4.05.2019

NASA's Mars 2020 Mission Passes Critical Heat Shield Test

This is how engineers recreate the hellish conditions of Martian reentry to test components that will go up against the real thing.

When your one-of-a-kind rover is 38 million miles from home, falling toward an alien planet at supersonic speed, it would be nice to know the spacecraft can handle the trip.

Today Lockheed Martin announced that its engineers have completed a slate of critical torture tests on the connection between the spacecraft carrying the Mars 2020 rover and its protective aeroshell, making sure it can handle the stress of the interplanetary journey.

Hammering Out Weaknesses

The final assembly of the Mars Science Laboratory with the Curiosity rover housed inside, November 10, 2011. The top section is the cruise stage, the middle is the aeroshell, and it’s all protected by the heat shield on the bottom, also built by Lockheed Martin.

There is an inherent weakness in any vehicle or structure wherever two different materials are joined together. Each side reacts to stress differently, deforming under pressure or reacting to temperature changes. In spacecraft these small flaws can become fatal, so the engineers have to simulate these insane pressure loads and temperature swings.

For the Mars 2020 mission, the spacecraft (made by CalTech and NASA) must deliver an automobile-sized rover to the surface of Mars. The aeroshell—shaped like a shallow-bowl on the “bottom” of the spacecraft—is made of material designed to burn away, protecting the craft and its cargo from the intense heat caused by the entering the Martian atmosphere.

But first, the craft has to get off of Earth safely. “The first environment is surviving launch, because of the high accelerations, and the vibration from the acoustic environment,” says Neil Tice, Lockheed Martin Mars 2020 heat shield program manager. “And then you’re going into space. You start out at room temperature. And shortly after you can get into orbit, the temperatures start dropping rapidly. As it turns out, the heat shield is looking towards deep space. It continues to cool for several days after getting into space and heading off to Mars.”

The Hell That Is EDL

Escaping Earth's gravitational grasp is tough enough, but the engineers don’t even test the spacecraft for this part of the mission. Reentry is so violent that passing those simulations is enough to ensure launch won’t be a problem.

“Typically, a space craft's worst environment is launch. But in this case EDL (entry, descent and landing) is so severe an environment, both mechanical and thermal, that it becomes the driving case,” Lockheed lead engineer for the test, Derek Shannon, told Popular Mechanicsafter the final verification test. “For example, launch G loading is on the order of 5 to 6 Gs. And the entry pressure is on the order of 12 Gs.”

The shield will be at about -250 Fahrenheit when the craft reaches Mars. That soon changes as the spacecraft starts EDL with the compression of the atmosphere forming a superhot plasma that reaches 3,800 Fahrenheit.

“THE TEST LAST WEEK WAS REALLY TO VERIFY THAT THE STRUCTURE CAN SURVIVE THAT ENTRY PRESSURE LOAD."

“The test last week was really to verify that the structure can survive that entry pressure load,” Shannon says, after his team set the shield on a test stand made to operate in a vacuum. “There's an air cavity in between the heat shield and test fixture, and there's a rubber bumper that goes between the rim of the heat shield and test fixture.”

When his team sucked the air out to create differential pressure on the surface of the heat shield, Shannon says it “bent the entire heat shield down, pushed it towards the plate, and splayed out the outer rim of the heat shield. That put a lot of bending stress and depression stress into the structure.”

This created a 6.1 psi differential pressure, which produced the 140,000-pound pressure load on the heat shield needed to simulate EDL.

A Needed Win

The successful test is good news for NASA and Lockheed, who discovered a crack in the aersoshell during tests in late April last year. NASA officials say that creating a new heat shield won't delay the launch. Which is a good thing, considering the next launch window after 2020 would be sometime in the second half of 2022.

“While the fracture was unexpected, it represents why spaceflight hardware is tested in advance so that design changes or fixes can be implemented prior to launch,” NASA said in a statement.

Lockheed also has more tests on the aeroshell beyond verifying that the new heat shield won’t also crack. Engineers say there are also tests of the shield’s ablative material planned later this year. One of the hallmarks of the Mars 2020 mission is how much it relies on previously-used designs, but the reality is that everything needs to be tested.

On a trip like this one, it pays to be thorough.

