9.01.2022

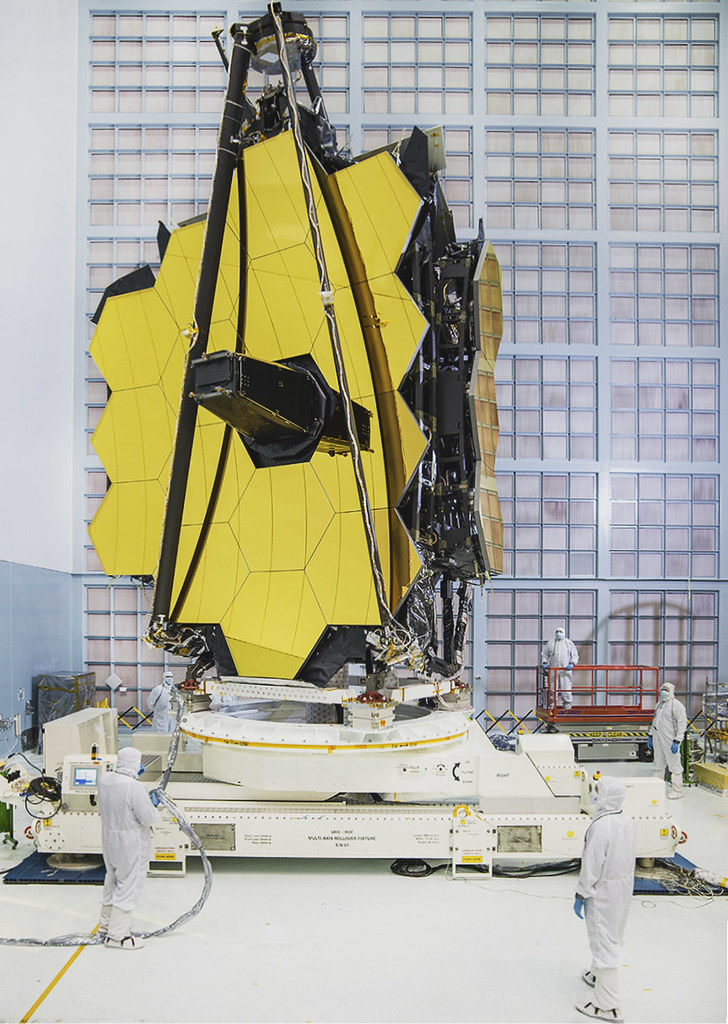

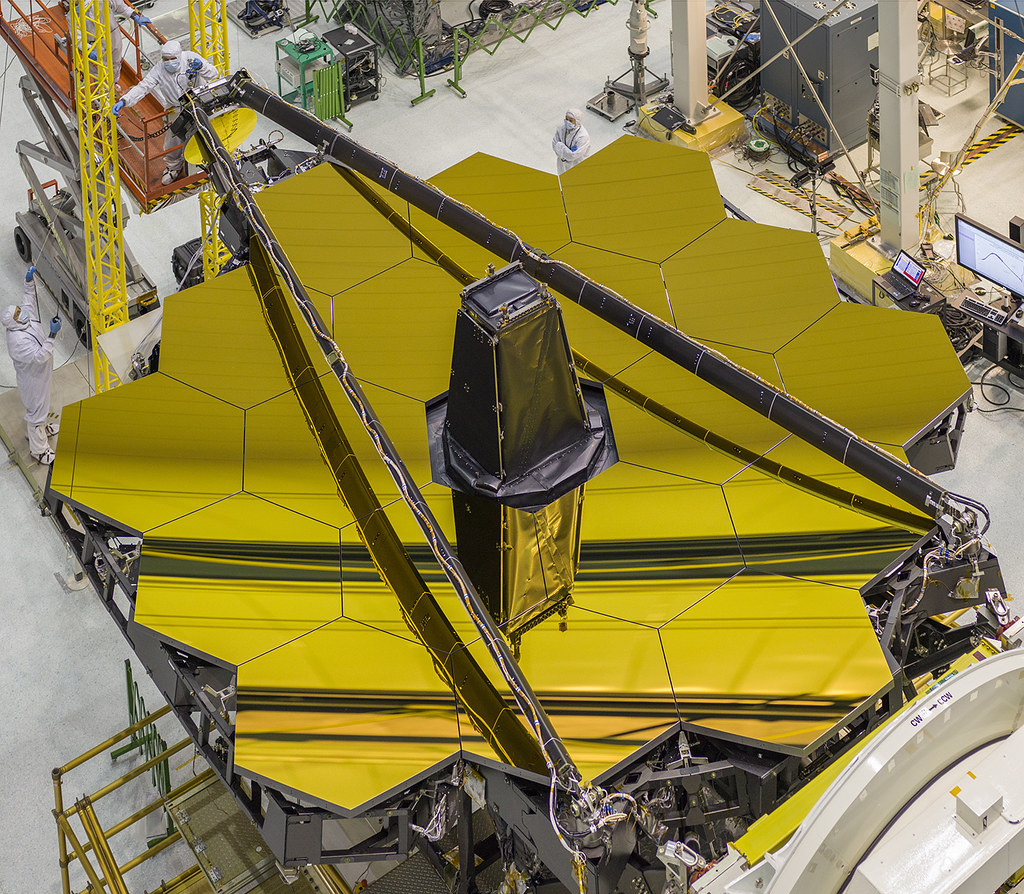

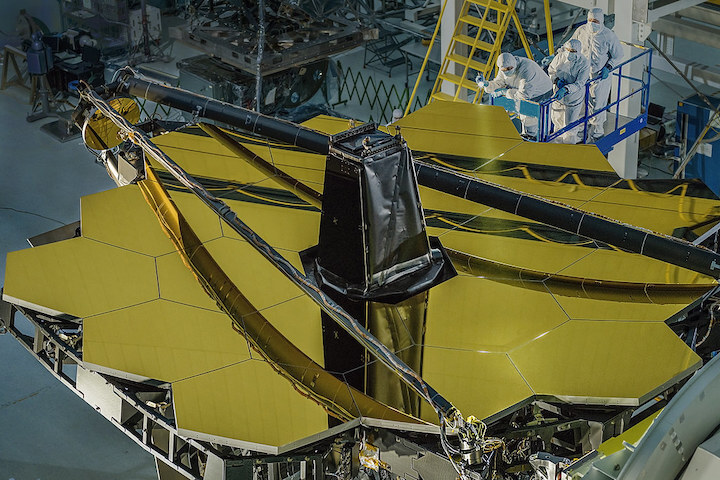

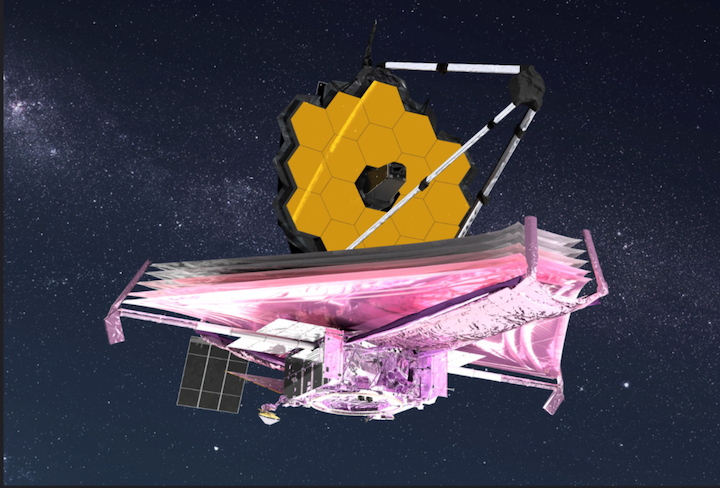

James Webb Space Telescope's primary mirror at NASA Goddard. The secondary mirror is the round mirror located at the end of the long booms, which are folded into their launch configuration. Webb's mirrors are covered in a microscopically thin layer of gold, which optimizes them for reflecting infrared light, which is the primary wavelength of light this telescope will observe.Photo: NASA/Chris Gunn

Overview

One of the James Webb Space Telescope's science goals is to look back through time to when galaxies were young. Webb will do this by observing galaxies that are very distant, at over 13 billion light years away from us. To see such far-off and faint objects, Webb needs a large mirror. A telescope’s sensitivity, or how much detail it can see, is directly related to the size of the mirror area that collects light from the objects being observed. A larger area collects more light, just like a larger bucket collects more water in a rain shower than a small one.

Engineering Challenges

