21.06.2019

EGS preparing ML-1 for validation tests at the Pad

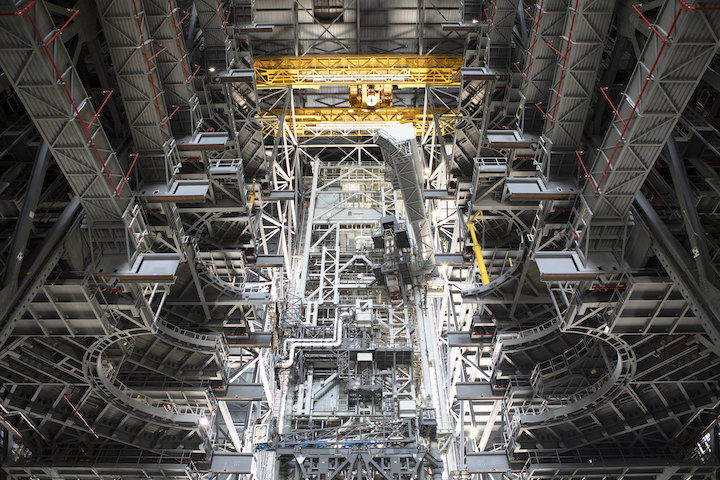

Exploration Ground Systems (EGS) is getting Mobile Launcher-1 (ML-1) ready to roll out to Kennedy Space Center (KSC) Launch Pad 39B next week as it moves through the final phases of integration and testing of the combination launch umbilical tower and platform ahead of the Artemis 1 launch. ML-1 is currently going through verification and validation (V&V) testing in the Vehicle Assembly Building (VAB) at KSC.

Along with confirming that installation of systems up and down the tower and on the platform are complete, the testing inside High Bay 3 of the VAB also verifies that the Launch Control Center can command and control ML-1 in anticipation of assembly of the first integrated Orion and Space Launch System (SLS) vehicle prior to a launch late in 2020 or 2021.

The current round of outfitting and V&V testing is working on data, electrical, mechanical, and other services employed during vehicle assembly, while the Summer at the launch pad will also checkout fluid and propellant-related connections to and operations with the pad systems needed to launch Artemis 1.

Wrapping up swing arm testing in the VAB ahead of pad rollout

ML-1 is the platform that the SLS launch vehicle stands on, along with the umbilicals that provide all the services needed by the launcher and the Orion spacecraft. Artemis 1 (also known as Exploration Mission-1) is the first launch of SLS and the first use of ML-1 and all the EGS-related Launch Complex 39 (LC-39) infrastructure.

The launch will also start the second Orion mission and is the first flight integrating all three Exploration Systems Development (ESD) programs (EGS, Orion, SLS). The upcoming rollout to Pad 39B, currently scheduled for June 27, marks completion of most of the installation and outfitting of the Mobile Launcher (ML) and the end of the first round of V&V testing in the VAB.

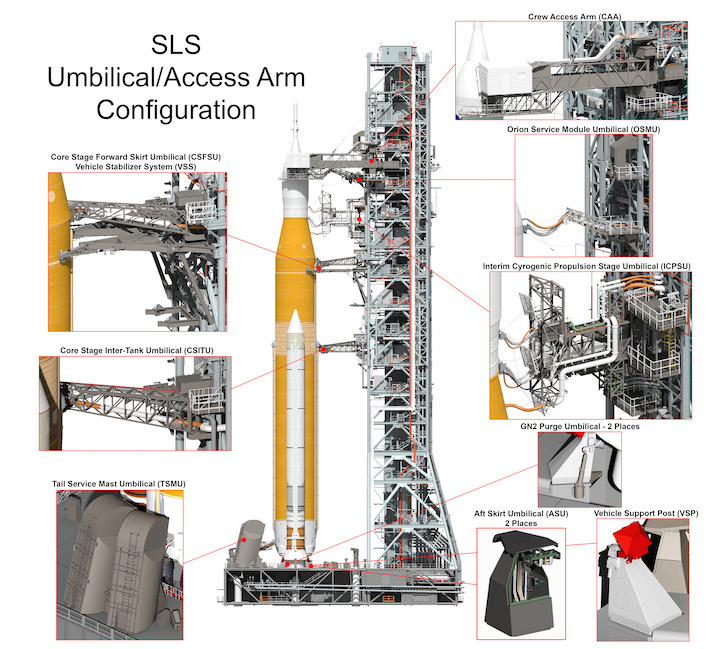

Photo Caption: The Mobile Launcher umbilicals and connections for the SLS Block 1 Crew vehicle configuration for Artemis 1. The umbilical arms attached to the Core Stage and Interim Cryogenic Propulsion Stage (ICPS) swing away from the rising vehicle after the umbilical plates disconnect at liftoff. Hydraulic extension and retraction of the arms individually and in groups is being tested in the VAB this month.)

