28.08.2024

Solar Panels for NASA’s Roman Space Telescope Pass Key Tests

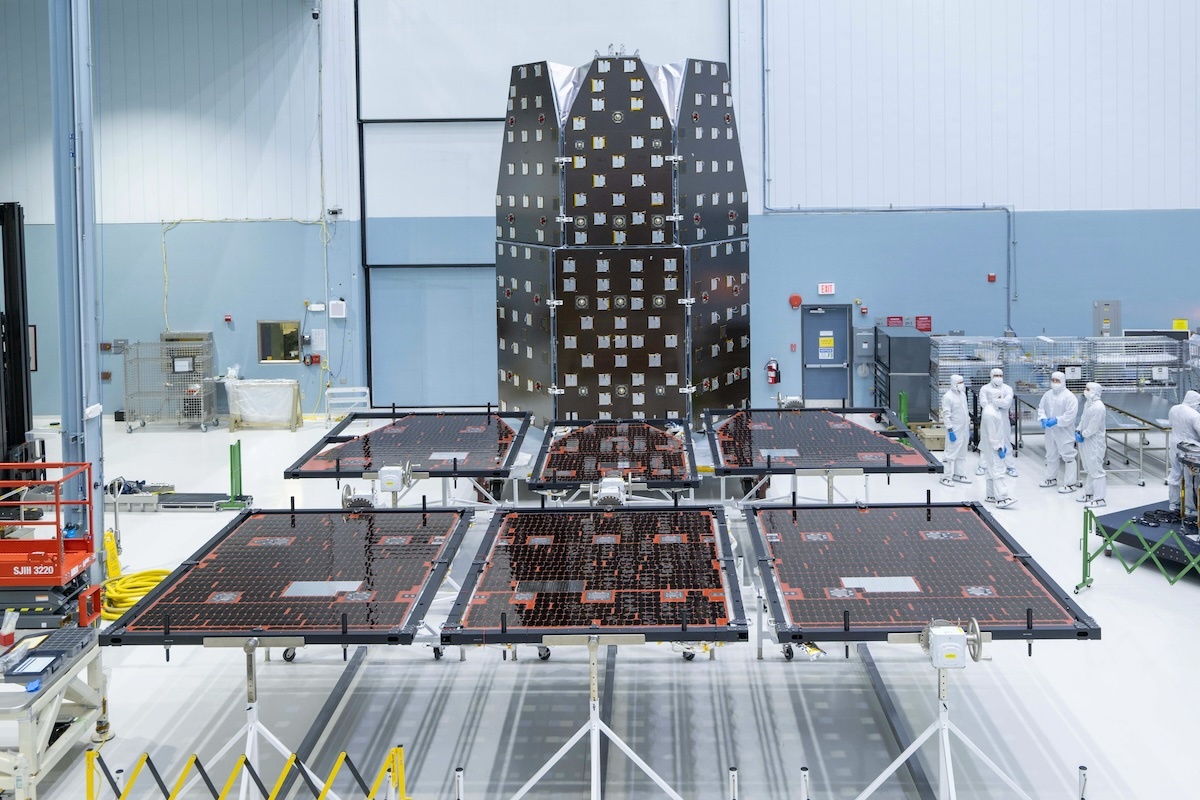

NASA’s Nancy Grace Roman Space Telescope’s Solar Array Sun Shield has successfully completed recent tests, signaling that the assembly is on track to be completed on schedule. The panels are designed to power and shade the observatory, enabling all the mission’s observations and helping keep the instruments cool.

The Roman team has two sets of these panels –– one that will fly aboard the observatory and another as a test structure, used specifically for preliminary assessments.

Engineers at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, evaluated the test version in a thermal vacuum chamber, which simulates the hot and cold temperatures and low-pressure environment the flight panels will experience in space. Since the panels will be stowed for launch, the team practiced deploying them in space-like conditions.

Meanwhile, a vendor built up the flight version by fitting the panels with solar cells. After delivery to Goddard, technicians tested the solar cells by flashing the panels with a bright light that simulates the Sun.

“We save a significant amount of time and money by using two versions of the panels, because we can do a lot of preliminary tests on a spare while moving further in the process with the flight version,” said Jack Marshall, the Solar Array Sun Shield lead at NASA Goddard. “It streamlines the process and also avoids risking damage to the panels that will go on the observatory, should testing reveal a flaw.”

