16.04.2024

Orion Spacecraft Enters Rarefied Air with Vacuum Test

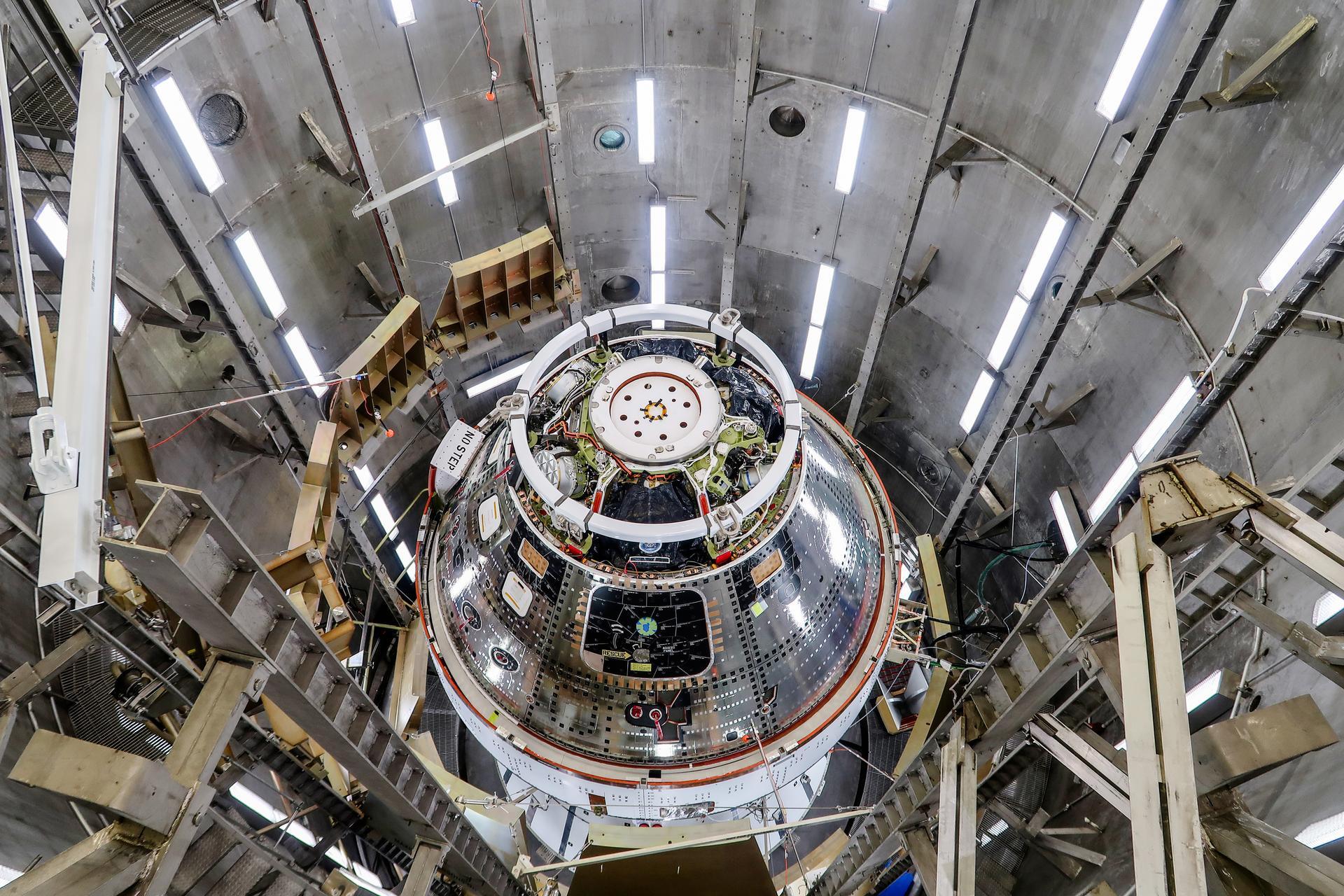

Artemis 2’s Orion crew and service modules await testing inside the refurbished Apollo vacuum chamber. Credit: NASA/David Wellendorf.

After nearly six years of work, the first human-rated Orion spacecraft is complete. The capsule will carry astronauts Reid Wiseman, Victor Glover, Christina Koch, and Jeremy Hansen to the Moon during next September’s Artemis 2 mission. Orion undoubtedly looks like a fully-functional spacecraft. The crew and service modules were mated last November, and the former is now shrouded in its reflective thermal protection system tiles. Inside the crew cabin, the control panels have been installed for an in-flight manual piloting test. With all this being said, the Artemis 2 spacecraft is still factory-fresh and must prove that it is ready to face the hostile environment of space. On April 4th, NASA transported Orion to a vacuum chamber to begin a fundamental sequence of preflight tests.

Artemis 2’s Orion capsule still lacks an official name. However, mission commander Reid Wiseman told AmericaSpace that the engineers at the Kennedy Space Center (KSC) have taken to calling it “The Ship.” “The young men and women working on this vehicle have a complete and personal attachment to ‘The Ship,’” said Wiseman. “They spoke of it so endearingly.”

Some of the engineers have been working on this magnificent spacecraft ever since it arrived at the Kennedy Space Center in October of 2018. At that point, the infant Orion was nothing more than an olive-green pressure vessel milled out of panels of aluminum-lithium alloy. It was no more a spacecraft than the framework of a chassis is a car. During the intervening six years, the KSC team outfitted it with propellant tanks and thrusters, a life support system, a heat shield, crew cabin furnishing, and 15 miles of wiring. They are undoubtedly proud to see the completed “Ship” preparing to spread its solar array wings.

Artemis 1’s Orion spacecraft was completed in November of 2019, but it had to wait three years to fly due to unforeseen development challenges with its SLS launch vehicle. For Artemis 2, the situation is inverted. The elements of the SLS are ready for stacking, while Orion is the pacing item for the schedule. NASA is working to resolve four issues which appeared during final preparations for the mission. AmericaSpace’s Ben Evans described the first three anomalies in detail in his January feature on Artemis; the final issue surfaced one month later. The Orion program’s approach to resolving these safety-critical issues is described below.

