.

Still probably many years in the future and most likely international in nature, a Mars Sample Return mission represents one of the most challenging space ventures possible for robotic exploration. First a sample container must be landed on Mars, along with a rover to retrieve a cache of samples carefully selected by a previous mission. Then, once filled, it will be launched back up to Mars orbit to be captured by a return spacecraft and transported back to Earth.

.

Mars, an object of fascination and mystery since ancient times, remains a primary target for robotic exploration.

The Red Planet is, for several reasons, the focus point in the international context of robotic exploration:

Mars is the most Earth-like planet in the Solar System. Geological structures show that long ago liquid water flowed on the surface of Mars. On Earth water implies life; an obvious question follows: Is there, or was there, life on Mars?

Mars is, to date, the most accessible planet for evaluating whether or not life exists, or has existed, elsewhere in the Universe. This accessibility allows us to address questions about the origins and evolution of life by sending a series of missions to the planet, progressively developing the technology need for exploration.

Mars is a potential staging post for human exploration of space.

A sample return mission – key to understanding the Red Planet

Bringing samples of Mars back to Earth, although technologically challenging, is essential for answering critical scientific questions that cannot be addressed by purely in situ missions. Only in laboratories on Earth can scientists study the samples in sufficient detail to be able to begin to answer questions related to habitability and life. The Mars Sample Return mission will address these questions.

Mars Sample Return represents a milestone in the exploration of the Solar System and, in particular, in the investigation of Mars and the questions regarding its potential habitability. Some important factors influencing the design and development of such a mission are: landing site, sample size, sample collection and sample protection.

A number of new technologies will be required to carry out this pioneering mission: landing system, the ascent vehicle, the rendezvous system in Mars orbit, and the Earth re-entry vehicle or capsule. These will be developed as part of the Mars Robotic Exploration Programme.

The importance and complexity of the Mars Sample Return mission necessitates a global effort, with particular collaboration between ESA and NASA, as well as the participation of other space agencies.

Protecting our neighbours, and ourselves

Careful measures will be needed to protect the sample to avoid contamination of Mars by organisms from Earth and vice versa. A Mars sample return mission would need to comply with planetary protection requirements more demanding than for any mission flown to date.

.

MARTIAN BOX OF DELIGHTS

Mars sample container

.

This spherical container has been engineered to house the most scientifically valuable cargo imaginable: samples brought back from the Red Planet.

Still probably many years in the future and most likely international in nature, a Mars sample-return mission is one of the most challenging space ventures possible for robotic exploration.

A robust, multifunctional sample container is an essential link in the long technical chain necessary to make such a mission successful.

Weighing less than 5 kg, this 23 cm-diameter sphere is designed to keep martian samples in pristine condition at under –10°C throughout their long journey back to Earth.

First, the sample container must be landed on Mars, along with a rover to retrieve a cache of samples carefully selected by a previous mission, according to current mission scenarios.

The container seen here hosts 11 sealable receptacles, including one set aside for a sample of martian air.

Then, once filled, it will be launched back up to Mars orbit. There it will remain for several days until a rendezvous spacecraft captures it. To ease the process of rendezvous, the sample container carries a radio emitter and retroreflectors for close-up laser ranging.

Before being returned to Earth, the container will be enclosed in another larger bio-sealed vessel to ensure perfect containment of any returned martian material. This container will then be returned to Earth for a high-speed entry.

“Because there is the potential, however remote, that the samples contain alien life, we have to comply with strict planetary protection protocols not to bring them into contact with Earth’s biosphere,” explained Benoit Laine, Head of ESA’s Thermal Analysis and Verification section, who oversaw the sample container project.

“In effect, the parachute technology is not reliable enough – which means the container must be able to withstand a crash landing without parachute.

“The mission design therefore does not include any parachute, and the capsule literally falls from Mars onto Earth, decelerated only by the pressure on the heatshield through Earth’s atmosphere, and by the impact at landing.”