Next spring, the flight version of the Solar Array Sun Shield will be installed on the Roman spacecraft. Then, the whole spacecraft will go through thorough testing to ensure it will hold up during launch and perform as expected in space.

Quelle: NASA

----

Update: 19.09.2024

.

NASA Completes Spacecraft to Transport, Support Roman Space Telescope

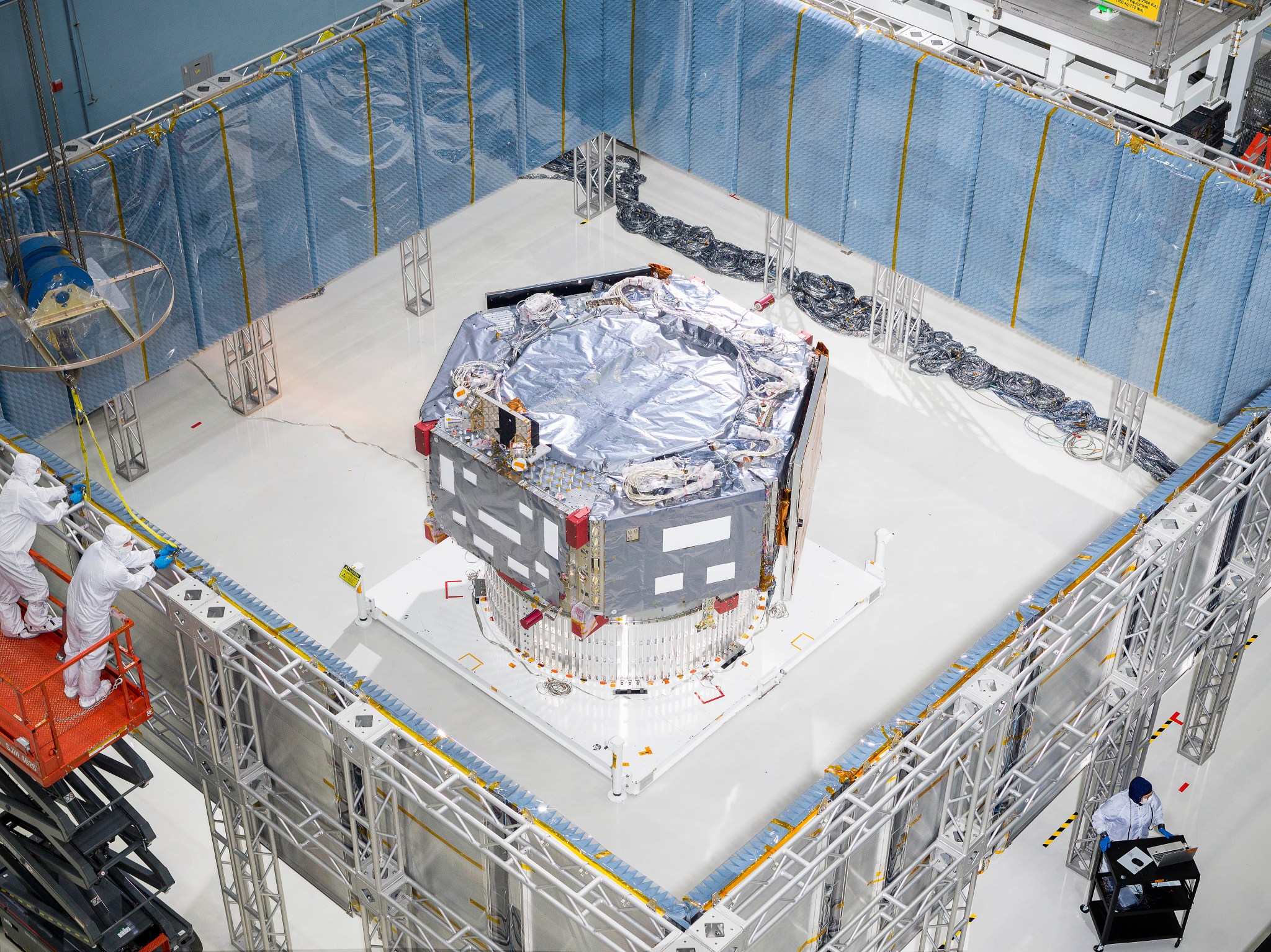

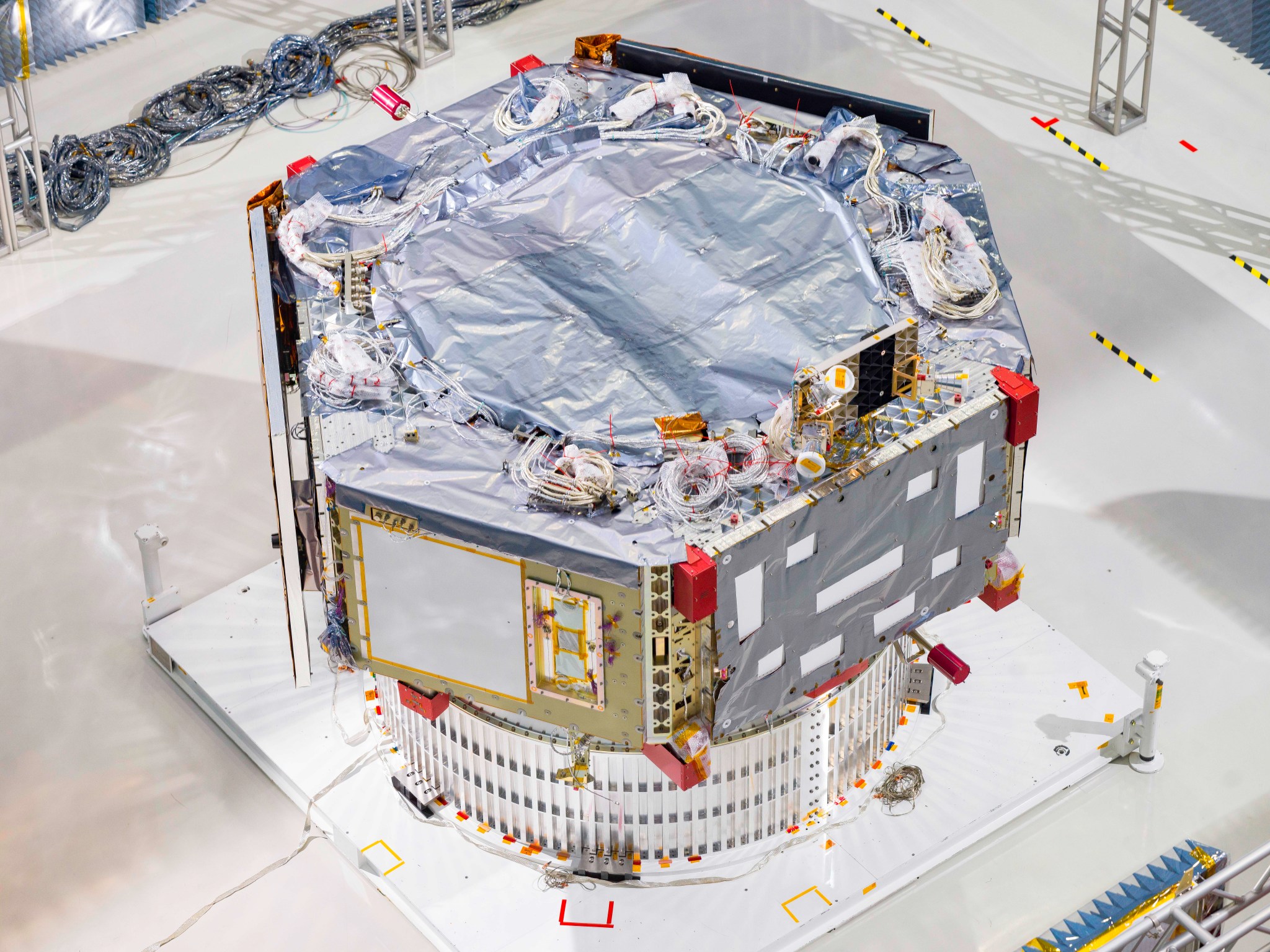

The spacecraft bus that will deliver NASA’s Nancy Grace Roman Space Telescope to its orbit and enable it to function once there is now complete after years of construction, installation, and testing.

