22.11.2020

NASA reschedules final SLS Core Stage Green Run tests for December

NASA’s Space Launch System (SLS) Program rescheduled the final two tests that will culminate the Core Stage Green Run campaign for December after successfully repairing one of the liquid hydrogen (LH2) prevalves inside the engine section of the stage.

The Wet Dress Rehearsal is now targeted for the week of December 7, and if that goes well the Hot-Fire test of the stage could occur two weeks later during the week of December 21.

Prevalve repaired in tight confines of engine section

The Artemis 1 core stage flight article is installed in the B-2 Test Stand at the Stennis Space Center in Southern Mississippi for the Green Run design verification campaign.

An intermittent failure of the LH2 prevalve for engine four was discovered during previous Green Run testing and after troubleshooting and partial disassembly, analysis narrowed the problem down to a clutch mechanism on the valve. Following the surgical clutch replacement, the fully-reconstructed valve assembly passed retesting and Core Stage prime contractor Boeing is now working to pick up preparations for the first of the two final critical tests: a Wet Dress Rehearsal (WDR) to prepare for a subsequent full-duration test firing of the stage.

NASA reported on November 18 that in-place repairs of the engine four LH2 prevalve in the Core Stage were successful. An intermittent issue with the operation of the prevalve interrupted the stage’s Green Run test campaign, delaying the final two of eight test cases while the problem was identified and resolved.

“Over the weekend, engineers at NASA’s Stennis Space Center near Bay St. Louis, Mississippi, successfully repaired a valve inside the core stage of the agency’s Space Launch System (SLS) rocket,” Kathryn Hambleton, Public Affairs Officer at NASA Headquarters, wrote in the agency’s Artemis blog.

“The team designed an innovative tool to remove and replace the valve’s faulty clutch while the core stage remained in the B-2 test stand, and without removing the entire valve.”

“Subsequent testing of the repaired valve confirmed that the system is operating as intended.” Torque checks showed the repaired valve responding to specification and the prevalve also passed leak checks.

Preparations to perform the last two tests in late October and mid-Novemberwere suspended when the prevalve failed a focused checkout procedure in mid-October. Following a few weeks of troubleshooting, fault tree analysis narrowed down the suspect to the clutch mechanism within the overall prevalve assembly. Engineers worked in cramped quarters inside the Core Stage’s engine section to do the troubleshooting and repairs.

The bottom of the LH2 propellant tank, the aft dome, takes up a significant part of the room inside the engine section, with the prevalves attached to the bottom of the tank in a small space above and around all the Main Propulsion System (MPS) equipment at the bottom of the engine section. The valves are attached to the salad bowl shaped aft manifold of the tank which itself extends out from its aft dome.

The manifold has openings for feedlines to flow propellant to each of the four engines and for a fill and drain line to load the tank from ground supplies during the countdown prior to engine ignition. The prevalves control the flow of LH2 from the tank through feedlines directly to the LH2 inlet of each of the four RS-25 engines.

Credit: NASA/Jared Lyons, Jude Guidry, Eric Bordelon, Steven Seipel.

(Photo Caption: The four LH2 prevalves on Core Stage-1 can be seen sticking out of the LH2 tank aft manifold in the upper right part of this image taken in September, 2019, at Michoud Assembly Facility during operations to mate the engine section (left) to the bottom of the hydrogen tank (right). A suspect clutch mechanism in one of the valves was recently repaired from inside the engine section with the stage installed vertically in the B-2 Test Stand.)

Engineers for Boeing and prevalve vendor Vacco had to position themselves on an erector set style work platform installed for access inside the engine section. The cryogenic propellant lines in the engine section are insulated with foam, including the valves, so that had to be removed during troubleshooting to be able to disassemble parts of the valve.

Working in shifts around the clock, the intricate repair of the valve required disassembling enough of the surrounding mechanism to remove the suspect clutch and replace it with a new unit. The valve was repaired with the overall housing remaining bolted in-place inside the aft compartment, so subassemblies like the actuator had to be removed to get to the clutch. As noted in NASA’s blog post, special tooling was built to help support the prevalve repair work.