Quelle: PM

+++

Take It Beyond The Limit: Lockheed Martin Completes Critical Testing Milestone For NASA JPL's Mars 2020 Rover Heat Shield

Protecting against the extremes of space travel is critical to the success of any mission. Lockheed Martin (NYSE: LMT) has successfully completed the flight hardware structure of the heat shield, validating the physical integrity with a final static test after exposing it to flight-like thermal conditions. The heat shield is half of the large and sophisticated two-part aeroshell that Lockheed Martin is designing and building to encapsulate NASA Jet Propulsion Laboratory's Mars 2020 rover from the punishing heat and friction of entry through the Martian atmosphere.

The Mars 2020 mission will be one of the most challenging entry, descent and landings ever attempted on the Red Planet. The heat shield aerodynamics serve as a "brake" to slow the spacecraft from about 12,000 mph (19,300 kph) so the structure needs to be flawless. As the tenth aeroshell system that Lockheed Martin has produced for NASA, this is one of the largest at 15 feet (4.5 meters) in diameter.

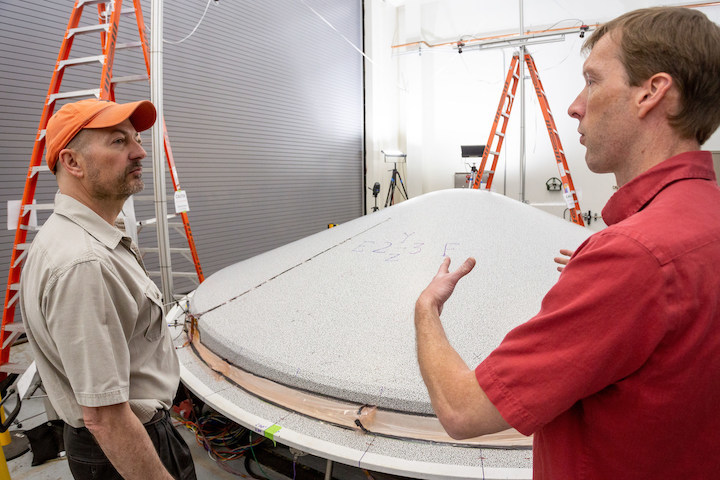

The Lockheed Martin-built heat shield, shown here in the testing phase, is just one component in the final aeroshell that will protect the Mars 2020 rover on its long journey to Mars.

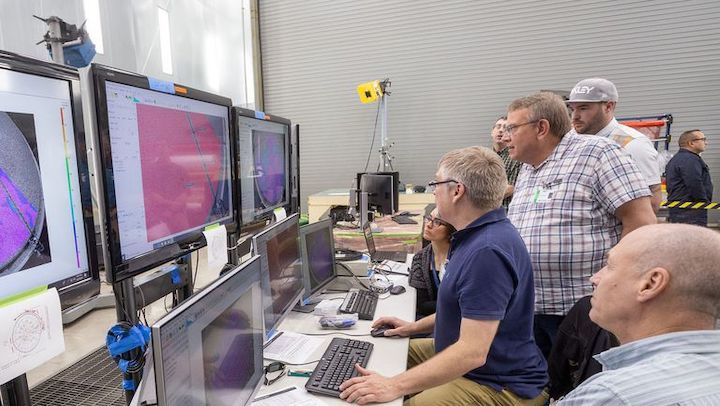

As seen in the control room, the photogrammetry visuals provide insight in to the real-time displacements and strains on the heat shield while pressure is being applied.

The Lockheed Martin-built heat shield, shown here in the testing phase, is just one component in the final aeroshell that will protect the Mars 2020 rover on its long journey to Mars.

"Our experience building aeroshells for NASA Mars missions does not mean that it is 'easy'," said Neil Tice, Lockheed Martin Mars 2020 Aeroshell program manager. "Tests like this structural test are absolutely essential to ensuring mission success in the long-run."

The static test was conducted on April 25 and was designed to mimic the load that the heat shield will experience during the most extreme part of its journey; the entry phase. To do that, engineers used vacuum pumps to simulate the pressure of approximately 140,000 pounds on the structure. The structure was tested to 120% of the expected flight load to push it to the limit.

For this particular test, the team also integrated a new form of instrumentation. Historically, this test utilizes conventional strain gauges and extensometers to monitor structural response at distinct points during loading. Partnering with NASA Langley Research Center, the team also applied a new tool called Photogrammetry or Digital Image Correlation. This allowed the team to monitor full-field strains and displacements over the entire visible area of the structure in real time. To use this technique, a vinyl wrap, similar to a decal, that has different visual cues (dark random speckles over a white background) was applied to the heat shield. During the test, a set of digital cameras optically monitor any changes in the pattern and generate a three-dimensional map of displacements and surface strains as the applied load increases.