Now that the spacecraft is assembled, engineers will begin working to integrate the observatory’s other major components, including the science instruments and the telescope itself.

“They call it a spacecraft bus for a reason — it gets the telescope to where it needs to be in space,” said Jackie Townsend, the Roman deputy project manager at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. “But it’s really more like an RV because it has a whole assortment of functions that enable Roman to accomplish its scientific goals while out there too.”

Those goals include surveying wide swaths of the universe to study things like: dark energy, a mysterious cosmic pressure thought to accelerate the universe’s expansion; dark matter, invisible matter seen only via its gravitational influence; and exoplanets, worlds beyond our solar system.

The mission’s science wouldn’t be possible without a spacecraft to transport the telescope, point the observatory toward different cosmic targets, provide power, communicate with Earth, control and store instrument data, and regulate Roman’s temperature. Nearly 50 miles of electrical cabling are laced throughout the assembly to enable different parts of the observatory to communicate with each other.

The spacecraft will also deploy several major elements that will be stowed for launch, including the solar panels, deployable aperture cover, lower instrument Sun shade, and high-gain antenna. It’s also responsible for collecting and beaming down data, which is no small task for a space observatory that will survey the cosmos like Roman will.

“Roman will send back 1.4 terabytes of data per day, compared to about 50 to 60 gigabytes from the James Webb Space Telescope and three gigabytes from the Hubble Space Telescope,” said Jason Hylan, the Roman observatory manager at NASA Goddard. “Webb’s daily downlink is roughly comparable to 13 hours of YouTube video at the highest quality while Roman’s would amount to about 2 weeks.”

A Goddard Grand Slam

This milestone is the culmination of eight years of spacecraft design work, building, and testing by hundreds of people at Goddard.

“Goddard employees were the brains, designers, and executors. And they worked with vendors who supplied all the right parts,” Townsend said. “We leaned on generations of expertise in the spacecraft arena to work around cost and schedule challenges that arose from supply chain issues and the pandemic.”

One time- and money-saving technique the team came up with was building a spacecraft mockup, called the structural verification unit. That allowed them to do two things at once: complete strength testing on the mockup, designed specifically for that purpose, while also assembling the actual spacecraft.

The spacecraft’s clever layout also allowed the team to adapt to changing schedules. It’s designed to be modular, “more like Trivial Pursuit pie pieces than a nesting egg, where interior components are buried inside,” Townsend said. “That’s been a game-changer because you can’t always count on things arriving in the order you planned or working perfectly right away with no tweaks.” It also increased efficiency because people could work on different portions of the bus at the same time without interfering with each other.

The slightly asymmetrical and hexagonal spacecraft bus is about 13 feet (4 meters) wide by 6.5 feet (2 meters) tall and weighs in at 8,400 pounds (3,800 kilograms).

One reason it doesn’t weigh more is that some components have been partially hollowed out. If you could peel back some of the spacecraft’s panels, you’d find superthin metallic honeycomb sandwiched between two slim layers of metal. And many of the components, such as the antenna dish, are made of strong yet lightweight composite materials.

When the spacecraft bus was fully assembled, engineers conducted a comprehensive performance test. Prior to this, each component had been tested individually, but just like with a sports team, the whole unit has to perform well together.

“The spacecraft passed the test, and now we’re getting ready to install the payload –– Roman’s instruments and the telescope itself,” said Missie Vess, a spacecraft systems engineer for Roman at NASA Goddard. “Next year, we’ll test these systems together and begin integrating the final components of the observatory, including the deployable aperture cover, outer barrel assembly, and solar panels. Then we’ll finally have ourselves a complete observatory, on track for launch by May 2027.”

Quelle: NASA

----

Update: 10.10.2024

.

NASA’s Roman Space Telescope’s ‘Exoskeleton’ Whirls Through Major Test

A major component of NASA’s Nancy Grace Roman Space Telescope just took a spin on the centrifuge at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. Called the Outer Barrel Assembly, this piece of the observatory is designed to keep the telescope at a stable temperature and shield it from stray light.