Following the part replacement, engineers then had to rebuild the internal prevalve mechanisms with the valve in its operational rocket position and orientation, as opposed to on a work bench in a well-lighted work area. Performing the repair in place helped to limit the scope of necessary rework and time it would take to do all that work.

TVC issue still being discussed but not stopping Green Run test schedule

While the prevalve repairs and retesting were being performed, an issue with the stage’s thrust vector control (TVC) system was still being discussed within the program. Test case five performed a checkout of the Core Stage Main Propulsion System (MPS) and RS-25 engines late in the Summer which included a test of the TVC systems for all four engines.

Credit: NASA/Stennis.

(Photo Caption: One of the RS-25 Core Stage engines is swung outwards by the stage’s hydraulically-powered TVC system in a gimbal test performed on August 31. Data from the TVC testing performed during Green Run test case five is still being discussed, but the issue is not holding up plans to run the final two test cases in December.)

In flight the Core Stage moves the four RS-25 engines for steering using hydraulic power; each engine has two TVC actuators connected to it, a pitch and a yaw actuator. The stage’s hydraulic system provides the power to drive all eight TVC actuators in addition to controlling the position of critical valves in the RS-25 engines for start and shutdown along with controlling engine thrust levels.

There still seems to be a disagreement between different sets of instrumentation and models of the TVC system performance during the tests. There was also some discussion about performing additional TVC testing on the Core Stage and in the TVC lab at the Marshall Space Flight Center in Huntsville, Alabama.

The TVC lab in Building 4205 at Marshall has a full Core Stage hydraulic system set up for qualification testing that was recently completed. In addition to the two TVC actuators on each hydraulic system, the lab also has connections to the two dedicated avionics boxes for a hydraulic system, a Core Stage Auxiliary Power Unit Controller (CAPUC) and a TVC Actuator Controller (TAC). The lab is located near the SLS avionics and software test lab which has operating sets of the Core Stage flight computers and avionics.

With NASA and Boeing moving ahead towards the final Green Run tests in December, the issue doesn’t appear to be a showstopper to the new schedule for finishing the Stennis campaign; however, careful positioning of the engines by the stage TVC system is a crucial element of the Hot-Fire test. While the engines are firing in the static ground test they must be positioned to minimize lateral forces imparted from the stage to the test stand, including the structural attachments and the umbilical connections between the stage and the stand.

Ground control and vehicle computers are both monitoring the position of the engines during the Hot-Fire test and a misalignment could cause the test-firing to be aborted.

Lead image credit: NASA/Karl Wilcox and Charles “Danny” Nowlin.

Quelle: NS

----

Update: 24.11.2020

.

NASA’s ‘Super Cool’ Engineers Rehearse Rocket Fueling for Artemis I

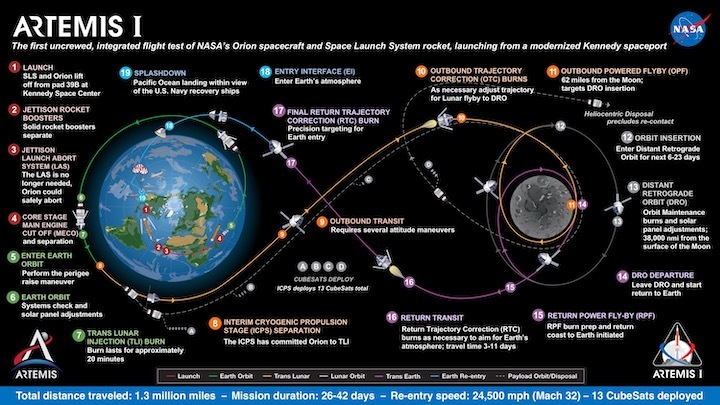

NASA’s Space Launch System (SLS) rocket will propel the Orion spacecraft on a journey beyond the Moon and back to Earth during an uncrewed flight test known as Artemis I. Well before liftoff, a group of engineers will be inside the Launch Control Center at NASA’s Kennedy Space Center in Florida, where they will monitor the loading of cryogenic liquid hydrogen and liquid oxygen – super-cooled fuels – into the rocket.

