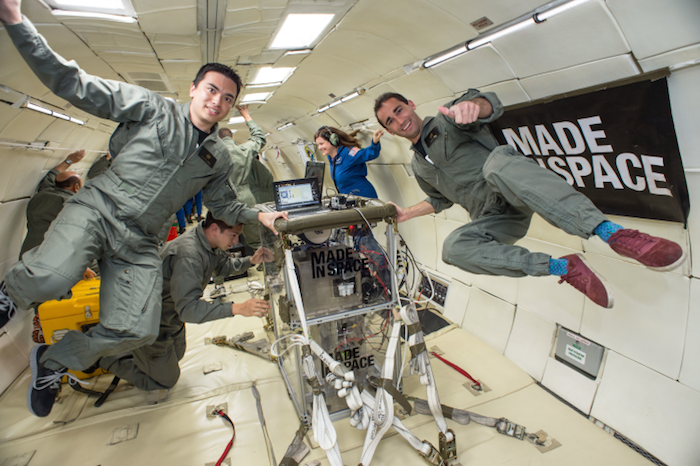

Made in Space testing their 3D printer on a parabolic flight / Image courtesy of NASA

AMF has been a few years in the making. Made in Space first demonstrated the capability to 3D print objects in a weightless environment in 2011 using parabolic flights. The company also sent an earlier version of their 3D printer to the ISS back in 2014. Known as the 3D Printing in Microgravity Experiment, their first printer conducted a series of tests with over a dozen different 3D printing materials.

Pitman stated that AMF improves on the 3D Printing in Microgravity Experiment in terms of robustness and longevity. AMF also includes a number of technology expansions and is able to manufacture products with over 30 different materials.

So why does NASA need a 3D printer on the space station in the first place? It has mostly to do with the amount of time and money it takes to send something into space. According to NASA, it costs roughly $10,000 to send just 1 pound of payload into orbit.

But Pitman says that the true cost is likely far higher than this because “all materials, parts, and hardware going to the station have to go through a lengthy and costly certification process.”

In addition to the hefty price tag, it takes over half a year to ultimately get your hardware on station. Even if you’re NASA, the wait times aren’t much better, which can be problematic if, for example, an ISS crew member misplaces or breaks a tool and quickly needs a replacement. In fact, the first tool that was uplinked to be 3D printed on the space station was a ratchet that would replace one that was lost.

.

Astronaut Barry Wilmore with a 3D printed ratchet / Image courtesy of NASA

With AMF, Made in Space aims to reduce both cost and wait times. According to Pitman, “Printing designs on AMF is comparatively immediate, and does not require the certification process since the materials we can print with have all gone through the certification process.”

Printing on AMF can help companies avoid the costly certification process and reduce the wait time to get to orbit. However, a 3D printer requires printing material which is just as costly as anything else to send to orbit. Because of this, Pitman said that the cost to 3D print on AMF will depend on the amount of print bed space taken up and generally ranges from $6,000 to $30,000, although there are discounts for STEM education initiatives.

So while 3D printing in space doesn’t come cheap, it could potentially be an attractive alternative for certain customers in unique situations. If anything, it’s an interesting new option that hasn’t been available up until now.

AMF is scheduled to launch on board the Cygnus cargo ship on Tuesday, March 22nd at 11:05 pm

Quelle: TC

.

Update: 21.03.2016.

.

SpaceX hopes to raise launch tempo after space station flight

.

