20.08.2025

NASA Begins Processing Artemis III Moon Rocket at Kennedy

Buildup of NASA’s SLS (Space Launch System) rocket for the Artemis III lunar mission has started at the agency’s Kennedy Space Center in Florida, even as NASA prepares for the launch of the Artemis II mission, the second Artemis mission in NASA’s efforts to l return humans to the Moon and eventually land on Mars.

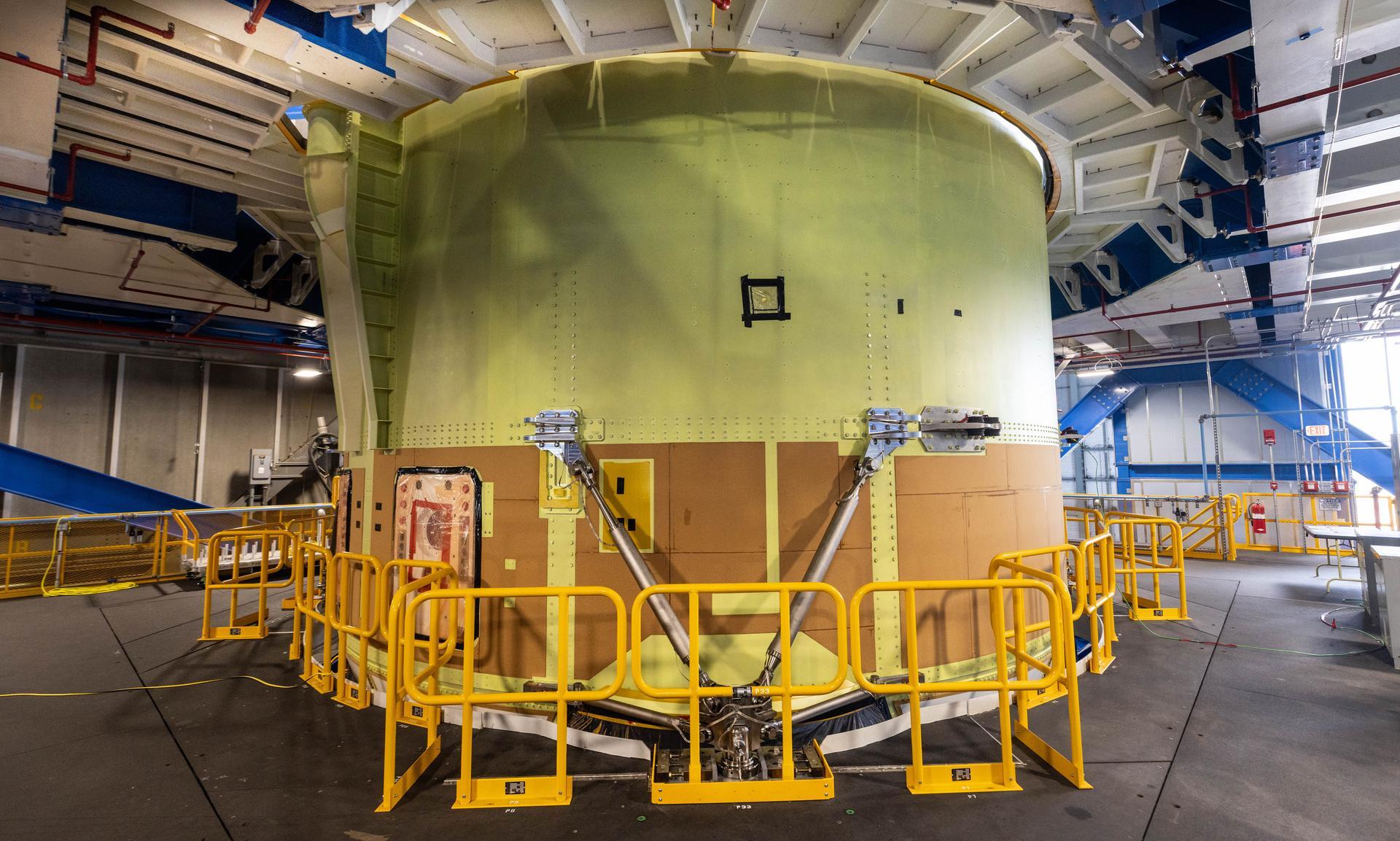

The Artemis III SLS engine section and boat-tail – which protects the engines during launch – moved from the Space Systems Processing Facility at NASA Kennedy to the mammoth Vehicle Assembly Building (VAB) in late July, just a few feet from where the Artemis II SLS is mostly stacked and undergoing integrated testing and checkouts.