To test this all-important tanking process, engineers from NASA’s Exploration Ground Systems and contractor Jacobs recently took their seats at consoles in Kennedy’s Firing Room 1. During a simulated launch, they tackled any challenges that arose and monitored the system’s performance.

“The [cryo] team always brings their ‘A’ game,” said Charlie Blackwell-Thompson, NASA Artemis launch director at Kennedy. “During these loading simulations, they demonstrate that they will be ready on launch day.”

Diane Stees, an engineer and former chief of the cryogenic propulsion console during the shuttle program, serves as the NASA lead for the Cryogenic Propulsion Ground and Flight Application Software Team. The software team has 20 members with a mix of seasoned and newer engineers.

Challyn Pfifer, a Jacobs cryogenic liquid hydrogen software technical lead, is one of the newer engineers. She sits on console for the liquid hydrogen team, which oversees loading the rocket and continuously monitors the system through launch.

“It’s an amazing honor and experience to be part of the next generation of space launches with the Artemis program; to be paving the way for future aerospace engineers who dream of launching rockets,” Pfifer said. “It’s also an uplifting experience to see more and more women get involved in the space program. I take great pride knowing I am a part of something bigger than myself.”

She added that the Artemis program benefits from having experienced engineers who launched space shuttles as well as new engineers who offer a different outlook and way of approaching the tasks at hand.

One of the experienced engineers is John Sterritt. He began his career with Rockwell International in October 1979 as a main propulsion systems engineer and worked on every space shuttle launch. Now a senior engineer and cryogenic propulsion launch system specialist with Jacobs, he transitioned to the SLS rocket in March 2013 and works closely with the hazardous gas detection system engineers.

“It’s always exciting to bring a new rocket online and bring some of that shuttle knowledge forward,” Sterritt said.

Sterritt monitors the internal volumes of the core and interim cryogenic propulsion stages, including the engines, propulsion systems, and tank interfaces, to verify that the detected levels of hydrogen, oxygen, and helium do not pose a threat to the rocket or spacecraft. In addition, Sterritt ensures the team takes appropriate actions if the levels exceed the prescribed limits for launch.

Ed Sikora, a propulsion specialist with the Jacobs team, also brings his Space Shuttle Program knowledge to the SLS team. Sikora arrived at Kennedy in May 1982 and supported 132 space shuttle flights. In 2015, he started writing ground systems requirements, working on the software, and participating in launch simulations in the firing rooms.

With more ground support equipment for Artemis than there was for the Space Shuttle Program, Sikora said it helps engineers working in the firing rooms to know how the hardware interfaces with the software when you push the button.

“It humbles me,” Sikora said. “We’re playing a part in putting astronauts back on the Moon and getting ready for human exploration of Mars.”

Quelle: NASA

----

Update: 1.12.2020

.