Webb Telescope's scientists and engineers determined that a primary mirror 6.5 meters (21 feet 4 inches) across is what was needed to measure the light from these distant galaxies. Building a mirror this large is challenging, even for use on the ground. A mirror this large has never before been launched into space!

If the Hubble Space Telescope's 2.4 meter mirror were scaled to be large enough for Webb, it would be too heavy to launch into orbit. The Webb team had to find new ways to build the mirror so that it would be light enough - only one-tenth of the mass of Hubble's mirror per unit area - yet very strong.

The Webb Telescope team decided to make the mirror segments from beryllium, which is both strong and light. Each segment weighs approximately 20 kilograms (46 pounds).

Image: NASA/Chris Gunn

Folding Mirrors

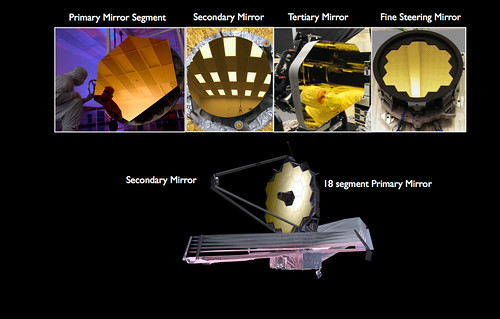

The Webb Telescope team also decided to build the mirror in segments on a structure which folds up, like the leaves of a drop-leaf table, so that it can fit into a rocket. The mirror would then unfold after launch. Each of the 18 hexagonal-shaped mirror segments is 1.32 meters (4.3 feet) in diameter, flat to flat. (Webb's secondary mirror is 0.74 meters in diameter.)

Why Hexagonal?

