12.10.2020

Crucial first fueling test on tap for SLS core stage later this month

If all goes according to plan, engineers in southern Mississippi later this month will load cryogenic propellants into the core stage of a rocket NASA says will launch astronauts back to the moon, exposing its tankage and internal plumbing to extreme operating conditions hundreds of degrees below zero for the first time.

The fueling test — a major milestone in its own right — is a precursor to a high-stakes eight-minute test-firing of the Space Launch System’s four shuttle-era main engines planned as soon as November.

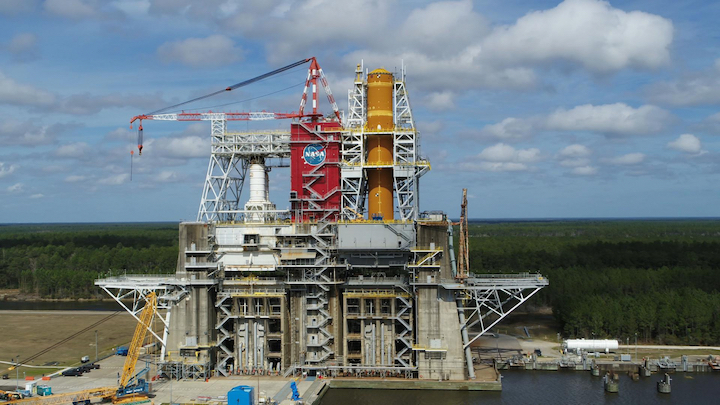

Covered in orange foam insulation, the huge Boeing-built rocket stage has been fastened in the B-2 test stand at NASA’s Stennis Space Center since January, when it arrived by barge from a manufacturing plant at NASA’s Michoud Assembly Facility in New Orleans.

Since January, work to ready the rocket stage for its first test-firing has been suspended several times, first by the coronavirus pandemic, and then by several close calls with hurricanes approaching the Gulf Coast.

With Hurricane Delta on track to make landfall in Louisiana Friday, hands-on work on the SLS core stage has again been paused on the B-2 test stand, according to Valerie Buckingham, a NASA spokesperson at the Stennis Space Center.

But Stennis is expected to receive limited impacts from Hurricane Delta, and assuming the forecast holds up, operations on the test stand could quickly resume.

The next step in the SLS test campaign at Stennis, known as the “Green Run,” will be to load 733,000 gallons of super-cold liquid hydrogen and liquid oxygen into the core stage. NASA expects that major step to occur later this month, according to Tracy McMahan, a spokesperson at the Marshall Space Flight Center, which manages the Space Launch System program.

Numerous sensors will measure how the core stage and its intricate plumbing respond to the loading of cryogenic propellants.

The liquid hydrogen is stored at minus 423 degrees (minus 253 degrees Celsius) in the case of liquid hydrogen, and liquid oxygen is kept at minus 298 degrees Fahrenheit (minus 183 degrees Celsius).

The fueling test, known as a wet dress rehearsal, is the penultimate test in the Green Run. If everything checks out in the wet dress rehearsal, engineers will load cryogenic propellants into the core stage again in November and ignite the rocket’s four RS-25 main engines for more than eight minutes, the duration of their burn during a real launch.

The hotfire test is a final exam in the development of the core stage, the tallest rocket stage ever built. The SLS core is derived from the space shuttle external tank, and its four RS-25 engines — built by Aerojet Rocketdyne — are leftovers from the shuttle program.

The 212-foot-long (64.6-meter), 27.6-foot-wide (8.4-meter) SLS core stage has the same diameter as the shuttle’s fuel tank. It weighs about 188,000 pounds (85 metric tons) empty, and will weigh around 2.3 million pounds (more than 1,000 metric tons) fully fueled.

After the core stage arrived at Stennis in January, ground teams lifted the rocket by crane and lowered it onto the B-2 test stand, a facility once used for test-firings of the powerful first stage of NASA’s Apollo-era Saturn 5 moon rocket.

The first major test on the core stage was a modal test on the core stage to measure the resonant frequency of the rocket.

In March, NASA halted operations on the test stand for two months with the onset of the coronavirus pandemic. NASA and Boeing engineers resumed work on the core stage in May after introducing new guidelines for physical distancing and other measures to guard against COVID-19.

Ground teams switched on the core stage’s avionics in June and performed a thorough checkout of the rocket, then proceeded into safing checks, which verified controllers can send commands to shut down the rocket’s engines and other major systems in the event of a problem.

Then engineers commenced testing of the core stage’s main propulsion system, searching for any signs of leaks and verifying all connections between the engines and the rocket’s tankage. That test, known as Test 4 in the Green Run, also included engine igniter checks and tests of the engine control valves.

With that test passed successfully over the summer, teams moved on to a checkout of the core stage’s hydraulic system, which drives thrust vector control actuators to swivel the four RS-25 engines and steer the rocket in flight.

Teams activated the rocket’s auxiliary power units, which drive the hydraulic loops for engine steering system. The engines then gimbaled individually to ensure they could be swiveled within an 8-degree cone, followed by gimbal test profiles to simulate how the engines will move together in flight.

The hydraulic thrust vector control test concluded Sept. 13, wrapping up a series of functional checks on the rocket as engineers moved into final reviews and rehearsals for the wet dress rehearsal and hotfire.

The next milestone, known as Test 6, was completed Oct. 5 after control teams at Stennis ran through a simulated 48-hour launch countdown to validate activation, fuel loading, and pressurization sequences.