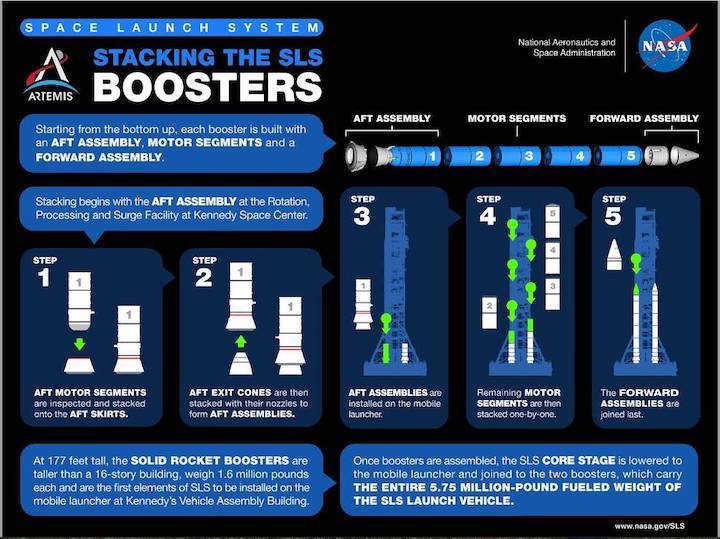

Artemis I Launch Preparations Are Stacking Up

By Madison Tuttle

NASA's Kennedy Space Center

NASA has stacked the first piece of the Space Launch System(SLS) rocket on the mobile launcher in preparation for the Artemis I launch next year. At NASA’s Kennedy Space Center in Florida, engineers lowered the first of 10 segments into place Nov. 21 for the twin solid rocket boosters that will power the first flight of the agency’s new deep space rocket. Artemis I will be an uncrewed flight to test the SLS rocket and Orion spacecraft as an integrated system ahead of crewed flights to the Moon with the Artemis program.

The booster segments arrived by train at the Florida spaceport in June from Northrop Grumman’s manufacturing facility in Utah to undergo final launch preparations. Stacking operations began Nov. 19 with engineers transporting a booster segment from the Rotation, Processing and Surge Facility to the 525-foot-tall Vehicle Assembly Building (VAB).

Each booster consists of five segments and will provide 7 million pounds of thrust for the liftoff from Launch Pad 39B. When assembled, each booster will be about half the length of a football field, and together they will generate more thrust than 14 four-engine jumbo commercial airliners. Once stacked, the SLS rocket will stand taller than the Statue of Liberty and have about 15% more thrust at liftoff than the Apollo program Saturn V rocket, making it the most powerful rocket ever built.

“Stacking the first piece of the SLS rocket on the mobile launcher marks a major milestone for the Artemis Program,” said Andrew Shroble, an integrated operations flow manager with Jacobs. “It shows the mission is truly taking shape and will soon head to the launch pad.”

The solid rocket boosters are the first components of the SLS rocket to be stacked and will help support the remaining rocket pieces and the Orion spacecraft. Over the next several weeks, workers will use an overhead crane that can hold up to 325 tons (the weight of about 50 elephants), to lift the remaining segments one by one and place them carefully onto the 380-foot-tall mobile launcher, the structure used to process, assemble, and launch the SLS rocket. The cranes are precise enough to lower an object onto an egg without cracking it.

The first booster segments to be stacked are the bottom sections known as the aft assemblies. These house the system that controls 70% of the steering during initial ascent of the rocket. This section includes the aft motor segment and skirt, and the nozzle that directs the hot gas leaving the motor. After stacking the other four segments, the final pieces of the boosters are the forward assemblies, which include the nose cone that serves as the aerodynamic leading edge of the boosters. The forward assemblies will attach to the core stage when it arrives next year.

Under the Artemis program, NASA aims to land the first woman and the next man on the Moon in 2024 and establish sustainable lunar exploration by the end of the decade. SLS and Orion, along with the human landing system and the Gateway in orbit around the Moon, are NASA’s backbone for deep space exploration.

Quelle: NASA

----

Update: 7.12.2020

.

NASA's Orion spacecraft suffers hardware failure that could add months to timeline

NASA's program to develop a new spacecraft to carry humans to the moon and back, already years behind schedule and billions of dollars over budget, has hit yet another roadblock.

A recently discovered fault in the agency's Orion capsule has engineers troubleshooting solutions that could impact the timing of its test flight, currently scheduled for liftoff from Kennedy Space Center next November.

The spacecraft, along with the giant Space Launch System rocket also under development, are key components in NASA ambitious Artemis program, which aims to put Americans back on the surface of the moon by 2024.

Last month, Lockheed Martin engineers at KSC discovered a fault in one of eight power and data units, or PDUs, used by the spacecraft: a redundancy channel was not working as planned. Though the PDU itself still works, what is essentially part of its backup system is out of the picture.