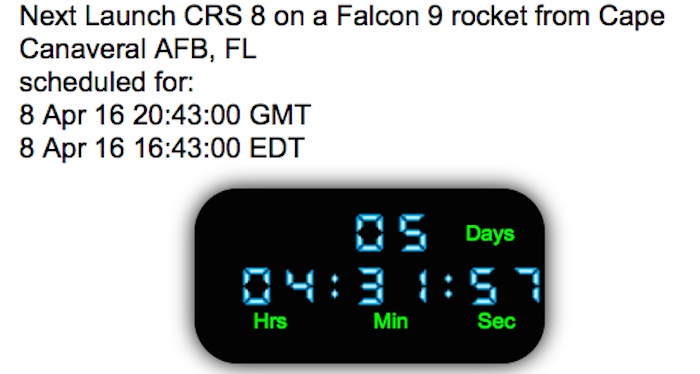

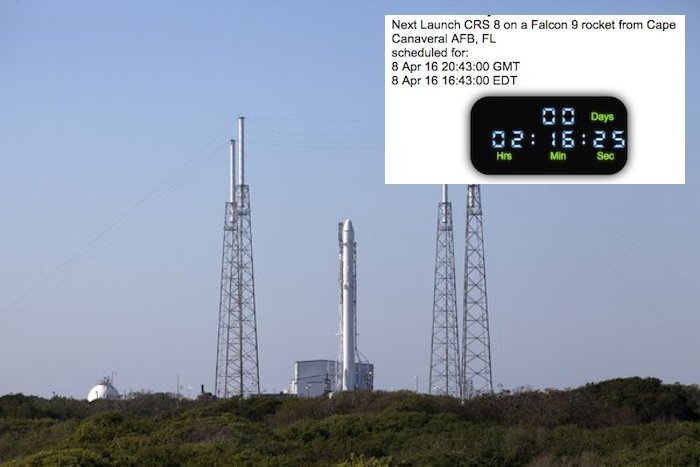

SpaceX is targeting April 8 for the launch of its first resupply run to the International Space Station in nearly a year, a mission that the company hopes will mark the start of a rapid-fire launch manifest full of payloads waiting to fly.

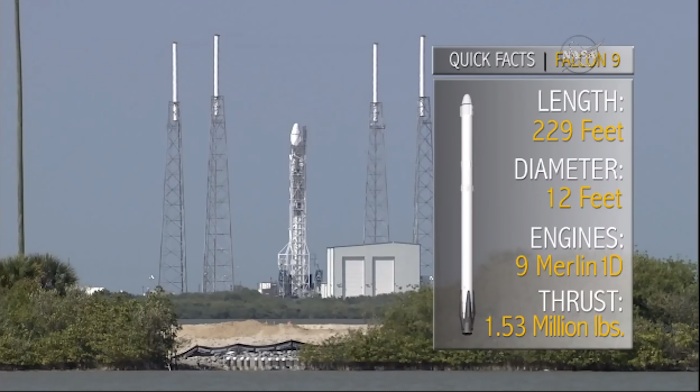

The early April blastoff aboard SpaceX’s Falcon 9 rocket will be the company’s eighth of at least 26 space station cargo missions under contracts to NASA.

