.

25.08.2014

SHELTER FROM THE SUN

Here on Earth, under the protection of the layers of our atmosphere, we can still find the heat from the Sun sometimes almost unbearable. This is also a problem for space-based telescopes like the James Webb Space Telescope (JWST).

Once in its operational orbit, JWST will be exposed directly to the Sun’s intense glare – not ideal when most of JWST needs to be kept at very cool, infrared-friendly temperatures. To cater for this, the observatory needs to be equipped with a protective parasol.

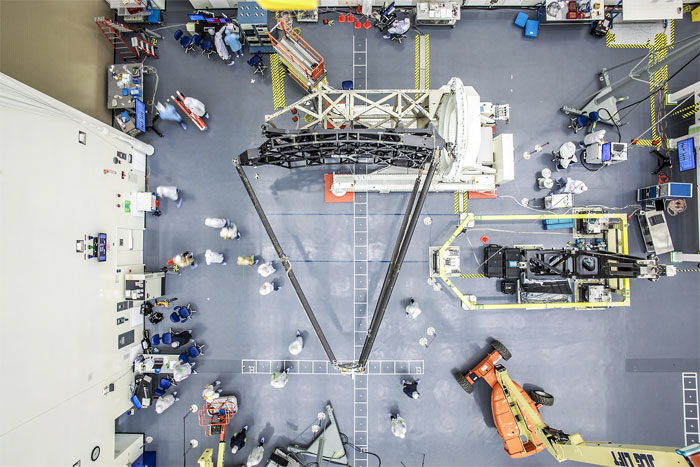

The kite-shaped piece of foil shown here is the sunshield test unit for JWST. This image captures the first time the deployment of the sunshield was fully and successfully tested, at a cleanroom in the Northrop Grumman facility in Redondo Beach, California, USA, during the first week of July 2014.

This sunshield is the largest part of JWST and offers intense protection from the Sun, letting through less than a millionth of the Sun’s heat! This massive parasol is as long as a tennis court, but incredibly light. It is composed of five super-thin membranes that will separate and unfurl into a precise arrangement once the telescope is in space. During launch, this shield will be folded up like an umbrella to fit neatly around the telescope’s mirrors and other instruments within the Ariane 5 rocket fairing.

When unfurled, the sunshield will protect JWST’s ‘cold’ side, where very sensitive infrared instruments are located inside the Integrated Science Instruments Module, maintaining a thermally stable cold environment, around –233 ºC!

Thanks to the sunshield, these low temperatures are reached passively, without the help of any active cooling system, by radiating heat into deep space. Just one of JWST's instruments, the Mid-Infrared Instrument (MIRI), will be cooled even further by a dedicated cryogenic cooler, reaching around –266 ºC. Although parts of JWST will reach such low temperatures, the shield will create a thermal barrier so that on JWST’s ‘hot’ side, the spacecraft electronics can work at room temperature.

Unlike its predecessor, the Hubble Space Telescope, JWST does not have a baffle protecting its optics from unwanted incoming light. This makes the sunshield’s role even more important because it will not only block heat, but also unwanted light, allowing JWST to operate to the best of its near-infrared capabilities.

When completed, JWST will be the most powerful space observatory ever built. JWST is an international collaboration between NASA, ESA and the Canadian Space Agency.

Quelle: ESA

.

Update: 31.08.2014

.

A "NIRSpec-tacular View" of NASA's Webb Telescope Instrument

Photo Credit: NASA/Chris Gunn

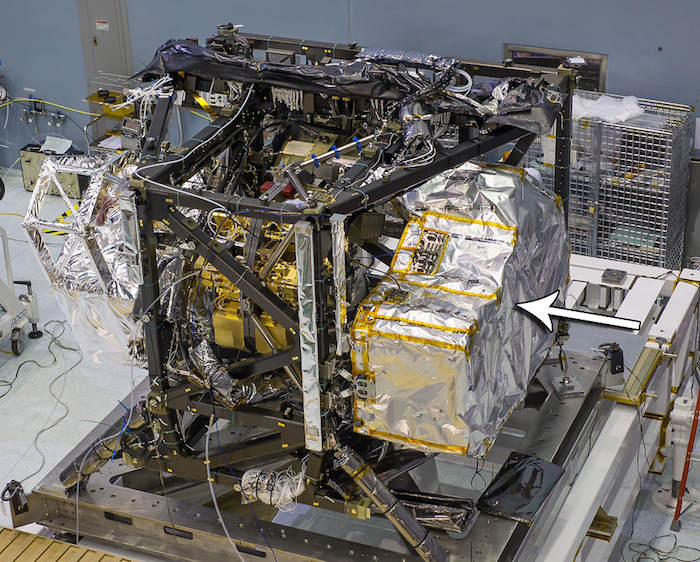

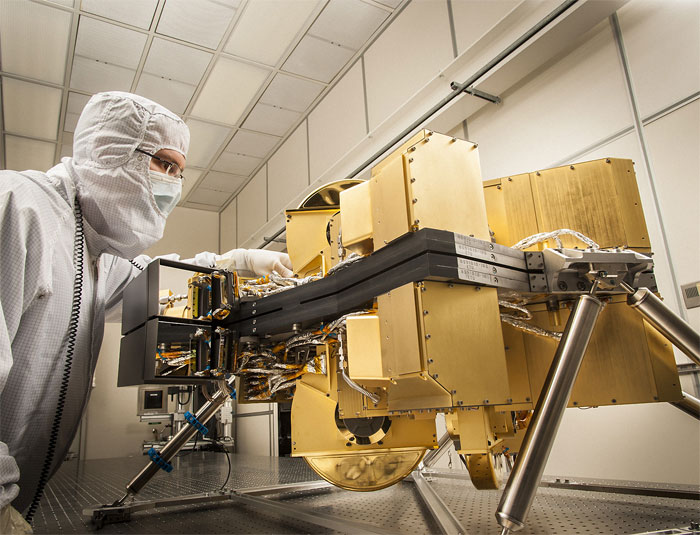

A NASA photographer recently captured a "NIRSpec-tacular" photo of an instrument that will fly aboard NASA's James Webb Space Telescope when it launches in 2018.