In early 2026, NASA will launch Artemis II, the first crewed flight of the SLS rocket and Orion spacecraft, on an approximately 10-day journey around the Moon. This will be followed by the Artemis III lunar landing mission in 2027, the first ever to the lunar South Pole region, which will launch an SLS with a crew of four aboard an Orion spacecraft to rendezvous with the Starship Human Landing System. These missions set the stage for NASA to land the first American on the Martian surface.

Teams lifted the engine section onto a stand and mated the boat-tail to the bottom. They installed a canopy on top of the engine section to allow the segment to be air conditioned, preventing moisture build-up and contamination.

Teams then lifted the completed assembly into High Bay 2 in the VAB where it will complete integration and check-out testing until the arrival of the rest of the Artemis III SLS core stage components to complete stage integration, targeted for Spring 2026.

Called the top four-fifths, the remaining elements of the core stage – the liquid hydrogen tank, liquid oxygen tank, intertank, and forward skirt – are at NASA’s Michoud Assembly Facility in New Orleans undergoing processing and integration. The four core stage RS-25 engines are scheduled to ship from NASA’s Stennis Space Center in Bay St. Louis, Mississippi, in early 2026 for integration into the engine section.

The engine section is one of the most complex parts of the rocket, containing the four RS-25 engines and related ducts, valves, electronics, and more than 18 miles of cabling that connect to the core stage propellant tanks and rocket.

The move is part of a change to the SLS production process. The Artemis I and Artemis II SLS core stages were manufactured entirely at NASA Michoud and transferred to NASA Kennedy to be integrated with the SLS solid boosters, upper stage, and the Orion crew spacecraft. Beginning with the Artemis III hardware, NASA moved engine section internal outfitting and integration with the top of the core stage to NASA Kennedy to streamline the manufacturing process and enable simultaneous production operations of two core stages.

Quelle: NASA

----

Update: 30.10.2025

.

Blue Origin details lunar exploration progress amid Artemis 3 contract shakeup

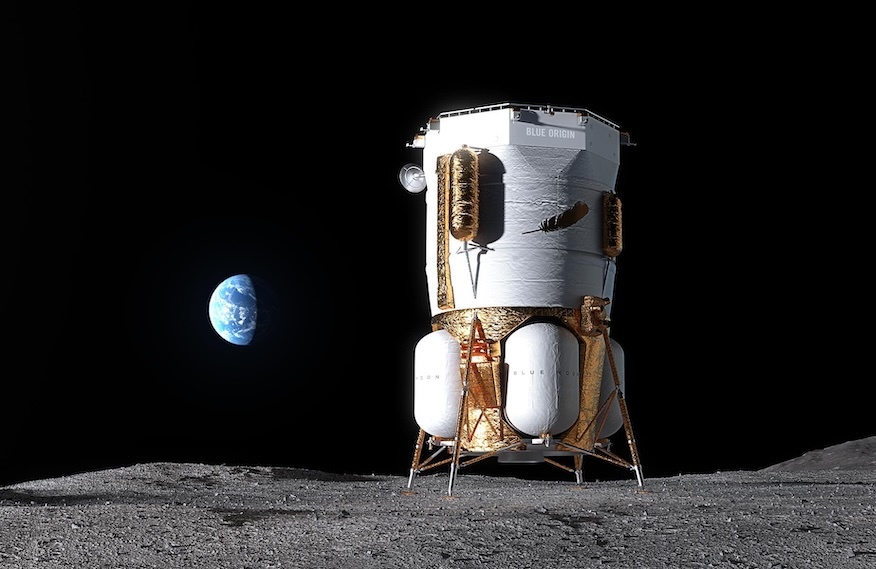

An artist’s rendering of Blue Origin’s Blue Moon Mark 1 lunar lander on the surface of the Moon. Graphic: Blue Origin

Correction Oct. 29: Fixed reference to the engines on the Lunar Transporter from BE-4 to BE-7.