"While the PDU is still fully operational without this redundant channel we are swiftly troubleshooting the card while also continuing closeout activities on Orion," Gary Napier, a Lockheed Martin spokesperson, said in a statement. "We are fully committed to seeing Orion launch next year on its historic Artemis I mission to the moon."

NASA also confirmed the issue, which was discovered as teams were in the final processing stages leading up to a 1.2-mile transport from the Operations and Checkout Building to the Multi-Payload Processing Facility on Dec. 7. There, it would have been fueled and mated with the launch abort system.

"While powering up the spacecraft to prepare for the pressurization of the crew module uprighting system, which ensures the capsule is oriented upward after splashdown, engineers identified an issue with a redundant channel in a PDU on Orion’s crew module adapter," NASA said in a statement.

Redundancies and backup systems are critical to spacecraft. They're built into nearly every aspect ranging from electrical to communications to moving components.

NASA did not confirm details surrounding delays or how engineers plan on addressing the issue, but an internal email and presentation obtained by The Verge point to most options adding months to the readiness timeline.

The presentation mentions three paths forward: disassemble Orion and replace the PDU, located deep in an adapter that connects the capsule to its service module, adding a year to the timeline; find a way through panels on the exterior to access the PDU, which is risky and could take about four months; and finally, since the PDU works, simply continue as is.

For an agency pushing for Orion to become the temporary home of astronauts living and working in space, the last option seems unlikely but possible given that Orion's November 2021 mission won't have humans on board. The three-week test will see the 16-foot-diameter capsule launch on SLS, orbit the moon for six days, then return for splashdown off the California coast.

If successful, Artemis II will take flight two years later with astronauts on a similar orbit around the moon and pave the way for Artemis III, which aims to put astronauts on the surface in 2024. All missions would be processed in KSC's Vehicle Assembly Building, then rolled out to pad 39B for liftoff.

But sticking to the Artemis program's ambitious schedule isn't solely on Orion's shoulders. While Lockheed Martin builds the capsule, Boeing is responsible for most of the SLS rocket, which has been plagued by years of cost overruns and delays – the first flight was actually slated to launch in 2017.

NASA's own inspector general recently said the entirety of the Artemis program's timeline is prone to delays caused by hardware-related slowdowns, cost overruns, and changing winds in the political climate. Combined, the SLS-Orion effort is expected to cost the agency some $50 billion by 2024.

In its July report, the OIG said continuing to produce Orion capsules for all Artemis missions before certain milestones are complete, like Artemis I, poses serious risks. Last month's discovery of the PDU issue appears to reinforce their position.

"Orion is proceeding with production of crew capsules for future Artemis missions before completing key development activities, increasing the risk of additional cost growth and schedule delays as issues are discovered late in the development effort, potentially requiring costly rework," the OIG said.

Quelle: Florida Today

----

Update: 12.12.2020

.

Latest SLS core stage test issues leave little margin in schedule for first launch

WASHINGTON — The latest in a series of delays in a test campaign for the core stage of the Space Launch System now leaves “very little margin” in the schedule for its launch next November, NASA managers said Dec. 10.

NASA had planned to conduct a test known as a “wet dress rehearsal” of the SLS core stage at the Stennis Space Center Dec. 7. In that test, the core stage is loaded with liquid hydrogen and liquid oxygen propellants and goes through a countdown that stops just a half a minute before ignition of the stage’s four RS-25 engines. The wet dress rehearsal is the final milestone before a full-duration static-fire test of the engines that wraps up the overall Green Run test campaign.

In the early phases of the wet dress rehearsal, engineers successfully loaded a small amount of liquid hydrogen into the stage and saw no signs of leaks or other problems. However, when starting to load liquid oxygen, they found that the propellant was not as cold as required.

