14.02.2022

Musk foresees Florida as a home for Starship operations

Elon Musk, SpaceX’s founder and CEO, stands with a fully-stacked Starship launch vehicle in South Texas on Thursday night. Credit: SpaceX

SpaceX plans to transform parts of NASA’s Kennedy Space Center to become an operational base for the company’s super-powerful Starship launcher, while keeping a sprawling complex in South Texas as a research and development location for the heavy-lift rocket program, Elon Musk said Thursday.

Musk, the founder and chief executive of SpaceX, said in December that SpaceX had started construction of an orbital launch site for the Starship on Launch Complex 39A at Kennedy Space Center, but his comments Thursday suggested the company has carved out long-term roles for the government-owned Florida spaceport and the privately-run test site in Cameron County, Texas, also known as Starbase.

“The future role of Starbase, I think it’s well-suited to be our advanced R&D location,” Musk said. “So it’s like where we will try out new designs and new versions of the rocket, and I think probably … Kennedy will be our sort of main operational launch site.”

Under such a plan, SpaceX would have teams at two locations building Starships. After rapidly expanding its factory footprint in Texas over the last few years, SpaceX is planning to construct a rocket production facility inside the gates of Kennedy Space Center.

SpaceX currently operates two launch pads at Cape Canaveral for its Falcon rockets.

At pad 39A, once home to NASA’s Saturn 5 moon rocket and space shuttle launches, SpaceX launches astronaut crews to the International Space Station and Falcon Heavy rockets, made by combining three Falcon rocket cores together to generate some 5.1 million pounds of thrust, more than any other operational launcher in the world.

The Starship dwarfs all of those rockets, with the ability to haul up to 100 tons of cargo into a “usable” orbit a few hundred miles above Earth, Musk said.