"While we have used this full-field photogrammetry technique on test articles in the past, this is the first successful implementation on official flight hardware," said Dr. Sotiris Kellas, NASA Langley aerospace engineer and lead for the technical demonstration. "This technology will allow us to safeguard hardware during testing but more importantly provide data for test analysis correlation and improvement of our design and analysis tools."

Following this test, the Lockheed Martin team will apply Phenolic Impregnated Carbon Ablator (PICA) thermal protection system tiles to the structure. Once complete and through all environmental testing, the full heat shield will be mated to the backshell in early fall.

The Mars 2020 Project at NASA JPL manages rover development for the Science Mission Directorate at NASA Headquarters in Washington. The NASA Engineering and Safety Center at NASA Langley Research Center provided the photogrammetry support for this test.

Quelle: Lockheed Martin

----

Update: 18.05.2019

.

Mars 2020 Is Coming Together

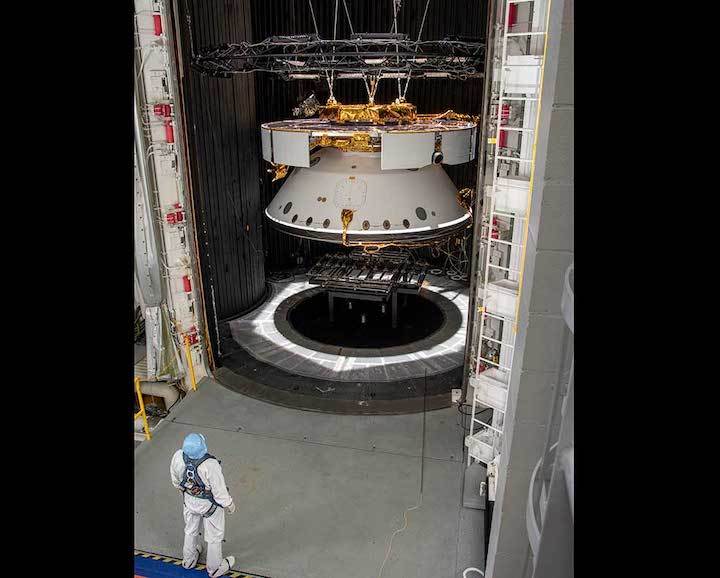

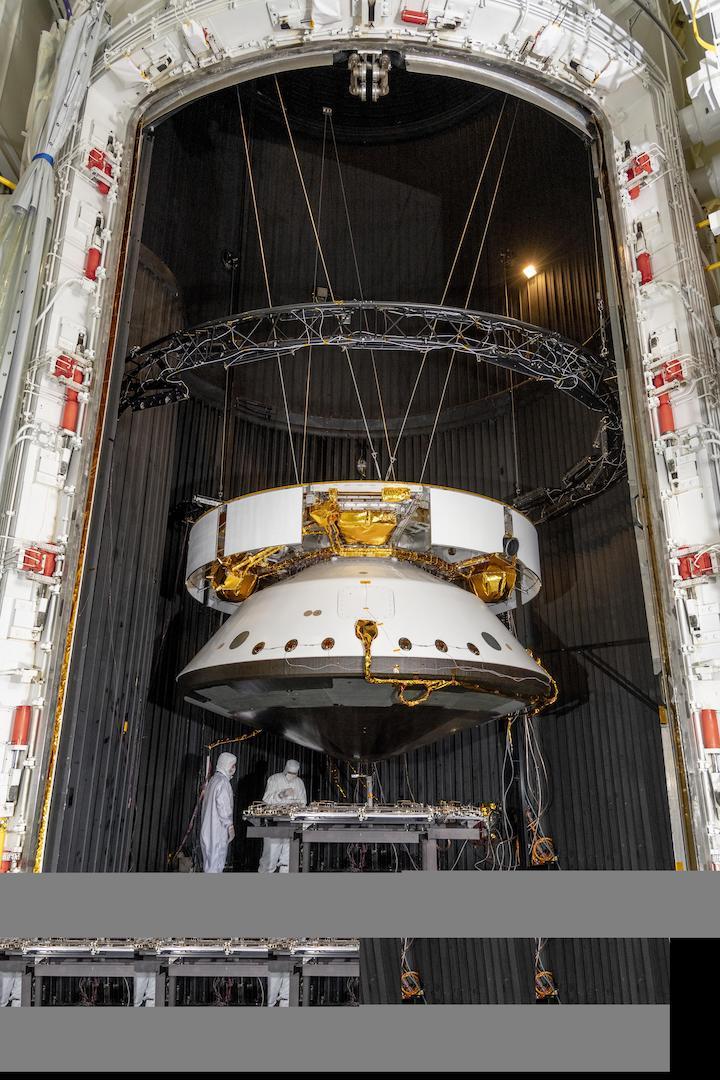

An engineer inspects the completed spacecraft that will carry NASA's next Mars rover to the Red Planet, prior to a test in the Space Simulator Facility at NASA's Jet Propulsion Laboratory in Pasadena, California.