Engineers and technicians from NASA, Boeing, and engine-builder Aerojet Rocketdyne participated in the countdown simulation, which provided a “refresher course” for test controllers to ensure they are ready to load cryogenic propellants into the rocket for the first time, according to Mark Nappi, Boeing’s Green Run test director.

“Once we’re done with that, we’ll stop, we’ll break, we’ll review the data, and we’ll go into the actual wet dress rehearsal,” Nappi said in an interview before the countdown simulation test.

NASA has not announced a target date for the cryogenic loading test, but it will mark a significant step for the SLS program, a milestone that comes with unknowns.

“Filling everything with cryo is huge because that’s the first time you have your tanks moving the way they’re going to move when they’re filled with cryo fluid,” said Alex Cagnola, a propulsion engineer at NASA’s Marshall Space Flight Center.

“You’re testing all your joints. You’re testing how everything basically acts under a cryogenic environment,” Cagnola said in an interview earlier this year.

John Shannon, SLS program manager at Boeing, said all of the testing on the rocket so far has been at ambient temperatures

“Things change when you get down at cryogenic temperatures, and as we saw after our experience with the shuttle, you can end up having systems perform differently,” said Shannon, a former NASA flight director and space shuttle program manager.

Teams will check for leaks, and ensure valves and other hardware still work at cryogenic temperatures. It takes about six hours to pump liquid hydrogen and liquid oxygen into the core stage.

“The next big unknown as a program is when we put the cryogenic liquids in the oxygen tank and the hydrogen tank, and we look at the plumbing and all the systems and make sure that they remain tight, and that they perform as expected through our qualification test,” Shannon told reporters earlier this year. “We have high confidence that they will, but until you see it in an integrated fashion, you don’t really know.”

Engineers will drain the core stage of its cryogenic propellants after the wet dress rehearsal, then analyze the test results and perform inspections of the rocket before proceeding with another fueling operation. That will culminate in ignition of the rocket’s four RS-25 engines.

All four engines on the SLS core stage have flown on multiple space shuttle missions, and the high-performance powerplants will provide up to 2 million pounds of thrust at full throttle. The reusable engines on the single-use core stage will be discarded after each SLS flight.

The RS-25 engines will fire for more than eight minutes. Programmed commands will adjust the engines’ power settings during the test, mimicking their thrust profile during launch.

Assuming a successful hotfire test, teams at Stennis will prepare the core stage for shipment to NASA’s Kennedy Space Center — likely early next year — for final processing to ready the rocket for its first test flight in late 2021.

Inside the Vehicle Assembly Building at Kennedy, technicians will begin stacking the rocket’s twin solid rocket boosters on a new mobile launch platform once the core stage passes its Green Run hotfire test. After arriving at Kennedy, the core stage will be lifted in between the solid-fueled boosters, then ground teams will raise an upper stage and an Orion crew capsule on top of the rocket before rollout to pad 39B for a countdown rehearsal and final launch preparations.

The first flight of the Space Launch System with the Orion spacecraft, known as Artemis 1, will not carry any astronauts. The Orion will fly to the moon and enter lunar orbit to demonstrate its performance and capabilities, then return to Earth for a splashdown in the Pacific Ocean after a mission of 26 to 42 days.

In 2023, NASA aims to launch the Artemis 2 mission with a crew on-board. After blasting off on the second SLS flight, the Orion crew will loop around the far side of the moon before coming back to Earth, the first trip by astronauts to the vicinity of the moon since 1972.

If NASA’s plans come to fruition — an open question that hinges on funding from Congress and no major technical obstacles — the Artemis 3 mission could launch by the end of 2024 on the third SLS/Orion mission. After flying their Orion spaceship near the moon, astronauts would link up with a commercial lunar lander to travel to the moon’s surface for a landing attempt.

In April, NASA contracted with commercial teams led by Blue Origin, Dynetics and SpaceX to begin developing human-rated lunar landing craft. The agency expects to select one or two of the teams next year to continue lunar lander development efforts, assuming Congress provides the money to support the effort.

The SLS and Orion programs stretch back years.

The Orion spacecraft has its roots in NASA’s Constellation moon landing program started under the George W. Bush administration. NASA chose Lockheed Martin as the prime contractor for the Orion crew capsule in 2006, and Orion survived the cancellation of the Constellation program by the Obama administration in 2010.

The Space Launch System was unveiled in 2011 as the centerpiece of a new space exploration initiative proposed by Congress. The Obama White House signed on to the program, and NASA repurposed the ongoing Orion spacecraft work to support a broader exploration strategy focusing on Mars, not the moon, with intermediate missions involving visits by astronauts to asteroids in deep space.

Despite years of delays and cost overruns, the Space Launch System has retained support from lawmakers, particularly among members of Congress from states where the rocket is designed, built, and tested. The Trump administration redirected NASA’s space exploration strategy toward the moon, creating the Artemis program after a directive from Vice President Mike Pence last year to land astronauts on the moon by the end of 2024.

NASA has spent more than $15 billion on the SLS program to date, and NASA’s inspector general warned in March that the rocket’s development costs will increase to more than $22.8 billion by 2023, when the agency expects to certify it for astronaut flights.

The SLS core stage is the last major element for the Artemis 1 mission yet to be delivered to the spaceport in Florida for launch processing. The Orion spacecraft has completed its test campaign, and is ready to be fueled and mated with its launch abort system. Managers will give the go-ahead for those activities after the core stage completes its Green Run hotfire test.