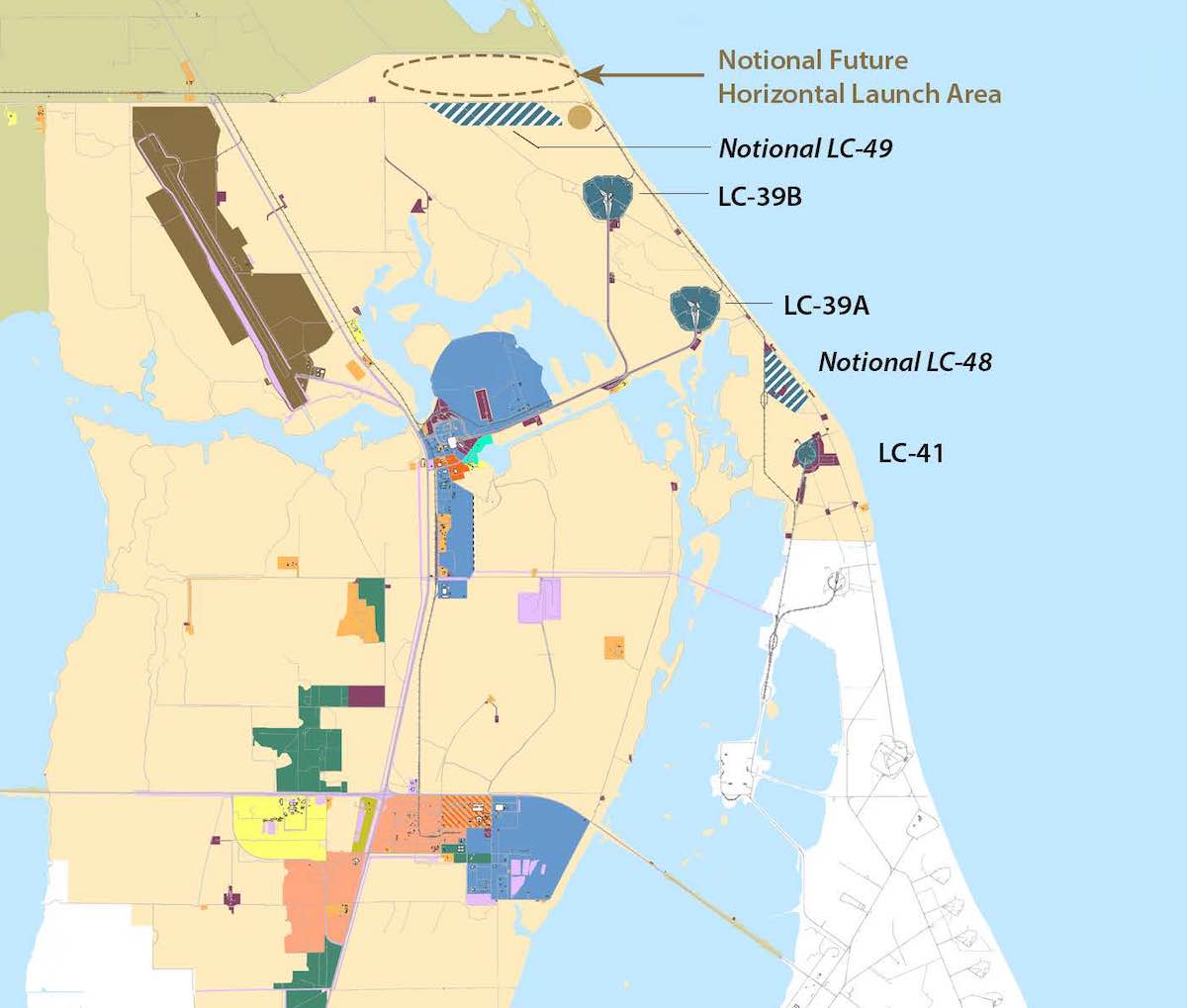

SpaceX is building a Starship pad just southeast of the Falcon rocket’s launch mount within the fenced-in perimeter of pad 39A, which officials hope to complete later this year. The company is also interested in developing another Starship launch pad, known as Launch Complex 49, a few miles to the north.

Musk presented an update on the huge Starship rocket program Thursday, standing in front of a towering fully-stacked Starship rocket, the tallest launch vehicle and most powerful ever built. SpaceX did not say whether the rocket used as a backdrop Thursday, which was once intended to blast off on the first Starship orbital launch attempt, is still expected to actually fly.

But other Starships are in production a few miles away at the Starbase factory.

“We are talking about a rocket that’s more than twice the mass and thrust of a Saturn 5 (used on NASA’s Apollo moon program), and also designed to be fully reusable,” Musk said. “And obviously it’s much better from an environmental standpoint to have a reusable rocket.”

SpaceX aims to complete the Starship at a development cost of between 5% and 10% that of the Saturn 5 in the 1960s, Musk said.

“Of course, we need to make it work,” Musk said. “It hasn’t worked yet. It will work. There might be a few bumps along the road, but it will work”

He said he was optimistic the nearly 400-foot-tall (120-meter) rocket will launch on a test flight into Earth orbit before the end of the year. Ground crews at the test facility near Boca Chica Beach east of Brownsville are racing to complete work on a series of Starship vehicles, Super Heavy boosters, and a towering launch pad just inland from the Gulf of Mexico.

“I feel, at this point, highly confident that we’ll get to orbit this year,” Musk said. “We’re making a lot of rockets, making a lot of engines.”

Musk’s update Thursday night was the first detailed presentation on the Starship program since September 2019. Much has changed since then, with five test flights of full-scale Starship prototypes in the books. The test flights focused on working out how to land the Starship, which comprises the upper portion of the overall rocket.

The first four Starship atmospheric test flights all ended in explosions, before the fifth test resulted in a successful landing last May. SpaceX’s attention in recent months has switched to building out the huge Starship launch pad tower.

Overnight Wednesday into Thursday, SpaceX teams stacked a Starship test vehicle on top of a Super Heavy rocket, creating a dramatic scene for Musk’s presentation Thursday night.

The privately-funded rocket, made of shiny stainless steel, will be the most powerful to ever fly. Future versions of the Super heavy will have 33 methane-fueled Raptor engines producing some 17 million pounds of thrust at liftoff. It’s also designed to be fully reusable, with the Super Heavy booster and Starship — essentially part upper stage and part in-space transporter — capable of returning to Earth with a vertical landing back on its launch pad, and then flying again.

The Starship itself will have six Raptor engines initially, but that could grow to nine engines — three designed for landing propulsion on Earth, and six for use in the vacuum of space.