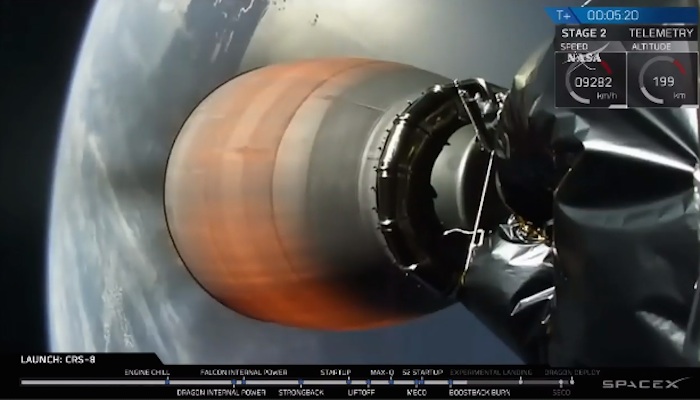

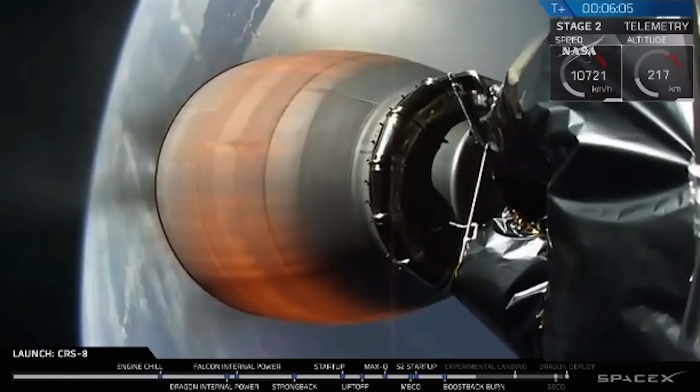

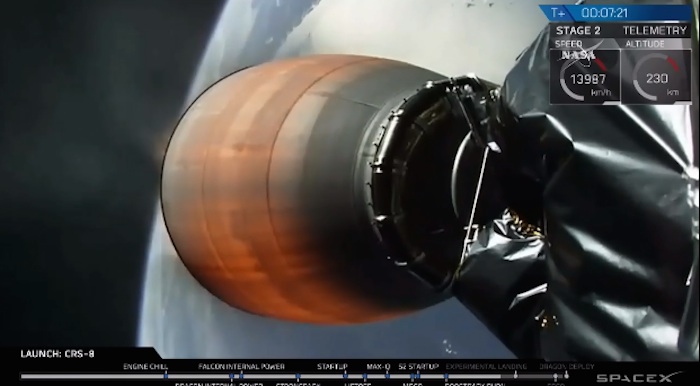

Launch of the Dragon supply ship from Cape Canaveral is set for approximately 4:43 p.m. EDT (2043 GMT) on April 8. It will mark the 23rd launch of SpaceX’s Falcon 9 rocket, and the third flight of an upgraded version of the two-stage booster burning densified, super-chilled liquid propellants.

The automated cargo capsule will reach the space station a few days later, delivering nearly 7,300 pounds (3,310 kilograms) of cargo, including spare parts, crew provisions, experiments and an experimental inflatable module to the research outpost.

SpaceX’s first cargo resupply contract signed in 2008 has been extended from 12 logistics missions to 20 flights, according to NASA. Orbital ATK, the other U.S. company currently flying supplies to the space station, initially had a contract for eight launches, and now is on the hook for 10 flights.

Both companies, plus newcomer Sierra Nevada Corp., won a fresh round of contracts with NASA in January to deliver cargo to the space station through 2024. The follow-on agreements guarantee each of the space transport providers at least six resupply missions to the space station.

SpaceX aims for up to 18 launches before the end of the year, three times more than the number of successful missions the company achieved in 2015.

“We hope to grow year-over-year,” said Gwynne Shotwell, president of SpaceX. “We only launched for half a year last year, and we still did six (successful) launches. This year, we’ll probably do about 18, and we’ll increase 30 to 50 percent year-over-year.”

Quelle: SN

-

Update: 29.03.2016

.

NASA’s Inflatable Room Is Almost Ready

After years of planning, the Bigelow BEAM module is due to arrive at the space station next month.

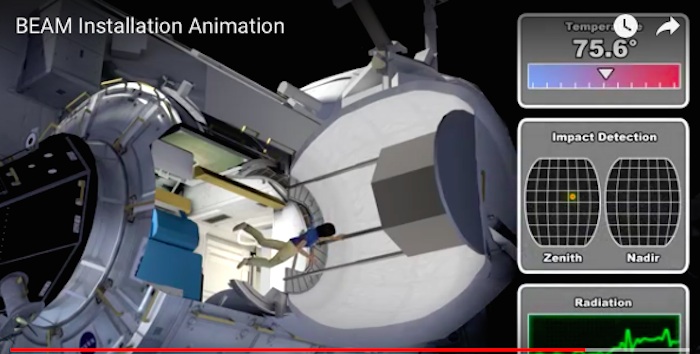

We’ve written about inflatable space habitats several times since our first article on the subject appeared in 1999. Now, after years of planning, Bigelow Aerospace’s BEAM (Bigelow Expandable Activity Module) is getting ready for an April 8 launch to the space station, packed inside the “trunk” of a SpaceX Dragon cargo ship.