“It’s really an integrated issue between the facility and the core stage,” said Julie Bassler, SLS stages manager at NASA’s Marshall Space Flight Center, in a call with reporters. Models of how the liquid oxygen temperature would change as it was transferred through the test stand and into the tank didn’t match what engineers saw, with temperatures about 2.2 degrees Celsius warmer than required for the test.

The difference appears minor, but is intended to prevent the formation of gas bubbles in a long feed line in the core stage, said John Honeycutt, SLS program manager at NASA Marshall. Those bubbles could then collapse, releasing energy as the liquid oxygen above it falls.

Honeycutt emphasized that the issue was not a flaw with the core stage itself. “There’s not anything wrong with the rocket,” he said. “This is an operational activity associated with how we load the liquid oxygen, and I have a high level of confidence that the team is going to be able to fix it. It’s going to have to be on the ground side to do that.”

NASA is coming up with new procedures for loading the liquid oxygen into the core stage, and is tentatively planning to reschedule the wet dress rehearsal for the week of Dec. 14. That would then allow them to proceed with the hotfire test as soon as the last week of December.

If that test schedule holds, the core stage would be shipped to the Kennedy Space Center in February, where it be mated to its two solid rocket boosters, upper stage and Orion spacecraft for the Artemis 1 mission. That schedule would still allow the Artemis 1 launch to take place in November 2021.

However, Honeycutt acknowledged that there’s little margin for any additional delays. “We’re getting to a point where we’ve got very little margin left in the schedule relative to our commitment to our delivery date,” he said. The overall margin in the Green Run test has been eroded by various issues, from a closure of the center in the spring because of the pandemic to a series of shorter closures because of tropical storms and hurricanes, as well as technical issues with the test campaign itself. “The margin that we had built into the schedule for the Green Run is getting pretty slim.”

He said he has been in discussions with the Kennedy Space Center about coordinating activities there, such as stacking the solid rocket booster segments. Once stacked, the boosters have to be flown within a year. He said it’s likely that booster stacking work can proceed after the wet dress rehearsal is complete.

Honeycutt added he was confident that, once the liquid oxygen loading issue was resolved, the remainder of the Green Run test campaign will go quickly. That confidence was bolstered by the lack of hydrogen leaks, a problem during the shuttle program, found during the initial wet dress rehearsal effort. “We’re likely to see some small things we’ll have to go work,” he said. “We’ve learned enough to know that, in all likelihood, we’re not going to have a big issue that causes us to stand down for any significant amount of time.”

Officials, though, will still be nervous about the hotfire test itself. “Once the thing starts firing, I guess I’m going to see if I can hold my breath for 480 seconds,” said Maury Vander, chief of test operations at Stennis. “It should be a heck of a ride.”

Quelle: SN

----

Update: 22.12.2020

.

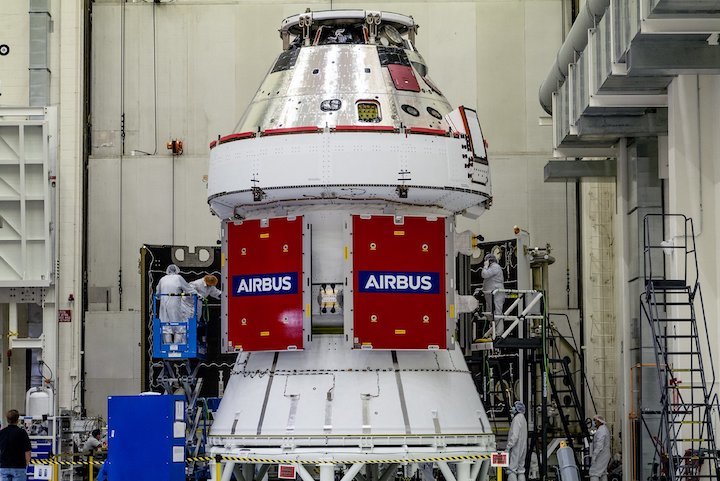

First European Service Module for Artemis accepted and handed over to NASA

On 11 December the first European Service Module passed its Acceptance Review and was formally handed over to NASA, the hardware is now officially NASA property. This marks the end of 9 years of designing, building and putting all the pieces together to make the next-generation powerhouse that will propel Orion spacecraft to the Moon.