Access into a clean room to get a close-up view of a complicated, high-value scientific instrument is carefully controlled, but NASA photographers get such exclusive entry all the time. Photographer Chris Gunn took this image of the NIRSpec instrument inside the giant cleanroom at NASA's Goddard Space Flight Center in Greenbelt, Maryland.

The Near-Infrared Spectrograph or NIRSpec is a multi-object spectrograph, which is a tool for observing many objects in the cosmos simultaneously. The NIRSpec takes in light from around 100 distant objects and records their spectra (band of colors produced when sunlight is passed through a prism), separating the light into its components using prisms and other optical devices.

The NIRSpec will join three other Webb science instruments that will be mounted on the Integrated Science Instrument Module (ISIM). The ISIM structure is like the frame of a in a car providing support for the engine and other components.

In the photo, the NIRSpec is the large silver mass on the right-hand side. The silver frame-like object on the left side is part of the ISIM structure.

The NIRSpec can gather data on over 100 objects at the same time over a 9-square-arcminute field of view (the sun seen from Earth is about 32 arcminutes across). The NIRSpec will be the first spectrograph in space that has this remarkable multi-object technology. To make it possible, Goddard scientists and engineers had to invent a new device using a microshutter system to control how light enters the NIRSpec.

NIRSpec weighs about 430 pounds (195 kg), about as much as an upright piano. It is one of four instruments that will fly aboard the Webb telescope. The other instruments include the Near-Infrared Camera (NIRCam), the Mid-Infrared Instrument (MIRI) and the Fine Guidance Sensor/ Near InfraRed Imager and Slitless Spectrograph (FGS/NIRISS).

The ISIM and NIRSpec are now in a months-long cryo-vacuum test. This test duplicates the vacuum and extreme temperatures of space to ensure that the ISIM and the NIRSpec can function properly in those conditions.

NIRSpec was provided by the European Space Agency and built by Airbus Defense and Space in Germany. Webb is an international project led by NASA with its partners the European Space Agency and the Canadian Space Agency.

Quelle: NASA

.

Update: 5.09.2014

.

NASA Engineers Conduct Low Light Test on New Technology for Webb Telescope

NASA engineers inspect a new piece of technology developed for the James Webb Space Telescope, the micro shutter array, with a low light test at NASA's Goddard Space Flight Center in Greenbelt, Maryland. Developed at Goddard to allow Webb's Near Infrared Spectrograph to obtain spectra of more than 100 objects in the universe simultaneously, the micro shutter array uses thousands of tiny shutters to capture spectra from selected objects of interest in space and block out light from all other sources.

The James Webb Space Telescope is a large space telescope, optimized for infrared wavelengths. It is scheduled for launch later in this decade. Webb will find the first galaxies that formed in the early universe, connecting the Big Bang to our own Milky Way galaxy. Webb will peer through dusty clouds to see stars forming planetary systems, connecting the Milky Way to our own solar system.

Quelle: NASA

.

Update: 22.10.2014

.