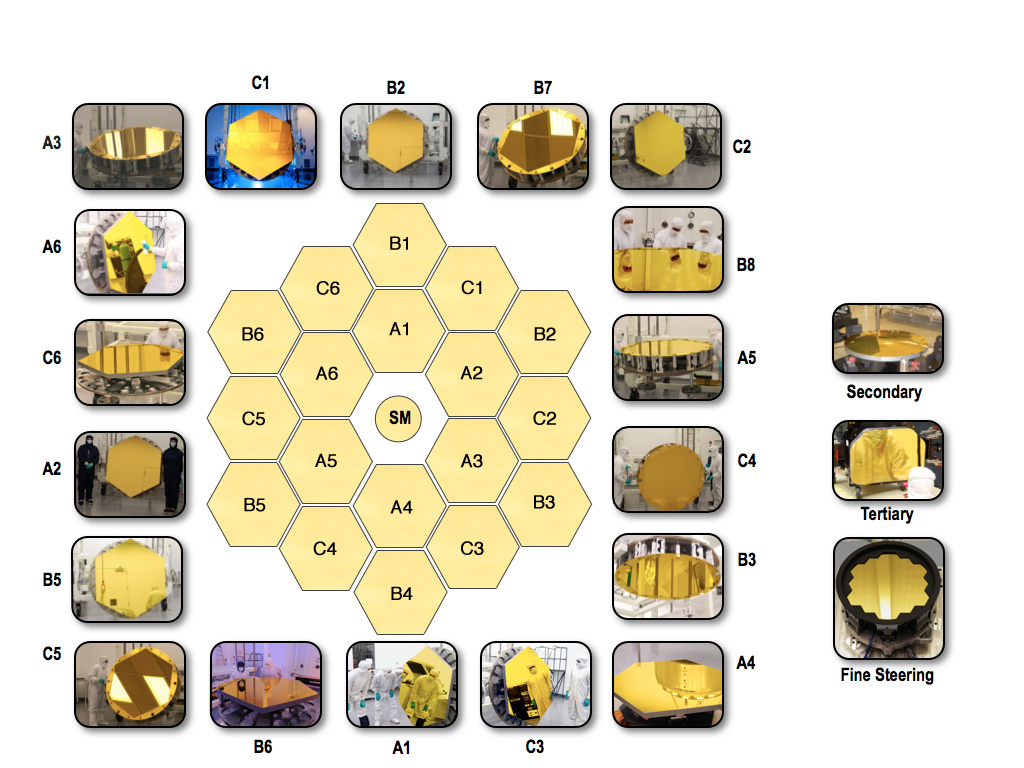

The hexagonal shape allows for a roughly circular, segmented mirror with "high filling factor and six-fold symmetry." High filling factor means the segments fit together without gaps. If the segments were circular, there would be gaps between them. Symmetry is good because there need only be 3 different optical prescriptions for 18 segments, 6 of each (see above right diagram). Finally, a roughly circular overall mirror shape is desired because that focuses the light into the most compact region on the detectors. A oval mirror, for example, would give images that are elongated in one direction. A square mirror would send a lot of the light out of the central region.

different optical prescriptions for Webb's mirror.

Each of Webb's mirrors has an individual designation. A, B, or C denotes which of the three mirror prescriptions a segment is. The photos show the flight version of every mirror on the telescope!

