14.10.2024

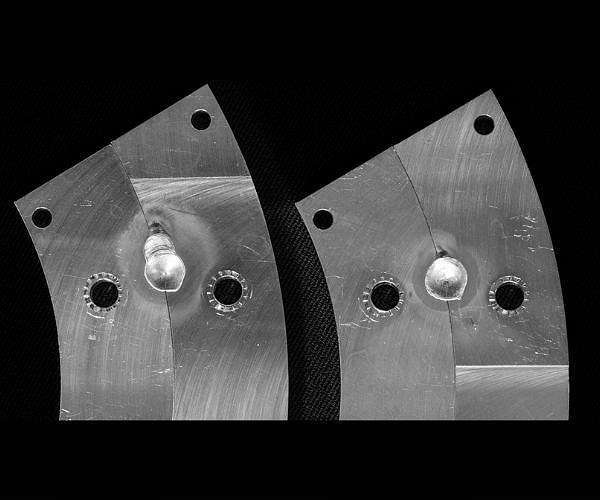

Comparing the in-space weld to its terrestrial equivalent.

ESA engineers have closely examined an aluminium weld produced in space, marking a historic achievement as the first autonomous welding conducted in orbit, and the first of its kind involving ESA. The weld, just one centimeter in size, was produced using electron beam welding during an experiment initiated by ThinkOrbital, a US startup.

This weld, created aboard a spacecraft launched via a SpaceX Falcon 9 in May, is being scrutinized at ESA's Materials and Electrical Components Laboratory in the Netherlands, using various testing tools such as microscopes and X-ray tomography. The goal is to compare this space-made weld with identical samples produced on Earth.

"If human space exploration is going to become truly sustainable and self-supporting, then in-space manufacturing will become commonplace, with the ability to weld being an important element of that vision," explained Joao Gandra, ESA Materials Engineer. "So we need to check how easy it is to weld in space."

The experiment highlights the unique challenges of welding in microgravity, where the absence of Earth's gravity affects molten metal behavior. "In microgravity, molten metals behave more like liquid blobs, shaped by surface tension instead of convection currents," Joao added. Factors like space radiation and vacuum conditions further complicate the process, making empirical data from these experiments critical for future predictions and space-based manufacturing.

Although welding is a fundamental industrial process on Earth, no welds have been made in space since the 1980s. The International Space Station (ISS), for example, was entirely bolted together. The recent experiment utilized the same electron beam welding method first used by the USSR in 1969 during the Soyuz-6 mission. This technique is well-suited to space since it can be performed in a vacuum, delivering deep, controllable welds.

ThinkOrbital's CEO, Colonel Lee Rosen (USAF, retired), commented, "It's an honor to work with ESA and NASA on this important technology. Not only are we demonstrating ThinkOrbital's technology for in-space construction, we're also contributing to ESA's scientific research and understanding of revolutionary technologies that will improve our collective ability to work and live in space."

The ESA team hopes this is the first of many space-based welding tests. "We hope to be involved in further test flights, targeting progressively more ambitious welding operations," Joao concluded. "This campaign is extremely well aligned with ESA's strategy to develop in-space manufacturing and servicing."

Samples of the welded material have been returned to Earth for analysis by ESA and NASA, with future tests set to further advance the capabilities of in-space manufacturing - an essential component of the emerging space economy.

Quelle: SD