From the top down, and suspended by cables, is the complete cruise stage, which will power and guide the Mars 2020 spacecraft on its seven-month voyage to the Red Planet. Directly below that is the aeroshell (white back shell and barely visible black heat shield), which will protect the vehicle during cruise as well as during its fiery descent into the Martian atmosphere. Not visible (because it's cocooned inside the aeroshell) is the completed rocket-powered descent stage and the surrogate rover (a stand-in for the real rover, which is undergoing final assembly in JPL's High Bay 1 cleanroom).

The Mars 2020 spacecraft was tested in the 25-foot-wide, 85-foot-tall (8-meter-by-26-meter) chamber in the same configuration it will be in while flying through interplanetary space. The 2020 rover carries an entirely new suite of instruments, including a sample-caching system that will collect samples of Mars for return to Earth on subsequent missions. The mission will launch from Cape Canaveral Air Force Station in Florida in July of 2020 and land at Jezero Crater on Feb. 18, 2021.

The image was taken on May 9, 2019.

JPL is building and will manage operations of the Mars 2020 rover for the NASA Science Mission Directorate at the agency's headquarters in Washington.

Quelle: NASA

----

Update: 26.05.2019

.

NASA's Mars 2020 Mission Drops in on Death Valley

On a test flight in Death Valley, California, anAirbus helicopter carried an engineering model of the Lander Vision System (LVS) that will help guide NASA's next Mars mission to a safe touchdown on the Red Planet. During the flight - one in a series -- the helicopter (which is not part of the mission and was used just for testing) and its two-person crew flew a pre-planned sequence of maneuvers while LVS collected and analyzed imagery of the barren, mountainous terrain below.

LVS is an integral part of a guidance system called Terrain-Relative Navigation (TRN) that will steer NASA's Mars 2020 rover away from hazardous areas during its final descent to Jezero Crater on Feb. 18, 2021.

Mars 2020 will be the first spacecraft in the history of planetary exploration with the ability to accurately retarget its point of touchdown during the landing sequence. Also among the firsts of the mission, the 2020 rover carries a sample-caching system that will collect samples of Martian rock and soil and store them on the surface of the planet for retrieval and return to Earth by subsequent missions.

Mars 2020 will launch from Cape Canaveral Air Force Station in Florida in July of 2020.

JPL is building and will manage operations of the Mars 2020 rover for the NASA Science Mission Directorate at the agency's headquarters in Washington.

Quelle: NASA

----

Update: 27.05.2019

.

NASA's Mars 2020 Gets a Dose of Space Here on Earth

The completed spacecraft that will carry the Mars 2020 rover to the Red Planet, next year hangs suspended by cables inside the Space Simulator Facility at NASA's Jet Propulsion Laboratory in Pasadena, California. The image was taken on May 9, 2019.Credit: NASA/JPL-Caltech

Engineers prepare the Mars 2020 spacecraft for a thermal vacuum (TVAC) test in the Space Simulator Facility at NASA's Jet Propulsion Laboratory in Pasadena, California.The image was taken on May 9, 2019.Credit: NASA/JPL-Caltech

NASA's Mars 2020 spacecraft undergoes examination prior to an acoustic test in the Environmental Test Facility at NASA's Jet Propulsion Laboratory in Pasadena, California. The image was taken on April 11, 2019, at JPL. Credit: NASA/JPL-Caltech

NASA's Mars 2020 spacecraft has completed acoustic and thermal vacuum (TVAC) testing at the Jet Propulsion Laboratory in Pasadena, California. The acoustic test of the spacecraft that will carry the Mars 2020 rover to a soft touchdown in Jezero Crater on Feb. 18, 2021, is the best Earthly approximation for what the spacecraft will endure during launch, where it will encounter potentially destructive levels of sound and vibration. TVAC introduces the vacuum and extreme temperatures of space that could cause components to malfunction or fail.