“We rolled into the VAB back in early September and at that point we still had some installation work to do and then we got into our Multi Element Verification and Validation (MEV&V) testing which is our big testing effort between the VAB and the Mobile Launcher,” Cliff Lanham, EGS Senior Project Manager for the Mobile Launcher, said in a June 10 interview.

As all of the subsystems and components are installed on the ML, the MEV&V testing makes sure they are meeting their functional and other requirements, both as standalone systems, but also connected to VAB services.

Testing also verifies the command and control infrastructure to the ML from the Firing Rooms in the LC-39 Launch Control Center adjacent to the assembly building. “Some of the series of testing that went on was for each of our electrical systems,” Lanham explained.

“We went through and performed end-to-end testing where we basically run in many cases locally, meaning we can control from the Mobile Launcher the subsystem or the electrical system out to the end of the umbilicals. Then once we were confident in that we then go to a remote testing where test our systems from the Firing Room all the way through the VAB through the ML out to the end of the arms.”

“We also have been swinging the arms, so we have been testing the Core Stage Forward Skirt Umbilical (CSFSU) and swinging that, the Core Stage Inter-Tank Umbilical (CSITU), the Interim Cryo Propulsion Stage Umbilical (ICPSU), have all been going through a series of swing testing throughout the past several months,” he added.

“Along those same lines the Orion Service Module Umbilical (OSMU) has also been tested [and] we’ve been prepping the Tail Service Mast Umbilicals (TSMU) and getting ready for drop testing which we’ll be performing in the next week or so, hopefully this week, to get that done as we prep for the roll to the pad.”

Photo Caption: The Core Stage Inter-Tank Umbilical arm in February as swing arm testing was beginning in the VAB. The umbilical plate at the end of the arm (middle left) mates to a plate on the Core Stage intertank to (among other things) provide air conditioning to stage avionics and to allow hydrogen gas boil off from the liquid hydrogen tank to be vented away from the vehicle.)

“We make sure that we can control it when we extend the arm because obviously you don’t want something that could possible damage the vehicle, but primarily what you’re looking for, the big bulk of the testing is tuning the arm so that it will appropriately swing back and brake and connect to the tower the right way,” he explained.

Most of the other ML systems are in various phases of testing. “There’s also some other fluid-type systems, hydraulic systems,” Lanham noted.

“We’ve been testing the TVC (Thrust Vector Control)/hydraulic subsystem, which provides hydraulic servicing to the Boosters and the Core Stage systems and we’ve also been doing a lot of environmental control system (ECS) testing. There we test out through the system to a portable purge unit outside the VAB.”

“They provide the air-conditioning and such up through the VAB, through the Mobile Launcher system out to the ends of the arms and we’ve been doing testing there to ensure we can deliver all the proper air and temperatures and humidities, those types of things out to the ends of the arms where they feed the vehicle,” he added. “We’ve also done the backup testing where if we were to have a failure with a portable purge unit we [have] mini-purge units.”

(Photo Caption: The Core Stage Inter-Tank Umbilical arm in an extended position away from the ML tower during swing arm testing in the VAB. At liftoff, the ground and vehicle plates are separated and the ML’s hydraulic arm subsystem swings this and other T-0 umbilicals away from the rising vehicle.)

“We do all the same testing to make sure we can supply what’s needed to the vehicle.”

In addition to the vehicle’s hydraulic system needs, the ML swing arms are also hydraulically actuated and an additional, pre-rollout swing test is planned to retract the ICPSU, the CSFSU, and CSITU at the same time. “It’s called an Integrated System Verification and Validation (ISVV) test,” Lanham said.

“The HAASP (Hydraulic Arms and Accessories Service Pressure subsystem) is the hydraulic system that controls the arms, so we’ll do a simultaneous retract of those three arms.” Lanham said the simultaneous retract ISVV test is an end-to-end test that will be commanded from the Firing Room.

He also noted they are wrapping up drop testing of the Vehicle Stabilizer and working on testing and checkout of the hazardous gas detection system.