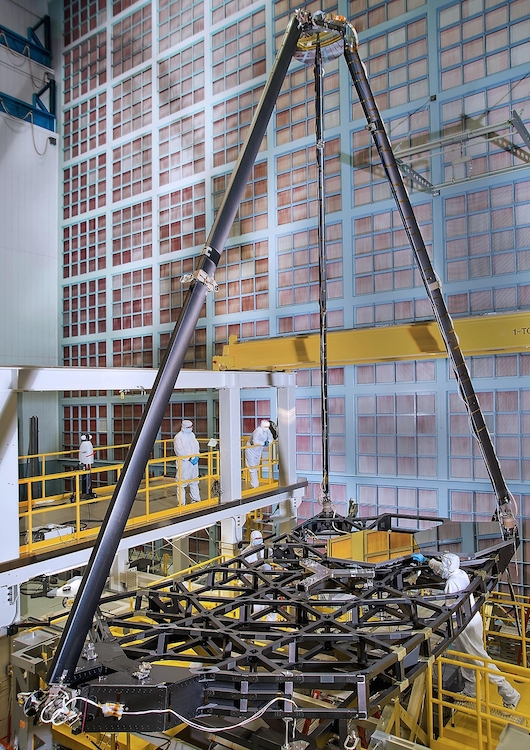

NASA Webb's Heart Survives Deep Freeze Test

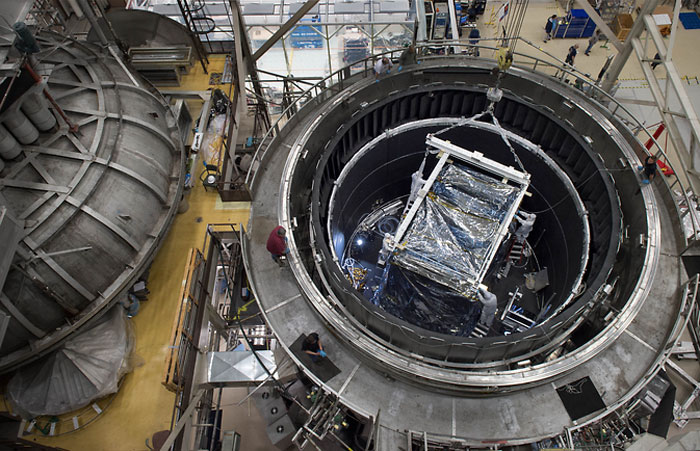

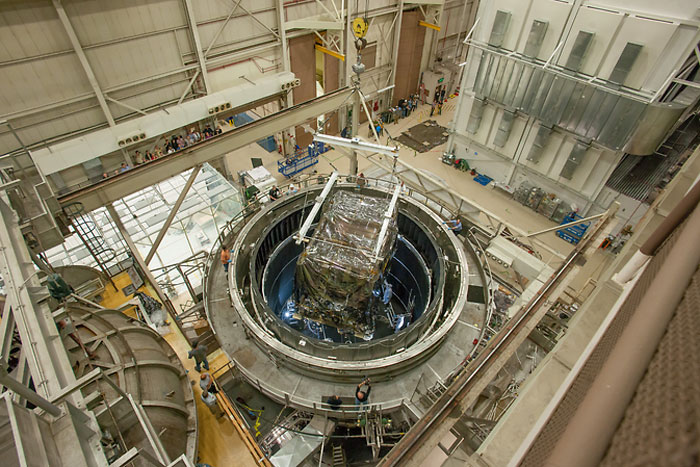

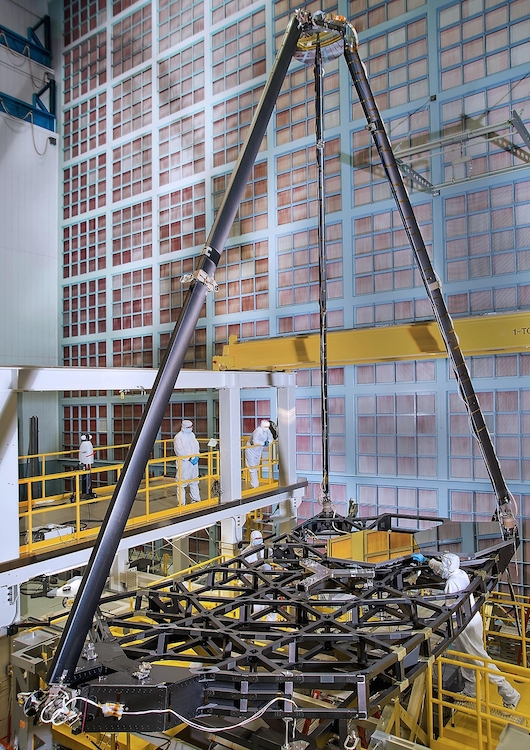

A crane lifts the heart of the James Webb Space Telescope from the Goddard Thermal Vacuum Chamber where it spent weeks in a space-like environment.

Image Credit: NASA/Chris Gunn

.

After 116 days of being subjected to extremely frigid temperatures like that in space, the heart of the James Webb Space Telescope, the Integrated Science Instrument Module (ISIM) and its sensitive instruments, emerged unscathed from the thermal vacuum chamber at NASA’s Goddard Space Flight Center in Greenbelt, Maryland.

Teams of engineers and technicians have been on heart-monitoring duty around the clock since this complicated assembly was lowered into the chamber for its summer-long test.

Engineer Mike Drury, the ISIM Lead Integration and Test Engineer, is one of the test directors making sure that Webb will thrive in the frigid conditions at its final destination in space one million miles away from Earth. "The telescope is going to L2 or Lagrange Point 2, which is a very extreme environment," said Drury. "The heart of Webb called ISIM is a very important part of the observatory and will provide all of Webb's images."

These images will reveal the first galaxies forming 13.5 billion years ago. The telescope will also pierce through interstellar dust clouds to capture stars and planets forming in our own galaxy. Operating a telescope powerful enough to complete these tasks requires incredibly cold temperatures.

How cold? Try -387 degrees Fahrenheit, or 40 degrees Kelvin. This is 260 degrees Fahrenheit colder than any place on the Earth’s surface has ever been. To create temperatures that cold on Earth, the team uses the massive thermal vacuum chamber at Goddard called the Space Environment Simulator, or SES, that duplicates the vacuum and extreme temperatures of space. This 40-foot-tall, 27-foot-diameter cylindrical chamber eliminates the tiniest trace of air with vacuum pumps and uses liquid nitrogen and even colder liquid helium to drop the temperature simulating the space environment.

"We complete these tests to make sure that when this telescope cools down, the four parts of the heart are still positioned meticulously so that when light enters the telescope we capture it the right way," said Paul Geithner, Webb's deputy project manger. "The biggest stress for this telescope will be when it cools down. When the telescope structure goes from room temperature to its super cold operating temperature, it will see more stress from shrinkage than it will from violent vibration during launch,” said Geithner.

NASA photographer Desiree Stover captured the photo of ISIM as it was lowered into the chamber for testing. The heart of the telescope weighs about as much as an elephant. Inside its black composite frame the four science instruments are tightly packed and are specially designed to capture specific information about distant light in the universe.