While the sample container is a proof-of-concept design rather than actual mission hardware, it is fully functional and has undergone testing in simulated thermal conditions, including a 400 g shock test.

“This challenging project drew on the expertise of multiple ESA specialists,” added Benoit. “It incorporates mechanical systems covering structural, thermal and mechanisms engineering but also communications, antennas and power – it has of course to incorporate a highly reliable battery.”

The prime contractor for the project, which was supported through ESA’s Aurora programme, was French company Mecano I&D. Activities to prepare for a Mars sample mission continue, including a refinement of the sample container design, coordinated by the future missions preparatory office of ESA’s Directorate of Science and Robotic Exploration.

.

ESA Director General Jean-Jacques Dordain and Head of Roscosmos Vladimir Popovkin met at ESA Headquarters in Paris on 14 March 2013 to sign an agreement that seals ExoMars as a partnership between the two space agencies.

.

Date: 08 Apr 2013

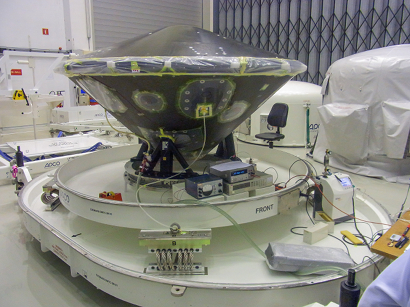

Satellite: ExoMars 2016 - EDM

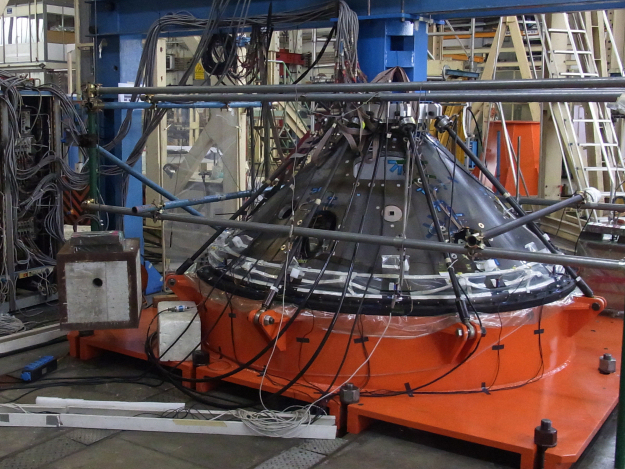

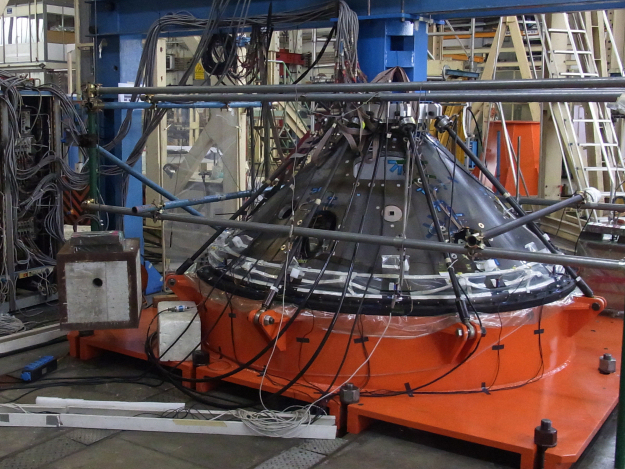

Depicts: ExoMars Entry, Descent and Landing Demonstrator Module Structural Model

Location: ESA's European Space Research and Technology Centre, Noordwijk, The Netherlands

Copyright: ESA - Anneke Le Floc'h

Lowering the ExoMars Entry, Descent and Landing Demonstrator Module (EDM) Structural Model (SM) onto the Multishaker at ESA's European Space Research and Technology Centre (ESTEC) in Noordwijk, the Netherlands, for vibration testing.

Six metal brackets, three of which are being used here to hoist the EDM, also compensate for the mass of items not present in the SM.