Finishing pre-rollout installations

In addition to all of the testing on completed sections of the ML, installations and other work also continue ahead of the rollout. “From the standpoint of installation work in the VAB we’ve had to do some structural mods and we’ve been working through those,” Lanham noted.

“We’re about ninety, ninety-five percent complete on the structural mods that we’ve been working. We’ve been doing a lot of pneumatics work, finalizing the tubing throughout the Mobile Launcher and then getting all those systems cleaned.”

“Basically what you’ve got to do is go through and you pressure test the systems, then you’ve got to clean them and then you’ve got to dry them and then once the pneumatic pieces are in place we get into testing pneumatic systems as well,” he added. Testing of the pneumatic system, which functions as a part of the propellant loading infrastructure will continue at the pad ahead of a propellant loading demonstration planned there.

Photo Caption: The south-facing side of the flame deflector, showing some of the Ignition Over-Pressure/Sound Suppression water system plumbing. The pad deluge and other water flows will be tested with the Mobile Launcher in place for the first time this Summer.)

“We’ve also been putting in nozzles which are [for] the IOP (Ignition Over-Pressure)/Sound Suppression system,” Lanham said. “We’ve had to weld [them] into the flame hole and get those positioned properly, they’re all in.”

Lanham said there are twenty-eight nozzles around the flame hole. “There’s eight on each side for the Core Stage and then six on each booster,” he noted. “This week we’ll be putting on the rainbirds, which go on the 0-deck.”

Lanham also noted that testing of the IOP/Sound Suppression water system with the ML is one of the first set of Pad-ML MEV&V tests. “We’ve got to get the rainbirds installed to be ready for our water flows when we first get out to the pad, so we’re working to get that done,” he said.

“Right now what we’re trying to get accomplished before we leave would be the engine service platforms, we’re trying to get those installed and tested but again if we don’t get that done we can do that at the pad. That’s one area we’re trying to complete.”

“We’ve got some ICPSU arm swings to complete so we’re still working on those,” he added. “We’re doing some haz gas testing that’ll go right up to when we’re ready to leave.”

Modal testing on second shift

Lanham said that the team is current working two shifts in the VAB to get ready for rollout. In addition to the integration and testing work to complete the ML to support its first launch, a modal test of the ML is being conducted prior to rollout.

“We’re getting ready for the modal test which will be our next really big test, which kicks off second shift this coming Sunday night the sixteenth,” he said. “That’s where we’ll be driving the Mobile Launcher and seeing how it responds to different inputs and then they’ll be recording all that data, so we’ll be doing that over the next several weeks just about right up until when we roll.”

“So the idea here is we’re going to do the modal on second shift,” he explained. “What we’ll be doing is a 12-hour shift and then we’ll be doing our regular work and other testing on the first shift, so we’ll continue to test right on up to when we’re ready to roll out.”

(Photo Caption: The upper umbilical/access arms on the Mobile Launcher umbilical tower back in September following roll into VAB High Bay 3. Pictured here, from the top are the extended Crew Access Arm and Orion Service Module Umbilical, then the retracted Interim Cryogenic Propulsion Stage Umbilical and Core Stage Forward Skirt Umbilical.)

The plan is to finish as much work as possible before rolling out to the pad, but in addition to finishing leftover systems testing there will also be some other work done out at the pad along with the MEV&V.

“There will be some what I would call ‘punch list’ items that remain from the installation and the construction work, so we’ll be doing punch list items,” Lanham said. “We do have just a little bit of structural work that we’ve got to complete that we won’t finish in the VAB that we’re going to finish up at the pad.”

“Things like painting and architectural finishes, where we’ve got to put like acoustic tile in the electrical rooms, that type of stuff will be finalized. Really ‘cats and dogs’ types of stuff that we’ll have to finish up, including all the other testing at the pad, MEVV testing.”

The testing will continue during the rollout. “On the way out we’ll be essentially capturing the vibrations of the system as we roll out,” Lanhan said.

“It’s a dynamic check of how things are reacting during the actual roll. So we’ll be checking that for both the base and tower of the Mobile Launcher, we’ll be capturing that. There’s some ECS testing, Environmental Control System testing, we’ll be doing as we roll out.”

Getting ready for handover to operations

The multi-element testing first in the VAB and next out at the launch pad is pointed at finishing construction of the ML so it can be turned over to ground operations to begin launch preparations for Artemis 1. Testing at Pad 39B is scheduled to run through the Summer, with the ML being rolled back to the VAB around the end of September.