"First we blast it with sound to make sure nothing vibrates loose," said David Gruel, the Mars 2020 assembly, test and launch operations manager at JPL. "Then, after a thorough examination, we 'put it in space' by placing the spacecraft in this huge vacuum chamber we have here at JPL. We pump out the atmosphere, then chill parts of it and cook others while testing the performance of the entire spacecraft."

The first part of the process occurred on April 12, when the spacecraft "stack" was bombarded by sound from nitrogen-pressurized speakers in JPL's Acoustic Test Chamber. The stack includes the aeroshell as well as a rover stand-in (the real rover is undergoing final assembly in JPL's High Bay 1 cleanroom) and other components. Together, they are assembled, or stacked, in the same configuration as when it launches toward Mars in July 2020.

"We test the hardware components with a random noise spectrum in order to replicate a launch environment," said Andy Rose, manager of the Environmental Test Facilities at JPL. "We reach sound levels as high as 150 decibels, which would really rattle your fillings if you were inside the chamber at the time."

Of course, the technicians waited for each several-minute run to end before opening the chamber door to inspect the spacecraft in their cleanroom attire (the spacecraft must remain contamination-free to adhere to planetary protection rules). By day's end, the stack had been acoustically tested and inspected six times. Then the vehicle was double-bagged in clean antistatic nylon film and transported back to the Spacecraft Assembly Facility's High Bay 1 cleanroom.

"For the acoustic test, the stack had the heat shield pointed up, but for the thermal vacuum test, it had to be down," said Gruel. "The best place to turn it over is the cleanroom, where we have a fixture designed for that process." Once the stack passed muster, the team rebagged it and sent it out for thermal testing.

Into the Cold

On April 26, the stack entered JPL's 25-foot-wide, 85-foot-tall (8-meter-by-26-meter) Space Simulator Facility. The historic chamber has hosted spacecraft from NASA's Mariner missions of the early 1960s to Voyager and Cassini to all of the Mars rovers. The 2020 stack was suspended from cables so the cold realities of interplanetary cruise could hit the spacecraft from every angle.

With the 16-ton door closed, a near-vacuum environment was established. Then, as the Mars 2020 test team looked on, the baffled chamber walls were flooded with liquid nitrogen to chill it to -200 degrees Fahrenheit (-129 degrees Celsius). To simulate the Sun's rays that Mars 2020 will encounter during its voyage, powerful xenon lamps several floors below the chamber illuminated, their light directed onto a mirror at the top of the chamber and reflected down on the spacecraft. Eight days later the lamps were turned off, atmosphere was reintroduced to the chamber, and the door opened. Acoustic and thermal vacuum testing was complete.

"This is the most comprehensive stress test you can put a spacecraft through here on Earth," said Gruel. "We flew in our simulated space environment for a week and a day, checking and rechecking the performance of every onboard system and subsystem. And everything looked great - which is a good thing, because next time this spacecraft stack hits a vacuum, it will be on its way to Mars for real."

On May 10, the stack returned yet again to the High Bay 1 cleanroom. Just feet away, technicians worked on the 2,314-pound (1,050-kilogram) Mars 2020 rover that will be part of the stack at launch. The rover already had more than 90% of the components that will make up the interior of the chassis, from the science instruments and computers to subsystems and electrical boxes to the organized tangle of electrical wiring connecting them all.

The 2020 rover carries an entirely new suite of instruments, including a sample-caching system that will collect samples of Mars for return to Earth on subsequent missions. The mission will launch from Cape Canaveral Air Force Station in Florida in July of 2020 and land at Jezero Crater on Feb. 18, 2021.

The Mars 2020 Project at JPL manages rover development for NASA's Science Mission Directorate. NASA's Launch Services Program, based at the agency's Kennedy Space Center in Florida, is responsible for launch management. Mars 2020 will launch from Cape Canaveral Air Force Station in Florida.

Quelle: NASA

----

Update: 1.06.2019

.