The Starship’s first orbital test flight, though audacious in scale, will aim to prove out the rocket’s basic launch and re-entry capabilities without fully testing out the complicated landing and recovery systems, according to a SpaceX filing with the Federal Communications Commission last year.

On the first orbital mission, SpaceX plans for the Starship to re-enter the atmosphere after one trip around Earth, heading for a controlled landing at sea in the Pacific Ocean near Hawaii. The Super Heavy booster will splash down in the Gulf of Mexico.

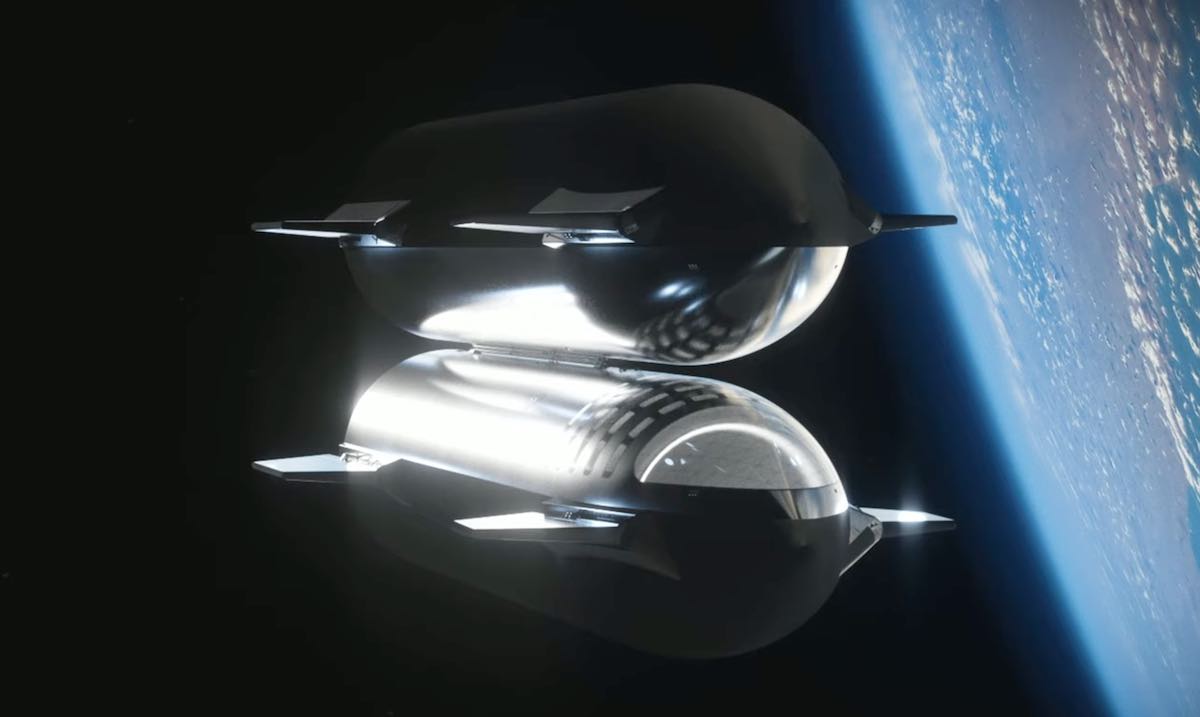

Since Musk’s last Starship presentation two-and-a-half years ago, SpaceX has also won a contract with NASA to develop the Starship into a human-rated lander for the agency’s Artemis moon missions. A moon derivative of the Starship, assisted by Starship refueling tankers, will be utilized for a lunar landing with astronauts, an event NASA says could happen no earlier than 2025.

NASA, meanwhile, is in the final stages of readying its government-owned heavy-lifter called the Space Launch System at Kennedy Space Center. It’s scheduled to launch for the first time this spring with an Orion crew capsule on an unpiloted Artemis test flight to lunar orbit and back to Earth.

The U.S. space agency plans to use the SLS and Orion as a transportation system for astronauts traveling between Earth and the moon. The Starship, and eventually more commercial lunar landers, will meet up with the Orion capsule near the moon to ferry crews to and from the lunar surface.

While engineers plow toward the Starship’s first orbital test flight, SpaceX is also awaiting the conclusions of an environmental review by the Federal Aviation Administration before regulators give the green light for Starship launch operations at the South Texas site.