After returning to the VAB from the pad, a few more tests and a partial booster stacking exercise will be conducted along with formal reviews to certify the ML is complete and ready to support its first launch.

(Photo Caption: A fire extinguishing system (Firex) test of Mobile Launcher-1 (ML-1) while at Pad 39B for fit checks last September. A more exhaustive set of water flow tests are planned early in the ML’s Summer-long stay at the pad. Early water flows will help determine if any adjustments need to be made to fine tune the system configuration.)

The booster stacking exercise will use test hardware similar to booster stacking practice that has occurred in the past in VAB High Bay 4. With the ML complete, technicians can practice lifting inert aft segments onto the ML’s Vehicle Support Posts and run through stacking a center segment on top.

Certifications will cover all the development work. “Certifications meaning where each and every subsystem will show their paperwork essentially,” Lanham explained.

“Showing where they tested, showing their data packages, and saying we’ve met our requirements and we’re ready to go. That gets bought off and then we’ll transition the system over to operations and they’ll begin operations and maintenance, so that kind of work will continue on the Mobile Launcher that’s got to occur periodically or however they have it laid out.”

“But the big phase will finish testing and then get into the whole certification process,” he added. “I’m the project manager for the Mobile Launcher for development, so I take it all the way through certification and then again it transitions over to operations and then they’ll give me something else to go do.”

Quelle: NS

+++

Watchdogs issue warning about NASA’s SLS moon rocket plan, but Boeing CEO stays the course

The federal government’s watchdog agency says getting NASA’s heavy-lift Space Launch System rocket off the ground is likely to take longer and cost more than the space agency says it will.

Any issues that crop up in the months ahead could push the first uncrewed SLS launch, known as Artemis 1, from its planned mid-2020 timetable to mid-2021, the Government Accountability Office said in a study issued today.

What’s more, the GAO says NASA has been shifting costs forward to make it look as if expenses for the first launch have grown by $1 billion, when the actual adjusted cost growth is $1.8 billion.

Schedule and cost issues for SLS are particularly problematic because the rocket has been selected to carry NASA astronauts to the moon by 2024.

When Vice President Mike Pence, who heads the White House’s National Space Council, announced the 2024 deadline in March, he issued a veiled warning to the Boeing Co. and other SLS contractors about the consequences of missing the date.

“If our current contractors can’t meet this objective, then we’ll find ones who will,” Pence said. “If commercial rockets are the only way to get American astronauts to the moon in the next five years, then commercial rockets it will be,”

During a conference held today in Boston at the John F. Kennedy Presidential Library and Museum to mark the 50th anniversary of the Apollo 11 moon mission, Boeing CEO Dennis Muilenburg insisted that SLS was on track for 2020.

“First launch is next year,” he said. “We’re looking forward to making that happen.”

Muilenburg acknowledged that “the technology challenges are very significant.”

“The first rocket is now about 80% assembled, and we’re going through the detailed system integration,” he said. “These are very complex, sophisticated machines, so the technology itself is a challenge. I think it’s manageable. It’s work we know how to do. But it’s tough, challenging work, and we have to do it in a way that ensures safety in the end.”

Muilenburg said having consistent political and funding support for such a big space project was at least as challenging.

“We’ve seen that to date on the Space Launch System,” he said. “If we’re going to get back to the moon by 2024, we can do that, but we can’t if we don’t have stable, consistent support and funding. So the political and funding side of this, I would say, is actually the greater risk.”

In its report, the GAO noted that between 2014 and 2018, NASA paid more than $200 million in award fees relating to contractor performance on the SLS stages and the Orion deep-space crew capsule.

“But the programs continue to fall behind schedule and overrun costs,” the GAO said. “Ongoing contract negotiations with Boeing for the SLS and Lockheed Martin for the Orion program provide NASA an opportunity to re-evaluate its strategy to incentivize contractors to obtain better outcomes.”

In its response to the study, NASA said it agreed with the recommendation to re-evaluate how it paid out incentives to Boeing and other contractors.

NASA is gradually moving away from a “cost plus” model and favoring a model that specifies a fixed price and development milestones for space projects. That’s the way its contracts with SpaceX and Northrop Grumman for cargo resupply missions to the International Space Station are structured, for example.

Muilenburg discussed other space issues as well:

- Boeing is shifting the headquarters of its Space and Launch division from Arlington, Va., to Titusville, Fla., not far from NASA’s Kennedy Space Center. Muilenburg said the move made sense not only because of SLS activities, but also because of Boeing’s work on its CST-100 Starliner space taxi, X-37B and Phantom Express space planes, as well as its role as the prime contractor for the International Space Station.