Segments for the rocket’s twin side-mounted solid boosters arrived at Kennedy in June from their Northrop Grumman factory in Utah. Technicians plan to start stacking the boosters on mobile launch platform in the Vehicle Assembly Building once the Green Run testing on the core stage concludes in Mississippi.

Quelle: SN

----

Update: 20.10.2020

.

Northrop Grumman to Support NASA’s Artemis Missions with Motors for Orion Spacecraft’s Launch Abort System

Abort and attitude control motors to support six crewed Artemis missions

Northrop Grumman Corporation (NYSE: NOC) will continue supporting NASA’s Artemis missions by providing six additional abort motors and attitude control motors (ACM) for the Orion human spaceflight capsule’s Launch Abort System (LAS), under an agreement with Lockheed Martin, Orion’s prime contractor.

These motors will be used for six crewed Artemis missions III-VIII and are the first procured under the new Orion production contract.

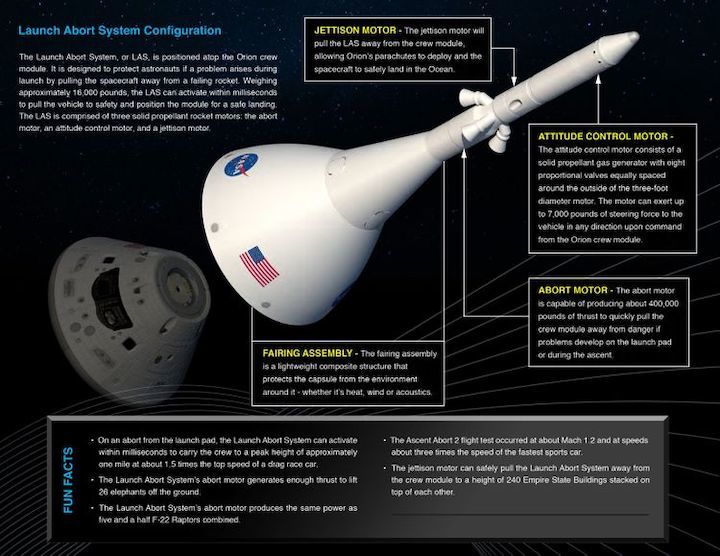

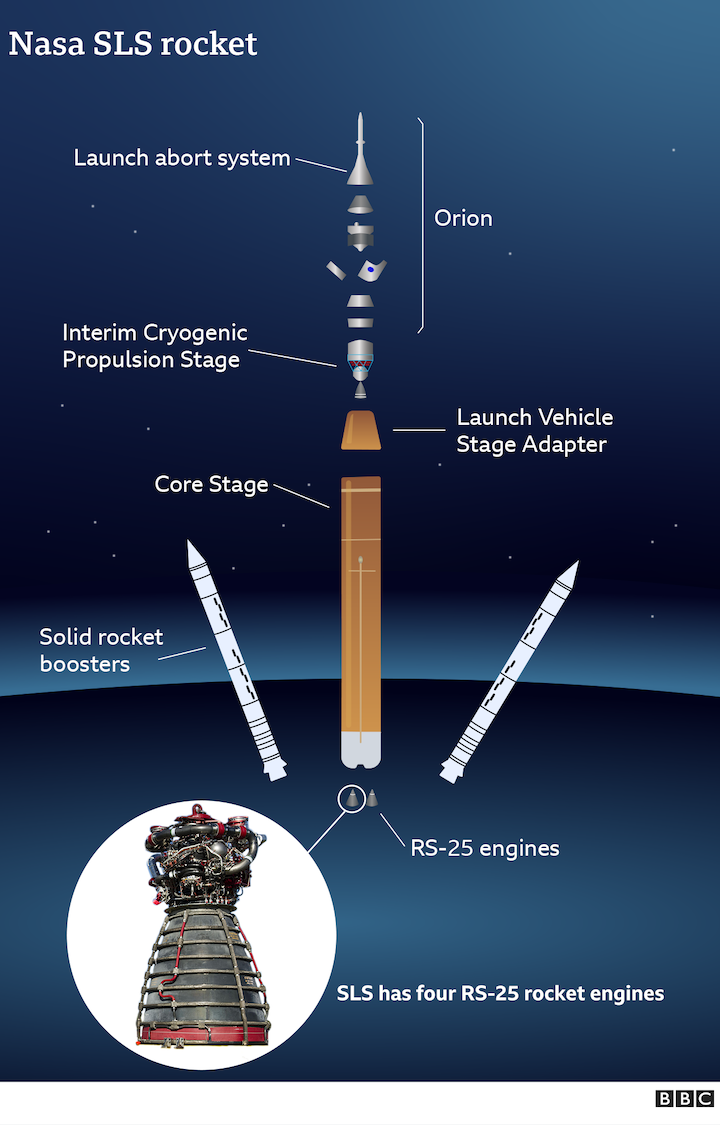

The Launch Abort System is a three-motor stack consisting of an abort motor, an attitude control motor and the jettison motor all mounted atop the Orion spacecraft crew capsule, and the combined Orion and LAS sit atop of NASA’s Space Launch System.

“As a former astronaut, there is nothing more important to me than ensuring crew safety to the greatest extent possible,” said Charlie Precourt, vice president, propulsion systems, Northrop Grumman. “Our contribution to Orion’s Launch Abort System helps to ensure it is equipped with trusted, reliable propulsion to safeguard Artemis crews.”