The two-part spin test took place in a large, round test chamber. Stretching across the room, a 600,000-pound (272,000-kilogram) steel arm extends from a giant rotating bearing in the center of the floor.

The test itself is like a sophisticated version of a popular carnival attraction, designed to apply centrifugal force to the rider — in this case, the outer covering for Roman’s telescope. It spun up to 18.4 rotations per minute. That may not sound like much, but it generated force equivalent to just over seven times Earth’s gravity, or 7 g, and sent the assembly whipping around at 80 miles per hour.

“We couldn’t test the entire Outer Barrel Assembly in the centrifuge in one piece because it’s too large to fit in the room,” said Jay Parker, product design lead for the assembly at Goddard. The structure stands about 17 feet (5 meters) tall and is about 13.5 feet (4 meters) wide. “It’s designed a bit like a house on stilts, so we tested the ‘house’ and ‘stilts’ separately.”

The “stilts” went first. Technically referred to as the elephant stand because of its similarity to structures used in circuses, this part of the assembly is designed to surround Roman’s Wide Field Instrument and Coronagraph Instrument like scaffolding. It connects the upper portion of the Outer Barrel Assembly to the spacecraft bus, which will maneuver the observatory to its place in space and support it while there. The elephant stand was tested with weights attached to it to simulate the rest of the assembly’s mass.

Next, the team tested the “house” — the shell and a connecting ring that surround the telescope. These parts of the assembly will ultimately be fitted with heaters to help ensure the telescope’s mirrors won’t experience wide temperature swings, which make materials expand and contract.

To further protect against temperature fluctuations, the Outer Barrel Assembly is mainly made of two types of carbon fibers mixed with reinforced plastic and connected with titanium end fittings. These materials are both stiff (so they won’t warp or flex during temperature swings) and lightweight (reducing launch demands).

If you could peel back the side of the upper portion –– the house’s “siding” –– you’d see another weight-reducing measure. Between inner and outer panels, the material is structured like honeycomb. This pattern is very strong and lowers weight by hollowing out portions of the interior.

Designed at Goddard and built by Applied Composites in Los Alamitos, California, Roman’s Outer Barrel Assembly was delivered in pieces and then put together in a series of crane lifts in Goddard’s largest clean room. It was partially disassembled for centrifuge testing, but will now be put back together and integrated with Roman’s solar panels and Deployable Aperture Coverat the end of the year.

In 2025, these freshly integrated components will go through thermal vacuum testing together to ensure they will withstand the temperature and pressure environment of space. Then they’ll move to a shake test to make sure they will hold up against the vibrations they’ll experience during launch. Toward the end of next year, they will be integrated with rest of the observatory.

To virtually tour an interactive version of the telescope, visit:

https://roman.gsfc.nasa.gov/interactive

The Nancy Grace Roman Space Telescope is managed at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, with participation by NASA’s Jet Propulsion Laboratory and Caltech/IPAC in Southern California, the Space Telescope Science Institute in Baltimore, and a science team comprising scientists from various research institutions. The primary industrial partners are BAE Systems, Inc in Boulder, Colorado; L3Harris Technologies in Rochester, New York; and Teledyne Scientific & Imaging in Thousand Oaks, California.

Quelle: NASA

----

Update: 30.10.2024

.

NASA Successfully Integrates Coronagraph for Roman Space Telescope

NASA’s Nancy Grace Roman Space Telescope team has successfully completed integration of the Roman Coronagraph Instrument onto Roman’s Instrument Carrier, a piece of infrastructure that will hold the mission’s instruments, which will be integrated onto the larger spacecraft at a later date. The Roman Coronagraph is a technology demonstration that scientists will use to take an important step in the search for habitable worlds, and eventually life beyond Earth.

This integration took place at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, where the space telescope is located and in development. This milestone follows the coronagraph’s arrival at the center earlier this year from NASA’s Jet Propulsion Laboratory (JPL) in Southern California where the instrument was developed, built, and tested.

The Roman Coronagraph Instrument is a technology demonstration that will launch aboard the Nancy Grace Roman Space Telescope, NASA’s next flagship astrophysics mission. Roman will have a field of view at least 100 times larger than the agency’s Hubble Space Telescope and explore scientific mysteries surrounding dark energy, exoplanets, and infrared astrophysics. Roman is expected to launch no later than May 2027.