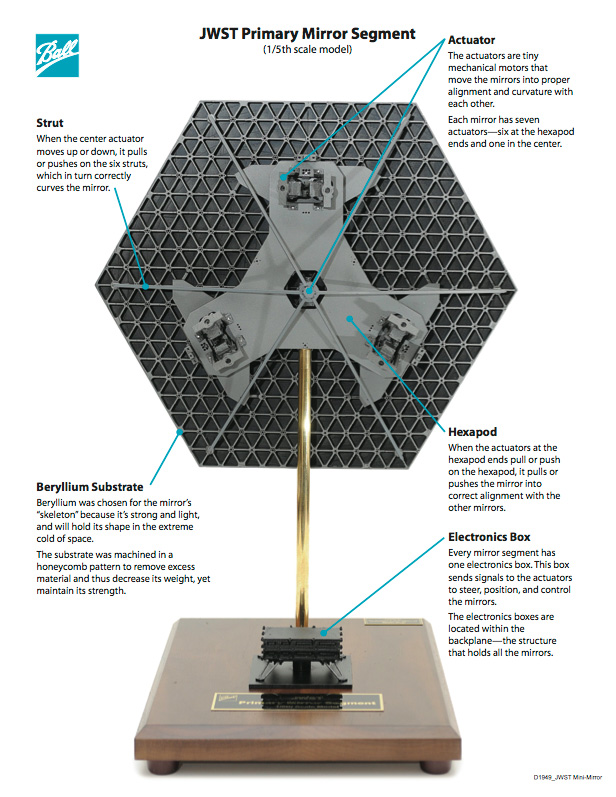

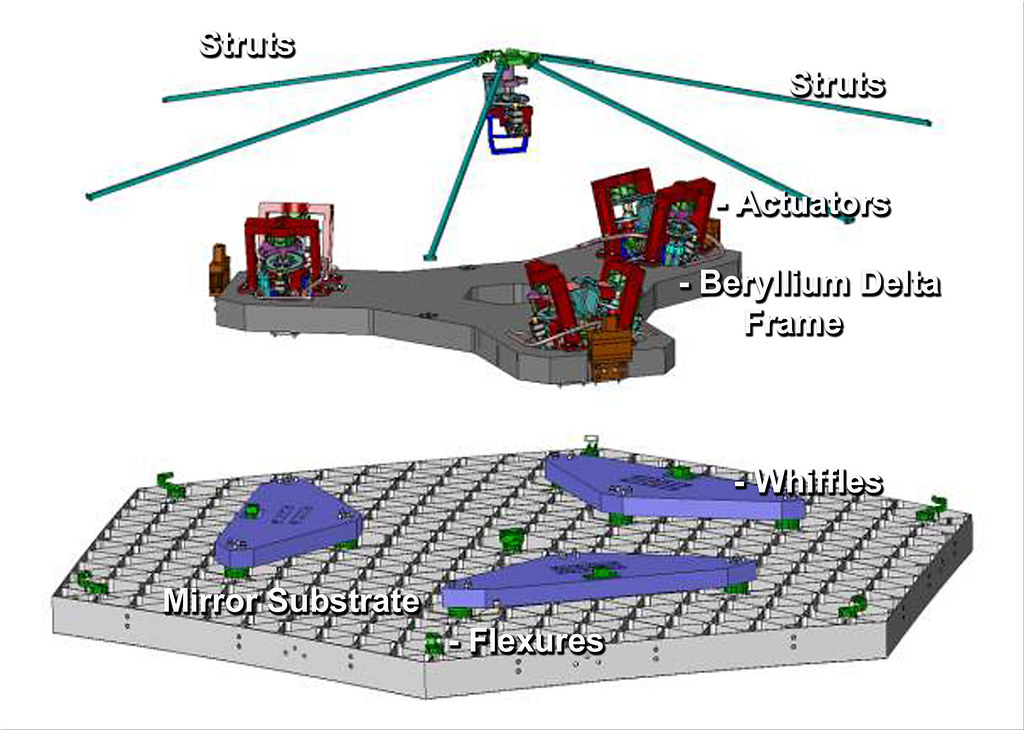

Achieving A Single Perfect Focus- Actuators

Once in space, getting these mirrors to focus correctly on faraway galaxies is another challenge. Actuators, or tiny mechanical motors, provide the answer to achieving a single perfect focus. The primary mirror segments and secondary mirror are moved by six actuators that are attached to the back of each mirror piece. The primary mirror segments also have an additional actuator at its center that adjusts its curvature. The telescope's tertiary mirror remains stationary.

Lee Feinberg, Webb Optical Telescope Element Manager at NASA Goddard explains, "Aligning the primary mirror segments as though they are a single large mirror means each mirror is aligned to 1/10,000th the thickness of a human hair. What's even more amazing is that the engineers and scientists working on the Webb telescope literally had to invent how to do this."

Watch the the actuators being attached to the back of a telescope mirror in this "Behind the Webb" video.

Engineering Challenge: Keeping Webb's Mirrors Cold

One further challenge is to keep Webb's mirror cold. To see the first stars and galaxies in the early Universe, astronomers have to observe the infrared light given off by them, and use a telescope and instruments optimized for this light. Because warm objects give off infrared light, or heat, if Webb's mirror was the same temperature as the Hubble Space Telescope's, the faint infrared light from distant galaxies would be lost in the infrared glow of the mirror. Thus, Webb needs to be very cold ("cryogenic"), with its mirrors at around -220 degrees C (-364 degree F). The mirror as a whole must be able to withstand very cold temperatures as well as hold its shape.

To keep Webb cold, it will be sent into deep space, far from the Earth. Sunshields will shade the mirrors and instruments from the Sun's heat , as well as keep them separated from the warm spacecraft bus.

What Kind Of Telescope Is Webb?

Webb is what is known as a three mirror anastigmat telescope. In this configuration, the primary mirror is concave, the secondary is convex, and it works slightly off-axis. The tertiary removes the resulting astigmatism and also flattens the focal plane. This also allows for a wider field of view.

Mirror Research & Innovation

NASA set out to research new ways to build mirrors for telescopes. The Advanced Mirror System Demonstrator (AMSD) program was a four-year partnership between NASA, the National Reconnaissance Office and the US Air Force to study ways to build lightweight mirrors. Based on the ASMD studies, two test mirrors were built and fully tested. One was made from beryllium by Ball Aerospace; the other was built by Kodak (formerly ITT, now the Harris Corporation) and was made from a special type of glass.

A team of experts was chosen to test both of these mirrors, to determine how well they worked, how much they cost, and how easy (or difficult) it would be to build a full-size, 6.5-meter mirror. The experts recommended that the beryllium mirror be selected for the James Webb Space Telescope, for several reasons, one being that beryllium holds its shape at cryogenic temperatures. Based on the expert team's recommendation, Northrop Grumman (the company that is leading the effort to build Webb) selected a beryllium mirror, and the project management at NASA Goddard approved this decision.

Why Beryllium?

Beryllium is a light metal (atomic symbol: Be) that has many features that make it desirable for Webb's primary mirror. In particular, beryllium is very strong for its weight and is good at holding its shape across a range of temperatures. Beryllium is a good conductor of electricity and heat, and is not magnetic.

Because it is light and strong, beryllium is often used to build parts for supersonic (faster-than-the-speed-of-sound) airplanes and the Space Shuttle. It is also used in more down-to-Earth applications like springs and tools. Special care has to be taken when working with beryllium, because it is unhealthy to breathe in or swallow beryllium dust.

How And Where The Beryllium Mirrors Were Made

The James Webb Space Telescope's 18 special lightweight beryllium mirrors had to make 14 stops to 11 different places around the U.S. to complete their manufacturing. They came to life at beryllium mines in Utah, and then moved across the country for processing and polishing. In fact, the mirrors made stops in eight states along the way, visiting some states more than once, before they will journey to South America for lift-off and the beginning of their final journey to space. Explore an interactive map showing the journey of the mirrors.

