.

11.02.2016

Major work is beginning in three Alabama communities on a 213-foot, 230,000-pound simulation of the core stage of NASA’s new rocket, the Space Launch System (SLS).

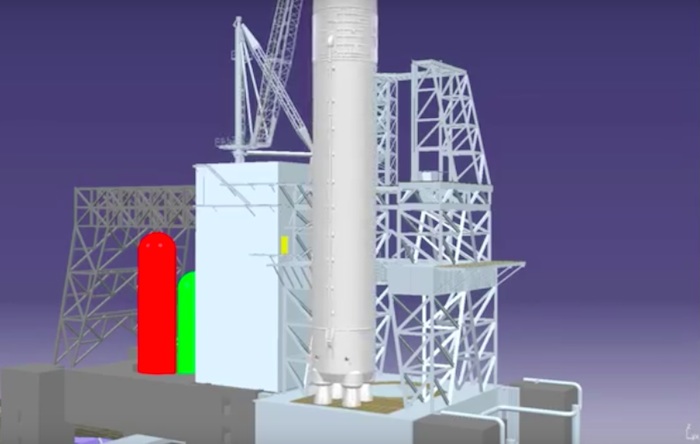

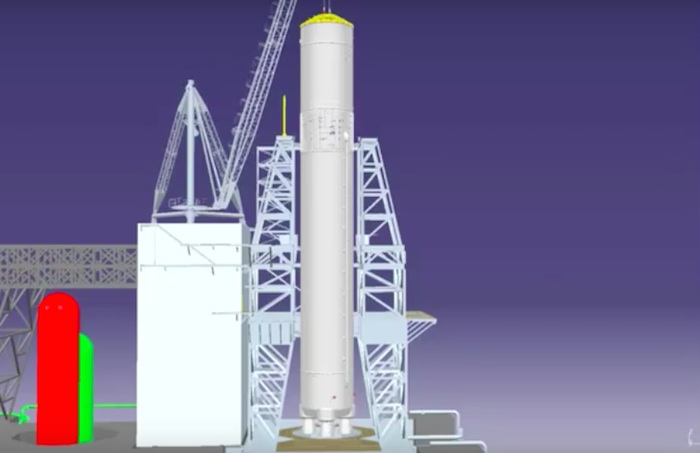

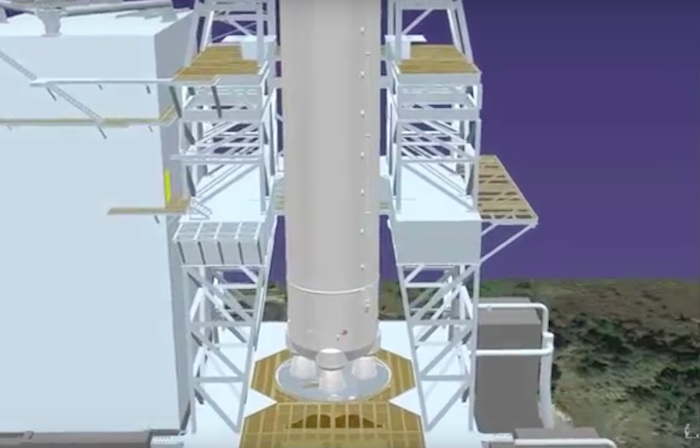

SLS will be the world’s most powerful rocket for deep-space missions. The core stage, with flight hardware currently in production at NASA’s Michoud Assembly Facility in New Orleans, will stand more than 200 feet tall and store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines.

The steel mockup, designed by engineers at NASA’s Marshall Space Flight Center in Huntsville, Alabama, will demonstrate core stage operations and transportation, including routes for testing, assembly and launch. “This hardware is an excellent proving ground for the core stage -- from manufacturing and assembly to the launch site,” said Shane Carpenter, engineering lead on the core stage pathfinder project at Marshall. “We don’t want the first time we transport the core stage to be with flight hardware. That’s why having a pathfinder is critical to the program.”

Radiance Technologies of Huntsville recently was selected by NASA to build, assemble and transport the pathfinder vehicle. The low-cost, core stage reproduction will be built at Dynetics’ facility in Huntsville and G&G Steel in Russellville, Alabama. It will be a “shell” of the core stage, with no engines or avionics.

“We look forward to working with these companies on such an important project for SLS,” said David Adcock, Stages pathfinder project lead at Marshall. “We want to ensure that the form and fit of the entire process for the core stage is successful, and any issues are addressed, before the flight hardware leaves Michoud. It helps reduce risk and keeps us on schedule.”

After manufacturing, the high-precision pieces will be trucked to the G&G Steel plant in the small town of Cordova, Alabama, for final welding and assembly. The company stands close to the Black Warrior River, where the pathfinder will travel by barge to Michoud. Transport will be done by Barnhart Crane and Rigging of Huntsville.

The pathfinder is scheduled to be completed and delivered to NASA in early 2017.