- Muilenburg noted that the Starliner is due to have its first uncrewed launch to the space station this summer, with the first crewed flight currently set for the end of this year. Boeing test pilot Chris Ferguson is due to fly on the inaugural crewed mission, and would become the first American commercial space pilot to go into orbit.

- Starliner could take on half a dozen missions a year, Muilenburg said. “So what we need is more destinations” in addition to the International Space Station, he said. Last month, Boeing and other commercial ventures laid out concepts for putting new outposts in low Earth orbit. “As we have more destinations come online — space factories, space hotels — that’ll add to it,” Muilenburg said.

- Another possibility is to take tourists on a short spaceflight and then bring them back to where they started. “You’re going to do a space tour, to do three orbits around the world, right?” Muilenburg said. “That could be an exciting afternoon activity. You say, ‘Let’s go down to Kennedy, do a few orbits, come back and have lunch.’ That’ll happen.”

Quelle: GeekWire

----

Update: 26.06.2019

.

Coverage Set for NASA Test of Orion Abort System for Moon to Mars Missions

NASA Television will broadcast launch and prelaunch activities for the Ascent Abort-2 flight test of the launch abort system for NASA’s Orion spacecraft’s, which will help pave the way for Artemis missions with astronauts to the Moon and then Mars.

The test’s four-hour launch window opens at 7 a.m. EDT Tuesday, July 2. A test version of the crew module will launch from Space Launch Complex 46 at Cape Canaveral Air Force Station in Florida. NASA TV coverage will begin at 6:40 a.m.

NASA also will host a test preview news conference at 11:30 a.m. Monday, July 1, at NASA’s Kennedy Space Center in Florida. Participants include:

- Mark Kirasich, Orion program manager

- Jenny Devolites, Ascent Abort-2 test conductor

- Randy Bresnik, NASA astronaut

The launch and preview news conference will air on NASA TV and the agency’s website. A postlaunch news conference is not planned.

Ascent Abort-2 will verify Orion’s abort system can pull the crew module away from an emergency during its ascent to space. During approximately three minutes of flight, a booster will loft the test capsule about six miles into the atmosphere to experience high-stress aerodynamic conditions, at which point the abort sequence will be triggered to carry the crew module a safe distance from the rocket. The test flight will help ensure the safety of astronauts in the unlikely event an emergency arises as they rocket into space.

Orion is part of NASA’s backbone for deep space exploration, along with the Space Launch System and Gateway, which will land the first woman and next man on the Moon by 2024. Through the Artemis program, the next American Moon walkers will depart Earth aboard Orion and begin a new era of exploration.

Quelle: NASA

----

Update: 28.06.2019

.

Last Test Article for NASA's SLS Rocket Departs Michoud Assembly Facility

SLS is the only rocket that can send Orion, astronauts and supplies to the Moon on a single mission.

The last of four structural test articles for NASA's Space Launch System (SLS) was loaded onto NASA's Pegasus barge Wednesday, June 26, 2019, at NASA's Michoud Assembly Facility in New Orleans.

The barge will deliver the liquid oxygen (LOX) tank structural test article from Michoud to NASA's Marshall Space Flight Center in Huntsville, Alabama, for critical structural testing.

The liquid oxygen tank is one of two propellant tanks in the rocket's core stage that will produce more than 2 million pounds of thrust to help send Artemis 1, the first flight of NASA's Orion spacecraft and SLS, to the Moon.

The nearly 70-foot-long test article is structurally identical to the flight version, which will hold 196,000 gallons of liquid oxygen super cooled to minus 297 degrees Fahrenheit.

NASA is working to land the first woman and next man on the Moon by 2024. SLS is part of NASA's backbone for deep space exploration, along with Orion and the Gateway in orbit around the Moon.

SLS is the only rocket that can send Orion, astronauts and supplies to the Moon on a single mission.

Quelle: SD

----

Update: 30.06.2019

.