The LAS is designed to carry the Orion spacecraft and its crew to safety if an anomaly occurs on the launch pad or during the SLS rocket’s climb to orbit. The abort motor would provide thrust of about 400,000 pounds in less than two seconds to lift the crew away from the launch vehicle. In this event, the attitude control motor would steer the Orion crew capsule away from the launch vehicle and orient the capsule for parachute deployment once the crew module is clear of all hazards.

The abort motor is manufactured at Northrop Grumman facilities in Magna, Promontory and Clearfield, Utah, and the attitude control motor is produced at the company’s Elkton, Maryland, facility. Northrop Grumman previously delivered its LAS motors to Kennedy Space Center for the Artemis I mission, set to occur next year, and for Artemis II.

From the first lunar lander to the space shuttle boosters, to supplying the International Space Station with vital cargo, Northrop Grumman has pioneered new products and ideas that have been put into orbit, on the moon, and in deep space for more than 50 years. As a major contributor to NASA’s Artemis program, the company is building on its mission heritage with new innovations to enable NASA to return humans to the moon, with the ultimate goal of human exploration of Mars.

Northrop Grumman solves the toughest problems in space, aeronautics, defense and cyberspace to meet the ever evolving needs of our customers worldwide. Our 90,000 employees define possible every day using science, technology and engineering to create and deliver advanced systems, products and services.

Quelle: Northrop Grumman

----

Update: 22.10.2020

.

Mobile launcher arrives at Launch Pad 39B for tests, preps for Artemis I

The mobile launcher for Artemis I begins rollout from the Vehicle Assembly Building atop crawler-transporter 2 in the early morning on Oct. 20, 2020, at NASA's Kennedy Space Center in Florida.

NASA's mobile launcher that will carry the Space Launch System (SLS) and Orion spacecraft for Artemis I is on the road again. The Exploration Ground Systems and Jacobs teams rolled the mobile launcher, atop crawler-transporter 2, out of the Vehicle Assembly Building for its slow trek to Launch Pad 39B at Kennedy Space Center in Florida on Oct. 20.

The roll began just after midnight, and the mobile launcher arrived at the top of the pad Tuesday morning. This trek to the pad will help prepare the launch team for the actual wet dress rehearsal and launch of SLS and Orion on Artemis I next year. The wet dress rehearsal is when SLS and Orion will be rolled out to the pad atop the mobile launcher to practice fueling operations a couple months before launch. The last time the mobile launcher was rolled to the pad was in December 2019.

During its two-week stay at the pad, engineers will perform several tasks, including a timing test to validate the launch team's countdown timeline, and a thorough, top-to-bottom wash down of the mobile launcher to remove any debris remaining from construction and installation of the umbilical arms.

"While these tasks have been rehearsed individually, the return to Pad 39B allows the team to perform this sequence altogether," said Charlie Blackwell-Thompson, Artemis launch director.

To begin, technicians will lower the engine service platform that is under the core stage RS-25 engines from the mobile launcher and move it to the launch position. The platform allows access to the engines for routine work or inspections. Engineers and technicians will rehearse a timely completion of removing platforms used to access SLS core stage engines.

They will position both side flame deflectors in the flame trench and raise the extensible columns to launch configuration that are critical to support an on-time launch. The extensible columns are designed to provide extra support to the mobile launcher at liftoff, when the loads are the greatest. The team also will perform preparations of mobile launcher umbilical arms along with other mobile launcher and pad subsystems.

"During the Artemis launch countdown, this work will be performed prior to tanking," Blackwell-Thompson said. "As part of this demonstration, the team will exercise the ground hardware in order to determine the timing of these critical elements."

During its time at the pad, the mobile launcher also will receive a bath.

"The wash down will reduce the risk to the SLS/Orion during launch," said Cliff Lanham, EGS flow director. "Some of the debris are inaccessible without using high-pressure water, available at the pad, to get into hard-to-reach areas."

To accomplish the wash down, the team will use the mobile launcher's fire protection system, which has hoses on each level and the deck. The high-pressure flow rate will wash debris into the flame trench, industrial wastewater retention tanks, and percolation ponds. Lanham said this is an added safety measure, in addition to the walk downs performed prior to launch.

While at the pad, the mobile launcher's fire suppression system also will be recertified. The last certification was in December 2019 and is due before launch in November 2021.

Artemis I will test the Orion spacecraft and SLS as an integrated system ahead of crewed flights to the Moon. Under the Artemis program, NASA will land the first woman and the next man on the Moon in 2024.

Quelle: SD

----

Update: 25.10.2020

.

SLS Core Stage nearing home stretch for Green Run tanking test

Final preparations are in work to ready the first Space Launch System (SLS) Core Stage flight article for its first-ever propellant loading in the B-2 Test Stand at NASA’s Stennis Space Center in Southern Mississippi. Prime contractor Boeing is leading the Green Run test campaign for the central component of the space agency’s new launch vehicle as the test team approaches the critical Wet Dress Rehearsal (WDR) now tentatively targeted for early November.

The WDR is the seventh of eight Green Run test cases and the precursor to a full-duration Hot-Fire test of the stage once the tanking test is completed. Final closeouts of the stage to configure it for its first live countdown will take up much of the remaining time before the full Green Run team meets for a Test Readiness Review (TRR); the meeting is planned two days before the test to verify that the vehicle, the test stand, and the test team are ready to proceed.

In the WDR, the Core Stage will be prepared for ignition exactly as it will for the Hot-Fire and for a launch, activating all its systems to run together and meet all their firing criteria before the countdown is stopped several seconds before engine start.