Once the pathfinder is successfully delivered to Michoud, NASA will place it on the Pegasus barge to further validate all modifications made to the vessel for core stage transportation. Refurbishments have been made to the barge to accommodate the sheer size of the massive core stage include a new, 165-foot center section, which brings the total length of the barge from 260 feet to 310 feet -- a little more than the length of a football field.

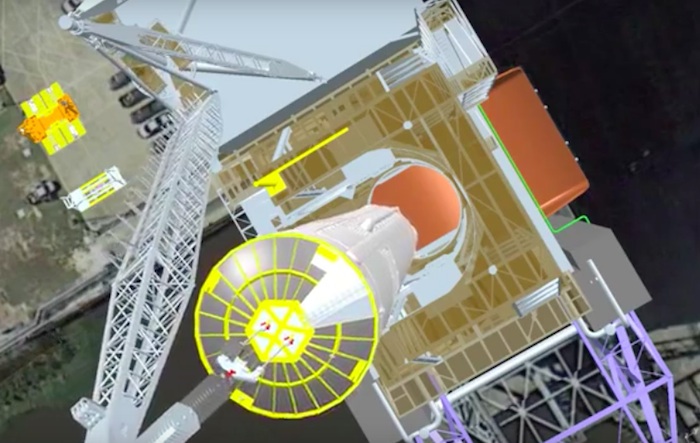

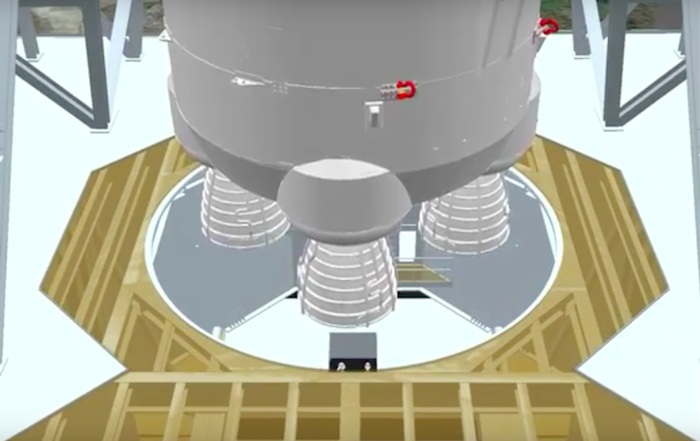

The mockup then will be shipped to NASA’s Stennis Space Center near Bay St. Louis, Mississippi, and fit vertically in the B-2 test stand. The test stand is being completely refurbished for core stage testing in 2017. The pathfinder will travel again to NASA’s Kennedy Space Center in Florida and placed vertically in the Vehicle Assembly Building, which also is undergoing major renovations for SLS. At both locations, the pathfinder will be used to ensure all modifications meet SLS core stage specifications.

The SLS Block I configuration will have a minimum 70-metric-ton (77-ton) lift capability and be powered by twin boosters and four RS-25 engines. The next planned upgrade of SLS, Block 1B, would use a more powerful exploration upper stage for more ambitious missions with a 105-metric-ton (115-ton) lift capacity. Block 2 will add a pair of advanced solid or liquid propellant boosters to provide a 130-metric-ton (143-ton) lift capacity. In each configuration, SLS will continue to use the same core stage and four RS-25 engines.

.

QMajor work is under way on a 213-foot, 230,000-pound simulation of the core stage of NASA’s new rocket, the Space Launch System (SLS). The steel mockup, designed by engineers at NASA’s Marshall Space Flight Center in Huntsville, Alabama, will be used to demonstrate core stage operations, transport and routes for testing, assembly and launch. Radiance Technologies of Huntsville recently was selected by NASA to build, assemble and transport the pathfinder vehicle. The low-cost, core stage reproduction will be built at Dynetics’ facility in Huntsville and G&G Steel in Russellville, Alabama. The animation shows how the pathfinder will be placed vertically in the B-2 test stand at NASA's Stennis Space Center near Bay St. Louis, Mississippi. The test stand is being completely refurbished for core stage testing in 2017, and the pathfinder will be used to ensure all modifications made to that test stand meet SLS core stage specifications.

Quelle: NASA

-

Update: 17.02.2016

.

A liquid hydrogen tank weld confidence article, at left, for the core stage of NASA’s new rocket, the Space Launch System, recently was completed on the Vertical Assembly Center at Michoud Assembly Facility in New Orleans. The completed confidence article, consisting of a dome and two barrels, verifies weld procedures are working as planned and tooling-to-hardware interfaces are correct. It also gives the weld team experience in bringing all aspects of hardware, tooling and software together to create a tank. Once a confidence article is completed, the structural qualification article is welded, which closely replicates flight hardware and processing procedures. The structural qualification article will be rigorously tested as part of the design verification process for the core stage. The Vertical Assembly Center is the largest spacecraft welding tool in the world and is part of six state-of-the-art tools designed to weld the core stage of SLS. More than 50 pieces of flight and qualification hardware for the core stage liquid oxygen and liquid hydrogen tanks have been completed and are ready for welding in the Vertical Assembly Center at Michoud. A fish-eye lens was used to capture the scale of the machinery.

Quelle: NASA

4800 Views