The mission’s coronagraph is designed to make direct observations of exoplanets, or planets outside of our solar system, by using a complex suite of masks and active mirrors to obscure the glare of the planets’ host stars, making the planets visible. Being a technology demonstration means that the coronagraph’s goal is to test this technology in space and showcase its capabilities. The Roman Coronagraph is poised to act as a technological stepping stone, enabling future technologies on missions like NASA’s proposed Habitable Worlds Observatory, which would be the first telescope designed specifically to search for signs of life on exoplanets.

“In order to get from where we are to where we want to be, we need the Roman Coronagraph to demonstrate this technology,” said Rob Zellem, Roman Space Telescope deputy project scientist for communications at NASA Goddard. “We’ll be applying those lessons learned to the next generation of NASA flagship missions that will be explicitly designed to look for Earth-like planets.”

A Major Mission Milestone

The coronagraph was successfully integrated into Roman’s Instrument Carrier, a large grid-like structure that sits between the space telescope’s primary mirror and spacecraft bus, which will deliver the telescope to orbit and enable the telescope’s functionality upon arrival in space. Assembly of the mission’s spacecraft bus was completed in September 2024.

The Instrument Carrier will hold both the coronagraph and Roman’s Wide Field Instrument, the mission’s primary science instrument, which is set to be integrated later this year along with the Roman telescope itself. “You can think of [the Instrument Carrier] as the skeleton of the observatory, what everything interfaces to,” said Brandon Creager, lead mechanical engineer for the Roman Coronagraph at JPL.

The integration process began months ago with mission teams from across NASA coming together to plan the maneuver. Additionally, after its arrival at NASA Goddard, mission teams ran tests to prepare the coronagraph to be joined to the spacecraft bus.

During the integration itself, the coronagraph, which is roughly the size and shape of a baby grand piano (measuring about 5.5 feet or 1.7 meters across), was mounted onto the Instrument Carrier using what’s called the Horizontal Integration Tool.

First, a specialized adapter developed at JPL was attached to the instrument, and then the Horizontal Integration Tool was attached to the adapter. The tool acts as a moveable counterweight, so the instrument was suspended from the tool as it was carefully moved into its final position in the Instrument Carrier. Then, the attached Horizontal Integration Tool and adapter were removed from the coronagraph. The Horizontal Integration Tool previously has been used for integrations on NASA’s Hubble and James Webb Space Telescope.

As part of the integration process, engineers also ensured blanketing layers were in place to insulate the coronagraph within its place in the Instrument Carrier. The coronagraph is designed to operate at room temperature, so insulation is critical to keep the instrument at the right temperature in the cold vacuum of space. This insulation also will provide an additional boundary to block stray light that could otherwise obscure observations.

Following this successful integration, engineers will perform different checks and tests to ensure that everything is connected properly and is correctly aligned before moving forward to integrate the Wide Field Instrument and the telescope itself. Successful alignment of the Roman Coronagraph’s optics is critical to the instrument’s success in orbit.

This latest mission milestone is the culmination of an enduring collaboration between a number of Roman partners, but especially between NASA Goddard and NASA JPL.

“It’s really rewarding to watch these teams come together and build up the Roman observatory. That’s the result of a lot of teams, long hours, hard work, sweat, and tears,” said Liz Daly, the integrated payload assembly integration and test lead for Roman at Goddard.

“Support and trust were shared across both teams … we were all just one team,” said Gasia Bedrosian, the integration and test lead for the Roman Coronagraph at JPL. Following the integration, “we celebrated our success together,” she added.

The Roman Coronagraph Instrument was designed and built at NASA JPL, which manages the instrument for NASA. Contributions were made by ESA (European Space Agency), JAXA (Japan Aerospace Exploration Agency), the French space agency CNES (Centre National d’Études Spatiales), and the Max Planck Institute for Astronomy in Germany. Caltech, in Pasadena, California, manages NASA JPL for the agency. The Roman Science Support Center at Caltech/IPAC partners with NASA JPL on data management for the Coronagraph and generating the instrument’s commands.

Quelle: NASA

----

Update: 11.11.2024

.

NASA's Roman space telescope gets ready to stare at distant suns to find alien planets