The FAA issued a draft environmental report in September after consultation with several federal and state agencies, then held two virtual meetings in October to collect input from the public. The FAA said in December that volume of public comments would cause the agency to miss its goal to complete the environmental review by the end of December. Officials shifted the timetable to the end of February, but that self-imposed deadline is now in doubt.

“I think we’re close to having the hardware ready to go,” Musk said. “Right now, I think we’re tracking to have the regulatory approval and hardware readiness around the same time … hopefully in basically a couple months for both.”

The review marks a re-evaluation of the FAA’s original environmental impact statement before SpaceX started construction of the Boca Chica site in 2014. At that time, SpaceX planned to launch Falcon 9 and Falcon Heavy rockets from South Texas, but the scope of the project has since changed to focus on development of Starship and Super Heavy.

The FAA is deciding whether to finalize the draft environmental assessment completed last year if regulators find Starship launch operations will not have a significant impact on the local environment. The agency could also decide to begin a new environmental impact statement if the environmental effects would be significant and could not be properly mitigated.

A new environmental impact statement would take months, or even years, to complete.

The development of a Starship launch site and factory at Kennedy Space Center is not only SpaceX’s insurance policy against delays caused by regulatory scrutiny. Musk said Thursday the Florida facility will serve as an operational base for Starship missions, while the Texas location is a better fit for testing.

“I am optimistic that we will get approval (from the FAA),” Musk said. “Objectively, I think this is not something that will be harmful to the environment. We’ve obviously flown the ship several times, and multiple landings, takeoffs and landings. We’ve fired the engines a lot. I think the reality is that it would not have a significant impact.”

“That doesn’t mean things don’t get delayed from a regulatory standpoint,” Musk continued. “We are in a litigious society, so there’s always lawsuits from someone. It’s lawsuit city.”

Musk said an FAA decision to require a new environmental impact statement would “set us back for quite some time,” requiring SpaceX to immediately shift more research and development work to Kennedy Space Center. He said SpaceX’s “worst case scenario” would be a delay of six to eight months, which Musk claimed would be enough time to build up a Starship launch tower at Kennedy Space Center.

The FAA said it is reviewing the environmental impacts from SpaceX’s Starship launch and re-entry operations, debris recovery, the launch pad integration tower and other launch-related construction, and local road closures at Boca Chica.

SpaceX can’t launch the Starship and Super Heavy vehicle until the FAA issues a license, which will only come after the completion of the environmental process.

SpaceX already has passed an environmental review for Starship launches from Launch Complex 39A. It would need to go through a new process at Launch Complex 49.

The company originally selected the Boca Chica Beach location for a Starship production and test site to avoid interfering with Falcon missions launching out of Florida.

“It’s basically here and Cape Canaveral are the two possibilities,” Musk said, referring to near-term Starship operations. “Because we had a lot of launches going out of the Cape, we didn’t want to disrupt the Cape activity … So we just wanted to decouple the operational launches from the R&D launches, and thats why we’re at this location.”

Musk also outlined technology challenges facing the Starship program. One topic he discussed at length Thursday night was the production and testing of a new version of the Raptor engine, called the Raptor 2, needed to power future Starship launches.

The uprated engine can produces at least 460,000 pounds of thrust, 25 percent more power than the original Raptor engine design. Musk said the Raptor 2 could be tuned to generate 500,000 pounds of thrust. It burns the same propellant mix of methane and liquid oxygen, but uses fewer parts and is cheaper and easier to manufacture, making it crucial for realizing SpaceX’s lofty cost and performance goals for the Starship program.

Testing of the Raptor 2 engine is moving the powerplant closer to being flight-ready, but engineers are still working to resolve technical issues with the engine.

Musk first discussed the Starship program in 2016, several years after technical work began on the project. Then known as an interplanetary transport system, the rocket has undergone countless design changes since 2016.

But the end goal has remained constant: Develop and fly a fully reusable rocket that can carry more cargo into space than any launcher in history, and then use it to establish a settlement on Mars.

“I think, maybe, roughly, you need about a million tons on Mars to have a self-sustaining city,” Musk said. “Starship is capable of doing that. It’s capable of getting a million tons to the surface of Mars and creating a self sustaining city, and I think we should try to do that is as soon as we can.”