Post-hurricane status, road to WDR

A couple of days after the Green Run test team completed the series of simulation practice runs that made up most of test case six in early October, Hurricane Delta became the fifth tropical weather system to disrupt the work schedule at Stennis.

Coupled with a two-month standdown from March to May due to the COVID-19 pandemic, natural causes are expected to stretch the Green Run campaign out to a full year; the stage arrived on NASA’s Pegasus barge at Stennis on January 12, 2020, and the current plan has Pegasus departing with the SLS Core in mid-January, 2021, assuming things go well with the last two Green Run tests.

The Mississippi space center returned to normal hurricane status on October 10 and back on-site, final preparations for the big Wet Dress Rehearsal and Hot-Fire tests resumed. “The next thing that we had to go do was load the new version of Stage Controller software, so that’s behind us and now what we’re doing is doing the last set of safing checks that basically validate that the new load of software is working just like the old one did,” Mark Nappi, Boeing Green Run Test Manager, said on October 15.

The safing checks were originally run earlier in the test campaign as test case three, but were executed again now that the ground control system’s software is updated for the big, fueled tests. “It is almost identical to test three, you’re just going to go through and check all that stuff again and make sure it’s still working right with the final check of the big red button, which is our cutoff button,” he explained.

“We’ve already run these tests once before but we’re doing it as a confidence-builder since the Phase 2 Stage Controller software was loaded. That will start tomorrow (October 16) and that’ll work through Sunday (October 18) and then in parallel with that we’ll be removing engine section platforms which is really our critical path on getting to the Wet Dress [Rehearsal] date.”

Credit: NASA/Joel Kowsky.

(Photo Caption: Boeing Green Run Test Manager Mark Nappi (left) is one of the NASA and Boeing SLS officials briefing agency administrator Jim Bridenstine (middle) while standing under the Core Stage in the B-2 Test Stand at Stennis on February 10. Mr. Bridenstine is situated under the boattail’s “manhole,” which provides one of the access points into the engine section/boattail compartment. The nozzles of the four RS-25 engines are covered with yellow bagging in part to keep the engine components dry.)

Internal work platforms are deployed in the dry volumes of the Core Stage, the forward skirt, intertank, and engine section for pre-launch processing and then must be removed before flight or flight-like operations such as the final two Green Run tests. The liquid oxygen (LOX) and liquid hydrogen (LH2) propellant tanks are the biggest elements and have some machinery and sensory equipment, but the dry volumes contain almost all of the moving parts of the rocket and the platforms provide the reach and support for workers to get to them when necessary.

The engine section is the most complicated and densely-packed area on the vehicle, with the aft dome of the LH2 tank filling the top and the RS-25 engine powerheads sticking up through the boattail into the bottom. In between and around those prominent parts are foam-covered propellant lines and valves, large, high-pressure bottles of helium gas, hydraulic power units and actuators, and dozens of computer devices all connected with miles of wiring runs.

The engine section has a two-level set of ground platforms that provides access when the Core Stage is oriented vertically; due to the cramped quarters inside the aft compartment the platforms must be brought inside mostly one piece at a time and assembled in place. Similarly, for disassembly and removal the platforms cannot be taken apart in sections, but piece-by-piece in order to minimize the chances of damaging the rocket machinery.

“The Engine Section platform set is two-hundred separate pieces small enough to fit thru the engine section access door and then can be assembled around all the engine section hardware to form a continuous area for employees to work off of,” Nappi explained. “It is two separate levels, one at the lower boat tail area and a second story right below the LH2 tank. It has to be disassembled piece by piece and removed from the engine section thru the access door while inspections are performed of the area that was uncovered.”

“Every time you take a platform out you’re looking for anything that may have been covered up so you can fix it and properly document it and move on,” Nappi added. “So that’s going to take a good ten, twelve days or so and that is our critical path.”

After completion of test case six, NASA and Boeing announced a forecast for the final two big Green Run tests on October 13. The WDR tanking test planned to culminate in the final countdown on October 30 and the Hot-Fire test about two weeks later. “What we’ll do is we’ll set up a couple of days beforehand. The vehicle will be all powered up and the team will be on console and then we’ll start the loading of the 537,000 gallons of liquid hydrogen and the 196,000 gallons of liquid oxygen,” John Shannon, Boeing’s Vice President and Program Manager for SLS, said.

“We’ll spend about two weeks of looking at data to make sure that that all the systems behaved as expected, we’ll go out and inspect the vehicle, make sure there are no surprises and that’ll set us up well for a hot-fire that right now we’re anticipating will be in the middle of November,” Shannon added.

Shannon gave a tentative date of November 14 for the Hot-Fire at the time; however, the tentative dates for both tests have subsequently slipped a few days. NASA Human Exploration and Operations Mission Directorate Associate Administrator Kathy Lueders indicated on October 20 that the Wet Dress Rehearsal had slipped into early November, which is likely to delay the Hot-Fire out a similar number of days.

WDR test and tanking preparations

On the eve of starting the WDR with the standard “call to stations” for the test team on console in the control center, NASA and Boeing SLS management will hold the Test Readiness Review (TRR). “The test readiness reviews are normally conducted the day before the test starts, so we start Test Case Seven on the 28th is what we’re planning right now and so the TRR will be on the 26th,” Nappi said prior to the delay.

“So that’s where we’ll start test case seven and then it’s a four-day test. Two days into it we start tanking, so it’s a pretty short-duration type of operation.”