NASA's Mars 2020 Gets HD Eyes

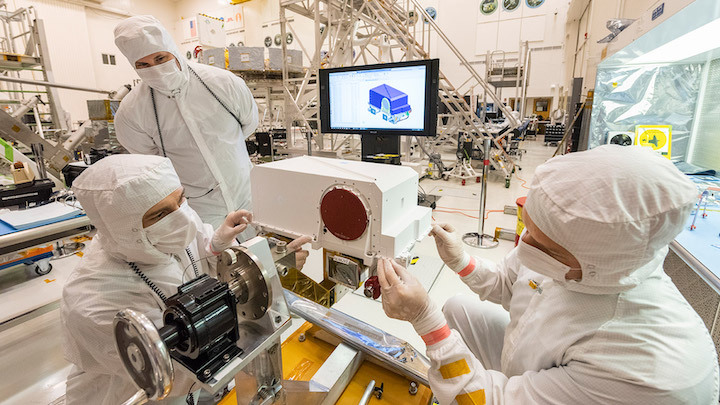

In this picture - taken on May 23, 2019, in the Spacecraft Assembly Facility's High Bay 1 clean room at the Jet Propulsion Laboratory in Pasadena, California - engineers re-install the cover to the remote sensing mast (RSM) head after integration of two Mastcam-Z high-definition cameras that will go on the Mars 2020 rover. Credit: NASA/JPL-Caltech

One of the first operations the Mars 2020 rover will perform after touching down on the Red Planet's Jezero Crater on Feb. 18, 2021, will be to raise its remote sensing mast (RSM), which carries important optics and instrumentation.

In this picture - taken on May 23, 2019, in the Spacecraft Assembly Facility's High Bay 1 clean room at the Jet Propulsion Laboratory in Pasadena, California - engineers re-install the cover to the RSM head after integration of two Mastcam-Z high-definition cameras. Visible below the red lens cover is the left Mastcam-Z camera (with the "Remove Before Flight" labels); support equipment blocks the right Mastcam-Z from view. The RSM and its twin cameras will be installed on the rover's deck the week of June 3, 2019.

Mastcam-Z is a multispectral, stereoscopic imaging instrument that will enhance the Mars 2020 rover's driving and core-sampling capabilities. It will also enable science team members to observe textural, mineralogical, structural and morphologic details in rocks and sediment at any location within the rover's field of view, helping them piece together the planet's geologic history.

"Mastcam-Z will be the first Mars color camera that can zoom, enabling 3D images at unprecedented resolution," said Mastcam-Z Principal Investigator Jim Bell of Arizona State University in Tempe. "With a resolution of three-hundredths of an inch [0.8 millimeters] in front of the rover and less than one-and-a-half inches [38 millimeters] from over 330 feet [100 meters] away - Mastcam-Z images will play a key role in selecting the best possible samples to return from Jezero Crater."

Mastcam Z's capabilities are not the only firsts of the mission. Mars 2020 will be the first spacecraft in the history of planetary exploration with the ability to accurately retarget its point of touchdown during the landing sequence. And the rover carries a sample-caching system that will collect Martian rock and soil samples and store them on the planet's surface for retrieval and return to Earth by subsequent missions.

Mars 2020 will launch from Cape Canaveral Air Force Station in Florida in July of 2020.

JPL is building and will manage operations of the Mars 2020 rover for the NASA Science Mission Directorate at the agency's headquarters in Washington.

If you want to send your name to Mars with NASA's 2020 mission, you can do so from now until Sept. 30, 2019. Add your name to the list and obtain a souvenir boarding pass to Mars here:

Quelle: NASA

----

Update: 7.06.2019

.

Watch NASA Build Its Next Mars Rover

A newly installed webcam offers the public a live, bird's-eye view of NASA's Mars 2020 rover as it takes shape at NASA's Jet Propulsion Laboratory in Pasadena, California. You can watch as JPL engineers and technicians assemble and test the rover before it embarks next year on one of the most technologically challenging interplanetary missions ever designed.

"There is so much happening and changing in the clean room, I come here every opportunity I get," said Mars 2020 project manager John McNamee of JPL. "It is great that we can share this part of our journey to the Red Planet with the public anytime they want."

Affectionately called "Seeing 2020," the webcam provides the video feed (without audio) from a viewing gallery above the clean room floor. You can also watch and participate in live webchats with members of JPL's social media team and the Mars 2020 team as they answer questions from the public about the mission. These "Seeing 2020" webchats will occur Mon.-Thu. at 11 a.m. and 4 p.m. PDT (2 p.m. and 7 p.m. EDT), with additional moderated chats when special activities (like drive tests) occur.

Continuous live video of rover construction is available at:

https://mars.nasa.gov/mars2020/mission/where-is-the-rover/

The feed is also available on YouTube with the scheduled, moderated chats at:

http://youtube.com/NASAJPL/live

Currently, work in the High Bay 1 clean room begins at 8 a.m. PDT (11 a.m. EDT) Mon.-Fri., much of it revolving around the rover. The back shell, descent stage and cruise stage have already been assembled and tested.

The clean room may be or appear to be empty when assembly activity has shifted to other JPL facilities or when work on 2020 moves out of view of the camera to other parts of the clean room. The camera may also be turned off periodically for maintenance or technical issues.