Pulling off a Mars mission, and then establishing a repeatable cadence of sorties to the Red Planet, will require numerous launches of Starship tankers, cargo and crew transporters, and propellant depots.

SpaceX eventually wants to have Starship variants designed to refill deep space transporters with methane and liquid oxygen propellants in Earth orbit. That capability could be tested in Earth orbit by the end of next year, Musk said. In-orbit cryogenic refilling is a prerequisite for using a Starship vehicle to land astronauts on the moon for NASA’s Artemis program.

The Starship launch complex at pad 39A could be used in NASA’s Artemis lunar campaign. Getting the Starship lander to the moon will require multiple orbital refilling missions using a tanker variant of the Starship vehicle.

The rapid-fire launch campaign for an Artemis lunar landing mission may require SpaceX to use multiple launch pads. NASA’s SLS moon rocket will launch from pad 39B, another Apollo-era launch facility located less than 1.7 miles (2.7 kilometers) north of pad 39A.

Japanese billionaire Yusaku Maezawa announced in 2018 he plans to fly around the moon on a Starship in 2023. Last year, he said he wanted to take eight members of the public with him on the journey. A launch schedule for Maezawa’s flight has not been updated recently, but is not likely to happen next year.

Other versions of the Starship could be designed with a cargo bay to deploy satellites, either huge spacecraft like an astronomical telescope, or hundreds of smaller satellites, such as those used for SpaceX’s own Starlink internet service.

And SpaceX has toyed with the idea of using Starship as a point-to-point transporter for cargo and people traveling from one side of Earth to another. The U.S. Air Force said last year it awarded SpaceX a contract to study using the Starship as an intercontinental ferry for military cargo.

Musk provided few details about the potential uses for the Starship rocket, beyond Mars and lunar flights. But he projected that within a few years Starship missions could launch for less than $10 million per flight, accounting for marginal costs like propellant and the overhead of running the program.

“This design, I’m confident, is capable of that,” Musk said. “It’s just a question of how long it will take to refine that and have it really dialed.”

Once the Starship program is humming along at an operational cadence — which could mean multiple flights per day if Musk’s vision is realized — SpaceX plans to field ocean-going launch pads to accommodate the volume of flights far away from cities and towns.

SpaceX has two former oil rigs it intends to convert into floating launch pads. That work was “de-prioritized” over the last year as SpaceX emphasized progress in Texas, Musk said, but one of the platforms could be fitted with a “catch tower” to receive landing booster rockets later the year.

Quelle: SN

----

Update: 17.02.2022

.

SpaceX preparing to assemble launch tower for Starship’s first Florida pad

SpaceX has slowly but surely begun the process of building Starship’s first Florida launch pad – including preparations for the off-site assembly of a second skyscraper-sized ‘launch tower.’

This is not the first time. Back in late 2019, SpaceX began work on a Starship launch pad located at NASA’s Kennedy Space Center (KSC) LC-39A pad, which the company already leased for Falcon 9 and Falcon Heavy launches. By the end of the year, some of the framework of the Starship launch mountwas already visible and parts of a giant water-cooled thrust diverter arrived in early 2020. However, work on the pad effectively halted around the same time and entered a state of limbo as SpaceX redirected all of its Starship program on South Texas.

Only two years later did activity finally return. Musk revealed the restart on December 3rd, 2021 and within a matter of weeks, the remnants of the old Starship launch pad – now outdated – had been scrapped and removed, returning the site to a more or less blank slate. Since then, save for occasional long-distance aerial views, it’s been almost impossible to document progress but views from SpaceX webcasts of Falcon 9 launches out of Pad 39A have shown that the company is mostly focused on preparing foundations. However, in early February 2022, a flyover of a different SpaceX KSC facility revealed the first clear signs of preparation for pad hardware assembly.

While unassuming, the small sets of square foundations recently constructed at SpaceX’s new Roberts Road Falcon storage, refurbishment, and processing center are virtually identical to the foundations where contractors assembled the first Starship launch tower in South Texas. Each completed section – measuring about 12m (40 ft) long and wide and 18m (60 ft) tall – was then transported a few miles by road to the launch site, where a crane would stack them.