Blue Origin is still several years off from its currently contracted mission to bring astronauts to the Moon’s South Pole on the Artemis 5 mission. But it has a number of spacecraft in development with at least one set to fly to the lunar surface as soon as potentially later this year.

The company is also developing plans that could expedite the Artemis 3 mission, which will be the first human landing on the Moon as part of NASA’s Artemis program.

Jacqueline Cortese, Blue Origin’s Senior Director of Civil Space, represented the company during a Tuesday panel at the American Astronautical Society’s 2025 von Braun Space Exploration Symposium. Dubbed “Artemis 3 and Beyond: Establishing a Permanent Lunar Presence,” Cortese was there to discuss Blue Origin’s plans for both astronaut and cargo flights to the Moon.

She said that Blue Origin’s first mission to the Moon will be an uncrewed Blue Moon Mark 1 lander is going through final stacking in Florida. The 8.1-meter-tall cargo lander will help with ongoing development of their crewed lander, named Blue Moon Mk. 2, which is 15.3 meters tall.

Both are powered by Blue Origin’s BE-7 engines, which are being tested on stands in Alabama, Texas and Washington. Company CEO Dave Limp shared a 17-minute-long video of one hot fire test in Texas meant to simulate the Apogee Raise Maneuver for the Blue Moon Mk. 1 lander.

“A big milestone for you to look out for online is that Mk. 1 is three modules that are being stacked as we speak: aft, forward and mid. And once it is stacked in its finished configuration, we will be barging it over to NASA Johnson Space Center Chamber A to do a full up thermal vac campaign,” Cortese said. “So when you see that on its boat, you will know that big things are happening.”

Both versions of the lander are powered by a combination of liquid hydrogen and liquid oxygen. A key difference though is that Mk.1 can be launched to the Moon with a single launch of Blue Origin’s New Glenn rocket while Mk. 2 requires orbital refueling.

Cortese said the stacking work for the first Blue Moon Mk.1 lander is happening at a dedicated production plant for the spacecraft located at Port Canaveral, which is south of Cape Canaveral Space Force Station in Florida. She said Blue Origin is ramping up a production line for the Blue Moon Mk. 1 landers, stating that the aft section for the second of these vehicles is currently in structural testing.

“That first Mk. 1 is intentionally not carrying 3,000 kilograms of payload because it’s a demo flight, right? It is sensored. So many instruments, so many sensors, PSI, instrumentation with NASA, etc., but that vehicle itself is intended to grow into a production line,” Cortese said.

The first of these landers will carry NASA’s SCALPSS (Stereo Cameras for Lunar-Plume Surface Studies) and LRA (Laser Retroreflective Array) payloads onboard. Cortese teased that it would launch “in the next couple of weeks,” but didn’t offer further details on the timeline.

During the 2025 International Astronautical Congress in Australia, Pat Remias, Blue Origin’s Vice President of Space Systems Development said the company intends to recover the first stage booster flying on the upcoming EscaPADE mission for NASA (planned to launch in early November) and then reuse it for the first flight of a Blue Moon Mk. 1 lander.