The beryllium to make Webb's mirror was mined in Utah and purified at Brush Wellman in Ohio. The particular type of beryllium used in the Webb mirrors is called O-30 and is a fine powder. The powder was placed into a stainless steel canister and pressed into a flat shape. Once the steel canister was removed, the resulting chunk of beryllium was cut in half to make two mirror blanks about 1.3 meters (4 feet) across. Each mirror blank was used to make one mirror segment; the full mirror is made from 18 hexagonal segments.

Once the mirror blanks passed inspection, they were sent to Axsys Technologies in Cullman, Alabama. The first two mirror blanks were completed in March 2004.

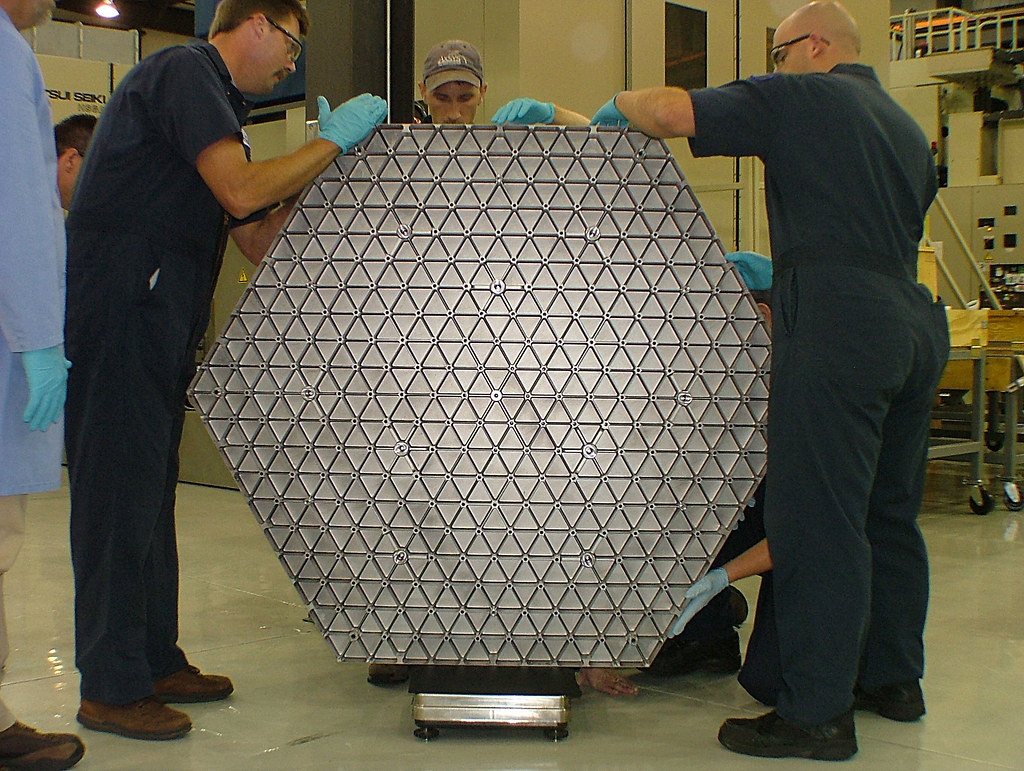

Axsys Technologies shaped the mirror blanks into their final shape. The process of shaping the mirror starts with cutting away most of the back side of the beryllium mirror blank, leaving just a thin "rib" structure. The ribs are only about 1 millimeter (about 1/25 of an inch) thick. Although most of the metal is gone, the ribs are enough to keep the segment's shape steady. This makes each segment very light. A beryllium mirror segment is 20 kilograms in mass. (A full primary mirror segment assembly including its actuator is about 40 kg.)

Pictured is the back of the mirror blank, which is carved out in this pattern to make the mirror segment light, yet maintain its integrity. Credit: Axsys Technologies

Mirror Polishing

Once the mirror segments were shaped by Axsys, they were sent to Richmond, CA, where SSG/Tinsley polished them.

SSG/Tinsley started by grinding down the surface of each mirror close to its final shape. After this was done, the mirrors were carefully smoothed out and polished. The process of smoothing and polishing was repeated until each mirror segment was nearly perfect. At that point, the segments traveld to NASA's Marshall Space Flight Center in Huntsville (MSFC), Alabama for cryogenic testing.

Since many materials change shape when they change temperature, a test team from Ball Aerospace worked together with NASA engineers at Marshall’s X-ray and Cryogenic Facility (XRCF) to cool the mirror segments down to the temperature Webb will expericence in deep space, -400 degrees Farenheit (-240 degrees Celsius).

Cryogenic testing of the primary mirror segments began in at Marshall's XRCF by Ball Aerospace in 2009.

The change in mirror segment shape due to the exposure to these cryogenic temperatures was recorded by Ball Aerospace Engineers using a laser interferometer. This information, together with the mirrors, traveled back to California for final surface polishing at Tinsley. The mirrors' final polish was completed in June of 2011.

Gold Coating

Once a mirror segment's final shape is corrected for any imaging effects due to cold temperatures, and polishing is complete, a thin coating of gold is applied. Gold improves the mirror's reflection of infrared light.