Roberts Road happens to be located about seven miles (11 km) away from Pad 39A, with a single paved, well-maintained road optimized for wide and tall loads standing between them. It’s clear, in other words, that SpaceX will build Pad 39A’s Starship launch tower at its Roberts Road facility and transport the sections to the pad for assembly. More likely than not, to avoid the regular disruption of Falcon launches, SpaceX will do the same with virtually all transportable pad hardware, including the tower arms and launch mount.

In fact, SpaceX has only developed about a third of the land it leased at Roberts Road. Just last month, development plans indicating that SpaceX intends to build two immense warehouse-like buildings to fill out the rest of the site were published by a local water agency. Based on their footprints, they would collectively have more covered floor space than the entirety of the South Texas ‘Starbase’ factory where all Starships are currently built. During a February 10th, 2022 update presentation, CEO Elon Musk confirmed that SpaceX will build and launch Starships out of Florida, all but guaranteeing that the new facility will be a massive new Starship factory.

In the last week, satellite imagery indicates that SpaceX has begun to level the unfinished portion of Roberts Road, likely paving the way for the start of foundation work in the near future. All things considered, it remains to be seen if SpaceX will truly replicate Starbase, Boca Chica at Kennedy Space Center or – much like how the company systematically upgrades its rockets – if the new Starship factory will represent a block upgrade with a wide range of improvements and refinements. Regardless, it won’t be long before Starbase East and the first of several East Coast Starship launch towers begin to take shape.

Quelle: TESLARATI

----

Update: 22.02.2022

.

When will SpaceX's Starship fly to space?

An unmistakable fact of SpaceX’s Starship, stacked atop the Superheavy rocket, is its immensity. The rocket ship is a gleaming, stainless-steel tower the height of a skyscraper at SpaceX’s South Texas Starbase facility. Its purpose is to deliver 100 metric tons of people and material anywhere in the solar system, either to Earth orbit or to the moon and Mars with refueling. When it flies, it will revolutionize the art and science of space travel just as the ocean-going caravel did sea travel centuries ago.

Recently, SpaceX CEO Elon Musk gave a presentation about the Starship to a crowd at the Starbase with the launch vehicle as a backdrop.

Of main interest, Musk says he will be able to conduct the first orbital test of the Starship this year, pending an environmental approval that he expects to happen in March. The Federal Aviation Administration (FAA) has announced that the report has been delayed to March 28.

Musk does have a contingency plan to move operations to Florida if the regulators decide to throw some roadblocks in his way — but a move to Florida would delay the development of Starship by six to eight months. NASA, which is depending on it to land astronauts on the moon, would not be too pleased either.

Certain parties would not be displeased if the Starship were to be delayed somewhat. Politico reports that SpaceX’s competitors are in a panic over the implications of an operational Starship. It is bad enough, from their standpoint, that the SpaceX Falcon 9 has greatly reduced the cost of launching things and people into space. The Starship, according to Musk, will be able to take an absurd amount of material and people, first into low-Earth orbit, then to the moon and Mars, for a few tens of millions of dollars a launch. Beyond competition at home, Russia and China, which have their own space ambitions, are also likely watching closely.

In any case, whether the Starship/Superheavy rocket is approved for launches from Texas or has to move to Florida, the first orbital test will see the Superheavy splash down in the ocean near the launch site, and the Starship will land in the ocean near Hawaii. Subsequent launches will no doubt test the two stages’ ability to land intact back at the spaceport launch site.

Once the Starship proves its ability to launch, conduct orbital operations and then land safely, the possibilities are almost endless. SpaceX already has plans for the rocket to launch Starlink satellites, hundreds at a time rather than a few dozen that the Falcon 9 can deliver. The Starship could deliver a space telescope many times the size and capabilities of the Hubble or a complete commercial space station.

Billionaire Jared Isaacman, who already flew with a group on SpaceX’s Crewed Dragon, now plans a series of flights culminating in the first crewed Starship. Farther in the future, billionaire Yusaku Maezawa still plans to take a group of artists on a Starship on an epic voyage around the moon.

A version of the Starship has already been chosen to be the Human Landing System that will deliver astronauts to the lunar surface for the first time in decades. SpaceX has contracted to do one uncrewed test in advance of the human landing, currently scheduled to take place in 2025.