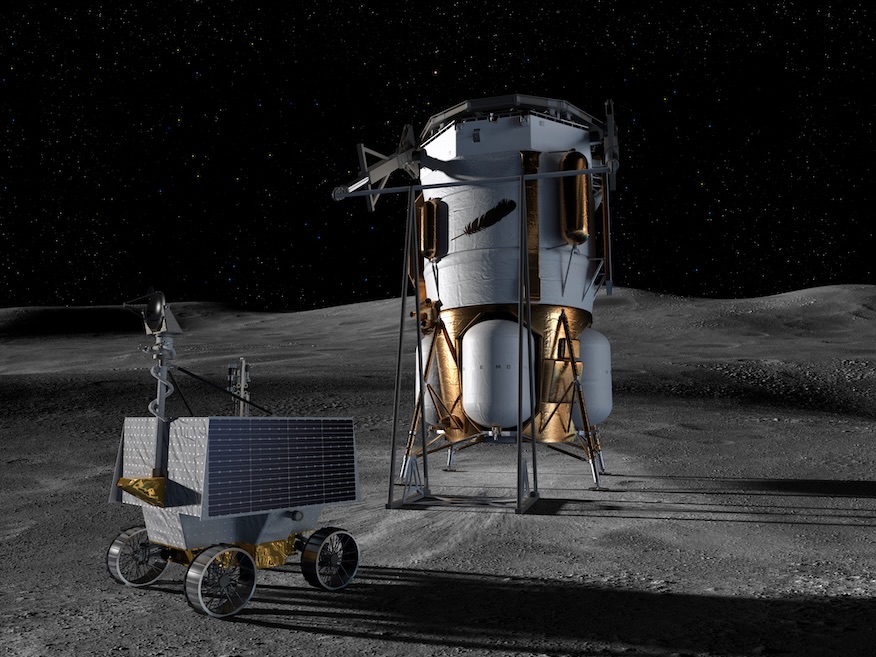

Last month, NASA tapped the Blue Moon Mk. 1 as the vehicle that will deliver its VIPER (Volatiles Investigating Polar Exploration Rover) mission to the Moon’s South Pole as part of the agency’s CLPS (Commercial Lunar Payload Services) task order. This new contract is valued at $190 million and it will be the second flight of a Blue Moon Mk. 1 lander.

“We’re very excited for that one, not just as a test bed for what we’re doing on HLS (Human Landing System program), but as its future for logistics infrastructure and big permanence on the Moon,” Cortese said.

Returning humans to the Moon

While Blue Origin is preparing to send these cargo landers to the Moon, the far more challenging endeavor is creating a safe passage for astronauts to travel to and from the lunar surface. In May 2023, NASA awarded Blue Origin a firm-fixed price contract valued at $3.4 billion to develop a crewed lander for the Artemis 5 mission, which was scheduled for 2029 at the time.

The contract calls for at least one uncrewed landing demonstration of a Blue Moon Mk.2 lander before the vehicle can host NASA’s astronauts as part of the Human Landing System (HLS) program.

For the Artemis 5 mission, Blue Origin will use the Blue Moon Mk. 2 lander, which will require the use of their Lunar Transporter for in-space cryogenic propellant transfer. Work has been underway for some time to prepare systems to store propellant at the necessary temperatures to mitigate or prevent boil off.

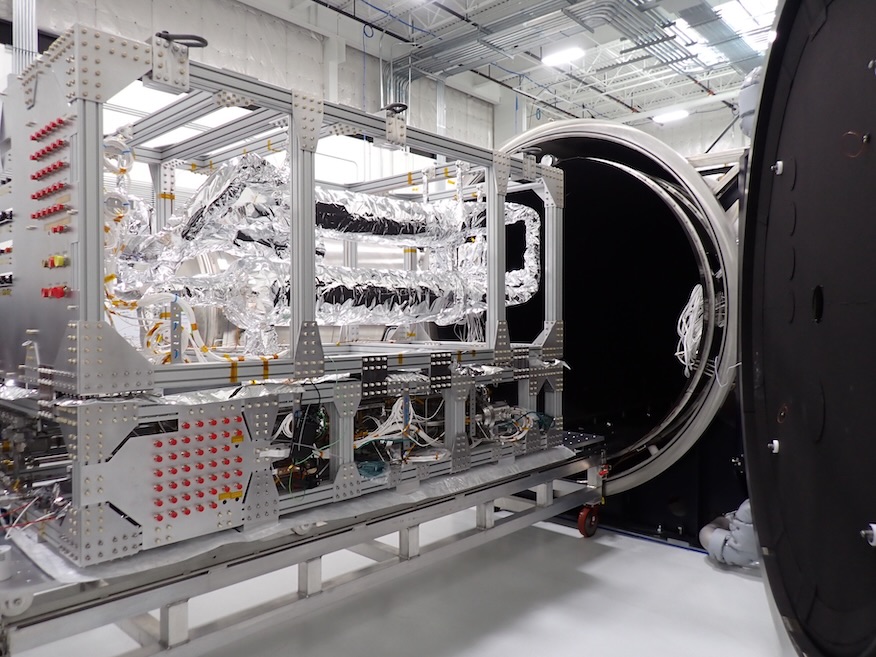

“Blue Origin has been working to mature our cryo cooling capabilities over the last several years and we’re now holding, with proto-flight hardware, 90 and 20 Kelvin in lab environments and we have some big, upcoming milestones for that,” Cortese said. “We worked with NASA super hard this summer on this test campaign.”