1) Heat shield: During reentry, Orion is protected an ablative material called Avcoat. As it is heated, an ablative heat shield slowly chars, liberating microscopic flakes and gases; these products then carry thermal energy away from the spacecraft. Following the splashdown of Artemis 1, the recovery team documented that several larger chunks of Avcoat were also lost. While a healthy amount of material was left behind, NASA would like to understand this unexpected behavior before entrusting the heat shield with the lives of Wiseman, Glover, Koch, and Hansen.

The root cause of the anomaly is still under investigation. However, Amit Kshatriya, the associate administrator who leads NASA’s Moon to Mars program, noted that it could be a byproduct of Orion’s novel skip entry [1]. “We went frame by frame through every piece of video we had from Orion to determine when the initiation of that char liberation began, and most of it was after we stated climbing out of that first dive into the skip,” he said. If the excess ablation is, indeed, the result of the skip entry, NASA could elect to replace it with a direct trajectory; the tradeoff would be that Orion would endure higher peak heating and splash down further from shore.

2) ECLSS valves: The Orion Environmental Control and Life Support System (ECLSS) will make its debut on Artemis 2. The lunar flyby captures the lion’s share of publicity, but testing the ECLSS is considered the most important objective of the mission. Until late last year, Artemis 2’s completed life support system appeared to be flawless. However, its reliability was called into question when a controller for Artemis 3’s ventilation system failed during a preflight test.

The failure was traced back to a circuit within the motor which activates one of the valves adjusting the flow of gases through the crew cabin. Identical valves are spaced throughout the ECLSS, and every one of them had to be hardened to withstand excess voltage. In a subsequent interview with NASASpaceflight’s Phillip Sloss, Kshatriya revealed that the concerning issues with the ECLSS should soon be a thing of the past [2]. “They finished all that work (modifications) in the last three months, did the re-acceptance testing, shook it, did all the thermal sweeps, screened it for workmanship, and it’s over there at KSC.”

3) Battery disconnection: During launch, Orion is entirely dependent upon its batteries for power. A vibration test revealed that the batteries might become disconnected from the rest of the capsule’s systems during a worst-case abort scenario. Such a failure would render the spacecraft unable to deploy its parachutes and splash down safely. This is a fringe scenario, as it would require both a failure of the SLS and the most extreme vibrational environment possible as the abort motor fired. However, given the catastrophic consequences of a battery failure and unanticipated margin in the Artemis 2 schedule due to other anomalies, NASA elected to fix it anyway.

The resolution of the battery issue is lagging behind the work on the ECLSS system. In his interview with NASASpaceflight, Kshatriya said, “I think we have a good understanding of the environment (…), and so there are a couple of things that they’re working through in terms of either a repair of the existing batteries or an acceleration off the Artemis 3 shipment.” He added, “We have to settle on what the battery solution is going to be, so there is a fair bit of uncertainty there. I think we’ve accounted for it in the risk for the overall schedule.”

4: Side hatch: In a distant echo of the lessons learned from the Apollo 1 tragedy, there are also concerns about Orion’s side hatch. In the event of an emergency on the launch pad, such as a fire or a toxic gas leak, Wiseman, Glover, Koch, and Hansen must be able to evacuate Orion in a matter of seconds. In February, the Aerospace Safety Advisory Panel (ASAP)’s William Bray disclosed, “NASA has been investigating a number of issues associated with the side hatch design. It’s really specifically in an area where it could affect (the crew’s) ability to open the hatch in a contingency operation” [3]. He did not disclose the details of the anomaly, but ASAP later wrote that it can occur when there is a pressure differential between the crew cabin and the surrounding atmosphere. ASAP was concerned that, in some scenarios, the mechanisms which open the hatch might not be able to overcome a difference in pressure between the two environments.

NASA’s Public Affairs Office generously provided an update on the investigation in response to an inquiry from AmericaSpace: “NASA continues to work the design of Orion’s side hatch regarding operations under pressure changes across the hatch in normal and emergency scenarios. NASA previously noted that data on the hatch’s hinges required additional analysis and testing to ensure the hatch can safely open in all cases either by recovery personnel or by the crew themselves, if necessary. Full scale testing is underway to verify the capability and develop operations required to ensure the hatch can be opened in a variety of different potential pressure scenarios. This is not expected to drive the critical path for Artemis II.”

All four issues are still in various stages of investigation and/or repair. However, NASA is reasonably confident that it will be able to resolve all of them in time to meet Artemis 2’s current targeted launch date. “I would say there’s nothing I’ve seen in the recovery plans or the test plans that would give me any pause that we’re not going to be able to hold the date that we pushed out in January, with some margin,” Kshatriya told Sloss.

With that expectation in mind, NASA is pushing ahead with Orion’s most significant integrated test. Thermal and vacuum (TVAC) testing verifies that a space vehicle is able to withstand the negligible pressures and extreme temperatures found in space. It is standard protocol for all piloted and robotic spacecraft, including Artemis 2.

The Artemis 1 Orion served as a pathfinder for its sister ships. Prior to its lunar mission, the capsule and its service module were flown to NASA’s Glenn Research Center aboard a Super Guppy aircraft. There, they were placed inside the world’s largest vacuum chamber at the Plum Brook Facility for a comprehensive series of tests. The Plum Brook vacuum chamber is able to reproduce the pressures and temperatures found in space simultaneously. The drawback? It would be infeasible to shuttle Orion vehicles between Florida and Ohio while maintaining an annual cadence of Artemis missions.

To support Artemis 2 and future missions, NASA refurbished one of the two venerable vacuum chambers which were used to test the Apollo spacecraft. The Orion final assembly line is at one end of the Operations and Checkout Building, and it has been teeming with activity for over a decade. The derelict vacuum chambers were at the other end of the building. Each chamber is a 33-foot-wide, 44-foot-tall cylinder. They can replicate the negligible pressure found at 250,000 feet (47 miles), which is over six times higher than the cruising altitude of an airliner and just three miles beneath the U.S. demarcation line for the edge of space. Thermal testing is performed in separate facilities. For the Artemis program, NASA chose to upgrade the left (west) facility since it was closer to the Orion production area.