Final preparations in the area, also called “pre-operations,” will begin the week before the pre-test review. The new date for the TRR is still under review.

“[Pre-operations] is when Stennis will start getting ready with bringing the barges in and configuring the stand,” Nappi noted. “So there’s some work that we’ll do on the vehicle and there’s some work that Stennis will do leading up to the official start and call to stations for test case seven.”

The large, 212-foot long Core Stage will require all six of the space center’s LOX and LH2 barges to be docked at the B Test Complex. The cryogenic fuel boils off over time; once docked, their propellant loads will need to be topped off by tanker trucks brought to the test complex.

At the conclusion of the TRR, the SLS management team would give a go to start the test a day or two later. One of the first activities is to power up the Stage Controller, which then commands power up of the Core Stage computer system.

“Once we’re ready to power up, we have to power up the Stage Controller and then we move into vehicle power up and then we do a short check of all of our systems and black boxes to make sure everything is working properly,” Nappi explained. “In parallel with that Stennis operations will get the stand ready and that’s about a day and a half of operations for that to occur.”

The countdown clock won’t start until later in the test, but Nappi noted the WDR is a launch countdown type of operation. “We’ve got a good amount of time in there in case anything goes wrong because we want to get to our T-0 when we plan our T-0, so it’s similar to launch countdown time where on launch countdowns we used to put planned holds in,” he said.

“We don’t put planned holds into this count but we have plenty of time to get things down so we stay on schedule.”

Credit: Aerojet Rocketdyne.

(Photo Caption: Green Run infographic of the propellant storage that will be used to fill the Core Stage during the Wet Dress Rehearsal and Hot-Fire tests. Stennis Space Center uses barges docked to its A and B Test Complexes to support testing “hydrolox” rocket engines and rocket stages. The SLS Core Stage Green Run will use most of the barge propellant capacity and all six positions at the B Test Complex will be occupied for the two fueled Green Run tests.)

The remaining schedule leading up to the pre-test final review meeting includes some time for solving “non-conformances” (NCs) to the work plan, but with only a handful of days left to the test there’s not much time to account for climatological factors and nothing for another hurricane. “Between now and wet dress it’s a pretty sequential schedule,” Nappi said. “When we build the bars of work we account for some NCs that may happen. We don’t account for big weather events.”

“If we were shut out of the stand for days because of bad weather obviously that’s not accounted for,” he added. “We put a little of that in the plan that we create.”

The 2020 Atlantic hurricane season is not over yet; if another tropical weather system were forecast to get too close to Stennis, forward work would be put on hold. Nappi explained that it takes about three days of preparations to protect the Core Stage and the test stand against tropical storm force winds and weather conditions.

“What that involves is that you have to close out all of volumes, so you have to get the equipment out of each, the forward skirt, the intertank, and engine section, put the doors on and then you have to secure the outside of the vehicle,” he said. “So any scaffolding you have out has to come down, any tooling that you have up has to come down, and then we have these things that are in between the platforms and the vehicle called debris catchers that have to come out in case the winds got so strong that they could impact the vehicle and cause damage.”

The schedule impact each time the Green Run team had to stop and protect the hardware was different from one storm to the next, in part depending on the timing of the approach and what test work was being performed. “It usually is about seven days of an impact when a storm comes through unless we can figure out a way to perform critical path work at the same time, in parallel with the securing and post-storm reconfiguration,” Nappi noted.

“You have that three days of prep when you’re not doing anything else other than prepping for the storm, and then of course you’re down for the storm, and then you come back and you’ve got another three days that you’ve got to do to reconfigure the vehicle so that you can go back to work. So for example when Sally came through it was a seven-day impact, but when Delta came through it was only a two-day impact to the critical path because we managed to get a lot of critical path work done as we were securing and doing post-storm reconfiguration and so it really is dependent on where we are in the flow and what kind of work do we have going on at the time.”

WDR tanking and terminal countdown objectives

The current plan is for tanking day to be two days after the call to stations begins the WDR test. A pre-tanking management meeting will be held as a final decision point about twelve hours before the planned T-0 time. If a go is given to proceed, the primary test team will be on console in the test control center and they will begin final tanking preps.

Loading the Core Stage with propellant is a major objective of the test; it will be the first time in the SLS Program that a full-scale article is filled with its flight load of LOX and LH2. The tanking procedures have been analyzed with different math models for flow rates, temperatures, pressures, and other system behavior, and this will be the first opportunity to measure the predicted system response against an actual one by a flight article.

“The first fun thing is going to be to thermally condition the tank, where you put a little bit of cryos in and you start to chill the tank down before you go into what you call the fast fill time-frame and then it’s going to be a lot of looking at stable replenish and make sure we can keep pressure on the tank,” Shannon said back in January when the stage completed production at the Michoud Assembly Facility and was transported to Stennis.

“Primarily we’re looking at the [hazardous] gas [detection] system to make sure that we don’t have any leaks once we get down to cryogenic temperatures but it is called ‘wet dress,’ the dress is dress rehearsal, it’s the rehearsal for how we’re going to do things on hot-fire day so we will count and we will cut off and we will drain.”

Credit: NASA/SSC.

(Photo Caption: The top of the -Z side of Core Stage-1 in the B-2 Test Stand at Stennis in late January, showing fire-extinguisher water lines and platforms around the forward skirt and liquid oxgyen tank. The first working stage article will go on to Kennedy Space Center to help power the Artemis 1 mission to the Moon.)