While NASA plans only one Artemis mission per year, SpaceX may be able to land material and people on the moon multiple times a year. Everything depends on whether the company can master rapid launch, landing and turnaround, as well as reliable refueling in low-Earth orbit. If SpaceX can establish an Earth-to-moon transportation system on their own, NASA’s Orion/Space Launch System would become obsolete in short order.

Musk’s ultimate goal is to establish a city on Mars. He has suggested that he will need to transport a million tons of material across interplanetary gulfs, not to speak of those people who propose to become Mars colonists, to make that happen. If the Starship/Superheavy system can do that, the launch vehicle will have changed the course of history. Humankind truly will become an interplanetary civilization.

Quelle: The Hill

----

Update: 23.02.2022

.

SpaceX to send retired Starship to local Texas airport, says Elon Musk

In a brief Twitter exchange, the Brownsville/South Padre Island International Airport (BRO) appears to have talked SpaceX CEO Elon Musk into turning a retired Starship prototype into a public exhibit.

Operational in some form since 2020, SpaceX’s ‘Starbase’ Starship factory is already a bit of a tourist destination for Brownsville, Texas and the local Rio Grande Valley – particularly for fans of spaceflight and rockets. The substantial factory and a trio of orbital and suborbital launch pads are both located directly beside a public highway, a tiny private housing development, and a public beach – maintaining access to all of which has been a consistent challenge for SpaceX for years.

However, the company has continued to work to coexist with locals while simultaneously generating tourism and bringing unprecedented economic growth and publicity to the relatively quiet region. It’s increasingly unclear if SpaceX will be able to realize its full ambitions for Starbase and South Texas but Elon Musk recently reiterated the company’s commitment to maintaining a strong presence in the region whether or not the US government gives it the permissions it needs for regular Starship launches.

Musk’s drop-of-a-pin willingness to donate an entire Starship prototype to a local organization certainly exemplifies that commitment. While Starbase is already a de facto tourist destination where people can get within a stone’s throw of several prototypes of the largest rockets ever built, the setup for visitors is very impromptu, inconvenient, and right beside an active highway and rocket factory. A dedicated Starship display at a less frenetic site with dedicated parking and no need to tiptoe around a highway would undoubtedly be an improvement.

Situating that public Starship display directly beside the largest local airport would also preclude the need for prospective visitors to drive half an hour out of their way, ensuring that far more people actually get to experience a Starship up close and learn about SpaceX’s presence in the region. Thankfully, increasingly unusual behavior means that SpaceX has no shortage of prototypes to choose from.

Starship SN15 is the first prototype of any kind to fly to a moderate altitude (~10 km), fall back to Earth like a skydiver, flip around at the last second, and survive a soft landing in May 2021. Musk once said that the historic prototype would be reused on a second flight test but the ship never did and has instead sat at Starbase’s ‘Rocket Garden’ ever since. Starship SN16 – almost identical to SN15 – was also supposed to fly but never got to perform a single test before it was retired to the same garden.

Up next, SpaceX mostly finished an entire Super Heavy booster – standing almost 70 meters (230 ft) tall – late last year but sent it (B5) directly to the ‘garden’ without even attempting to finish or test the rocket. Its sister booster, Super Heavy B4, was at one point supposed to support Starship’s first orbital launch attempt but has only completed a fraction of the necessary proof tests after spending almost half a year floating around the orbital launch site. It’s entirely possible that B4 will meet its end beside B5 later this year.

Finally, SpaceX most recently decided to assemble Starship S22 – very similar to Starship S20, the other half of the first orbital test flight pair of B4/S20 – and stacked the ship to its full height on February 14th, 2022. After installing its nosecone and the last two of four flaps, though, SpaceX immediately sent the unfinished Starship to the same graveyard of retired prototypes, strongly implying that it, too, will never be used.

While increasingly confusing from a programmatic standpoint, SpaceX’s ever-growing supply of retired or fully unused Starship and Super Heavy hardware gives the company plenty of options for donating one or even several prototypes. The only real barriers are the need for a concrete foundation to secure the display vehicles and the challenge of transporting vertical, building-sized rockets by road. To get a Starship all the way to the Brownsville International Airport, a number of power lines and traffic lights would likely need to be temporarily removed or rerouted, but that’s a relatively minor inconvenience with enough political will.