Additionally, the Blue Origin Utility Transfer Mechanism was recently tested inside the TS300 thermal vacuum chamber at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Cortese said the Lunar Transporter will using similar propellant tanks to those flown on the company’s New Glenn rocket.

Like both of the landers, the Lunar Transporter will also use seven BE-7 engines as its main propulsion system. Both the Lunar Transporter and the Blue Moon Mk. 2 are being built at the Lunar Plant 1 building at Blue Origin’s Rocket Park campus in Florida.

While these spacecraft are coming together, Cortese said Blue Origin is also working closely with NASA on the habitation area of the Blue Moon Mk. 2, which will house two astronauts during their mission down to the lunar surface and back up to the Gateway, a space station being developed by NASA and other international partners.

“We’ve definitely decided to insource a lot of the ECLSS (environmental control and life support system) and environmental components,” Cortese said. “I think that supply chain is an area where we wanted to have a lot of robustness and redundancy.

“I think what we were seeing was some down range supply chain issues in the ECLSS area, so we are working to vertically integrate a number of those areas. We’ve made some great progress on that.”

Cortese added that there are some “awesome synergies” between their work for HLS and their bid for a successor to the International Space Station, which Blue Origin and its partners dubbed, Orbital Reef.

Lunar dust up

Looming over the “Artemis 3 and Beyond” panel was the fate of that mission itself. In the midst of the ongoing government shutdown —- which also prevented NASA employees from participating in this week’s conference -— NASA Acting Administrator Sean Duffy said he would be reopening the contract for the Artemis 3 mission because SpaceX is behind in its HLS work.

The company founded by billionaire Elon Musk is developing a variant of its Starship rocket that will be capable of taking crew down to the surface. It was granted a $2.89 billion contract for the Artemis 3 mission in April 2021 and a separate $1.15 billion contract for an Artemis 4 landing.

SpaceX completed 11 integrated test flights of its Starship-Super Heavy rocket and is preparing to transition to the third major version of the launch vehicle. However, the company was expected to have completed its in-space propellant transfer demo by mid-2025 and that operation now not expected until sometime in early- to mid-2026 at the earliest.

Through its most recent public update, NASA set the Artemis 3 launch for mid-2027, but many expect that this date won’t bear out.

“SpaceX had the contract for Artemis 3. By the way, I love SpaceX. They’re an amazing company. The problem is they’re behind. They pushed their timelines out and we’re in a race against China,” Duffy said in an Oct. 20 appearance on CNBC’s Squawk Box show.

“The President and I want to get to the Moon in this President’s term. So, I’m going to open up the contract. I’m going to let other space companies compete with SpaceX, like Blue Origin,” Duffy added. “And whatever one can get us there first, to the Moon, we’re gonna take. And if SpaceX is behind and Blue Origin can do it before them, good on Blue Origin.”

This led to Musk berating Duffy on X, formerly Twitter, with allegations about Duffy’s perceived competence to run NASA while simultaneously serving as the Secretary of Transportation.

Asked during the panel what work it was doing to capitalize on this new opportunity, Cortese played it close to the vest.

“Since it’s definitely a competitive environment, I probably won’t say too much about it, but we did just kick off that work with NASA. We’re super excited about it. We have a lot of ideas,” Cortese said.

“I will say it this way. Especially with Mk. 1 and some of our preceding work we’re doing, we have what we think are some good ideas about maybe a more incremental approach that could be taken advantage of for an acceleration-type scenario, which is ultimately still on that end path to sustainability, but is perhaps more incremental in near term.”

Aarti Matthews, Director of Starship Crew and Cargo Programs at SpaceX, was listed as one of the participants of Tuesday’s panel, but was missing from the final line up.

Quelle: SN

----

Update: 19.11.2025

.