The SM consists of all the structural components of the spacecraft, with the instruments, electronics boxes and other non-structural hardware represented by mass dummies. It is 2.4 m in diameter, 1.8 m high and weighs about 600 kg.

.

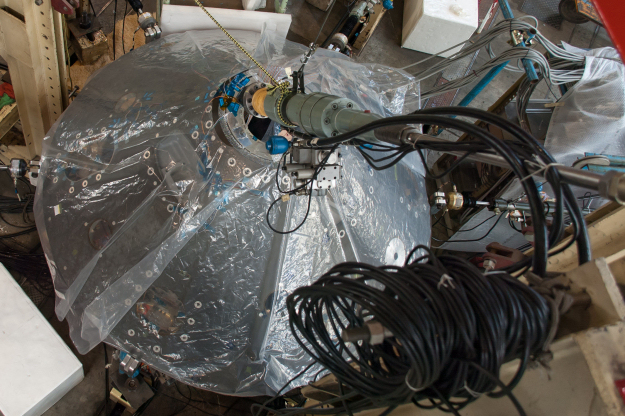

Date: 08 Apr 2013

Satellite: ExoMars 2016 - EDM

Depicts: ExoMars Entry, Descent and Landing Demonstrator Module Structural Model

Location: ESA's European Space Research and Technology Centre, Noordwijk, The Netherlands

Copyright: ESA - Boris Bethge

The ExoMars Entry, Descent and Landing Demonstrator Module Structural Model (SM) is subject to leak rate measurement of the seal between the front shield structure and the back cover, at ESA's European Space Research and Technology Centre in Noordwijk, the Netherlands, on 23 March 2013.

The SM consists of all the structural components of the spacecraft, with the instruments, electronics boxes and other non-structural hardware represented by mass dummies. It is 2.4 m in diameter, 1.8 m high and weighs about 600 kg.

.