The Kennedy Space Center’s vacuum chambers have a storied history. They were built in 1965 so that NASA could test the Apollo spacecraft in the same facility which prepared them for flight. They were used to test every Command and Service Module and every Lunar Module, from the ill-fated Apollo 1 capsule to Apollo 17’s America. Whenever a CSM was placed inside the chamber, the prime crew would board it and test procedures while the vacuum test was underway. As they could not take advantage of microgravity to move around the confined spacecraft in three dimensions, this was undoubtedly an uncomfortable experience.

The vacuum chambers were used to test the Apollo-Soyuz Test Project’s docking module. Once that mission lifted off, they were largely abandoned. However, the chambers were occasionally used to test the Spacelab modules which flew in the Space Shuttle’s payload bay, as well as the laboratories, habitats, and nodes of the International Space Station.

Given its age, a team of 70 engineers needed to upgrade the vacuum chamber in order to prepare it for the next chapter in its career. Upgrades included new vacuum pumps, improved lighting, and a new control room with up-to-date electronics. Once they finished the renovation, the Orion team carefully lifted the completed Artemis 2 spacecraft into the chamber on April 4th.

Next, Orion will be put through a series of tests which will replicate the environment found in cislunar space. Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) testing are already underway. These two tests sound similar, but they fulfill distinct purposes. The former confirms that the spacecraft will not be inhibited by radio wave emissions from external sources, such as the Sun, the Earth, and the galactic background. The latter verifies that the spacecraft itself does not release electromagnetic radiation which could disrupt its mission or damage its own components. In a statement to AmericaSpace on April 10th, NASA’s Public Affairs Office said that EMC and EMI testing should last through the end of the month.

Following the completion of these first two tests, Orion will be temporarily moved back to the production line for unspecified “further work” [4]. This might include repairing or replacing the spacecraft’s batteries if the disconnection anomaly is resolved. If the batteries are still not ready for installation, Kshatriya noted that they can be installed at a later date after the spacecraft is moved back into the vacuum chamber [2].

The Public Affairs Office informed AmericaSpace that the vacuum test itself is scheduled for July. This will be the pinnacle of the Artemis 2 test series. Even though the generic Orion design is space-rated, there are several worthwhile reasons to place each new vehicle in a vacuum while it is still on Earth. The test will confirm that there are no leaks in the pressure vessel. It will also allow any volatile compounds on the spacecraft to exsolve, preventing them from influencing Orion’s performance once it is in space. After the test is complete, Orion will be handed over to the launch processing team to be stacked with its SLS rocket.

Quelle: AS

----

Update: 27.04.2024

.

NASA begins delivering Artemis Moon Trees to be planted across US

Artemis II astronaut Christina Koch is seen the Governor's Mansion in her home state of North Carolina as Governor Roy Cooper looks on, on Wednesday, April 24, 2024. (NC Governor's Office)

The first woman slated to launch to the moon has delivered one of the first trees grown from seeds recently flown there.

NASA astronaut Christina Koch presented a Loblolly Pine "Moon Tree" sapling to her home state of North Carolina on Wednesday (April 24). The tree began as one of more than 1,000 seeds that were flown around the moon on NASA's uncrewed Artemis I mission in 2022.

"With the planting of an Artemis Moon Tree today at the governor's mansion, North Carolina is firmly planting the roots of exploration for generations to come," said Koch, who is targeted to launch in late 2025 as a member of the Artemis II crew.

Koch's presentation marked one of the first deliveries to a new generation of Moon Tree stewards, who NASA has selected from across the country. Koch's alma mater, White Oak High School in Jacksonville, North Carolina, is another of the chosen recipients.

"I used to dream about going to space by looking up through the pine trees, and so, it was just a really great symbol of our commitment to North Carolina, North Carolina's commitment back to NASA, and all the amazing universities here that produce people for the aerospace industry," said Koch according to The Daily News, the local newspaper in Jacksonville. "That whole Artemis generation that's coming up here and that we can't wait to see exploring space."

In addition to the loblolly pines, which are native to North Carolina, the Orion spacecraft that flew on Artemis I also carried sycamore, sweetgum, Douglas-fir and giant sequoia seeds on its 270,000-mile (435,000-kilometer), 25-day journey. Back on Earth, the U.S. Department of Agriculture's Forest Service oversaw that the seeds germinated and grew into seedlings for their distribution as Artemis Moon Trees.

In August 2023, NASA put out a call for interested educational and community organizations to apply to grow a Moon Tree. The space agency chose recipients based on their ability to care for the various tree species and their position to use the tree's growth as an outreach tool in their neighborhoods, cities or states.

"Together, NASA and the Forest Service will deliver a piece of science history to communities across our nation," said Mike Kincaid, associate administrator of NASA's Office of STEM (science, engineering technology and math) engagement. "Through this partnership, future explorers, scientists and environmentalists will have the opportunity to nurture and be inspired by these Artemis artifacts in the community where they live, work and learn."

NASA is notifying the selected institutions in waves, with the first now underway, followed by groups in the fall of this year, spring 2025 and fall 2025. The agency plans to keep a record of the recipients on its website, noting the species of tree they received and their planting cycle.

Moon Tree hosts will also be invited to engage with the public at quarterly virtual gatherings beginning this summer.

A full list of the first, almost 50 recipients has yet to be made public, but according to a social media post, Mary Chapa Academy in Greenfield, California received a sapling on Thursday (April 25).

The idea for the Artemis I Moon Trees was grown out of a similar project carried out by Apollo 14 command module pilot Stuart Roosa, who as a former Forest Service smoke jumper launched with hundreds of tree seeds in his personal preference kit on the 1971 moon mission. The Apollo Moon Tree seedlings were planted across the U.S., with many becoming part of the country's bicentennial celebration in 1976.