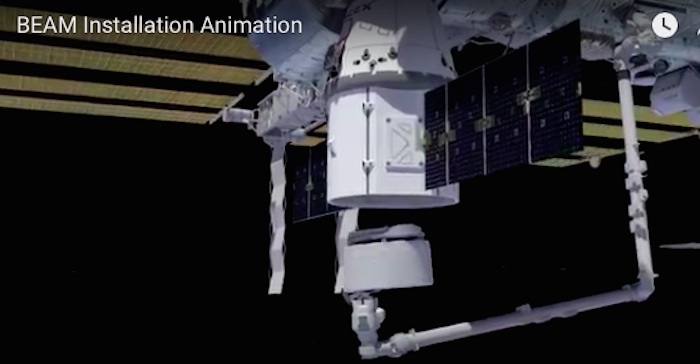

If the schedule holds, the Dragon will dock to the station a couple of days later. Then, sometime in late May or early June, ground controllers in Houston will use the station’s robotic arm to grab the BEAM and berth it to the orbiting outpost’s Tranquility node, where it will remain attached for the next two years.

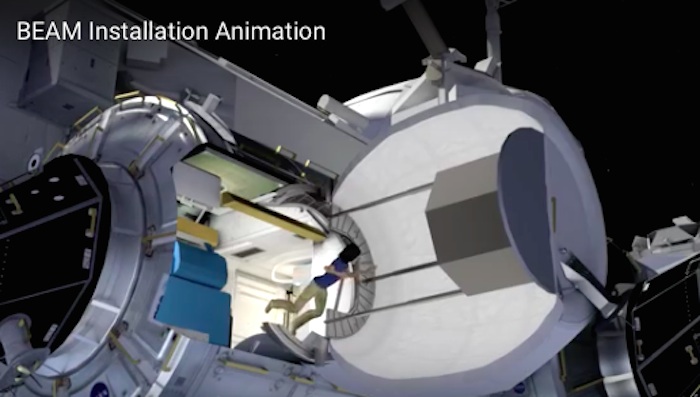

Once berthed, BEAM will take about 45 minutes to inflate to its full length and diameter (see the inflation sequence in the video above), after which it will have an internal volume comparable to a small room. The module is made of tough fabric of a propriety formula (think of a tough spacesuit rather than a thin balloon), and should behave pretty much like any metal module already attached to the station.

This first mission is all about testing. Sensors will monitor temperature and air pressure inside the BEAM, keep watch on radiation levels, and check for meteoroid impacts. The plan is for astronauts to enter the module just two or three times in the first six months, and then only for a few hours at a time, although they can visit more frequently if they choose. The hatch will stay shut when nobody’s inside.

Based on their experience with two previous Genesis modules, which are still in orbit even though they’re no longr returning data, Bigelow engineers expect the BEAM to prove as good as any other module attached to the station, which should open the way for even bigger inflatables in the future.

-

Anbringen von BEAM-Modul an ISS

Quelle: Air&Space

-

-

Update: 3.04.2016

.

-

Update: 6.04.2016

.

NASA Progresses Toward SpaceX Resupply Mission to Space Station

The Bigelow Expandable Activity Module (BEAM), developed for NASA by Bigelow Aerospace, is lifted into SpaceX's Dragon spacecraft for transport to the International Space Station when the spacecraft launches at 4:43 p.m. Friday, April 8, from Space Launch Complex 40 at Cape Canaveral Air Force Station (CCAFS) in Florida

Credits: SpaceX

-

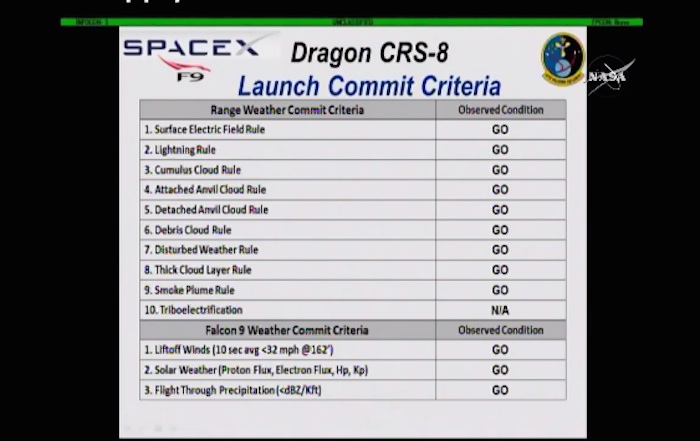

NASA provider SpaceX is scheduled to launch its eighth Commercial Resupply Services mission to the International Space Station on Friday, April 8. NASA Television coverage of the launch begins at 3:30 p.m. EDT.