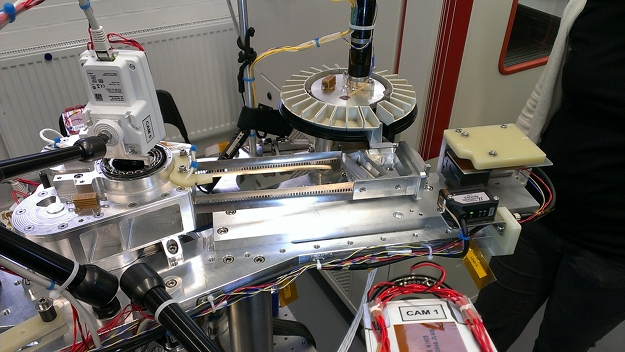

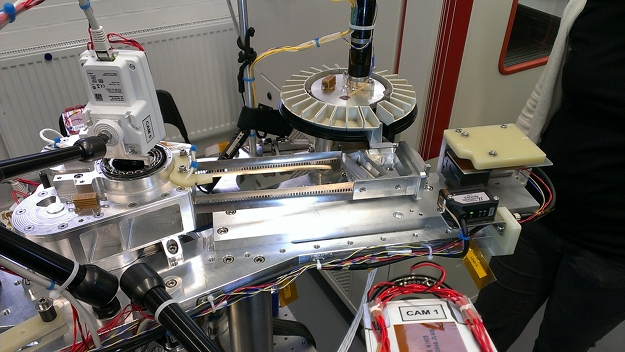

Date: 03 Jul 2013

Satellite: ExoMars 2018

Copyright: Kayser-Threde GmbH

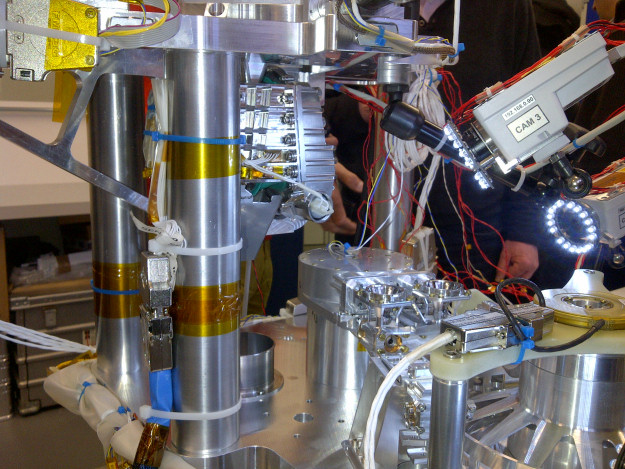

Engineering prototype, or 'breadboard' of the Core Sample Transportation Mechanism (CSTM) component of the ExoMars rover Sample Preparation and Distribution System (SPDS), which will form part of the Analytical Laboratory Drawer (ALD).

The CSTM will carry samples collected by the rover's drill (simulated here by the carousel of hoppers) into the ALD, where they will be released through a trapdoor into the Crushing Station and be reduced to powder.

The test system is fitted with a number of cameras, each with an LED lighting system, to monitor the movements of the mechanisms and view the sample as it moves through the SPDS.

.

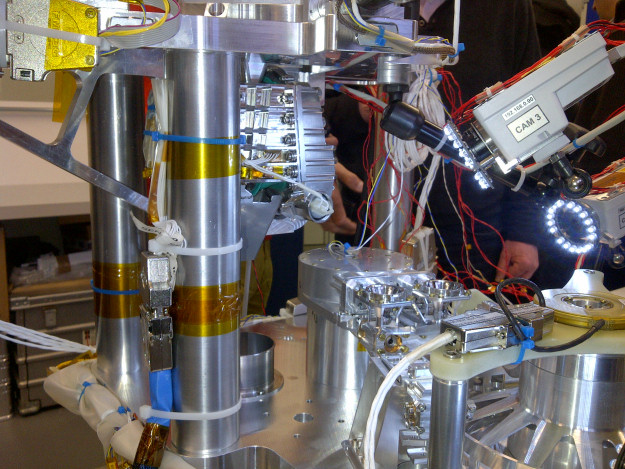

Date: 03 Jul 2013

Satellite: ExoMars 2018

Copyright: Kayser-Threde GmbH

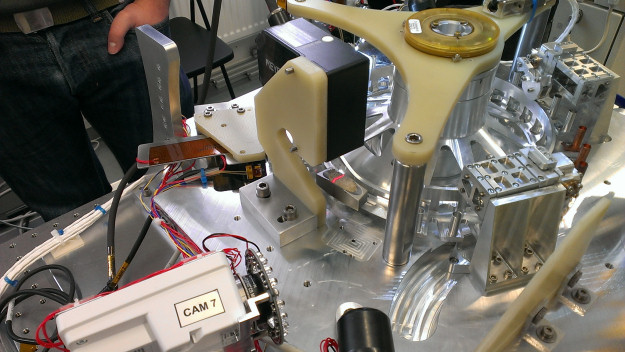

In the upper part of the image is the engineering prototype, or 'breadboard' of the Crushing Station (CS) component of the ExoMars rover Sample Preparation and Distribution System (SPDS), which will form part of the Analytical Laboratory Drawer (ALD).

In the centre of the image, the Powder Sample Dosing and Distribution System (PSDDS) is visible. The PSDDS rotates about its support cylinder to collect samples from the CS and deliver them to the Powdered Sample Handling System (PSHS) (bottom left). The PSHS is a carousel that will move the samples to various stations for processing and analysis.

The test system is fitted with a number of cameras, each with an LED lighting system, to monitor the movements of the mechanisms and view the sample as it moves through the SPDS.

.