"A new era of Moon trees will one day stand tall in communities across America," said Bill Nelson, NASA's Administrator. "NASA is bringing the spirit of exploration back down to Earth because space belongs to everyone. The Artemis Generation will carry forth these seedlings that will be fertile ground for creativity, inspiration, and discovery for years to come."

Quelle: CS

----

Update: 9.06.2024

.

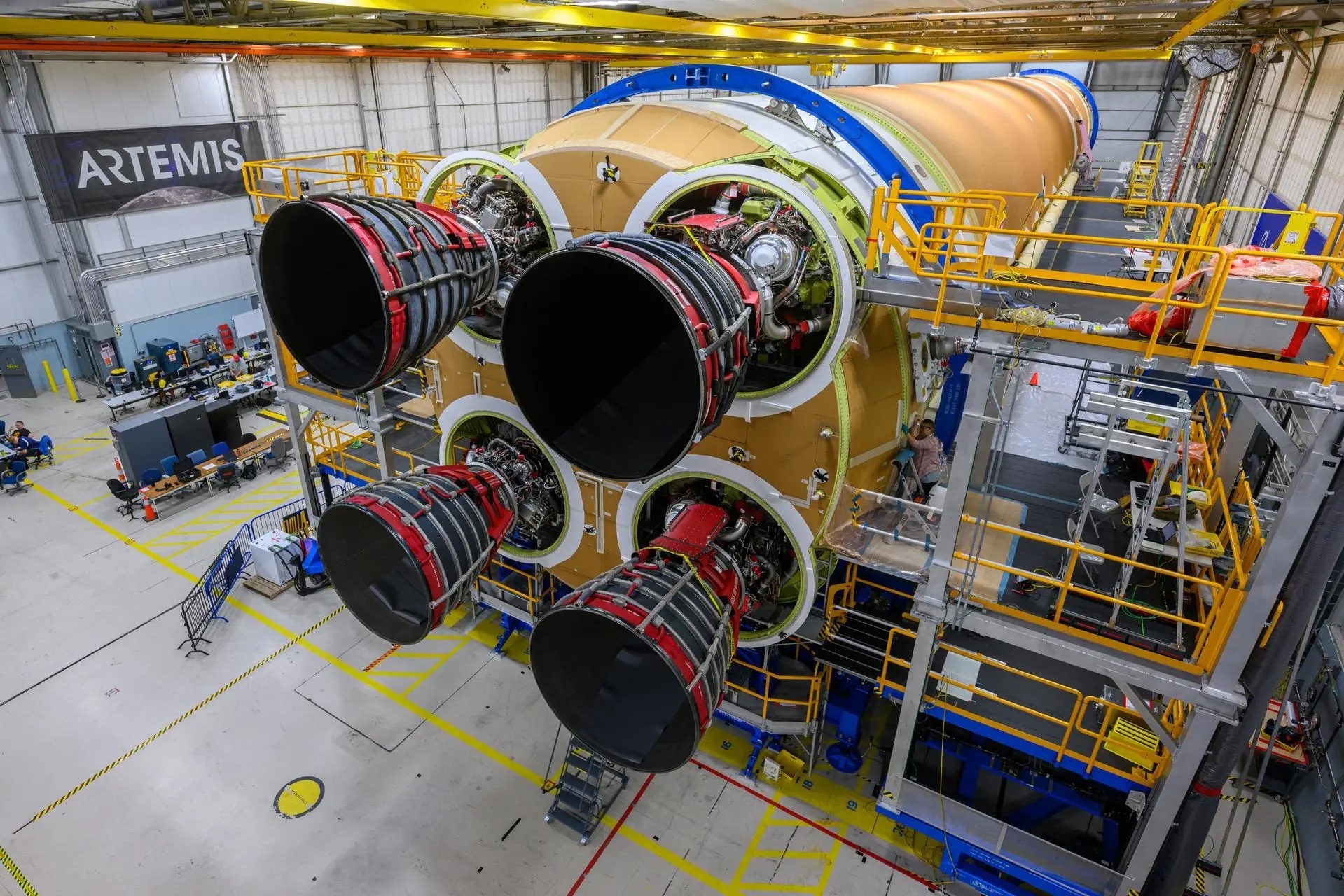

NASA Invites Media to Rollout Event for Artemis II Moon Rocket Stage

The core stage is the backbone of the SLS (Space Launch System) rocket that will help power NASA’s Artemis II mission to send a crew of four astronauts around the Moon in 2025. Here, the core stage is currently behind scaffolding to allow work to continue at NASA’s Michoud Assembly Facility in New Orleans. The stage’s two massive propellant tanks hold a collective 733,000 gallons of liquid propellant to power the four RS-25 engines at its base. Following hardware acceptance reviews and final checkouts, the stage will be readied for delivery via the agency’s Pegasus barge to NASA’s Kennedy Space Center in Florida for Artemis II launch preparations. (NASA/ Eric Bordelon)

NASA will roll the fully assembled core stage for the agency’s SLS (Space Launch System) rocket that will launch the first crewed Artemis mission out of NASA’s Michoud Assembly Facility in New Orleans in mid-July. The 212-foot-tall stage will be loaded on the agency’s Pegasus barge for delivery to Kennedy Space Center in Florida.

Media will have the opportunity to capture images and video, hear remarks from agency and industry leadership, and speak to subject matter experts with NASA and its Artemis industry partners as crews move the rocket stage to the Pegasus barge.

NASA will provide additional information on specific timing later, along with interview opportunities. This event is open to U.S. and international media. International media must apply by June 14. U.S. media must apply by July 3. The agency’s media credentialing policy is available online.

Interested media must contact Corinne Beckinger at corinne.m.beckinger@nasa.gov and Craig Betbeze at craig.c.betbeze@nasa.gov. Registered media will receive a confirmation by email.

The rocket stage with its four RS-25 engines will provide more than 2 million pounds of thrust to send astronauts aboard the Orion spacecraft for the Artemis II mission. Once at Kennedy, teams with NASA’s Exploration Ground Systems Program will finish outfitting the stage and prepare it for stacking and launch. Artemis II is currently scheduled for launch in September 2025.