The countdown and the pre-ignition cutoff is the other major objective of the WDR test; the test team will be running a live, fueled Core Stage through a terminal countdown for the first time. The terminal sequence was simulated during test case six but a full-up, final countdown requires the ground control and test stand infrastructure to support preparing the Core Stage to fire its engines under launch conditions.

Beginning at T-10 minutes on the countdown clock, the automated final countdown sequence arranges activation of the final remaining unpowered systems around completing the thermal conditioning of the engines so they reach their start box temperatures and pressures at the right time. Replenishment of LOX and LH2 boiloff in the fully-loaded fuel tanks will be terminated and the tanks will be pressurized for engine start. The vehicle’s Core Stage Auxiliary Power Units (CAPU) will be started and the hydraulic systems will be tested by running the four RS-25 engines through a canned sequence of movements.

One of the design verification objectives unique to the WDR is a two-hour hold with the stage configured to proceed into the terminal countdown sequence; this will demonstrate the capability of the vehicle to wait through a hold as long as the two-hour long launch windows that SLS lunar missions will have.

An additional design verification objective for the WDR will be performed during the final minutes of the countdown to demonstrate the ability of the vehicle in a “ready to start” configuration to hold for a short period of time without needing to cutoff and recycle the clock back to the top of the automated sequence.

The countdown will be taken all the way down to a few seconds before the hand-off of control from the Stage Controller to the Core Stage flight computers. After the countdown is stopped, safing will begin on the ready-to-fire vehicle and both the stage and ground systems will be recycled back to the T-10 minute configuration.

Following recycle and safing, the propellants will drained out of the two tanks. The test will conclude after residual propellant boils off, the tanks are inerted, and the vehicle and ground control systems are powered down.

Gulf Storms Delay Critical Testing Of NASA’s Next Moon Rocket

The massive core stage for NASA’s Space Launch System (SLS) rocket is in the B-2 Test Stand at NASA’s Stennis Space Center near Bay St. Louis, Mississippi, for the core stage Green Run test series. Photo: NASA

An active tropical storm season in the Gulf has delayed a critical test of SLS, NASA’s next moon rocket. The Green Run is a critical test campaign of the core stage booster, culminating with a firing of the rocket’s four main engines.

The test is conducted at NASA’s Stennis Space Flight Center in Mississippi. The full firing of the engines for eight minutes — called a hot fire — was scheduled for mid November. But an active hurricane season is delaying that final test.

“We did have it in our schedule that we might incur some severe weather, but not four to five major named storms coming down to do some possible impacts,” said Boeing engineer Kristine Ramos. “It shut us all down. It has been very interesting this season this year, just because of all the hurricanes.”

NASA said it will evaluate a new date soon. Once the test is complete and the booster certified for flight, the vehicle will travel to Kennedy Space Center before launching an uncrewed mission around the moon, currently slated for late 2021.

Quelle: 90.7 WMFE

----

Update: 12.11.2020

.

BYE BYE, EUROPEAN SERVICE MODULE, SEE YOU IN SPACE

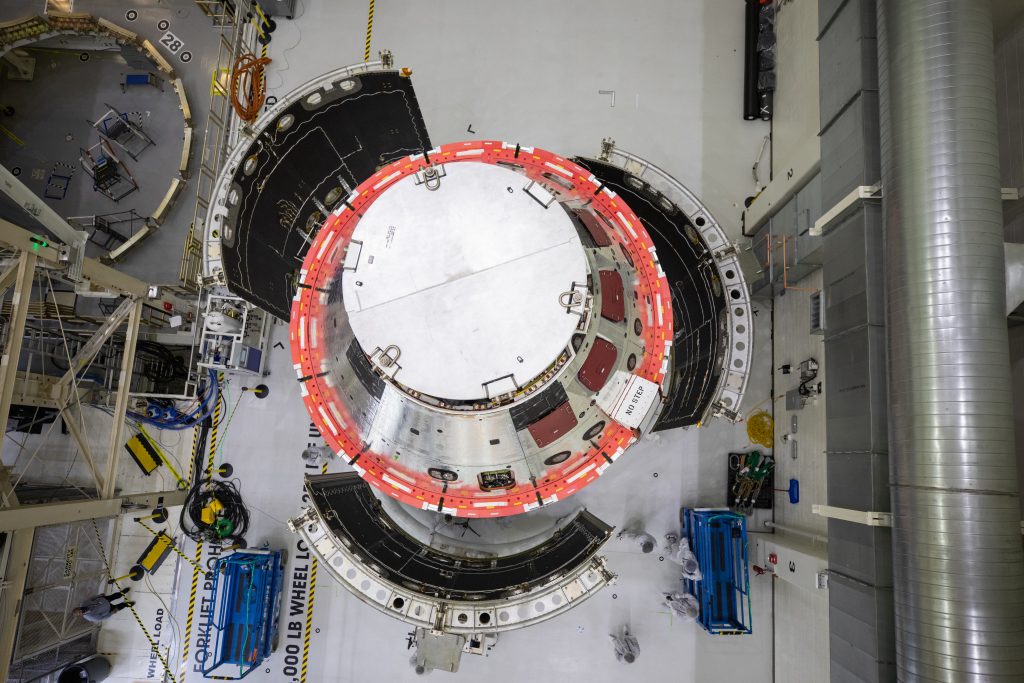

Technicians have finished encapsulating the European Service Module for NASA’s Orion spacecraft that will travel around the Moon on the first Artemis mission.