Some Technical Details: How is the gold applied to the mirrors? The answer is vacuum vapor deposition. Quantum Coating Incorporated did the coatings on our telescope mirrors. Essentially, the mirrors are put inside a vacuum chamber and a small quantity of gold is vaporized and it deposits on the mirror. Areas that we don't want coated (like the backside and all the mechanisms and such) are masked-off. Typical thickness of the gold is 1000 Angstroms (100 nanometers). A thin layer of amorphous SiO2 (glass) is deposited on top of the gold to protect it from scratches in case of handling or if particles get on the surface and move around (the gold is pure and very soft).

Photos of Webb's mirrors.

The engineering design unit primary mirror segment (flight spare) coated in gold by Quantum Coating Incorporated. Photo by Drew Noel.

The secondary mirror went through a similar process - here it is after being gold-coated by Quantum Coating Incorporated.

After the gold coating was applied, the mirrors once again traveled back to Marshall Space Flight Center for a final verification of mirror surface shape at cryogenic temperatures. The mirror segments were now complete. Next, they traveled to NASA's Goddard Space Flight Center in Greenbelt, Maryland.

The Assembled Mirrors

The first two flight mirrors arrived at NASA Goddard in September of 2012. By the end of 2013, all the flight primary mirror segments, as well as the secondary and tertiary mirrors would be at Goddard. The mirrors were stored in special protective canisters in the cleanroom, awaiting the arrival of the flight telescope structure.

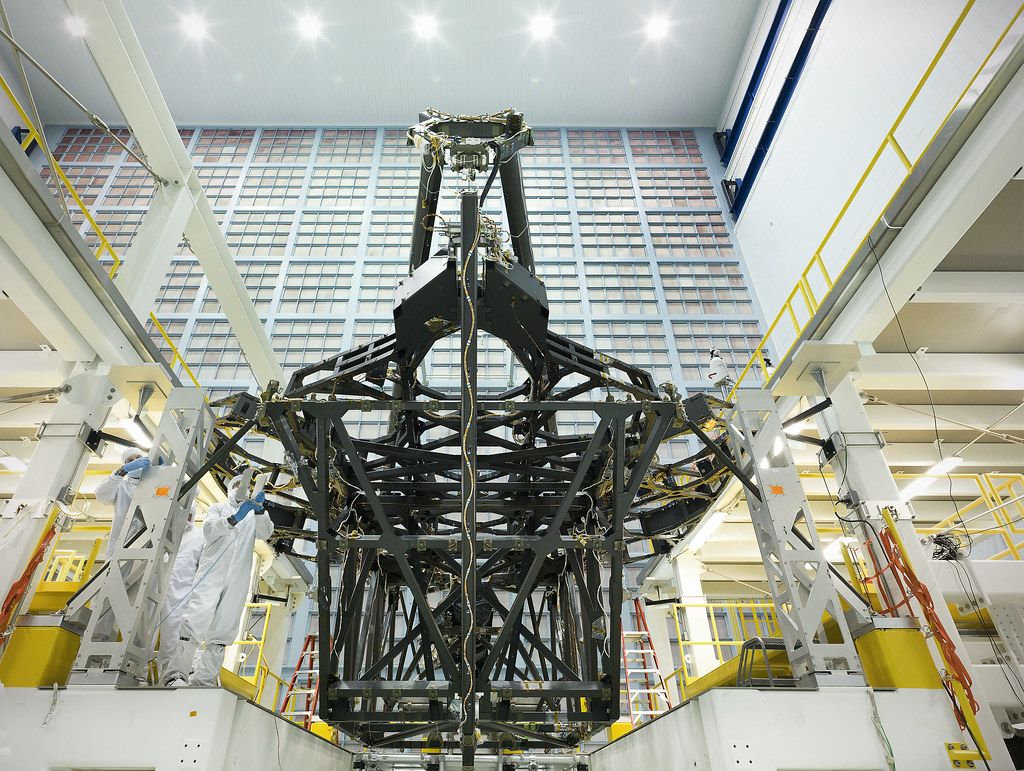

The flight telescope stucture (essentially the bones of the telescope, which the mirrors would be mounted on) was shipped from Northrop Grumman, and arrived at NASA Goddard in August of 2015. It was moved to the assembly stand in November of 2015. On November 22, 2015, the first mirror was installed.

The flight telescope structure sits in the assembly stand at NASA Goddard, ready for mirror assembly.

Note that to protect the mirrors during assembly, they were fitted with lightweight, black covers, which were removed once the mirror was fully assembled.

The last mirror was installed in February of 2016. Not long after, the protective covers were removed, and the full mirror was revealed.