The SpaceX Dragon spacecraft is targeted to lift off on the company's Falcon 9 rocket at 4:43 p.m. from Space Launch Complex 40 at Cape Canaveral Air Force Station (CCAFS) in Florida, carrying science research, crew supplies and hardware to the orbiting laboratory in support of the Expedition 47 and 48 crews.

NASA TV also will air two briefings on Thursday, April 7. At 1 p.m., scientists and researchers will discuss some of the investigations to be delivered to the station, followed by a briefing by mission managers at 3:30 p.m. The briefings also will stream live on the agency’s website.

About 10 minutes after launch, Dragon will reach its preliminary orbit, deploy its solar arrays and begin a carefully choreographed series of thruster firings to reach the space station.

The spacecraft will arrive at the station Sunday, April 10, at which time NASA astronaut Jeff Williams and ESA (European Space Agency) astronaut Tim Peake will use the station’s robotic arm to capture the Dragon spacecraft. Ground commands will be sent from Houston to the station’s arm to install Dragon on the bottom side of the Harmony module for its stay at the space station. Live coverage of the rendezvous and capture will begin at 5:30 a.m. on NASA TV, with installation set to begin at 9:30 a.m.

The following day, the crew will pressurize the space between the station and Dragon and open the hatch between the two spacecraft.

The Dragon spacecraft will deliver almost 7,000 pounds of supplies and vehicle hardware to the orbital outpost and its crew. The cargo includes the Bigelow Expandable Activity Module (BEAM), which will be attached to the space station to test the use of an expandable space habitat in microgravity. Scheduled to return to Earth in May, the Dragon spacecraft will bring back biological samples from astronauts, including those collected during NASA’s one-year mission.

The new experiments arriving to the station will help investigators study muscle atrophy and bone loss in space, use microgravity to seek insight into the interactions of particle flows at the nanoscale level and use protein crystal growth in microgravity to help in the design of new drugs to fight disease.

Dragon is scheduled to return to Earth on May 11. About five-and-a-half hours after it leaves the station, it will splash down in the Pacific Ocean off the coast of Baja California.

Media at the agency’s Kennedy Space Center in Florida will have the opportunity to participate in special tours and briefings on April 7 and 8, as well as view the launch. The deadline for media to apply for accreditation for this launch has passed. For more information about media accreditation, contact Jennifer Horner at 321-867-6598 or jennifer.p.horner@nasa.gov.

If the launch does not occur on Friday, April 8, the next launch opportunity is 4:20 p.m. Saturday, April 9, with NASA TV coverage starting at 3:15 p.m.

Quelle: NASA

-

Update: 8.04.2016 / 20.26 MESZ

.

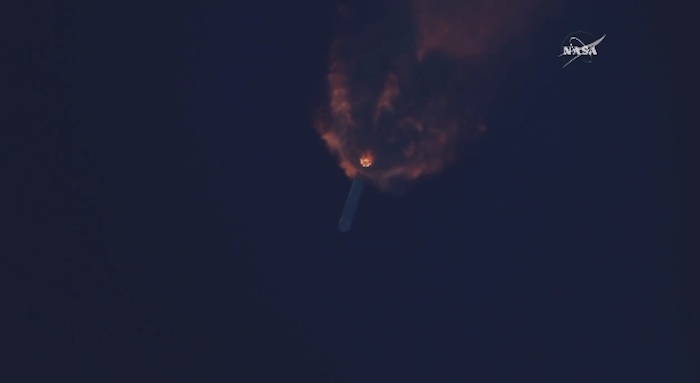

Start von SpaceX-8 Dragon Cargo LIVE-Frams

...21.42 MESZ

.

...21.58 MESZ

...22.16 MESZ

...22.36 MESZ

...23.00 MESZ

...Quelle: NASA-TV

Quelle: SpaceX

5048 Views