Like most spacecraft Orion will be launched inside protective fairings on top of its Space Launch System rocket. The spacecraft adapter jettison fairings have now been installed that protect the European Service Module during launch and are ejected shortly after liftoff.

The next time the European Service Module will be visible it will be in space, when the four 7-m-long solar wings unfold to start generating power for the spacecraft. The three fairings are each around 4 m square, the size of a small room, after launch they will be blown away by small pyrotechnic explosions revealing the four solar panels and the European Service Module underneath.

Above the European Service Module is the Crew Module where up to four astronauts will live and work on a typical two-week flight to the Moon and back. The first mission, Artemis I, will be uncrewed and is set to launch next year.

With the spacecraft jettisonable adapters installed at NASA’s Kennedy Space Center in Florida, USA, the European Service Module will not be easily visible on Earth again, although technicians can access the module to service it and fill the tanks with fuel, helium, nitrogen and ammonia for the cooling system and other consumables.

The final assembly activities for the spacecraft include installation of the forward bay cover, which protects the upper part of Orion including its parachutes throughout its mission, final adjustments of the main parachutes, securing and testing of electrical connections, along with closure and latching of the side hatch.

As each area of the spacecraft is closed out, it will undergo final inspections to complete production. The spacecraft will then begin its path to the pad, including stops along the way to be fuelled and integrated with its launch abort system and, ultimately, the SLS rocket for launch.

In December the European Service Module will be officially handed over to NASA’s launch preparation teams with ESA in a supporting role for Exploration Ground Support, during the mission and for post-flight analysis, as the spacecraft heads into final preparations for launch – a milestone for the hundreds of people involved who worked securely and tirelessly to make humankind’s next-generation exploration vessel.

Meanwhile in Bremen, Germany, work is progressing smoothly on the second and third European Service Modules that will send astronauts around and to the Moon. Technicians are currently installing the four propellant tanks for the European Service Module for Artemis II.

Quelle: ESA

----

Update: 14.11.2020

.

Nasa's new 'megarocket' set for critical tests

Nasa has been developing a "megarocket" to send humans to the Moon and, eventually, Mars. The last critical tests of the giant launcher's core section are expected to take place within the next few weeks. Sometimes compared to the iconic Saturn V, can the Space Launch System (SLS) help capture the excitement of lunar exploration for a new generation?

In southern Mississippi, near the border with Louisiana, engineers have been putting a remarkable piece of hardware through its paces.

A giant orange cylinder is suspended on an equally imposing steel structure called the B-2 test stand on the grounds of Stennis Space Center, a Nasa test facility outside the city of Bay St Louis.

Measuring about 65m (212ft) from top to bottom, the cylinder represents the core of a space vehicle more powerful than anything the world has seen since the 1960s.

It's called the Space Launch System (SLS) and it consists of the liquid-fuelled core stage - with four powerful RS-25 engines at its base - and two solid fuel boosters which are strapped to the sides.

The fully assembled vehicle provides the massive thrust force necessary to blast astronauts off the Earth and hurl them towards the Moon. Under Nasa's Artemis programme, the next man and the first woman will be despatched to the lunar surface in 2024. It will be the first crewed landing on Earth's only natural satellite since Apollo 17 in 1972.

It may use technology developed for the space shuttle, but in many ways, the SLS is a modern heir to the Saturn V, the gigantic rocket that lofted the Apollo lunar missions.

After a decade of development, the SLS is now approaching a critical stage. A year-long programme of testing for the core stage is coming to an end. Called the Green Run, it's designed to iron out any issues before the rocket's maiden flight, scheduled for November 2021.

On 12 January this year, the first SLS core stage was shipped to Stennis on a barge from the New Orleans factory where it was assembled. It was then lifted by cranes and installed in a vertical position on the B-2 test stand.

Ryan McKibben, SLS Green Run test conductor at Stennis Space Center, told BBC News: "When you actually see the real deal, with the real avionics, the real tanks - the liquid hydrogen tank which holds 500,000 gallons and the liquid oxygen tank with over 200,000 gallons - it is an incredible vehicle."

IMAGE COPYRIGHTNASA

IMAGE COPYRIGHTNASAThe Green Run is split into eight parts - or test cases. Since the beginning of the year, engineers from Nasa and Boeing, the rocket's prime contractor, have been working through these individual tests. They have included powering up the avionics (flight electronics), evaluating the performance of different systems and components, and simulating problems.

"We're very fortunate to be able to put it through its paces: power it up, do leak checks, even pressurise some systems," says Ryan McKibben.

"One of the test cases, test case five, we ended up gimballing the engines - that's when we move them around hydraulically so that you can do course corrections during flight. It's been a lot of fun."

During its first mission next year, known as Artemis-1, the SLS will launch an uncrewed Orion capsule on a loop around the Moon. It will allow Nasa to evaluate the capsule before astronauts are allowed on.

IMAGE COPYRIGHTNASA

IMAGE COPYRIGHTNASAThe remaining two core stage tests are crucial. Number seven, known as the wet dress rehearsal (WDR) involves a full loading of the core stage tanks with liquid hydrogen (LH2) - the rocket's fuel - and liquid oxygen (LOX), which makes the fuel burn. Together, these are known as propellants.

A waterway snakes through the grounds of Stennis Space Center, linking it to the nearby Pearl River. This allows heavy equipment and hardware to be shipped between different Nasa sites. A total of six barges carrying LH2 and LOX will be docked near the B-2 test stand during the wet dress rehearsal.