The Uncovered Mirrors

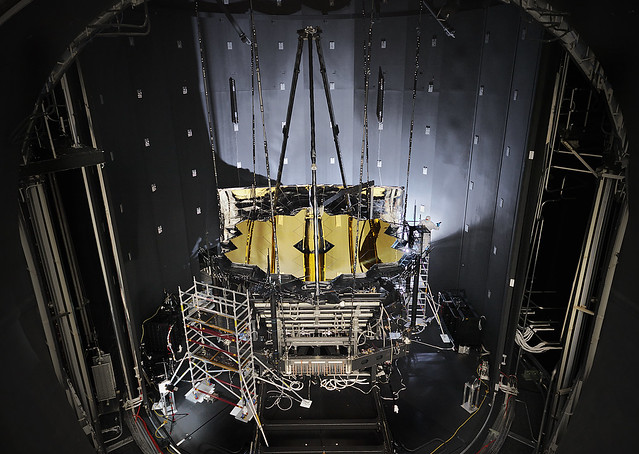

Once the mirrors were completed, the science instruments were integrated into the telescope. While at Goddard, the telescope also underwent environmental testing - both acoustic and vibration - to ensure it will be able to withstand the rigors of launch. That successfully completed, the telescope was sent off to NASA Johnson in Houston, Texas, for tests of the optics and instruments at cryogenic temperatures. NASA Johnson's Chamber A is the only thermal vacuum chamber NASA has that is large enough for Webb!

Aligning The Mirrors On Earth And In Space

Once the telescope is in orbit, Engineers on Earth will need to make corrections to the positioning of the Webb telescope's primary mirror segments to bring them into alignment - ensuring they will produce sharp, focused images.

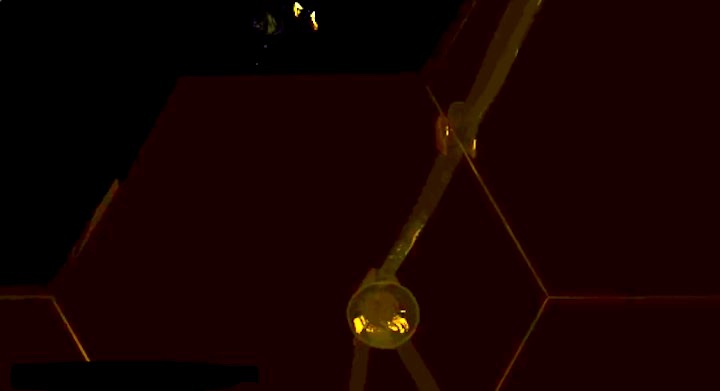

These corrections are made through a process called wavefront sensing and control, which aligns the mirrors to within tens of nanometers. During this process, a wavefront sensor (NIRCam in this case) measures any imperfections in the alignment of the mirror segments that prevent them from acting like a single, 6.5-meter (21.3-foot) mirror. Engineers will use NIRCam to take 18 out-of-focus images of a star - one from each mirror segment. The engineers then use computer algorithms to determine the overall shape of the primary mirror from those individual images, and to determine how they must move the mirrors to align them.

Engineers tested this alignment process in the cryogenic, vacuum environment of Chamber A at NASA's Johnson Space Center during about 100 days of cryogenic testing. The environment of the chamber simulates the frigid space environment where Webb will operate, and where it will collect data of never-before-observed portions of the universe. Inside the chamber, engineers fed laser light into and out of the telescope, acting like a source of artificial stars. The test verified the entire telescope, including its optics and instruments, worked correctly in this cold environment and ensured the telescope will work correctly in space.

Having passed its tests at NASA Johnson, Webb and its mirrors have moved to Northrop Grumman, where the telescope will be mated with the sunshield and spacecraft bus.

Quelle: NASA

----

NASA’s Webb Telescope Reaches Major Milestone as Mirror Unfolds

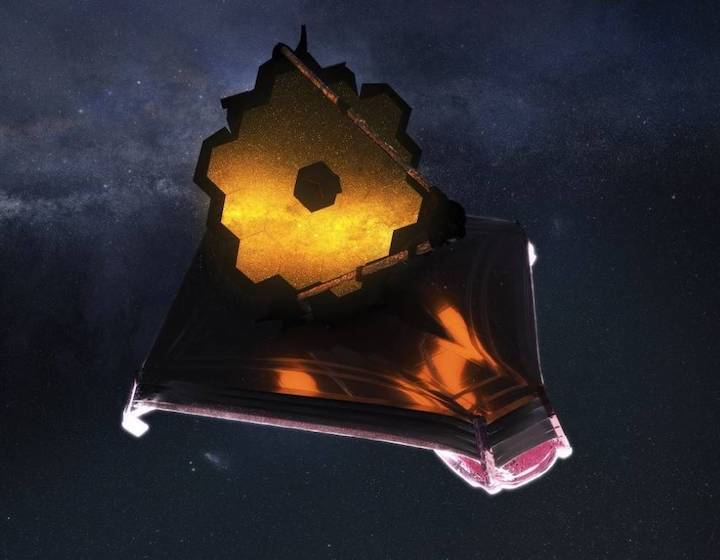

NASA’s James Webb Space Telescope team fully deployed its 21-foot, gold-coated primary mirror, successfully completing the final stage of all major spacecraft deployments to prepare for science operations.

A joint effort with the European Space Agency (ESA) and Canadian Space Agency, the Webb mission will explore every phase of cosmic history – from within our solar system to the most distant observable galaxies in the early universe.

“Today, NASA achieved another engineering milestone decades in the making. While the journey is not complete, I join the Webb team in breathing a little easier and imagining the future breakthroughs bound to inspire the world,” said NASA Administrator Bill Nelson. “The James Webb Space Telescope is an unprecedented mission that is on the precipice of seeing the light from the first galaxies and discovering the mysteries of our universe. Each feat already achieved and future accomplishment is a testament to the thousands of innovators who poured their life’s passion into this mission.”