.

A crane lowers the heart of the James Webb Space Telescope into the Goddard Thermal Vacuum Chamber where it will spend 116 days in a space-like environment.

.

"When I first started here at Goddard, the ISIM structure was completely bare," said Stover who has been at Goddard for two years. "Leading up to this test all four science instruments were integrated onto it, along with heat straps, harnesses and blankets."

.

The view from inside NASA Goddard's Thermal Vacuum Chamber shows the JWST heart being lowered by crane in preparation of weeks of space environment testing.

.

Tightening the bolts and putting everything together beforehand required very dedicated teams. "When ISIM was lowered into the chamber at the start of the test, that was a pretty emotional moment that represented an intense amount of work," said Marc Sansebastian, a mechanical assembly, integration and test technician. "After ISIM traveled overhead, we shifted back to technical mode because there are a million things that happen that you don't see."

At any given time of day during the test, the control room held representatives from all four-instrument teams. Each instrument has a test engineer, who makes sure the test is going well, and a data analyzer. Those teams are testing the hundreds of electrical connections and computer programs that give life to Webb's heart. "Kind of like having a car in a garage in the winter. You want to check the car to make sure that it is still working," said Alistair Glasse, instrument scientist for the Mid-Infrared Instrument (MIRI).

"The weather this year was phenomenal for the test. When the weather is bad, when it's humid and when it gets stormy that's when we run into problems with the chamber," said Ray Lundquist, ISIM Lead Systems Engineer. "At the beginning of the test, we had a couple of storms and the building got hit by lightning that shut the whole system down for 30 minutes, but since that storm we have had really great weather."

Once the test was completed, the team warmed up the chamber, and completed the final functional test and a series of data analyses before they opened up the chamber.

"We've been very fortunate on this test. We've worked with all of the different teams. We have all been working shifts and pitching in," said Drury. "I'm really amazed at how well everyone is getting along together. We have a lot of people who are willing to help out."

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Quelle: NASA

.

Update: 29.11.2014

.