SLS CORE STAGE RECEIVES FOUR RS-25 ENGINES FOR FIRST FLIGHT

Aerojet Rocketdyne delivered four RS-25 engines for integration with NASA’s Space Launch System core stage from its facility at NASA’s Stennis Space Center to NASA’s Michoud Assembly Facility

- Aerojet Rocketdyne delivered four RS-25 engines for integration with NASA’s first SLS rocket core stage

- The four RS-25 engines that will fly on the first flight of SLS also powered the space shuttle

- Aerojet Rocketdyne has powered every astronaut launched from U.S. soil; RS-25 engines will enable the SLS to return humans to the Moon and eventually to Mars

STENNIS SPACE CENTER, Miss., June 28, 2019 (GLOBE NEWSWIRE) -- Aerojet Rocketdyne recently delivered four RS-25 engines to NASA’s Michoud Assembly Facility (MAF) for integration with the core stage of NASA’s Space Launch System (SLS) in anticipation of the rocket’s first flight on the Artemis 1 mission.

“The Space Launch System is a foundational element of our nation’s deep space exploration architecture that will allow humans to return to the Moon and eventually set foot on Mars,” said Eileen Drake, Aerojet Rocketdyne CEO and president. “Built on the proven propulsion system that powered space shuttles to orbit for more than three decades, SLS will enable more complex exploration missions and will send astronauts and large cargo farther and faster than any rocket in history.”

The RS-25 engine, an advanced version of the Space Shuttle Main Engine, has a strong legacy of safely and reliably powering human spaceflight. All four of the RS-25 engines that will fly on the first SLS flight also flew during the Space Shuttle Program; they have since been updated with new controllers and adapted for the unique operating environment of SLS. The engines will be operated at a higher power level than was used during the shuttle flights, providing SLS with additional thrust. An infographic about the first four engines and their flight history can be found here.

“Aerojet Rocketdyne engines have powered every astronaut launched from U.S. soil and, with SLS, we will build on this strong legacy,” added Drake. “There is no other rocket built or in production with the lift capability of SLS.”

In addition to the RS-25 engines, Aerojet Rocketdyne is also providing the RL10 engine that will power the SLS upper stage, known as the Interim Cryogenic Propulsion Stage (ICPS), as well as the composite overwrapped pressure vessels and reaction control system thrusters. The ICPS is complete and ready for integration with the rest of the SLS rocket components at Kennedy Space Center.

Earlier this year, Aerojet Rocketdyne delivered the jettison motor, which is part of the Launch Abort System that will ensure crew safety in the event of a launch or pad anomaly. Additionally, Aerojet Rocketdyne has assisted in refurbishing the main engine for the service module, and delivered the reaction control system engines for the Orion crew module and eight auxiliary engines for Orion’s European Service Module, which will ride atop the SLS.

+++

AEROJET ROCKETDYNE DELIVERS ORION AUXILIARY ENGINES FOR ARTEMIS 2

- Engines manufactured by Aerojet Rocketdyne will support the first crewed mission of the Orion spacecraft

- Eight auxiliary engines that control Orion’s orbital maneuvering will be integrated into the service module

- Aerojet Rocketdyne is contracted to supply Orion’s auxiliary engines through Artemis 2

REDMOND, Wash., June 25, 2019 (GLOBE NEWSWIRE) -- Aerojet Rocketdyne has delivered eight auxiliary engines for integration into the European Service Module (ESM) of NASA’s Orion spacecraft. During Artemis 2, Orion’s first mission to carry astronauts, the engines will maintain the spacecraft’s in-space trajectory and position, as well as serve as backup to the main engine.

Orion will be capable of taking crews to deep space destinations and returning them safely to Earth. Launched on NASA’s new Space Launch System (SLS) heavy-lift rocket, Orion is designed to carry people farther into space for longer periods of time than ever before, withstanding higher levels of radiation and re-entry speeds than any previous human-rated spacecraft.

“Based on the flight-proven R-4D engine, our auxiliary engines will provide critical maneuverability and propulsive support to Orion throughout its mission,” said Aerojet Rocketdyne CEO and President Eileen Drake.

The eight 110-pound-thrust bipropellant engines will be coupled into four pairs on the bottom of the ESM. The ESM, which remains connected to the spacecraft throughout the mission until just prior to Orion's re-entry to Earth’s atmosphere, provides propulsion, power, temperature control, air and water for crew members.

The auxiliary engines for Orion are manufactured, tested and qualified at Aerojet Rocketdyne’s Redmond, Washington facility under a contract to Lockheed Martin, NASA’s prime contractor for Orion. Aerojet Rocketdyne also provides the service module main engine components, Launch Abort System jettison motor, crew module reaction control system and composite overwrapped pressure vessels for the Orion spacecraft.

Quelle: Aerojet Rocketdyne