The two wings of Webb’s primary mirror had been folded to fit inside the nose cone of an Arianespace Ariane 5 rocket prior to launch. After more than a week of other critical spacecraft deployments, the Webb team began remotely unfolding the hexagonal segments of the primary mirror, the largest ever launched into space. This was a multi-day process, with the first side deployed Jan. 7 and the second Jan. 8.

Mission Operations Center ground control at the Space Telescope Science Institute in Baltimore began deploying the second side panel of the mirror at 8:53 a.m. EST. Once it extended and latched into position at 1:17 p.m. EST, the team declared all major deployments successfully completed.

The world’s largest and most complex space science telescope will now begin moving its 18 primary mirror segments to align the telescope optics. The ground team will command 126 actuators on the backsides of the segments to flex each mirror – an alignment that will take months to complete. Then the team will calibrate the science instruments prior to delivering Webb’s first images this summer.

“I am so proud of the team – spanning continents and decades – that delivered this first-of-its kind achievement,” said Thomas Zurbuchen, associate administrator for the Science Mission Directorate in NASA Headquarters in Washington. “Webb’s successful deployment exemplifies the best of what NASA has to offer: the willingness to attempt bold and challenging things in the name of discoveries still unknown.”

Soon, Webb will also undergo a third mid-course correction burn – one of three planned to place the telescope precisely in orbit around the second Lagrange point, commonly known as L2, nearly 1 million miles from Earth. This is Webb’s final orbital position, where its sunshield will protect it from light from the Sun, Earth, and Moon that could interfere with observations of infrared light. Webb is designed to peer back over 13.5 billion years to capture infrared light from celestial objects, with much higher resolution than ever before, and to study our own solar system as well as distant worlds.

“The successful completion of all of the Webb Space Telescope’s deployments is historic,” said Gregory L. Robinson, Webb program director at NASA Headquarters. “This is the first time a NASA-led mission has ever attempted to complete a complex sequence to unfold an observatory in space – a remarkable feat for our team, NASA, and the world.”

NASA’s Science Mission Directorate oversees the mission. NASA’s Goddard Space Flight Center in Greenbelt, Maryland, manages the project for the agency and oversees the Space Telescope Science Institute, Northrop Grumman, and other mission partners. In addition to Goddard, several NASA centers contributed to the project, including Johnson Space Center in Houston, the Jet Propulsion Laboratory in Pasadena, Marshall Space Flight Center in Huntsville, Alabama, Ames Research Center in Silicon Valley, and others.

Quelle: NASA

----

Update: 11.01.2022

.

All hail the Ariane 5 rocket, which doubled the Webb telescope’s lifetime

"It would have been criminal not to do it."

There were two stunningly good pieces of news about the James Webb Space Telescope this past weekend. One was widely reported—that after an intricate, two-week process, the telescope completed its deployment without any difficulties. The next steps toward science operations are more conventional.

The other piece of news, less well-covered but still important, emerged during a news conference on Saturday. NASA's Mission Systems Engineer for the Webb telescope, Mike Menzel, said the agency had completed its analysis of how much "extra" fuel remained on board the telescope. Roughly speaking, Menzel said, Webb has enough propellant on board for 20 years of life.

This is twice the conservative pre-launch estimate for Webb's lifetime of a decade, and it largely comes down to the performance of the European Ariane 5 rocket that launched Webb on a precise trajectory on Christmas Day.

Prior to launch, the telescope was fueled with 240 liters of hydrazine fuel and dinitrogen tetroxide oxidizer. Some of this fuel was needed for course adjustments along the journey to the point in space, about 1.5 million km from Earth, where Webb will conduct science observations. The remainder will be used at Webb's final orbit around the L2 Lagrange point for station-keeping and to maintain its orbit.

So every kilogram of fuel saved on Webb's journey to the Lagrange point could be used to extend its life there. Because ten years seemed like a fairly short operational period for such an expensive and capable space telescope, NASA had already been contemplating a costly and risky robotic refueling mission. But now that should not be necessary, as Webb has at least two decades of life.

A lot of this comes down to the performance of the venerable Ariane 5 rocket. NASA and the European Space Agency reached an agreement more than a decade ago by which Europe would use its reliable Ariane 5 rocket to lift the telescope into space, and in exchange, European scientists would get time to use the telescope.

During an interview with The Interplanetary Podcast, Ariane 5 program manager Rudiger Albat explained how European rocket scientists approached the Webb launch. Each Ariane 5 vehicle is interchangeable, but engineers and technicians involved in the production of the rocket know which components are going on which rocket. So when they were building a part of Webb, an engineer might say, "I'll take a second look" to make sure the piece was the best it could be.

The Ariane 5 program also selected the best components for Webb based upon pre-flight testing. For example, for the Webb-designated rocket, the program used a main engine that had been especially precise during testing. "It was one of the best Vulcain engines that we've ever built," Albat said. "It has very precise performance. It would have been criminal not to do it."

A similar attitude was taken toward other components, including the solid rocket motors that were used to build the Ariane 5 that launched two weeks ago.

Albat admitted that the days prior to launch were exhausting and nerve-wracking. But soon after the launch, Albat said he and the entire European space community could take pride as Webb took flight and began to unfurl its wings. Now, he said, "I feel totally relaxed." The same can be said for a lot of scientists who have been watching Webb's development for two decades.

Quelle: arsTechnica

----

Update: 16.01.2022

.

What will the James Webb Space Telescope look at first?