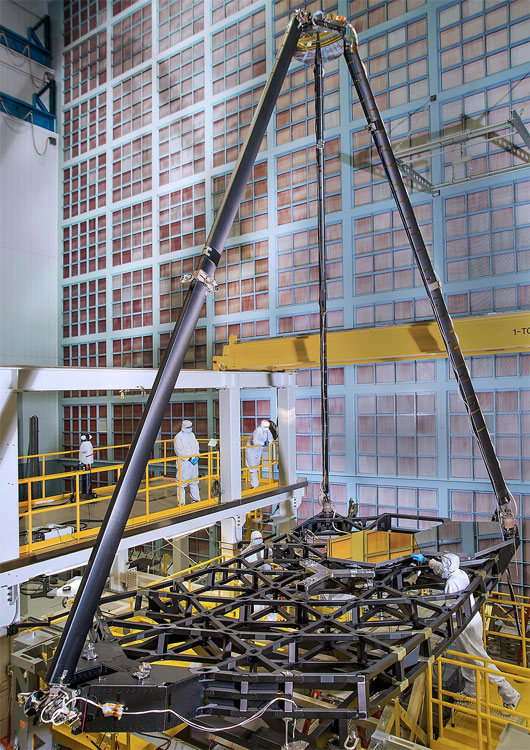

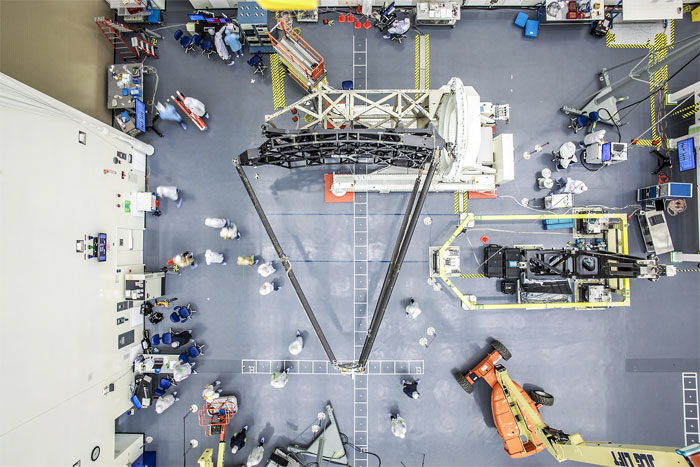

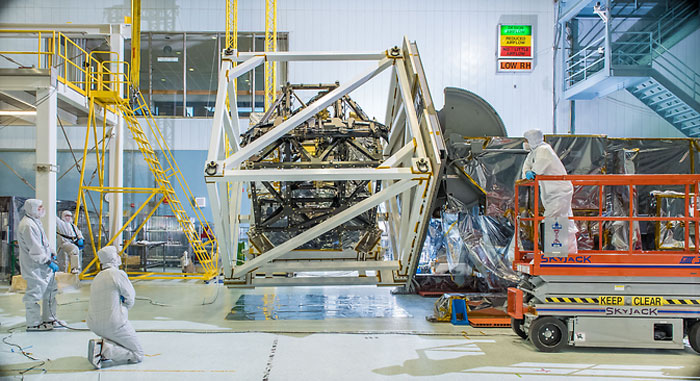

NASA Webb Telescope’s Mammoth Mirror Tripod Gets Tested in Action

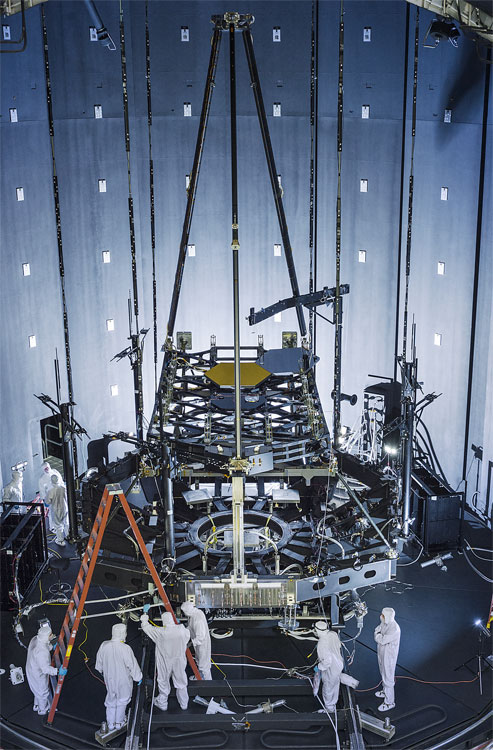

Inside a giant clean room at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, the pathfinder telescope, a practice section of the James Webb Space Telescope, stands fully assembled. Teams of engineers built and aligned the pathfinder telescope to rehearse assembly and testing before the actual telescope is built. Credit: NASA/Chris Gunn

.

NASA GODDARD SPACE FLIGHT CENTER, MD – The mammoth mirror tripod assembly that is a key structural element of NASA’s James Webb Space Telescope (JWST) is undergoing critical action packed testing at NASA’s Goddard Space Flight Center in Greenbelt, MD, and AmericaSpace was on site recently for a first hand look to observe some of the work in progress.

JWST is NASA’s top priority science mission launching in this decade and is the most powerful telescope ever built.

It will have the capability to “look back towards the very first objects that formed after the Big Bang,” said Dr. John Mather, NASA’s Nobel Prize Winning scientist, in a prior exclusive interview with AmericaSpace at NASA Goddard.

The telescope is currently in the midst of a multiyear testing and construction phase inside the world’s largest cleanroom at NASA Goddard.

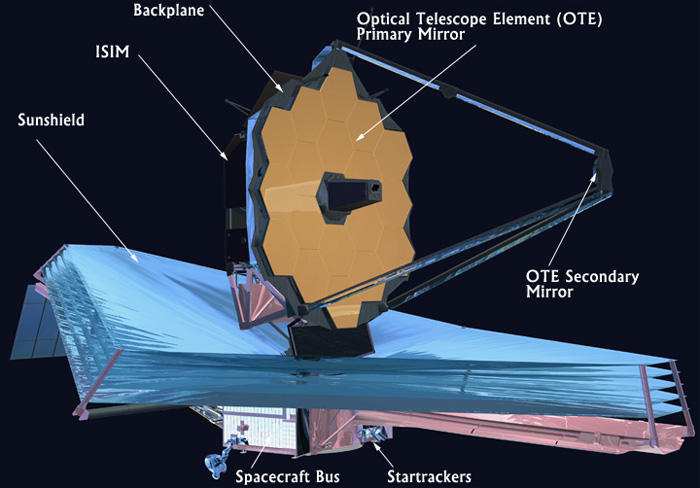

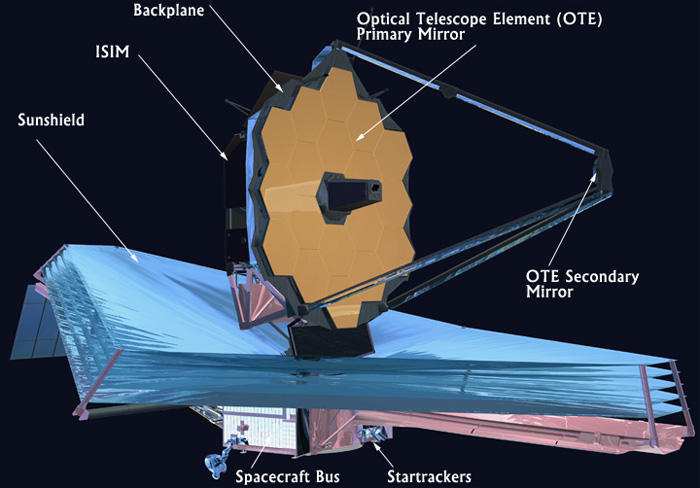

The lengthy tripod will hold Webb’s secondary mirror firmly in place above the honey comb like backplane assembly that holds the telescopes segmented primary mirror.

The round secondary mirror reflects light gathered by the primary mirror into the telescopes state of the art science instruments.

But like just about everything else involved with the unbelievably complicated Webb telescope, the legs comprising the tripods secondary mirror support structure will have to unfurl in space after the spacecraft is launched and deployed.

The huge telescope is now well on track to launch in October 2018 atop an ESA Ariane V ECA rocket from the Guiana Space Center in Kourou, French Guiana, following a series of delays and cost overruns earlier in the decade.

But before Webb is launched, all the hardware is being thoroughly tested to assure it meets specifications and will work as planned when in its orbit a million miles (1.5 million Km) from Earth at a position called L2 – the second Sun-Earth Lagrange point.

Webb must deploy and function as planned because it can’t be fixed by astronaut crews.

“JWST is not designed to be serviced,” Mather stated. “Our job is to make sure it works. We have two of everything. So it’s Practice , Practice, Practice.”