Building, assembling, and transporting the core stage is a collaborative process for NASA, Boeing, the core stage lead contractor, and lead RS-25 engines contractor Aerojet Rocketdyne, an L3 Harris Technologies company.

NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under the agency’s Artemis campaign. The SLS rocket is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. The SLS rocket is the only rocket designed to send Orion, astronauts, and supplies to the Moon in a single launch.

Quelle: NASA

----

Update: 16.06.2024

.

NASA Invites Media to See Artemis II Moon Rocket Elements at Kennedy

Media are invited in late July to NASA’s Kennedy Space Center in Florida to see progress on the agency’s SLS (Space Launch System) Moon rocket as preparations continue for the Artemis IItest flight around the Moon.

Participants joining the multi-day events will see the arrival and unloading of the 212-foot-tall SLS core stage at the center’s turn basin before it is transported to the nearby Vehicle Assembly Building. The stage will arrive on NASA’s Pegasus barge from the agency’s Michoud Assembly Facility in New Orleans, where it was manufactured and assembled.

Media also will see the twin pair of solid rocket boosters inside the Rotation, Processing, and Surge Facility at the spaceport, where NASA’s Exploration Ground Systems Program is processing the motor segments in preparation for rocket assembly. NASA and industry subject matter experts will be available to answer questions. At launch, the SLS rocket’s two solid rocket boosters and four RS-25 engines, located at the base of its core stage, will produce 8.8 million pounds of thrust to send the first crewed mission of the Artemis campaign around the Moon.

Media interested in participating must apply for credentials at:

To receive credentials, international media must apply by Friday, June 28, and U.S. citizens must apply by Thursday, July 5.

Credentialed media will receive a confirmation email upon approval, along with additional information about the specific date for the activities when they are finalized. NASA’s media accreditation policy is available online. For questions about accreditation, please email ksc-media-accreditat@mail.nasa.gov. For other questions, please contact Kennedy’s newsroom at: 321-867-2468.

Para obtener información sobre cobertura en español en el Centro Espacial Kennedy o si desea solicitar entrevistas en español, comuníquese con Antonia Jaramillo o Messod Bendayan a: antonia.jaramillobotero@nasa.gov o messod.c.bendayan@nasa.gov.

The approximately 10-day Artemis II flight will test NASA’s SLS rocket, Orion spacecraft, and ground systems for the first time with astronauts and will pave the way for lunar surface missions, including landing the first woman, first person of color, and first international partner astronaut on the Moon.

Quelle: NASA

----

Update: 10.07.2024

.

NASA Moon Rocket Stage for Artemis II Moved, Prepped for Shipment

NASA/Michael DeMocker

NASA is preparing the SLS (Space Launch System) rocket core stage that will help power the first crewed mission of NASA’s Artemis campaign for shipment. On July 6, NASA and Boeing, the core stage lead contractor, moved the Artemis II rocket stage to another part of the agency’s Michoud Assembly Facility in New Orleans. The move comes as teams prepare to roll the massive rocket stage to the agency’s Pegasus barge for delivery to NASA’s Kennedy Space Center in Florida in mid-July.

Prior to the move, technicians began removing external access stands, or scaffolding, surrounding the rocket stage in early June. NASA and Boeing teams used the scaffolding surrounding the core stage to assess the interior elements, including its complex avionics and propulsion systems. The 212-foot core stage has two huge propellant tanks, avionics and flight computer systems, and four RS-25 engines, which together enable the stage to operate during launch and flight.

The stage is fully manufactured and assembled at Michoud. Building, assembling, and transporting is a joint process for NASA, Boeing, and lead RS-25 engines contractor Aerojet Rocketdyne, an L3Harris Technologies company.

NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

Quelle: NASA

----

Update: 18.07.2024

.

NASA Ships Moon Rocket Stage Ahead of First Crewed Artemis Flight

NASA rolled out the SLS (Space Launch System) rocket’s core stage for the Artemis II test flight from its manufacturing facility in New Orleans on Tuesday for shipment to the agency’s spaceport in Florida. The rollout is key progress on the path to NASA’s first crewed mission to the Moon under the Artemis campaign.

Using highly specialized transporters, engineers maneuvered the giant core stage from inside NASA’s Michoud Assembly Facility in New Orleans to the agency’s Pegasus barge. The barge will ferry the stage more than 900 miles to NASA’s Kennedy Space Center in Florida, where engineers will prepare it in the Vehicle Assembly Building for attachment to other rocket and Orion spacecraft elements.

“With Artemis, we’ve set our sights on doing something big and incredibly complex that will inspire a new generation, advance our scientific endeavors, and move U.S. competitiveness forward,” said Catherine Koerner, associate administrator for NASA’s Exploration Systems Development Mission Directorate at NASA Headquarters in Washington. “The SLS rocket is a key component of our efforts to develop a long-term presence at the Moon.”

Technicians moved the SLS rocket stage from inside NASA Michoud on the 55th anniversary of the launch of Apollo 11 on July 16, 1969. The move of the rocket stage for Artemis marks the first time since the Apollo Program that a fully assembled Moon rocket stage for a crewed mission rolled out from NASA Michoud.

The SLS rocket’s core stage is the largest NASA has ever produced. At 212 feet tall, it consists of five major elements, including two huge propellant tanks that collectively hold more than 733,000 gallons of super-chilled liquid propellant to feed four RS-25 engines. During launch and flight, the stage will operate for just over eight minutes, producing more than 2 million pounds of thrust to propel four astronauts inside NASA’s Orion spacecraft toward the Moon.

“The delivery of the SLS core stage for Artemis II to Kennedy Space Center signals a shift from manufacturing to launch readiness as teams continue to make progress on hardware for all major elements for future SLS rockets,” said John Honeycutt, SLS program manager at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “We are motivated by the success of Artemis I and focused on working toward the first crewed flight under Artemis.”