Months of final assembly and testing lie ahead before the Mars 2020 rover is ready to ship to NASA's Kennedy Space Center in Florida. The launch period begins July 17, 2020. Once the Mars 2020 rover arrives at Mars on Feb. 18, 2021, it will not only seek signs of ancient habitable conditions — and past microbial life — but collect rock and soil samples, storing them in sample tubes on the planet's surface.

The Mars 2020 project at JPL manages rover development for NASA's Science Mission Directorate in Washington. NASA's Launch Services Program, based at the agency's Kennedy Space Center in Florida, is responsible for launch management. Mars 2020 will launch from Cape Canaveral Air Force Station in Florida.

Quelle: NASA

----

Update: 16.06.2019

.

The Mast Is Raised for NASA's Mars 2020 Rover

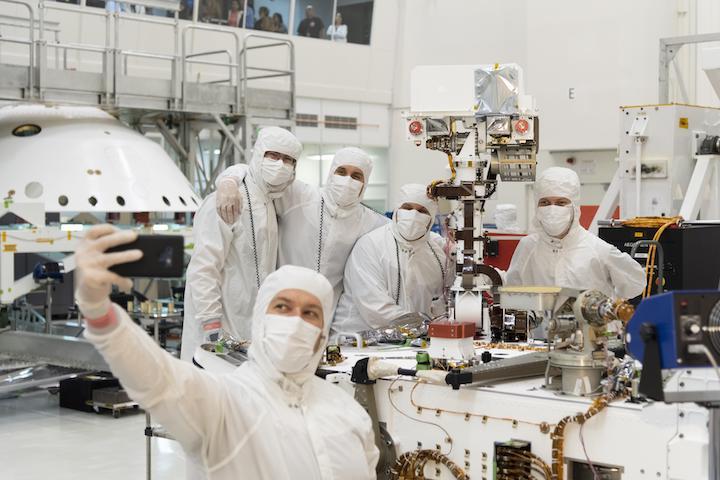

Engineers and technicians at NASA's Jet Propulsion Laboratory in Pasadena, California, install the remote sensing mast on the Mars 2020 rover. The image was taken on June 5, 2019, in the Spacecraft Assembly Facility's High Bay 1 clean room at JPL.Credit: NASA/JPL-Caltech

In this image, taken on June 5, 2019, engineers at NASA's Jet Propulsion Laboratory in Pasadena, California, take a moment after attaching the remote sensing mast to the Mars 2020 rover in the Spacecraft Assembly Facility's High Bay 1 clean room. Full integration of the mast - a process that includes installation of science instrument sensors, electrical wiring and checkout - continued into the following week, concluding on June 11.

During Mars 2020's launch, interplanetary cruise, and its fast and fiery descent toward the Martian surface, the mast will be in stowed flat on the rover's deck. Soon after touchdown, the mast (which tops out at over 7 feet, or 2.2 meters) will be raised to provide a high perch for the SuperCam, Mastcam-Z and Mars Environmental Dynamics Analyzerinstruments as well as four Navcam engineering cameras.

Mars 2020 will launch from Cape Canaveral Air Force Station in Florida in July of 2020. It will land at Jezero Crater on Feb. 18, 2021.

In a mission first, the rover carries a sample-caching system that will collect Martian rock and soil samples and store them on the planet's surface for retrieval and return to Earth by subsequent missions. Mars 2020 will also be the first spacecraft in the history of planetary exploration with the ability to accurately retarget its point of touchdown during the landing sequence - technology that could prove essential to future crewed missions to the Moon and Mars.

Charged with returning astronauts to the Moon by 2024, NASA's Artemis lunar exploration plans will establish a sustained human presence on and around the Moon by 2028. We will use what we learn on the Moon to prepare to send astronauts to Mars.

JPL is building and will manage operations of the Mars 2020 rover for the NASA Science Mission Directorate at the agency's headquarters in Washington.

Members of NASA's Mars 2020 project take a moment after attaching the remote sensing mast to the Mars 2020 rover. The image was taken on June 5, 2019, in the Spacecraft Assembly Facility's High Bay 1 clean room at NASA's Jet Propulsion Laboratory in Pasadena, California.Credit: NASA/JPL-Caltech

Quelle: NASA

----

Update: 22.06.2019

.