To get ready for the tripod unfurling test, Goddard technicians first assembled and tested an engineering version of the hardware to test procedures and gain experience before working with the actual flight units.

During a recent visit to Goddard, I observed as technicians were intricately carrying out the delicate installation of primary mirror flight spares onto the primary mirror backplane engineering unit to carry out a more realistic test.

The secondary mirror support tripod extends to about 8 meters (26.2 feet) long once it is fully deployed.

Goddard engineers recently completed a successful test run deployment of the tripod in Goddard’s giant clean room using Webb’s “Pathfinder” backplane, or test “backbone” structural hardware first.

“This is the first time we have performed a deployment with a mirror on it and is an important next step in proving the system will work in space as planned,” said Lee Feinberg NASA’s Optical Telescope Element manager at the agency’s Goddard Space Flight Center in Greenbelt, Maryland.

Once in space, Webb’s solar array will be deployed immediately followed by the high gain antenna two hours later. Thrusters will fire to start the journey to place it into orbit around the sun at L2.

During the journey to L2, the mirrors, sunshield and everything else about JWST will then be unfolded in a carefully choreographed and highly complex sequence lasting about six months. The four science instruments will also be calibrated.

.

Top-down view of the James Webb Space Telescope pathfinder backplane with the secondary mirror booms or “tripod” fully extended in a cleanroom at Northrop Grumman. Credit: Northrop Grumman/Alex Evers

.

Engineers did a test run using the Webb’s “Pathfinder” backplane, or test “backbone” structure, to ensure that one of the secondary mirrors would set up properly in its orbit a million miles from Earth.

“The deployment of the tripod that holds the secondary mirror has a tipping point, and this is controlled by the yellow gravity off-loading device,” said Ray Lundquist, the Webb telescope ISIM Lead Systems Engineer at NASA’s Goddard Space Flight Center in Greenbelt, Maryland.

The tripod consists of three supports and hinges that fold out from the telescopes backplane. The tripod was constructed from composite tubes built by ATK. The hinges were built by Northrop Grumman.

Both the round secondary and hexagonal shaped primary mirrors are made of beryllium, which was selected for its stiffness, light weight, and stability at cryogenic temperatures.

Webb is outfitted with a segmented 6.5 meter (21 ft 4 in) diameter aperture primary mirror. It’s the largest mirror ever placed in space and weighs 705 kg.

The primary mirror is comprised of 18 individual hexagonal segments and configured into a nearly circular arrangement.

Each of the primary mirrors are gold coated. They measure 1.3 meters (4.3 feet) in diameter and weigh about 20 kg (46 pounds).

.

The Webb telescope’s secondary mirror is labeled “OTE secondary mirror” is seen at the end of the tripod stretching out in front of the primary mirror. Credit: NASA

NASA has overall responsibility for JWST, which is a joint international collaborative project between NASA, ESA (European Space Agency) and CSA (Canadian Space Agency) comprising more than 17 countries.

NASA Goddard Space Flight Center provides overall management, systems engineering and the ISIM science module. Northrop Grumman is the prime contractor.

Stay tuned here for continuing developments.

Quelle: AS

.

Update: 14.12.2014

.

NASA's Webb Telescope ISIM Gets Cubed for Gravity Test

The Webb telescope's ISIM during the gravity sag test in NASA Goddard's cleanroom.

.

The James Webb Space Telescope's ISIM structure recently endured a "gravity sag test" as it was rotated in what looked like giant cube in a NASA clean room.

The Integrated Science Instrument Module (ISIM) that will fly on the Webb telescope was rotated upside down inside a cube-like structure in the cleanroom at NASA's Goddard Space Flight Center in Greenbelt, Maryland. The purpose of "cubing" the ISIM was to test it for "gravity sag," which is to see how much the structure changes under its own weight due to gravity.

The Integrated Science Instrument Module (ISIM) is one of three major elements that comprise the Webb Observatory flight system. The others are the Optical Telescope Element (OTE) and the Spacecraft Element (Spacecraft Bus and Sunshield).

Engineers need to see how gravity affects the alignment of the instruments within the module when ISIM is in different orientations on the ground. Engineers use measurements from this sag test to verify what the instrument alignments will really be in space, when there is no preferred direction from gravity, and take account of sag during assembly with the telescope.

.

The cube with the ISIM inside it was rotated using a massive machine called an Aronson table; the rotation was just the dramatic start to the test. The cube and ISIM were then lifted off of the rotation table while inverted and kept upside down for several days while lasers made precise position measurements.

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Quelle: NASA

.

Update: 23.12.2014

.