After arrival at NASA Kennedy, the stage will undergo additional outfitting inside the Vehicle Assembly Building. Engineers then will join it with the segments that form the rocket’s twin solid rocket boosters. Adapters for the Moon rocket that connect it to the Orion spacecraft will be shipped to NASA Kennedy this fall, while the interim cryogenic propulsion stage is already in Florida. Engineers continue to prepare Orion, already at Kennedy, and exploration ground systems for launch and flight.

All major structures for every SLS core stage are fully manufactured at NASA Michoud. Inside the factory, core stages and future exploration upper stages for the next evolution of SLS, called the Block 1B configuration, currently are in various phases of production for Artemis III, IV, and V. Beginning with Artemis III, to better optimize space at Michoud, Boeing, the SLS core stage prime contractor, will use space at NASA Kennedy for final assembly and outfitting activities.

Building, assembling, and transporting the SLS core stage is a collaborative effort for NASA, Boeing, and lead RS-25 engines contractor Aerojet Rocketdyne, an L3Harris Technologies company. All 10 NASA centers contribute to its development with more than 1,100 companies across the United States contributing to its production.

NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

Quelle: NASA

----

Update: 20.07.2024

.

Artemis II Core Stage on the Move

NASA/Eric Bordelon & Michael DeMocker

On July 16, 2024, the first core stage of NASA’s SLS (Space Launch System) rocket for the agency’s Artemis II mission began a journey from NASA’s Michoud Assembly Facility in New Orleans. The core stage was moved onto the agency’s Pegasus barge, where it will be ferried 900 miles to NASA’s Kennedy Space Center in Florida. Once at Kennedy, engineers will prepare it in the Vehicle Assembly Building for attachment to other rocket and Orion spacecraft elements.

The SLS rocket’s core stage is the largest NASA has ever produced. At 212 feet tall, it consists of five major elements, including two huge propellant tanks that collectively hold more than 733,000 gallons of super-chilled liquid propellant to feed four RS-25 engines. During launch and flight, the stage will operate for just over eight minutes, producing more than 2 million pounds of thrust to propel four astronauts inside NASA’s Orion spacecraft toward the Moon.

Quelle: NASA

----

Update: 27.07.2024

.

NASA’s Orion Spacecraft Gets Lift on Earth

Crane operator Rebekah Tolatovicz, a shift mechanical technician lead for Artic Slope Regional Corporation at NASA’s Kennedy Space Center in Florida, operates a 30-ton crane to lift the agency’s Artemis II Orion spacecraft out of the recently renovated altitude chamber to the Final Assembly and Systems Testing, or FAST, cell inside NASA Kennedy’s Neil A. Armstrong Operations and Checkout Building on April 27.

During her most recent lift July 10, Tolatovicz helped transfer Orion back to the FAST cell following vacuum chamber qualification testing in the altitude chamber earlier this month. This lift is one of around 250 annual lifts performed at NASA Kennedy by seven operator/directors and 14 crane operators on the ASRC Orion team.

“At the time of the spacecraft lift, I focus solely on what’s going on in the moment of the operation,” explains Tolatovicz. “Listening for the commands from the lift director, making sure everyone is safe, verifying the vehicle is clear, and ensuring the crane is moving correctly.”

All Orion crane operators are certified after classroom and on-the-job training focusing on areas such as rigging, weight and center of gravity, mastering crane controls, crane securing, assessing safety issues, and emergency procedures. Once certified, they progress through a series of the different lifts required for Orion spacecraft operations, from simple moves to the complex full spacecraft lift.

“It’s not until after the move is complete and the vehicle is secured that I have a moment to think about how awesome it is to be a part of history on the Orion Program and do what I get to do every day with a team of the most amazing people,” Tolatovicz said.

Quelle: NASA

----

Update: 8.08.2024

.