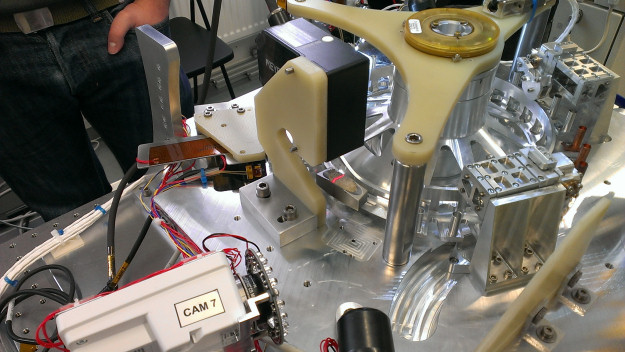

Date: 03 Jul 2013

Satellite: ExoMars 2018

Copyright: Kayser-Threde GmbH

Engineering prototype, or 'breadboard' of the Powdered Sample Handling System (PSHS) component of the ExoMars rover Sample Preparation and Distribution System (SPDS), which will form part of the Analytical Laboratory Drawer (ALD).

The PSHS is a carousel that will move the samples to various stations for processing and analysis. One station will be equipped with a fixed 'scraper', the Powder Sample Flattening Mechanism, which will level the surface of the powdered sample in the Refillable Container. Another station will house the Refillable Container Cleaning Mechanism, while further stations will have instruments to examine the surface of the samples and pyrolysis ovens to feed the Gas Chromatography Mass Spectrometer of the Mars Organics Molecule Analyser (MOMA GC-MS).

The test system is fitted with a number of cameras, each with an LED lighting system, to monitor the movements of the mechanisms and view the sample as it moves through the SPDS.

.

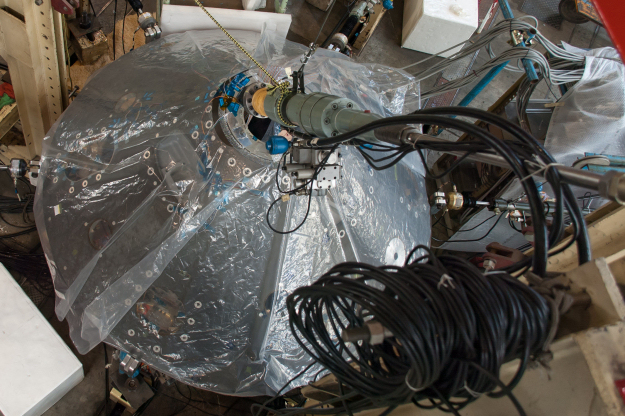

Date: 16 Oct 2013

Satellite: ExoMars 2016 - EDM

Depicts: ExoMars Entry, Descent and Landing Demonstrator Module Structural Model

Location: Thales Alenia Space, Turin, Italy

Copyright: ESA/B. Bethge

The ExoMars Entry, Descent and Landing Demonstrator Module (EDM) Structural Model during the entry load test. The air bag used to simulate the aerodynamic forces on the heat shield is hidden inside the orange test rig. Four of the eight steel bars used to keep the EDM in place and measure the resulting loads on the EDM are visible, connecting the base of the test jig with the clamp above the EDM.

.

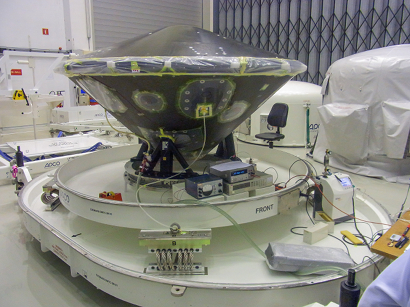

Date: 16 Oct 2013

Satellite: ExoMars 2016 - EDM

Depicts: ExoMars Entry, Descent and Landing Demonstrator Module Structural Model

Location: Thales Alenia Space, Turin, Italy

Copyright: ESA/B. Bethge

The ExoMars Entry, Descent and Landing Demonstrator Module (EDM) Structural Model during the parachute pull test, simulating the worst-case scenario where all the parachute force is transmitted to the EDM through only one of the three attachment bridles. The parachute force is simulated using a hydraulic jack, which is seen here above the EDM.

.

Quelle: ESA

6051 Views