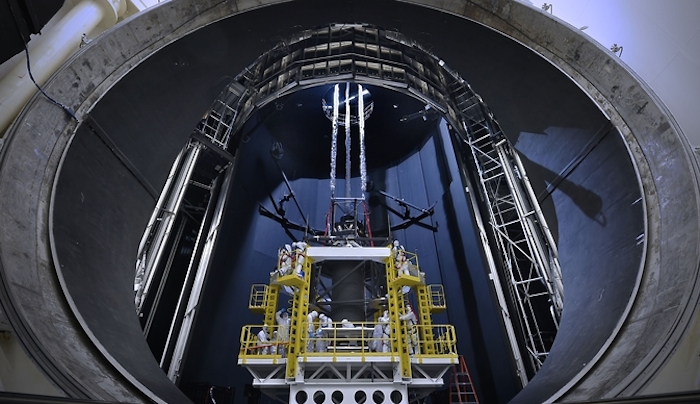

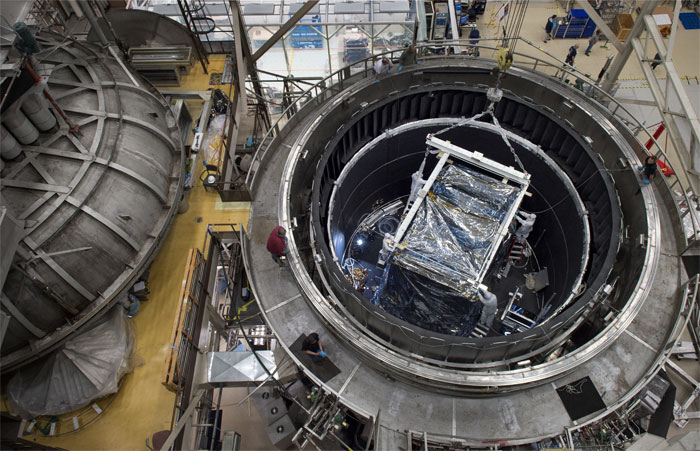

Amazing View of Engineers Preparing NASA's Gigantic Space Simulation Chamber for Massive Test

.

"This is what space science is all about," said NASA photographer Chris Gunn, who captured a photo from outside the enormous mouth of NASA's giant thermal vacuum chamber called Chamber A at Johnson Space Center in Houston. Previously used for manned spaceflight missions, this historic chamber is now filled with engineers and technicians preparing for one of NASA's biggest missions, the James Webb Space Telescope.

"There is nothing else like this that anyone will see in their day-to-day lives," said Gunn. Engineers and technicians, dressed in sterile suits and secured by harnesses to stands for safety, are seen inside Chamber A preparing a lift system that will be used to hold the telescope during testing.

Once fully assembled and launched into space, this telescope will allow us to explore ever further into the cosmos, seeing things that even the mighty Hubble Space Telescope can’t. Before this telescope is launched one million miles into space to its destination, it must undergo a series of detailed tests to ensure it's ready for the harsh environment of space. This spring, a model of the telescope called "Pathfinder" will begin cryogenic optical testing inside this chamber.

"Maintaining the schedule with a very large number of optical and ground support equipment integration efforts, while securing the telescope to a suspension system inside the chamber and conducting a cryo-strength test is an incredible integration and test challenge," said Mark Voyton, manager for the Optical Telescope Element and Integrated Science Instrument Module (OTIS).

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

.

NASA's Webb Telescope Pathfinder Telescope Fully Assembled

Inside a giant clean room at NASA's Goddard Space Flight Center in Greenbelt, Maryland, the pathfinder telescope, a practice section of the James Webb Space Telescope, stands fully assembled. Teams of engineers built and aligned the pathfinder telescope to rehearse assembly and testing before the actual telescope is built. After the team installs the test sensors and completes their final close out, the pathfinder telescope will be shipped to NASA's Johnson Space Center in Houston, Texas for cryo-optical testing.

Quelle: NASA

.

Update: 12.01.2015

.

NIRCam's Optical System Excels In Integrated Tests For James Webb Telescope

The Near Infrared Camera (NIRCam) instrument Lockheed Martin [NYSE: LMT] helped develop for NASA’s next deep space telescope surpassed expectations during tests in late 2014. It will see farther into the cosmos and further back in time than any other instrument. Scientists are preparing NIRCam for new trials beginning this year.

Produced under contract with the University of Arizona, NIRCam is the primary science camera on the James Webb Space Telescope (JWST), and it also functions as the sensor that is used to align the observatory’s primary mirror.

NIRCam performed significantly better than requirements during the first integrated, cryogenic testing program at Goddard Space Flight Center, Maryland. In April NASA installed the instrument alongside others in the Integrated Science Instrument Module (ISIM), which finished cryogenic and vacuum testing late last year. The ISIM is preparing for vibration testing, scheduled to occur in early 2015.

Unlike Hubble’s single monolithic primary mirror, JWST’s primary mirror is made up of 18 individual, adjustable segments that will be aligned in space. NIRCam’s performance is essential to the telescope’s success.

“We designed NIRCam to stringent optical and environmental requirements so it can deliver images from the early origins of the universe,” said Alison Nordt, NIRCam program manager at Lockheed Martin. “JWST is an infrared observatory, requiring all of the optical components to operate at a cryogenic temperature under 40 Kelvin, which is less than 40 degrees above absolute zero, the temperature at which all atomic motion ceases. That’s a significant challenge when you’re building low-distortion optical mounts, aligning optics at room temperature and designing mechanisms to move precisely.”

NIRCam is one of many precision optical payloads Lockheed Martin designs, develops and produces for scientific and commercial customers, NASA and other government organizations. Lockheed Martin has a deep understanding of optical and infrared missions and their technologies, building on decades of experience to deliver high performing and reliable optical systems.

Headquartered in Bethesda, Maryland, Lockheed Martin is a global security and aerospace company that employs approximately 113,000 people worldwide and is principally engaged in the research, design, development, manufacture, integration and sustainment of advanced technology systems, products and services. The Corporation’s net sales for 2013 were $45.4 billion.

.

NIRCam successfully completed its first integrated testing with NASA's James Webb Space Telescope. The optical sensor will see farther into the cosmos and further back in time than any other instrument.

.