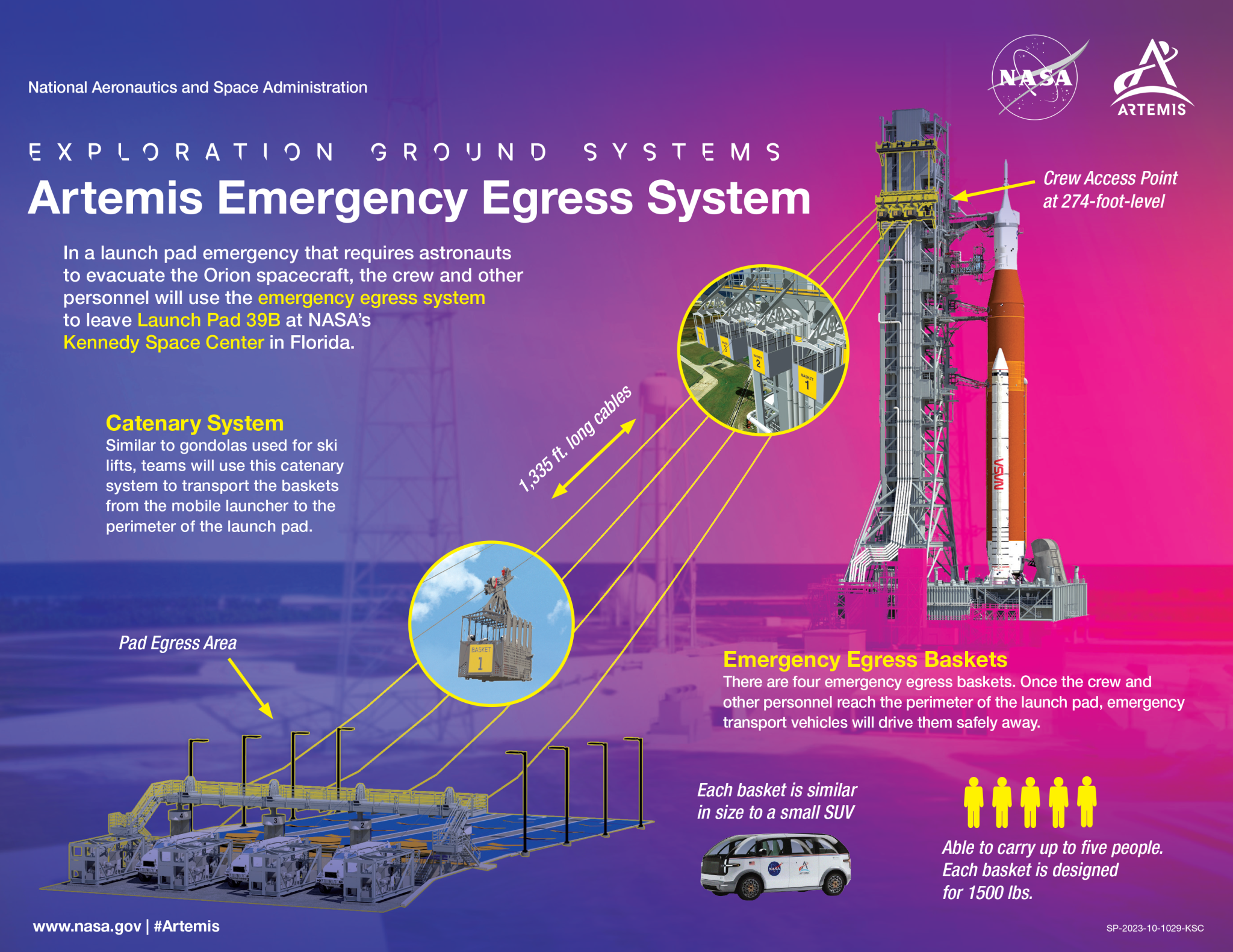

Artemis Emergency Egress System Emphasizes Crew Safety

Since NASA began sending astronauts to space, the agency has relied on emergency systems for personnel to safely leave the launch pad and escape the hazard in the unlikely event of an emergency during the launch countdown.

During the Mercury and Gemini programs, NASA used launch escape systems on spacecraft for the crew to safely evacuate if needed. Though these systems are still in use for spacecraft today, the emergency routes on the ground were updated starting with the Apollo missions to account for not only the crew, but all remaining personnel at the launch pad.

During Apollo, personnel relied on a ground-based emergency egress system – or emergency exit route – to allow for a quick and safe departure. Though the system has varied over time and different launch pads use different escape systems, the overall goal has stayed the same – quickly leave the launch pad and head to safety.

Beginning with Artemis II, the Exploration Ground Systems (EGS) Program at Kennedy Space Center in Florida, will use a track cable which connects the mobile launcher to the perimeter area of the launch pad where four baskets, similar to gondolas at ski lifts, can ride down. Once down at the ground level, armored emergency response vehicles are stationed to take personnel safely away from the launch pad to one of the triage site locations at Kennedy.

“We have four baskets that sit on the side of the mobile launcher tower at the same level as the crew access arm, the location where the crew enters the spacecraft,” said Amanda Arrieta, mobile launcher 1 senior element engineer for NASA’s EGS Program. “The intention is to provide another means of egress for the crew and the closeout crew in the event of an emergency. Each of these baskets will go down a wire. It’s a wire rope system that connects to the pad terminus, an area near the pad perimeter where the baskets will land after leaving the mobile launcher tower.”

The Artemis system works like this: personnel will exit the Orion spacecraft or the white room (depending where teams are at the time of the emergency) inside the crew access arm of the mobile launcher. Located on the 274-foot-level, teams are approximately 375 feet above the ground. From there, they will head down the 1,335-foot-long cables inside the emergency egress baskets to the launch pad perimeter, or the pad terminus area. Each basket, which is similar in size to a small SUV, is designed to carry up to five people or a maximum weight of 1,500 pounds.

Once teams have left the terminus area and arrive at the triage site location, emergency response crews are there to evaluate and take care of any personnel.

“When we send our crews to the pad during launch, their safety is always at the forefront of our minds. While it is very unlikely that we will need the emergency egress and pad abort systems, they are built and tested to ensure that if we do need them then they are ready to go,” said Charlie Blackwell-Thompson, Artemis launch director. “Our upcoming integrated ground systems training is about demonstrating the capability of the entire emergency egress response from the time an emergency condition is declared until we have the crews, both flight and ground, safely accounted for outside the hazardous area.”

For the agency’s Commercial Crew Program, SpaceX uses a slidewire cable with baskets that ride down the cable at the Launch Complex 39A pad. At Space Launch Complex 40, meanwhile, the team uses a deployable chute for its emergency egress system. Boeing and United Launch Alliance also use a slidewire, but instead of baskets, the team deploys seats that ride down the slide wires, similar to riding down a zip line, at Space Launch Complex 41 at Cape Canaveral Space Force Station.

Artemis II will be NASA’s first mission with crew aboard the SLS (Space Launch System) rocket and Orion spacecraft and will also introduce several new ground systems for the first time – including the emergency egress system. Though no NASA mission to date has needed to use its ground-based emergency egress system during launch countdown, those safety measures are still in place and maintained as a top priority for the agency.

----

Update: 16.08.2024

.

NASA Invites Media to Watch Artemis II Rocket Adapter Roll Out

To mark progress toward the first crewed flight test around the Moon in more than 50 years for the benefit of humanity, NASA will welcome media Wednesday, Aug. 21, to see a key adapter for the agency’s SLS (Space Launch System) rocket at its Marshall Space Flight Center in Huntsville, Alabama.

The cone-shaped launch vehicle stage adapter connects the rocket’s core stage to the upper stage and helps protect the upper stage’s engine that will help propel the Artemis II mission around the Moon. The event includes seeing the adapter on the move as it prepares for shipment to NASA’s Kennedy Space Center in Florida.

Media will have the opportunity to capture images and video and speak to subject matter experts as crews move the adapter out of NASA Marshall’s Building 4708 to the agency’s Pegasus barge. The barge will ferry the adapter first to NASA’s Michoud Assembly Facility, where it will pick up additional SLS hardware for future Artemis missions, and then travel to NASA Kennedy. In Florida, teams with NASA’s Exploration Ground Systems will prepare the adapter for stacking and launch.

This event is open to U.S. media, who must RSVP by 5 p.m. CDT on Monday, Aug. 19, to Jonathan Deal at jonathan.e.deal@nasa.gov. Additional details about timing and other details for the event are forthcoming to registered media.