Quelle: TESLARATI

----

Update: 7.03.2022

.

SpaceX’s South Texas Starship factory prepares for major upgrades

In what is probably a sign of things to come for SpaceX’s nascent Florida Starship factory, the company’s original Starbase facility in South Texas may be about to graduate from tents to more permanent buildings.

More than two years ago, in late 2019, SpaceX followed in the footsteps of Tesla and began constructing a surprisingly advanced factory out of a series of tents. Instead of Model 3s, though, SpaceX would be building and assembling sections of the largest and most powerful rocket ever built. Measuring approximately 120 meters (~390 ft) tall, 9 meters (~30 ft) wide, ~5000 tons (~11M lb) fully fueled, and capable of producing around 7500 tons (~16.5M lbf) of thrust at liftoff, Starship is a fully reusable rocket that aims to perfect what SpaceX has already achieved with partially reusable Falcon 9s and Heavies.

Nonetheless, Starship manufacturing represents a substantial departure from the methods SpaceX uses to build Falcon rockets.

Instead of heavily leaning on horizontal integration (meaning that the rockets are primarily assembled in a horizontal orientation), Starship and its Super Heavy booster are almost exclusively assembled vertically. Excluding the machining of major loadbearing structures, Starship manufacturing generally begins with giant rolls of thin (3-4mm or ~0.15 in) stainless steel. SpaceX uses a custom tool to unspool the sheet metal, cuts off a roughly 28-meter (~92 ft) long strip, and then welds the ends of that strip together to produce a cylindrical barrel. Repeat that process 57 times and you end up with enough rings to assemble a full Super Heavy booster and most of a Starship.

However, using increasingly custom tools, SpaceX first stacks and welds those individual rings together to form sections of two, three, four, or five. Each section is then prepared for its specific role with a range of cutouts, plumbing, reinforcements (vertical stringers or circumferential stiffeners), thrust structures (the plates that Raptor engines attach to), and other add-ons. Most importantly, certain stacks of rings are mated with large steel domes – welded together out of prefabricated steel plates – to form forward, common, and aft dome sections. For Starship, SpaceX also assembles the ship’s conical nose section in a similar manner.

Virtually all ring, dome, and nose assembly work is conducted in one of three massive tents – each about 114m x 35m (375′ x 110′) – that form the backbone of Starbase’s Starship factory. Finally, SpaceX has built a series of massive open-air bays where, once fully outfitted, each ship and booster section is stacked in a specific order and welded together to complete the basic structures of Starship and Super Heavy.

While SpaceX continues to speed towards the completion of Starbase’s largest and tallest Starship assembly bay yet, the latest news centers around Starbase’s tents. After physically relocating a smaller but still substantial tent believed to be used basic metalwork (laser/water cutting, presses, etc.), SpaceX has rapidly broken ground and partially completed the foundation of a massive, new building believed to be the start of an upgraded Starship factory.

According to RGV Aerial Photography, SpaceX isn’t merely expanding the main three-tent factory with a fourth larger, permanent building. Instead, it reportedly aims to replace all of Starbase’s tents with a single 300,000-square-foot (~28,000 square meter) building that will be about 18 meters (60 ft) tall and likely measure around 800 feet (250m) long and 400 feet (120m) wide. Starbase’s tents are roughly the same height but their tented roofs mean that only a fraction of that height can be used for ring work and only a fraction of the floor space for taller nose work.

In comparison, a 300,000 square-foot building would have almost two and half times as much covered floor space as Starbase’s three tents – all of which can theoretically be used for ring and nose section assembly. In fact, with a mostly flat 18-meter roof, SpaceX could feasibly expand most ‘stacks’ by a ring or two, which would reduce the number of sections (and thus stacking operations) needed to assemble a ship or booster.

All told, while tents (“sprung structures”) can clearly be indefinite solutions for things like automotive manufacturing, Starship production is one case in which a more permanent flat-ceiling building is undeniably superior. With more than two years of experience and data to draw from, SpaceX may finally be confident enough in its present-day Starship production methods to commit to the construction of Starbase’s next evolution. Stay tuned to see where it leads.

Quelle: TESLARATI