NIRCam, the primary science camera of the James Webb Space Telescope, emerges as part of the Integrated Science Instrument Module (ISIM) during a deep freeze test in late 2014. (Image courtesy of NASA)

Quelle: Lockheed Martin

.

Update: 18.02.2015

.

Space Simulation Chamber Prepared for Testing Webb Telescope

This photo was captured from outside the enormous mouth of NASA's giant thermal vacuum chamber, called Chamber A, at Johnson Space Center in Houston. Previously used for manned spaceflight missions, this historic chamber is now filled with engineers and technicians preparing a lift system that will be used to hold the James Webb Space Telescope during testing.

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

.

Quelle: NASA

.

Update: 25.02.2015

.

Key science elements of the James Webb Space Telescope have been upgraded ahead of the observatory’s launch in 2018.

The telescope, also known as JWST, is a joint project of NASA, ESA and the Canadian Space Agency. It carries a 6.5 m-diameter telescope and four state-of-the-art science instruments optimised for infrared observations. Europe has led the development of two of the instruments.

As a general-purpose observatory, it will tackle a wide range of topics, including detecting the first galaxies in the Universe and following their evolution over cosmic time, witnessing the birth of new stars and their planetary systems, and studying planets in our Solar System and around other stars.

Installation of the four instruments in the telescope’s Integrated Science Instrument Module, or ISIM, was completed last April. Since then, the module has undergone extensive testing to ensure it can withstand the stresses of launch and operation in space.

A critical part of this process saw the instruments complete cryogenic testing in a round-the-clock campaign running for 116 days last summer.

Following the campaign, several months were dedicated to replacing key components of some of the instruments already known to require additional work before the next stages.

Europe’s ‘NIRSpec’, the near-infrared multi-object spectrograph, was one of the instruments upgraded. NIRSpec will split infrared light from distant stars and galaxies into its colour components – a spectrum – providing scientists with vital information on their chemical composition, age and distance.

The first generation of JWST’s highly sensitive near-infrared detectors were found to suffer from a design flaw that resulted in a progressive degradation of their performance. New detectors have now been installed in all three near-infrared instruments.

“Excellent detectors are crucial to the outstanding instrument performance needed when you want to look at the extremely distant and faint early stars and galaxies that formed when our Universe was still young, and the new detectors secure this top priority of NIRSpec and JWST,” says Pierre Ferruit, ESA’s JWST project scientist.

Another crucial component of NIRSpec are its microshutter arrays, a new technology developed for JWST by NASA.

One of the defining and pioneering features of NIRSpec is its ability to analyse the light from more than 100 astronomical objects at the same time. This is made possible by an assembly of four microshutter arrays, totalling almost a quarter of a million individual shutters.

Armed with a pre-selected list of interesting targets, each shutter can be programmed to open or close individually. The light from the chosen targets passes through the selected open shutters before entering the next stage of the instrument, where it is split into a spectrum and projected onto the detectors for analysis.

.

One of the defining, and pioneering, features of the NIRSpec instrument is its ability to record the spectra of many (more than 100) objects at the same time. This is enabled by the use of a micro-shutter array (MSA) consisting of just under a quarter of a million individually controlled micro-shutters. By programming the array to only open those shutters coinciding with pre-selected objects of interest, light from these objects is isolated and directed to the spectroscopic stage of NIRSpec to produce the spectra.

The MSA has been developed at NASA's Goddard Space Flight Center. This photo shows NASA engineers at Goddard inspecting an MSA with a low light test. The inspection light source is held by the technician at the front of the picture. Four array quadrants are located within the octagonal frame in the centre of a titanium mosaic base plate. Each quadrant contains a grid of 365×171 micro-shutters, and each micro-shutter measures approximately 100 µm × 200 µm - the width of a human hair.

NIRSpec is built by European industry to ESA's specifications and managed by the ESA JWST Project at ESTEC, the Netherlands. The prime contractor is Airbus Defence and Space in Ottobrunn, Germany. The NIRSpec detector and micro-shutter array subsystems are provided by NASA's Goddard Space Flight Center.

Quelle: ESA

-

Update: 22.04.2015

.

Building Hubble's Successor: Crucial Pathfinder Test Set Up Inside Chamber A

Inside NASA's giant thermal vacuum chamber, called Chamber A, at NASA's Johnson Space Center in Houston, the James Webb Space Telescope's Pathfinder backplane test model, is being prepared for its cryogenic test. Previously used for manned spaceflight missions, this historic chamber is now filled with engineers and technicians preparing for a crucial test.

Exelis developed and installed the optical test equipment in the chamber.

"The optical test equipment was developed and installed in the chamber by Exelis," said Thomas Scorse, Exelis JWST Program Manager. "The Pathfinder telescope gives us our first opportunity for an end-to-end checkout of our equipment."

"This will be the first time on the program that we will be aligning two primary mirror segments together," said Lee Feinberg, NASA Optical Telescope Element Manager. "In the past, we have always tested one mirror at a time but this time we will use a single test system and align both mirrors to it as though they are a single monolithic mirror."

The James Webb Space Telescope is the scientific successor to NASA's Hubble Space Telescope. It will be the most powerful space telescope ever built. Webb is an international project led by NASA with its partners, the European Space Agency and the Canadian Space Agency.

Image credit: NASA/Chris Gunn

Text credit: Laura Betz, NASA's Goddard Space Flight Center, Greenbelt, Maryland

Quelle: NASA

5909 Views