Manufactured by prime contractor Teledyne Brown Engineering and the Jacobs Space Exploration Group’s ESSCA contract using NASA Marshall’s self-reacting friction-stir robotic and vertical weld tools, the launch vehicle stage adapter is the largest SLS component for Artemis II that is made at the center.

Through the Artemis campaign, NASA will land the first woman, first person of color, and its first international partner astronaut on the Moon. The rocket is part of NASA’s deep space exploration plans, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, Gateway in orbit around the Moon, and commercial human landing systems. NASA’s SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

Quelle: NASA

----

Update: 23.08.2024

.

NASA wants clarity on Orion heat shield issue before stacking Artemis II rocket

"We have still a lot of work to do to close out the heat shield investigation."

The Orion spacecraft for the Artemis II mission, comprising its crew and service modules, was lifted into a vacuum test chamber at NASA's Kennedy Space Center in Florida on April 4, 2024.

NASA would like to start stacking the Space Launch System rocket for the Artemis II mission—the first human flight around the Moon since 1972—sometime next month, but the agency's exploration chief says the milestone could be delayed as engineers continue studying the readiness of the Orion spacecraft's heat shield.

The heat shield, already installed at the base of the Orion spacecraft, will take the brunt of the heating when the capsule blazes through Earth's atmosphere at the end of the 10-day mission. On the Artemis I test flight in late 2022, NASA sent an Orion spacecraft to the Moon and back without a crew aboard. The only significant blemish on the test flight was a finding that charred chunks of the heat shield unexpectedly stripped away from the capsule during reentry as temperatures increased to nearly 5,000° Fahrenheit (2,760° Celsius).

The spacecraft safely splashed down, and if any astronauts had been aboard, they would have been fine. However, the inspections of the recovered spacecraft showed divots of heat shield material were missing. The heat shield material, called Avcoat, is designed to erode away in a controlled manner during reentry. Instead, fragments fell off the heat shield that left cavities resembling potholes.

“A lot of work to do”

NASA launched internal and independent investigations to look into the heat shield issue. Catherine Koerner, NASA's associate administrator for development of exploration systems, told Ars the inquiry remains open.

"We have not made any formal decisions on the forward path yet because we still are doing analysis," she said. "There are a lot of complications associated with the heat shield, not only with identifying a root cause, but also figuring out a path forward once we identify that root cause."

This is a complicated thermodynamic and aerodynamic problem, with engineers studying the combined effects of heating and air resistance as the Orion spacecraft dives deeper into the atmosphere. Victor Glover, the pilot of the Artemis II mission, told Ars earlier this year that ground testing and analyses can only go so far, and some of the dynamics may not be fully understood without more flight data.

Commander Reid Wiseman, mission specialist Christina Koch, and Canadian astronaut Jeremy Hansen will join Glover on the Artemis II mission. They will fly around the far side of the Moon inside the Orion capsule after lifting off from NASA's Kennedy Space Center in Florida on a Space Launch System (SLS) rocket. Artemis II will pave the way for future landing missions to deliver astronauts to the Moon's south pole.

But it's taking longer than NASA officials would have liked to complete the Orion heat shield investigation. Koerner said she didn't want to estimate how much longer it would take for NASA to come to a decision on what, if anything, to change on the Artemis II mission to reduce the risk to the astronauts.

"The best way to ensure crew safety on any activity, but especially this one in particular, is to make sure that they understand that they're doing this—the focus of this investigation and the forward path—with crew safety in mind, and not with schedule pressure or any other kind of external pressure from stakeholders," she said.

Potential solutions to the heat shield issue for Artemis II include altering the spacecraft's trajectory during reentry or making changes to the heat shield itself. The latter option would require partially disassembling the Orion spacecraft at NASA's Kennedy Space Center, something that would probably delay the launch date from September 2025 until 2027 at the earliest. Another alternative could be to do nothing and fly the Artemis II mission as is.

"The entire trade space is open," Koerner said. "But as far as the actual Artemis II mission, right now, we're still holding to the September ’25 launch date, knowing that we have still a lot of work to do to close out the heat shield investigation.”

Limited life

One decision NASA will soon have to make is whether to begin stacking each of the Space Launch System's twin five-segment solid rocket boosters inside the Vehicle Assembly Building (VAB) at Kennedy. That is supposed to begin next month, with the placement of the bottom segments of each booster on the rocket's mobile launch platform inside the VAB.

But there's a time limit on how long the boosters can be stacked vertically on their launch platform. The joints connecting each piece of the SLS rocket's side boosters were originally certified for one year, but NASA nearly doubled the time limit for the Artemis I launch and could do so again for Artemis II.

Nevertheless, Koerner said NASA wants a better idea of the direction it will go on the Orion heat shield issue before giving the green light to assemble the rocket inside the VAB. "We will wait until we have the decision on the heat shield, or at least understanding of that, before we make the decision on stacking," she told Ars.

The major elements of the SLS rocket and Orion spacecraft are all undergoing preparations at the Florida launch site. The SLS core stage arrived at Kennedy last month, and technicians will mount it between the rocket's twin solid-fueled boosters once those are fully stacked on the launch platform.

Right now, work on the Orion spacecraft is driving the schedule for the Artemis II launch. It's not just the heat shield but also hands-on preparations and testing on Orion inside the Neil Armstrong Operations and Checkout Building at Kennedy. The Orion crew and service modules—made by Lockheed Martin and Airbus, respectively—are bolted together and recently completed tests inside a vacuum chamber to simulate the airless conditions in space.

Ground teams are swapping out batteries and digital motor controllers on the Orion spacecraft to resolve two other technical issues with the vehicle. Once this work is complete, NASA will transfer the spacecraft to a separate facility at Kennedy for fueling and integration with Orion's launch abort system. Then, perhaps in the spring or summer of 2025, Orion will be ready for stacking on top of the SLS rocket.

All that, of course, hinges on NASA deciding Artemis II is safe enough to fly without any hardware changes to the Orion heat shield.

Quelle: arsTechnica