The Acceptance Review was held as teleconference with 85 people attending specifically for the first European Service Module – each module gets their own individual acceptance review.

Complete stack

The complete Orion stack will now be handed to NASA’s launch processing teams for a launch next year.

Didier Radola, Airbus head of the Orion’s European Service Module programme added, “this is a great achievement for the programme today, and I would like to underline the excellent ESA and Airbus teamwork that has led to this point.

“This is one step beyond to the Moon as well as a promise of more to come for the European Service Module in 2021!”

Orion is a foundational element of the Artemis program, beginning with Artemis I, the first integrated flight test of Orion and SLS next year. Artemis II will follow as the first human mission, taking astronauts farther into space than ever before.

Quelle: AIRBUS

----

Update: 6.01.2021

.

NASA Space Launch System Rocket Proceeding with Green Run Hot Fire

NASA is targeting the final test in the Green Run series, the hot fire, for as early as Jan.17. The hot fire is the culmination of the Green Run test series, an eight-part test campaign that gradually brings the core stage of the Space Launch System (SLS) — the deep space rocket that will power the agency’s next-generation human Moon missions — to life for the first time.

NASA conducted the seventh test of the SLS core stage Green Run test series – the wet dress rehearsal – on Dec. 20 at NASA’s Stennis Space Center near Bay St. Louis, Mississippi and marked the first time cryogenic, or super cold, liquid propellant was fully loaded into, and drained from, the SLS core stage’s two immense tanks. The wet dress rehearsal provided structural and environmental data, verified the stage’s cryogenic storage capabilities, demonstrated software with the stage’s flight computers and avionics, and conducted functional checks of all the stage’s systems. The end of the test was automatically stopped a few minutes early due to timing on a valve closure. Subsequent analysis of the data determined the valve’s predicted closure was off by a fraction of a second, and the hardware, software, and stage controller all performed properly to stop the test. The team has corrected the timing and is ready to proceed with the final test of the Green Run series.

“During our wet dress rehearsal Green Run test, the core stage, the stage controller, and the Green Run software all performed flawlessly, and there were no leaks when the tanks were fully loaded and replenished for approximately two hours,” said Julie Bassler, SLS Stages manager at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “Data from all the tests to date has given us the confidence to proceed with the hot fire.”

The upcoming hot fire test will fire all four of the stage’s RS-25 engines simultaneously for up to eight minutes to simulate the core stage’s performance during launch. After the firing at Stennis, the core stage for SLS will be refurbished and shipped on the agency's Pegasus barge to NASA’s Kennedy Space Center in Florida. The stage will then be assembled with the other parts of the rocket and NASA’s Orion spacecraft in preparation for Artemis I, the first integrated flight of SLS and Orion and the first mission of the agency’s Artemis program.

“The next few days are critical in preparing the Artemis I rocket stage, the B-2 Test Stand at NASA’s Stennis Space Center, and the test team for the finale of the Green Run test series,” said Barry Robinson, project manager for SLS core stage Green Run testing at Stennis. “The upcoming Green Run hot fire test is the culmination of a lot of hard work by this team as we approach a key milestone event for NASA’s Artemis missions.”

Testing the SLS rocket’s core stage is a combined effort for NASA and its industry partners. Boeing is the prime contractor for the core stage and Aerojet Rocketdyne is the lead contractor for the RS-25 engines. Prior tests in the Green Run test series evaluated the stage’s avionics systems, propulsion systems, and hydraulic systems.

NASA is working to land the first woman and the next man on the Moon by 2024. SLS, and Orion, along with the human landing system and the Gateway in orbit around the Moon, are NASA’s backbone for deep space exploration. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon on a single mission.

Quelle: NASA