Mars 2020 Rover Gets Its Wheels

In this image, taken on June 13, 2019, engineers prepare the starboard legs and wheels - otherwise known as the mobility suspension - for integration onto NASA's Mars 2020 rover.Credit: NASA/JPL-Caltech

In this image, taken on June 13, 2019, engineers at JPL install the starboard legs and wheels - otherwise known as the mobility suspension - on the Mars 2020 rover. Credit: NASA/JPL-Caltech

In this image, taken on June 13, 2019, engineers at NASA's Jet Propulsion Laboratory in Pasadena, California, install the starboard legs and wheels - otherwise known as the mobility suspension - on the Mars 2020 rover. They installed the port suspension later that day.

"Now that's a Mars rover," said David Gruel, the Mars 2020 assembly, test, and launch operations manager at JPL. "With the suspension on, not only does it look like a rover, but we have almost all our big-ticket items for integration in our rearview mirror - if our rover had one."

Within the next few weeks, the team expects to install the vehicle's robotic arm, the mast-mounted SuperCam instrument and the Sample Caching System, which includes 17 separate motors and will collect samples of Martian rock and soil that will be returned to Earth by a future mission.

Both of the rover's legs (the starboard leg's black tubing can be seen above the wheels) are composed of titanium tubing formed with the same process used to make high-end bicycle frames. The wheels in this picture are engineering models and will not make the trip to Mars. They will be swapped out for flight models of the wheels sometime next year.

Made of aluminum, each of the six wheels (each 20.7 inches, or 52.5 centimeters, in diameter) features 48 grousers, or cleats, machined into its surface to provide excellent traction both in soft sand and on hard rocks. Every wheel has its own motor. The two front and two rear wheels also have individual steering motors that enable the vehicle to turn a full 360 degrees in place.

When driving over uneven terrain, the suspension system - called a "rocker-bogie" system due to its multiple pivot points and struts -maintains a relatively constant weight on each wheel and minimizes rover tilt for stability. Rover drivers avoid terrain that would cause a tilt of more than 30 degrees, but even so, the rover can withstand a 45-degree tilt in any direction without tipping over. With its suspension, the rover can also roll over rocks and other obstacles as well as through depressions the size of its wheels.

Mars 2020 will launch from Cape Canaveral Air Force Station in Florida in July of 2020. It will land at Jezero Crater on Feb. 18, 2021.

Charged with returning astronauts to the Moon by 2024, NASA's Artemis lunar exploration plan will establish a sustained human presence on and around the Moon by 2028. We will use what we learn on the Moon to prepare to send astronauts to Mars.

JPL is building and will manage operations of the Mars 2020 rover for the NASA Science Mission Directorate at the agency's headquarters in Washington.

Quelle: NASA

----

Update: 29.06.2019

.

Mars 2020 Rover's 7-Foot-Long Robotic Arm Installed

On June 21, 2019, engineers at NASA's Jet Propulsion Laboratory install the main robotic arm on the Mars 2020 rover. Measuring 7 feet (2.1 meters) long, the arm will allow the rover to work as a human geologist would: by holding and using science tools with its turret. Image credit: NASA/JPL-Caltech

In this image, taken on June 21, 2019, engineers at NASA's Jet Propulsion Laboratory in Pasadena, California, install the main robotic arm on the Mars 2020 rover. (A smaller arm to handle Mars samples will be installed inside the rover as well.) The main arm includes five electrical motors and five joints (known as the shoulder azimuth joint, shoulder elevation joint, elbow joint, wrist joint and turret joint). Measuring 7 feet (2.1 meters) long, the arm will allow the rover to work as a human geologist would: by holding and using science tools with its turret, which is essentially its "hand."

"You have to give a hand to our rover arm installation team," said Ryan van Schilifgaarde, a support engineer at JPL for Mars 2020 assembly. "They made an extremely intricate operation look easy. We're looking forward to more of the same when the arm will receive its turret in the next few weeks."

The rover's turret will include high-definition cameras, science instruments, and a percussive drill and coring mechanism. Those tools will be used to analyze and collect samples of Martian rock and soil, which will be cached on the surface for return to Earth by a future mission.

Mars 2020 will launch from Cape Canaveral Air Force Station in Florida in July of 2020. It will land at Jezero Crater on Feb. 18, 2021.

Charged with returning astronauts to the Moon by 2024, NASA's Artemis lunar exploration plans will establish a sustained human presence on and around the Moon by 2028. We will use what we learn on the Moon to prepare to send astronauts to Mars.

JPL is building and will manage operations of the Mars 2020 rover for the NASA Science Mission Directorate at the agency's headquarters in Washington.

Quelle: NASA